Double-sided aluminium multilayer metal composite plate and production line thereof

A production line, multi-layer metal technology, applied in the direction of metal layered products, layered products, metal material coating process, etc., to achieve the effects of convenient manufacturing, good bonding force and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The double-sided aluminum multilayer metal composite board produced in this embodiment is an aluminum-copper-iron-copper-aluminum five-layer composite board.

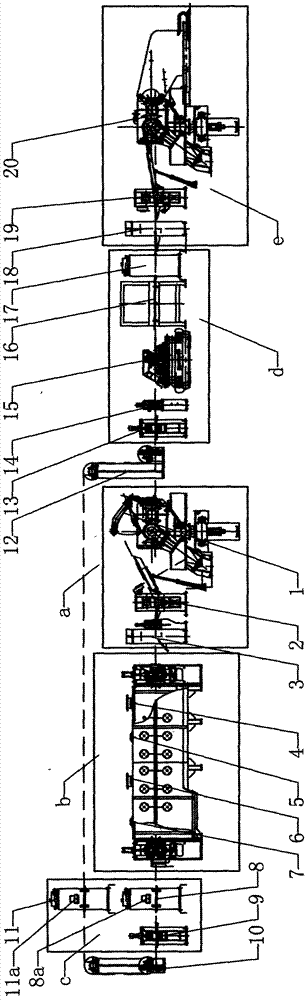

[0028] like figure 1 As shown, a production line of double-sided aluminum multilayer metal composite panels, which includes the production line entrance part a through which the iron plates pass sequentially, the production line passivation part b, the production line processing part (c, d), and the production line exit Part e. The dotted line in the figure represents the composite board.

[0029] The entry section a includes an uncoiler 1 , an entry pinch 2 and an entry shear 3 .

[0030] The passivation part b includes an ultrasonic cleaning machine 4 , a first clean water cleaning machine 5 , a passivation machine 6 and a second clean water cleaning machine 7 , which have an integrated structure and are arranged behind the inlet shear 3 .

[0031] The processing part is divided into two parts...

Embodiment 2

[0040] Embodiment 2: The difference between this embodiment and this embodiment 1 is that the double-sided aluminum multilayer metal composite board produced is an aluminum-zinc-iron-zinc-aluminum five-layer composite board.

[0041] What supporting use with the first cold rolling mill 9 is front, reverse high-frequency heating sprayer (8,11), and they finish the composite of zinc powder and iron plate front and back after cleaning and passivation process. The spraying of zinc powder on the iron plate can also use thermal spraying techniques such as arc spraying, plasma spraying or supersonic flame spraying.

[0042] An ultrasonic pressure welding device can also be installed on the high-frequency heating spraying machine. After the powder spraying device sprays zinc powder, the powder layer is pressurized and fused, and the high-frequency heating and ultrasonic welding work together to make the zinc and iron plate combined to form a composite plate. zinc layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com