Double-sided metal composite panel

A double-sided metal and composite board technology, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of high cost and poor strength performance of precious metal plates, and achieve good decorative effects, convenient production, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

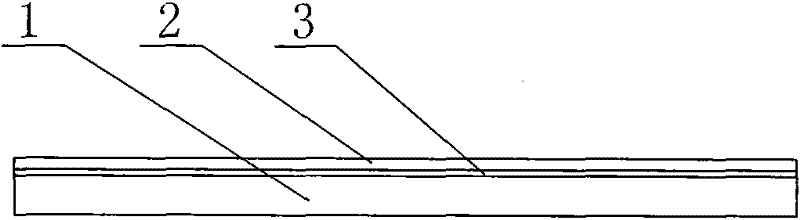

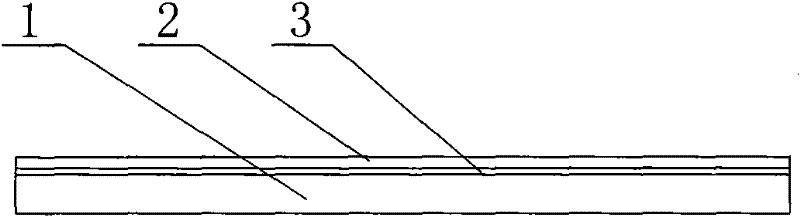

[0013] Such as figure 1 As shown, the double-sided metal composite board includes a substrate 1, a panel 2, and a polymer PVC material adhesive layer 3 for bonding the substrate 1 and the panel 2. The panel 2 adopts a thin layer, and the thickness of the substrate 1 is greater than that of the panel 2.

[0014] Substrate 1 is made of conventional metal material, which can be steel plate or alloy aluminum, etc., which can provide sufficient strength for panel 2;

[0015] Panel 2 is made of non-ferrous metal foil or metal plate, such as brass, red copper, etc., and the effect of decoration can be achieved with less material;

[0016] The adhesive layer 3 is made of polymer PVC material, which plays a role of firmly bonding the substrate and the panel.

[0017] The production process of double-sided metal composite panels includes: unwinding, splicing, degreasing, squeezing, washing, secondary squeezing, drying, cooling, baking, compounding, cooling again, filming, leveling, tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com