Patents

Literature

639results about How to "Strong stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

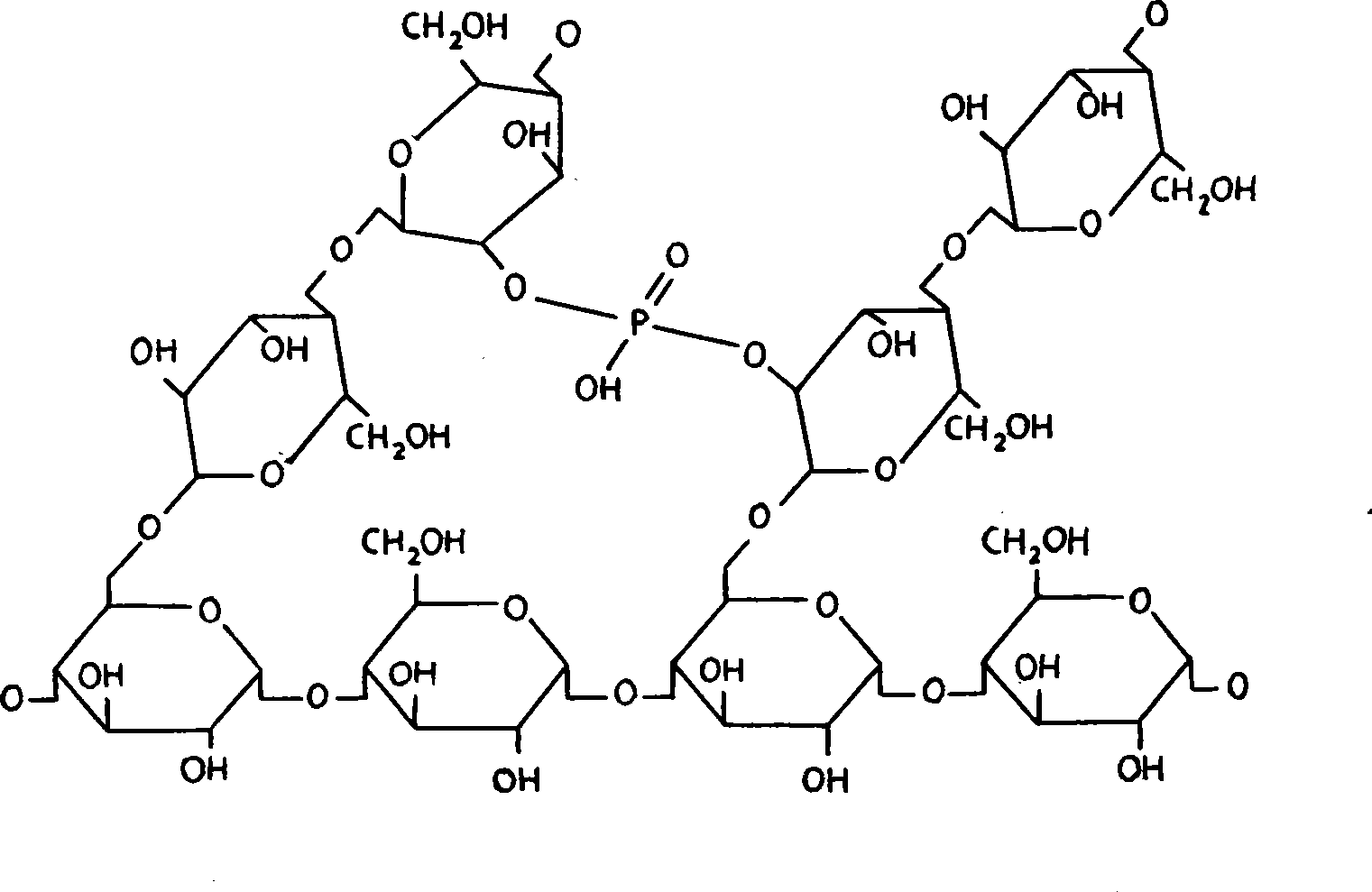

Denaturated starch absorbable hemostatic material and preparation method thereof

InactiveCN101121041AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismMedicineBlood plasma

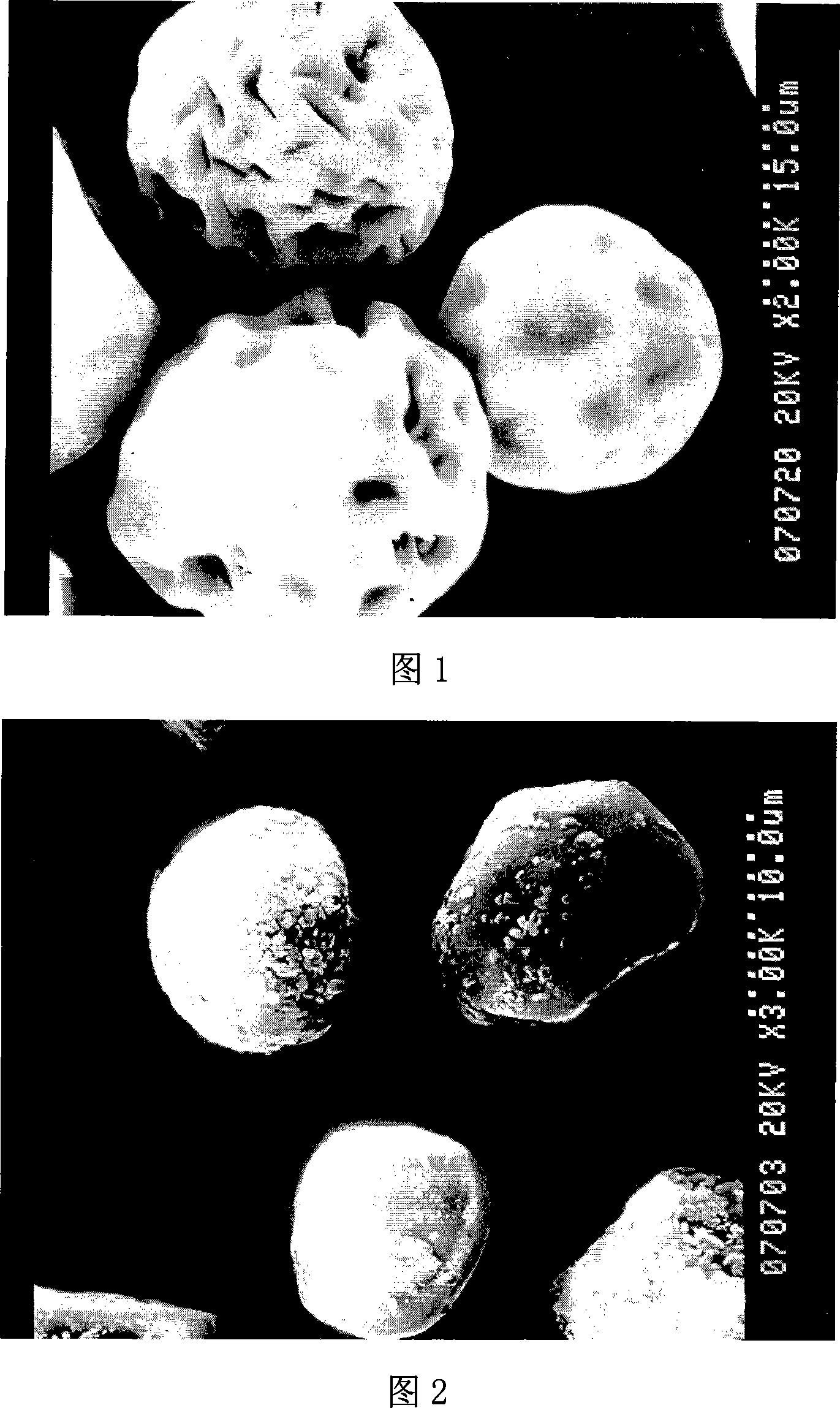

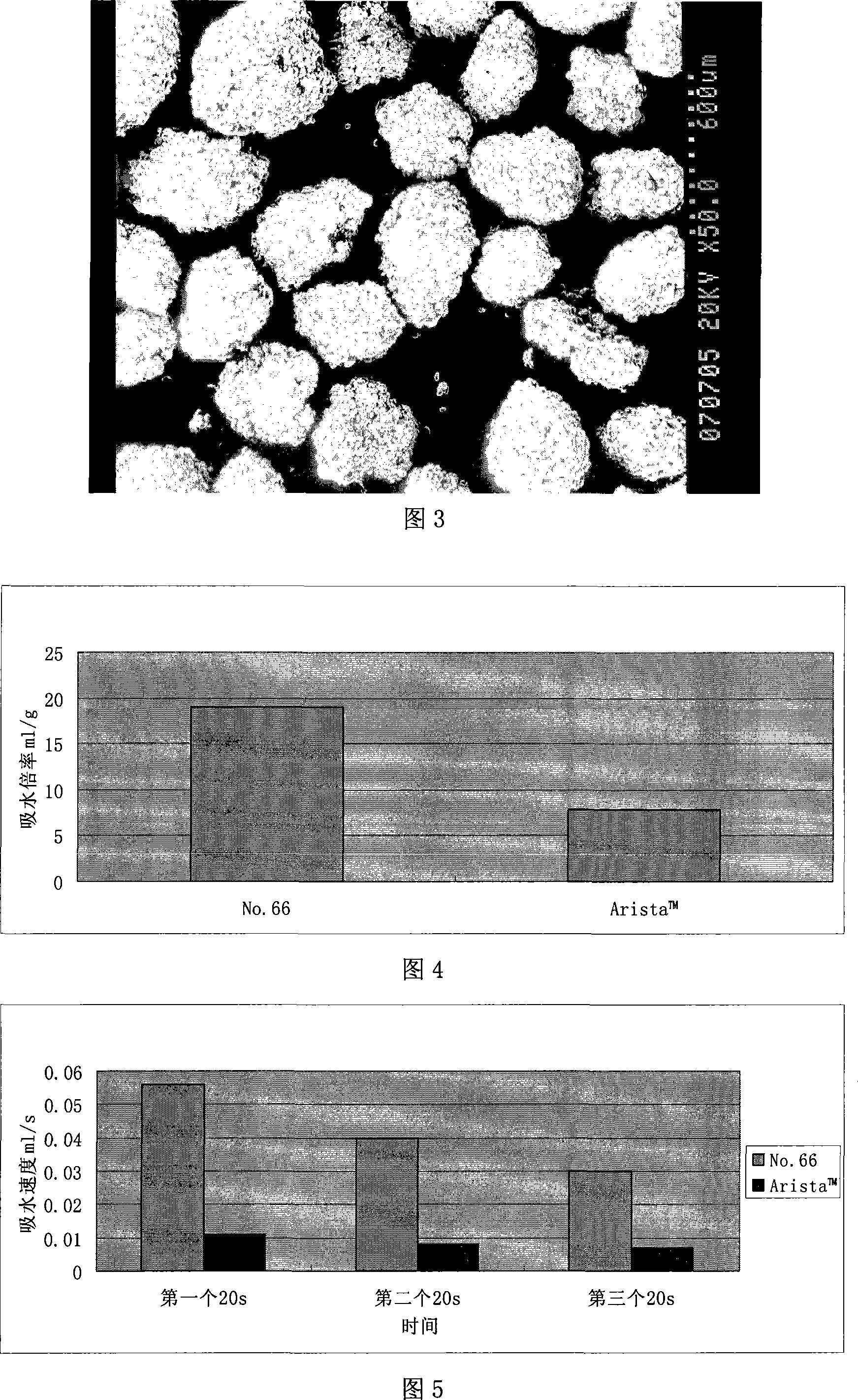

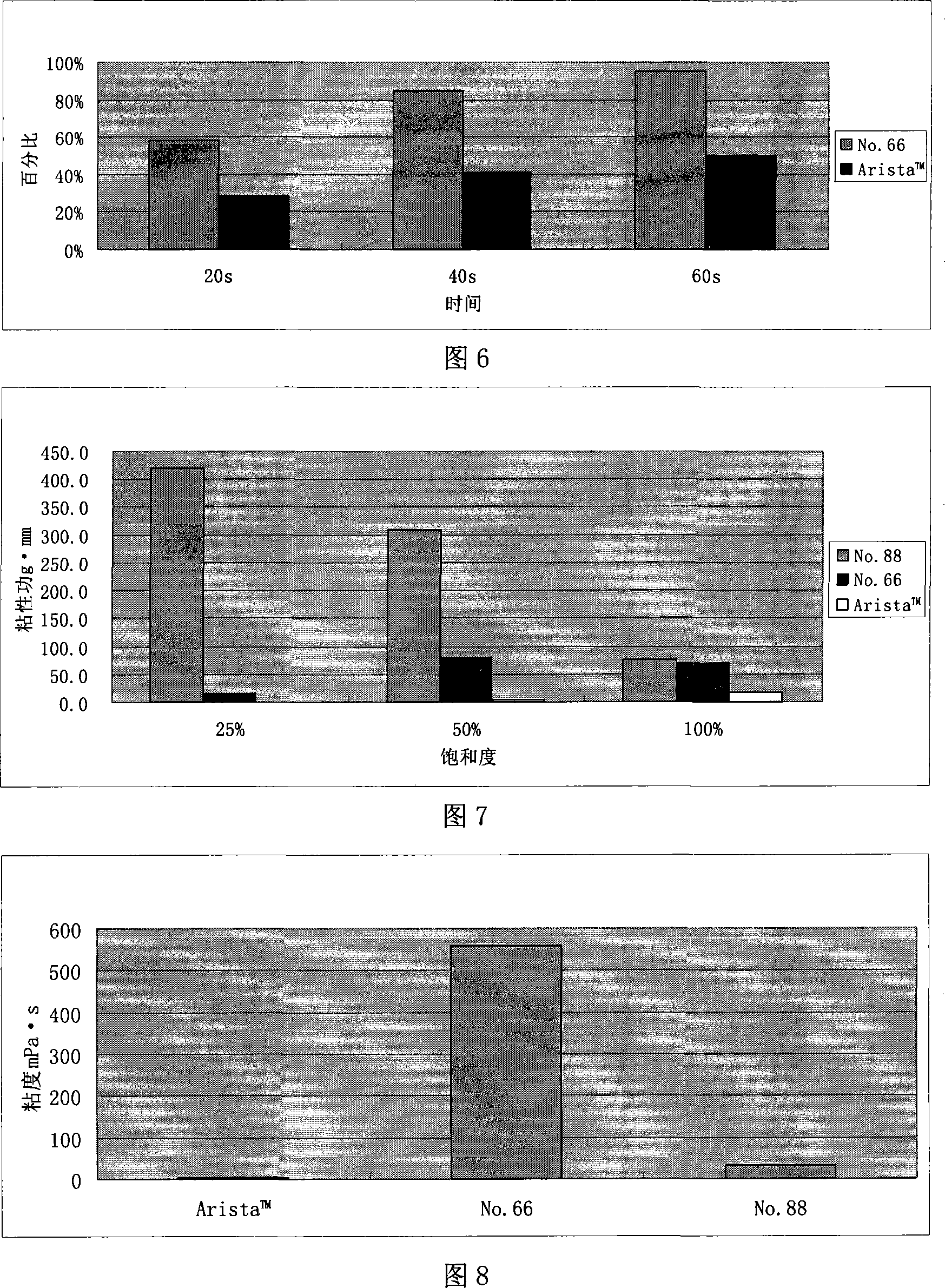

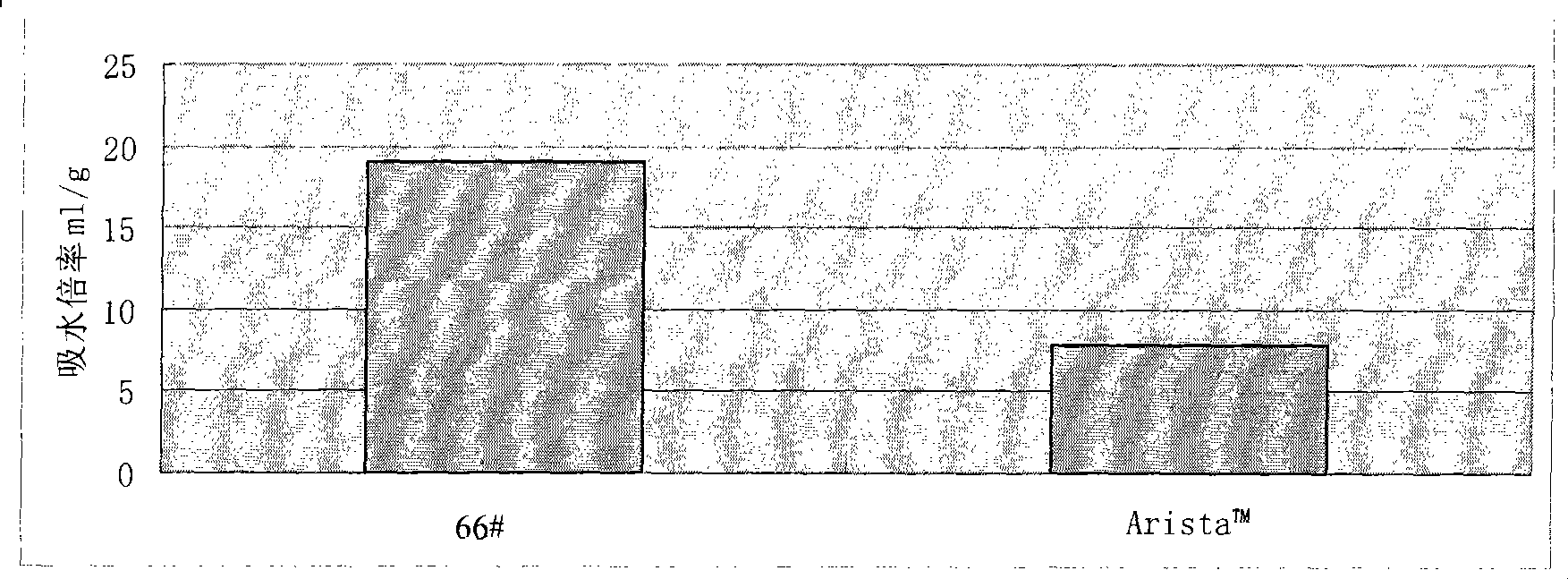

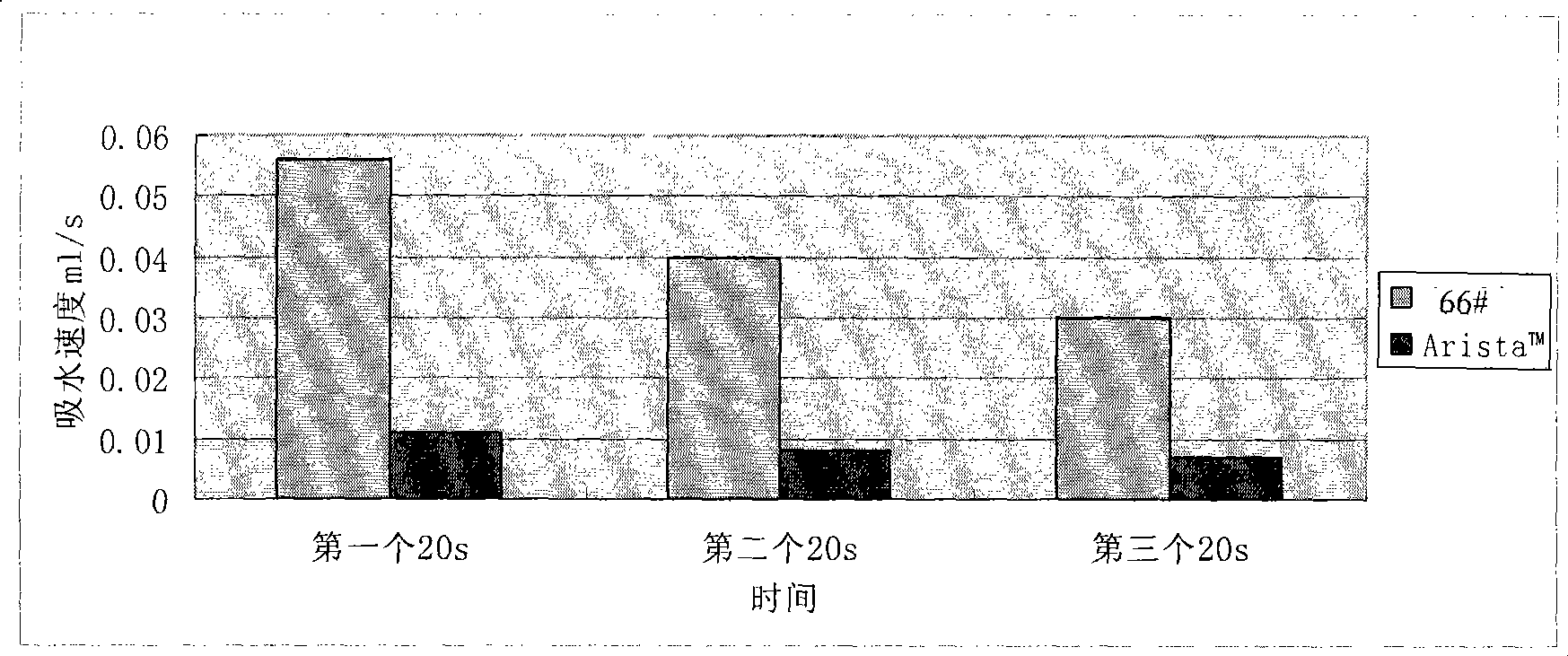

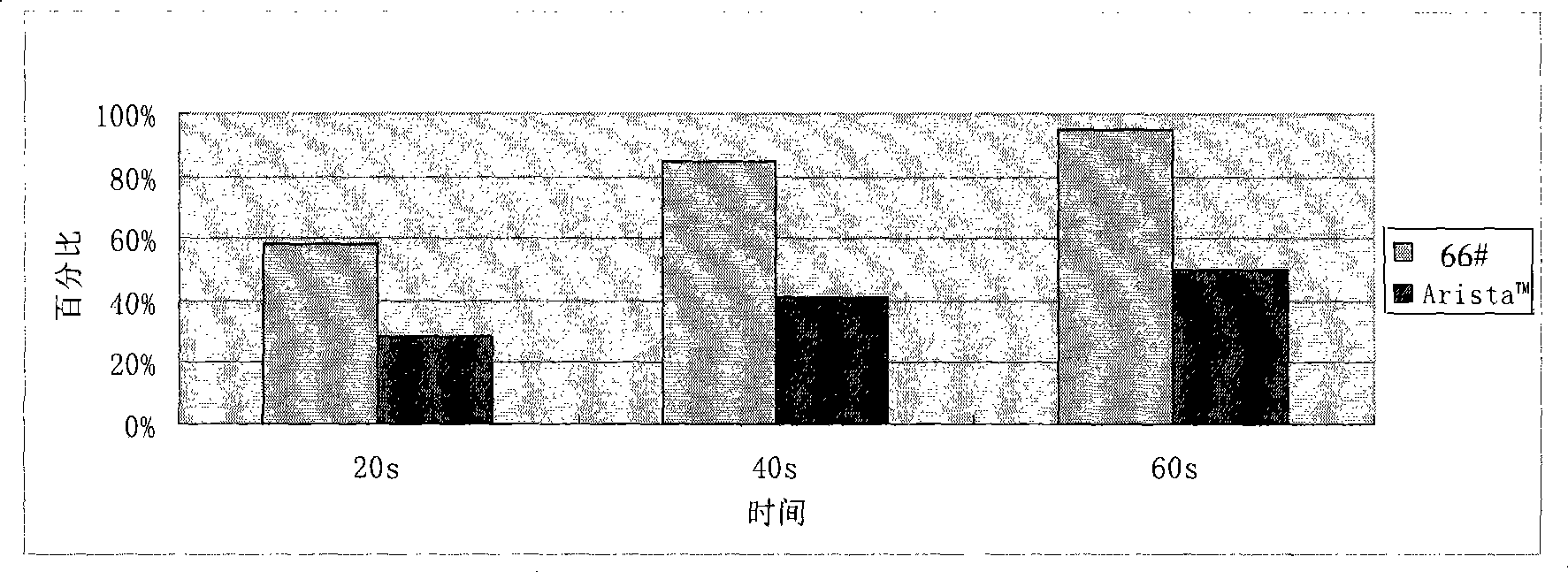

An absorbable modified starch hemostatic material and preparation thereof, wherein the hemostatic material is etherified starch, or a mixture of one or more etherified starches, crosslinked starches. The modified starch has a molecular weight of 15,000 - 10,000,000, a particle size of 10 - 1000µm, and a water absorption rate of 1 - 100. The biocompatible hemostatic material can directly effect on the wound with blood, concentrate the blood quickly to congulate blood; moreover, the gelatiniform mixture formed with blood has high viscosity, which can plug damaged tissue and blood vessel. The biocompatible hemostatic material is easy to swell in the water and easy to be washed so that the residue can be reduced; it is stable, not easy to decompose, and has long shelf life and storage advantage. The biocompatible hemostatic material can also be used as absorbable surgical antisticking material, promoting tissue healing material, surgical sealant and wound no-joint tissue adhesive.

Owner:美国淀粉医疗公司

Modified starch absorbable hemostasia material and preparation method thereof

ActiveCN101361986AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismWound healingBiomedical engineering

Owner:BEIJING UNIVERSAL LIKANG TECH CO LTD

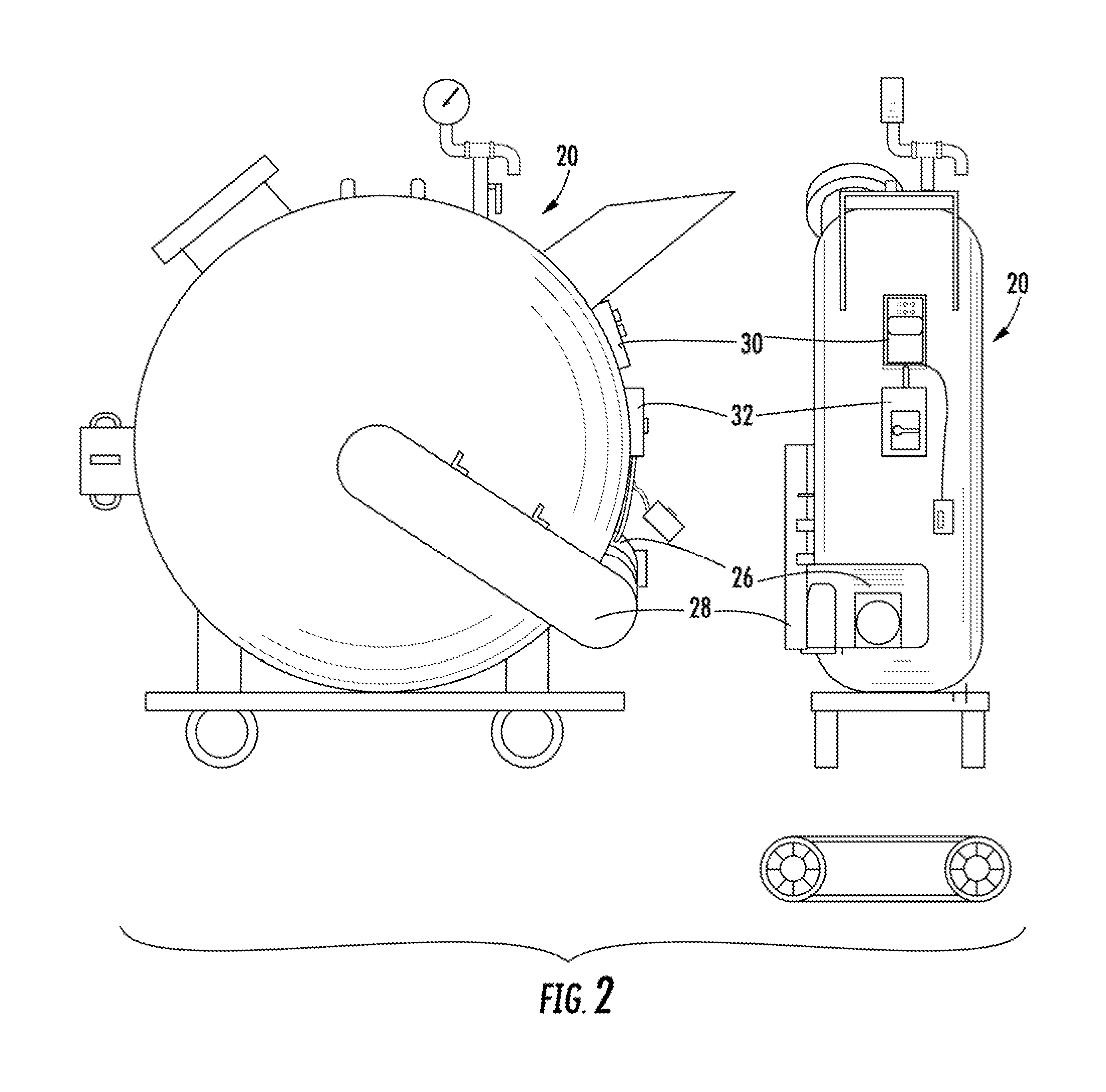

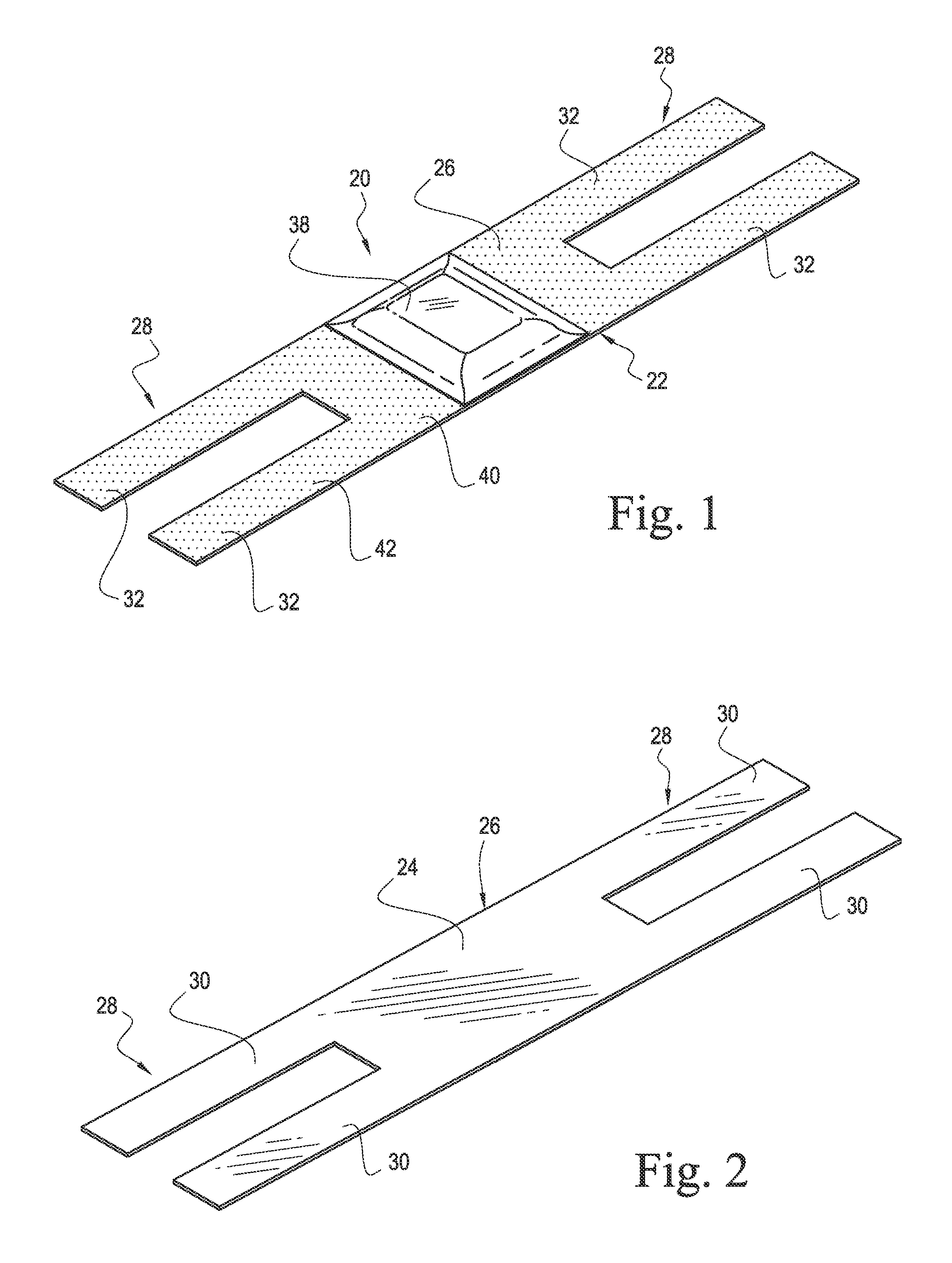

Pressure infusion lining system

InactiveUS20150020908A1Strong stickinessEffectively seal all crackDomestic sealsLayered productsInternal pressureEpoxy

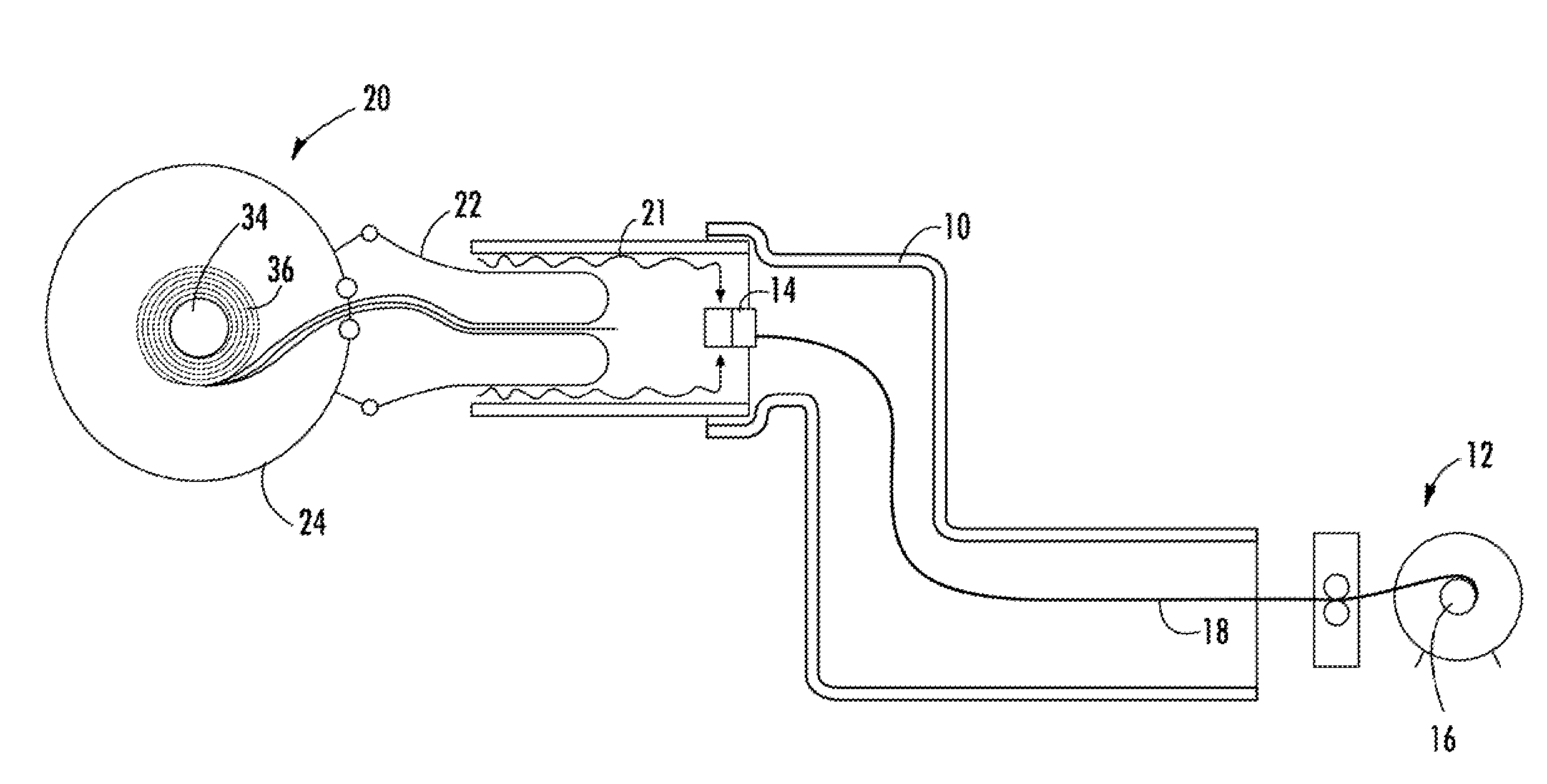

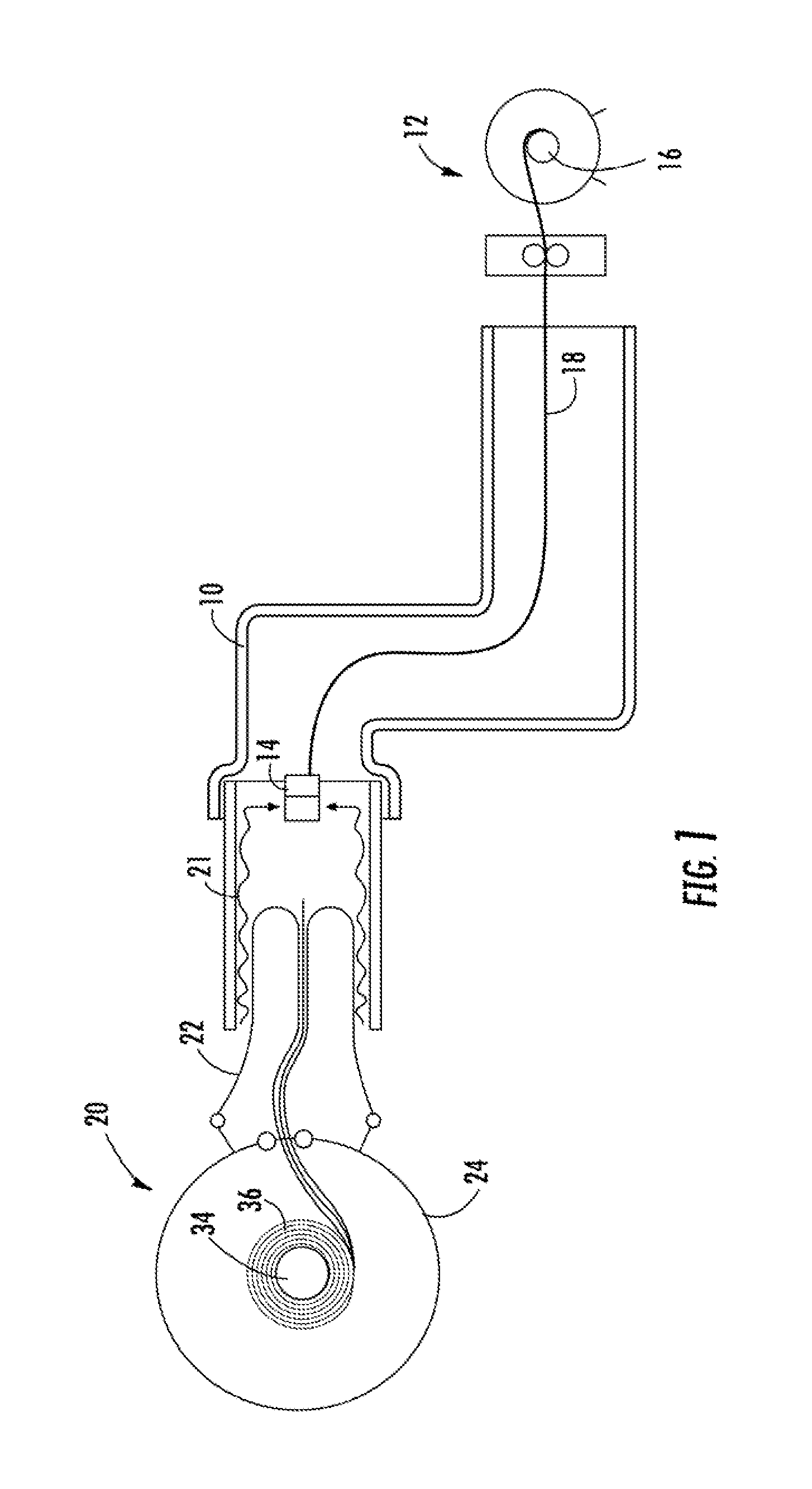

A method and system for applying a liner to an underground utility structure is provided. First a layer of epoxy is applied to the interior surface of the host pipe using a machine such as a spincast machine. A dry liner is inverted into the pipe directly behind the coating application at a limited speed and pressure. A drag is set on the inversion equipment relative to the speed of the epoxy spinner unit to control inversion speed. Once the liner is completely inverted the internal pressure of the liner is raised and infused into the uncured epoxy.

Owner:WARREN ENVIRONMENTAL & COATING LLC

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

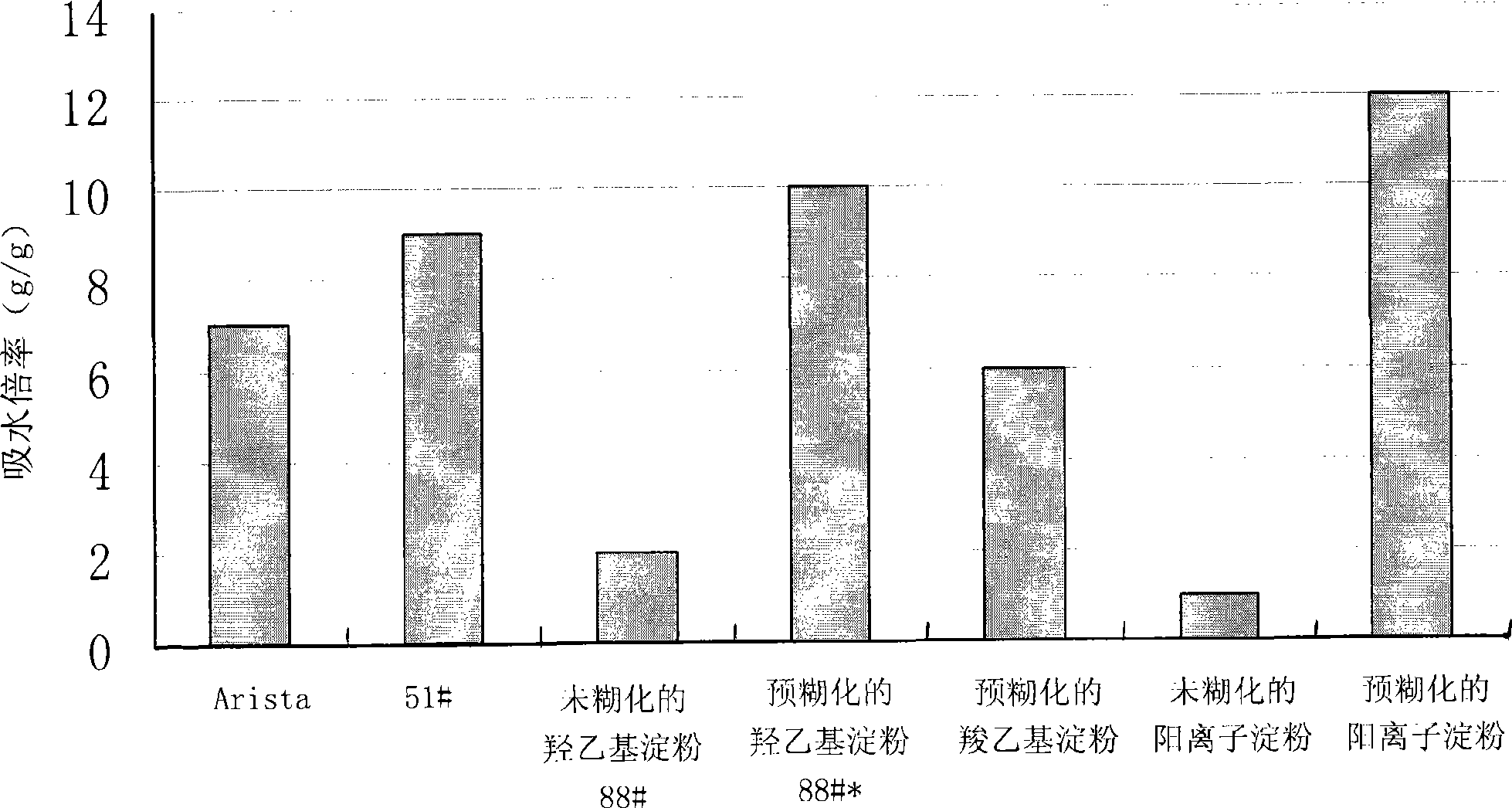

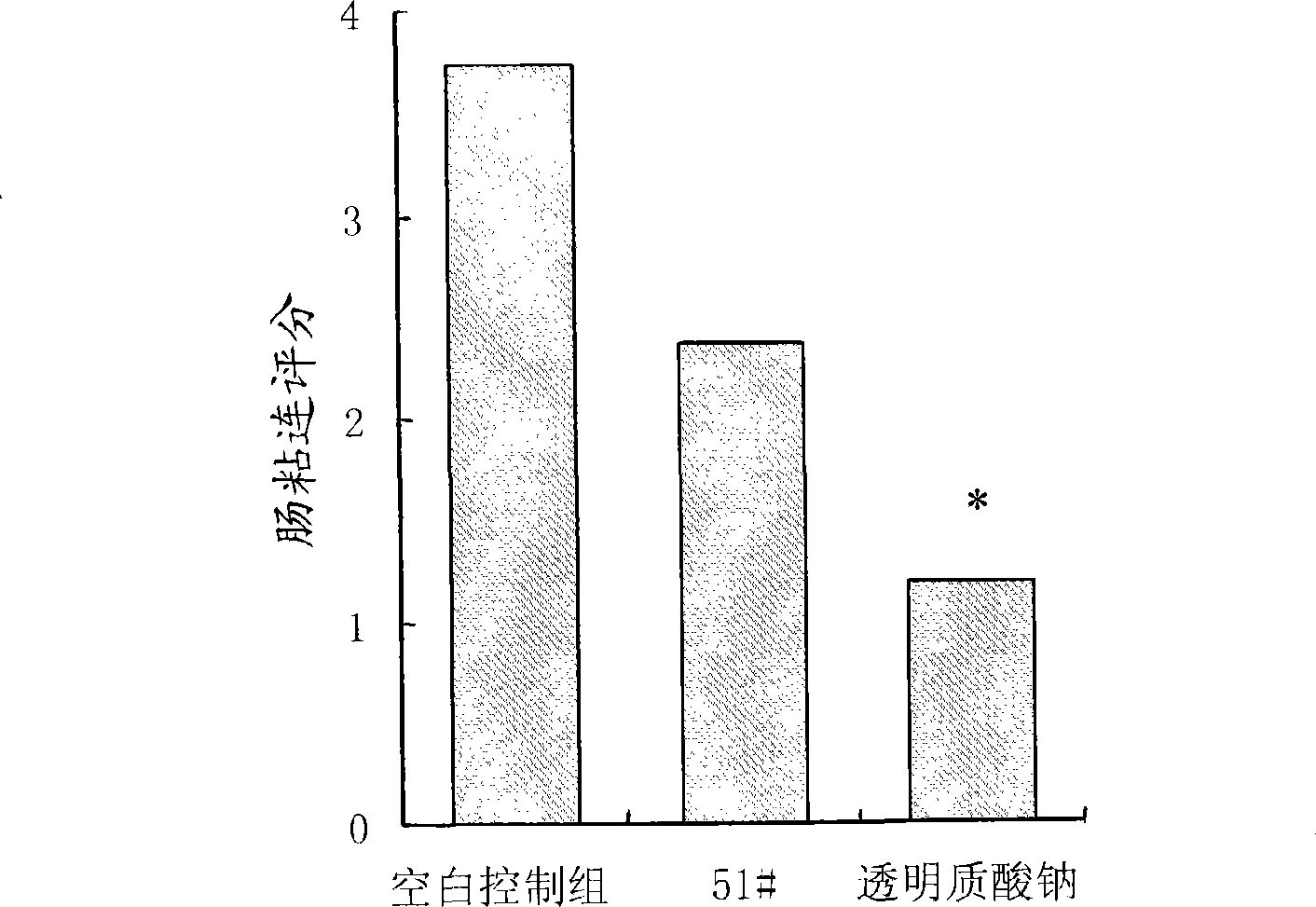

Biocompatibility pre-gelatinized modified starch and preparation thereof

InactiveCN101497670AAbsorbentSpeed up absorptionSurgical adhesivesFibre treatmentBiocompatibility TestingHigh pressure

The invention relates to a biocompatible pre-gelatinized modified starch. The water absorbency is not less than one time, and the biocompatible pre-gelatinized modified starch is taken as biocompatible hemostatic material, biocompatible anti-blocking material, biocompatible tissue-healing promoting material, biocompatible surgical sealant or biocompatible wound closure tissue glue. The invention has the advantages that the biocompatible pre-gelatinized modified starch is directly acted on the wounded area with blood for immediately stopping bleeding, has obviously increased water absorbency and speed of water absorption and greater viscosity and stickiness and further plays the role in preventing the tissue and the blood vessel from being damaged during the process of stopping bleeding; the modified starch is easy to swell or dissolve in water, and is washed by normal saline after the bleeding stopping so as to reduce the residual in the body, to be favorable for wound healing and to avoid the pain due to tearing the gauze and the bandage out; the pre-gelatinized modified starch has the actions of bacterial resistance and anti-inflammatory; and the pre-gelatinized modified starch is stable, not easy to decompose, long in guarantee period, convenient for storage, resistant at high pressure and low pressure, resistant at high temperature and low temperature and not easy to change the physicochemical characteristics.

Owner:纪欣

Electrically conductive paste for front electrode of solar cell and preparation method thereof

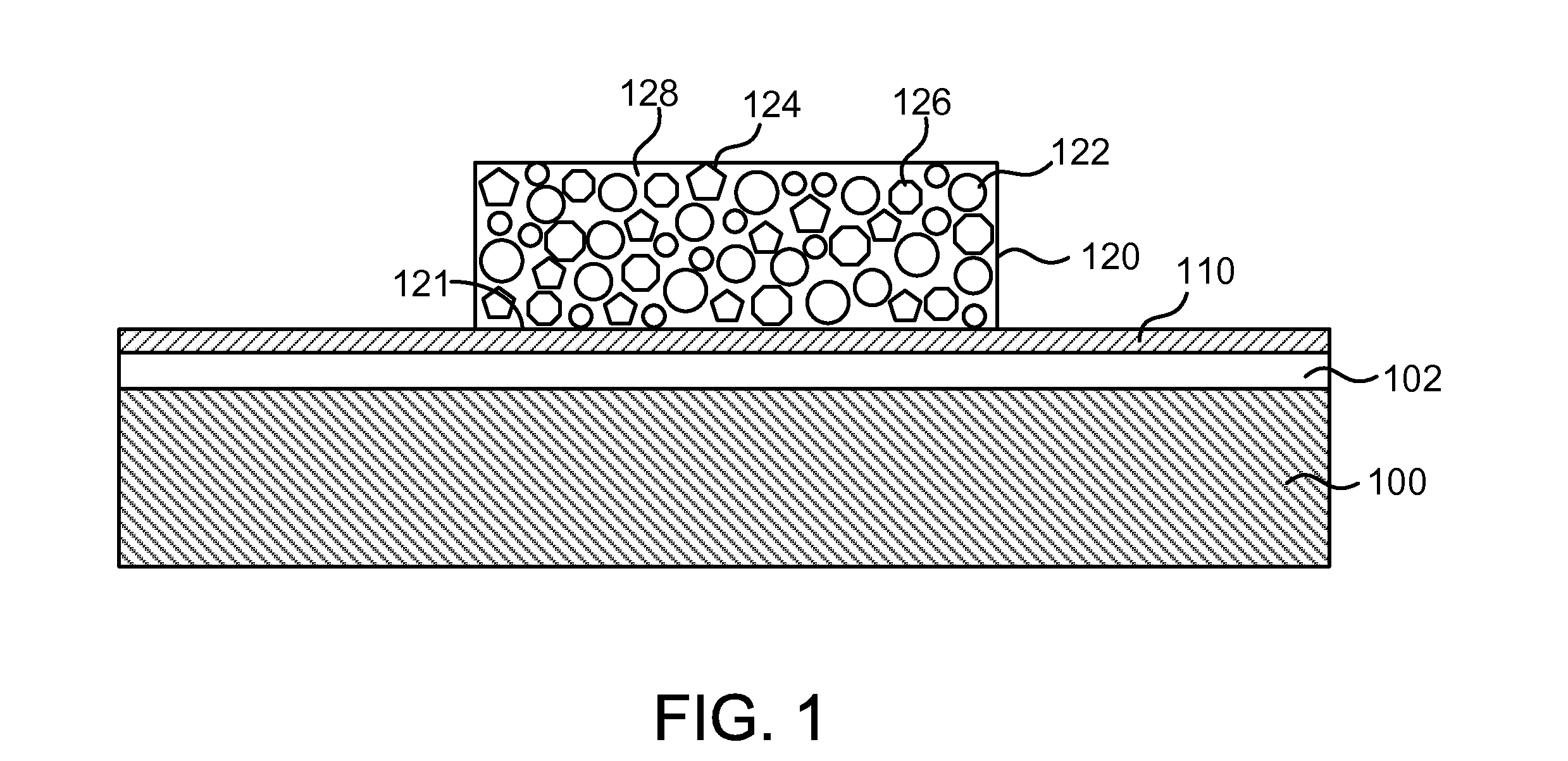

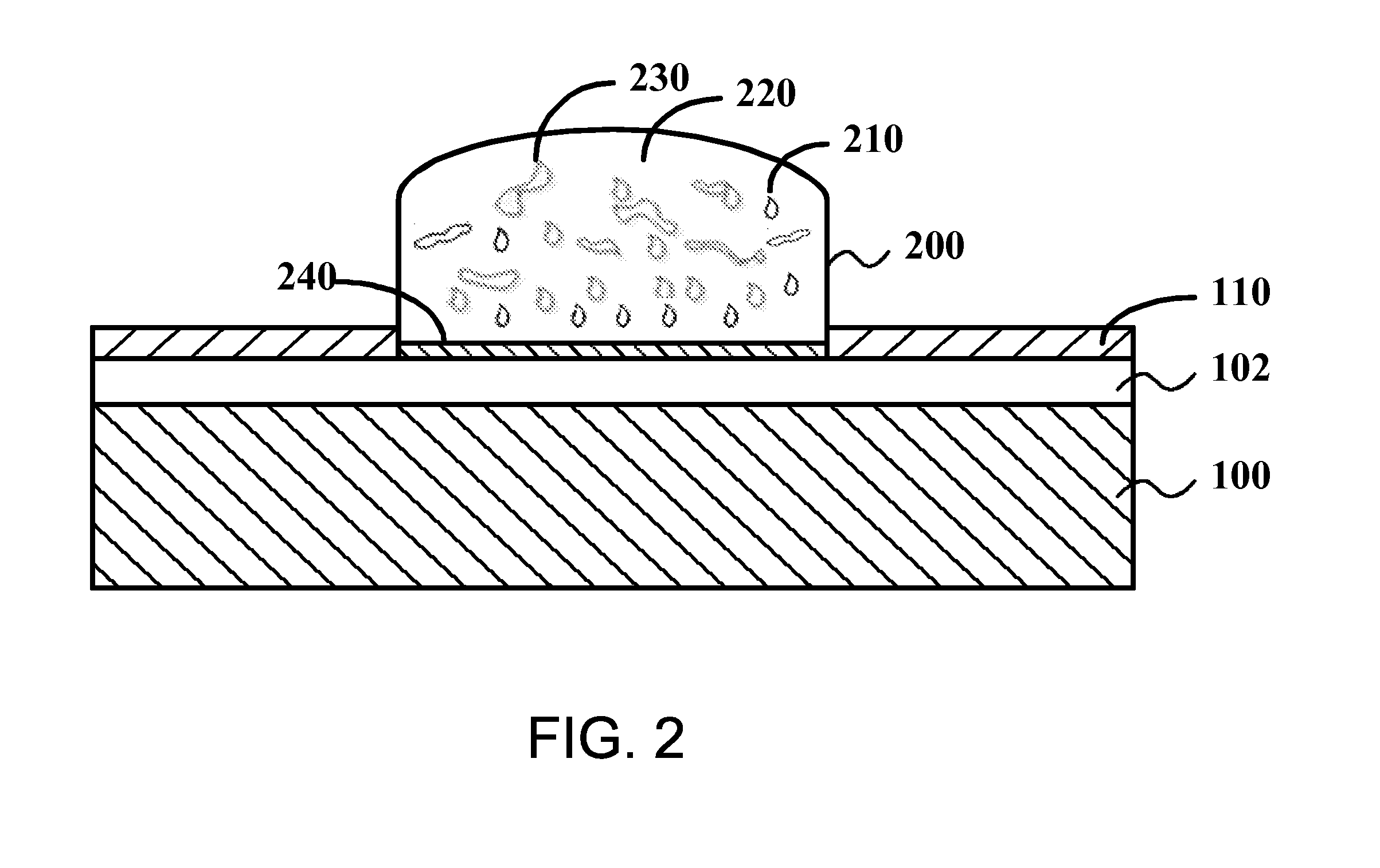

InactiveUS20140287583A1Reduced series resistanceImprove photovoltaic conversion efficiencyConductive materialSemiconductor/solid-state device manufacturingOhmic contactSilicon solar cell

The present invention provides an electrically conductive paste for a front electrode of a solar cell and a preparation method thereof. The electrically conductive paste is composed of a corrosion binder, a metallic powder and an organic carrier. The corrosion binder is one or more glass-free Pb—Te based crystalline compounds having a fixed melting temperature in a range of 440° C. to 760° C. During a sintering process of the electrically conductive paste for forming an electrode, the corrosion binder is converted into a liquid for easily corroding and penetrating an antireflective insulating layer on a front side of the solar cell, so that a good ohmic contact is formed. At the same time, the electrically conductive metallic powder is wetted, and the combination of the metallic powder is promoted. As a result, a high-conductivity front electrode of a crystalline silicon solar cell is formed.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

Clostridium butyricum active bacteria agent production method

The invention discloses a manufacturing method of butyrate spindle bacillus microecological agent, which comprises the following steps: preparing culture medium; dissolving the culture medium; adjusting pH value; loading in the ferment tank; heating to sterilize the culture medium in the ferment tank; inoculating the butyrate spindle bacillus seed; controlling temperature to ferment; detecting the bacteria number of ferment liquid; adsorbing ferment liquid through plant fiber powder; drying; grinding; obtaining the powder agent.

Owner:HUAZHONG AGRI UNIV

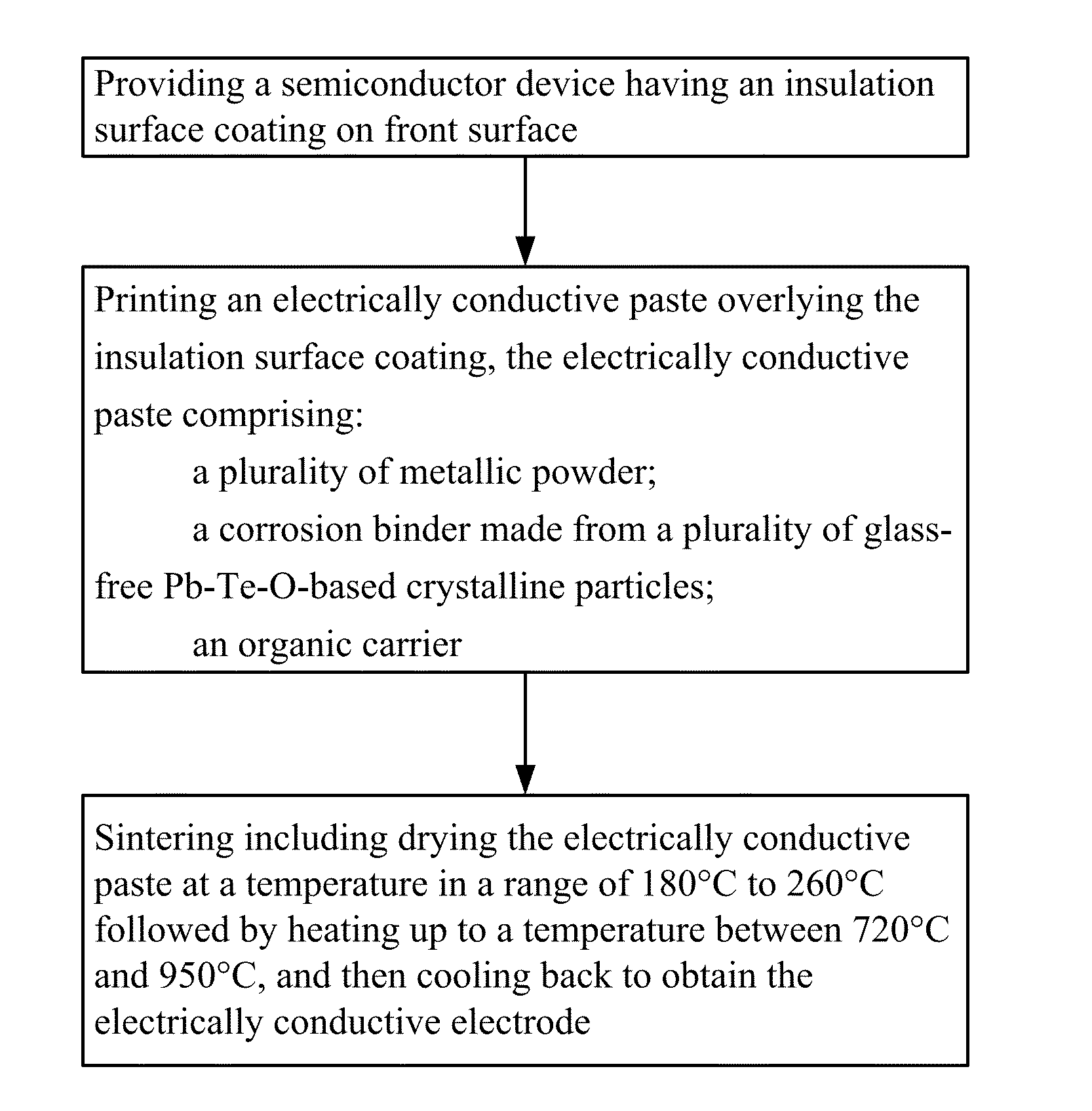

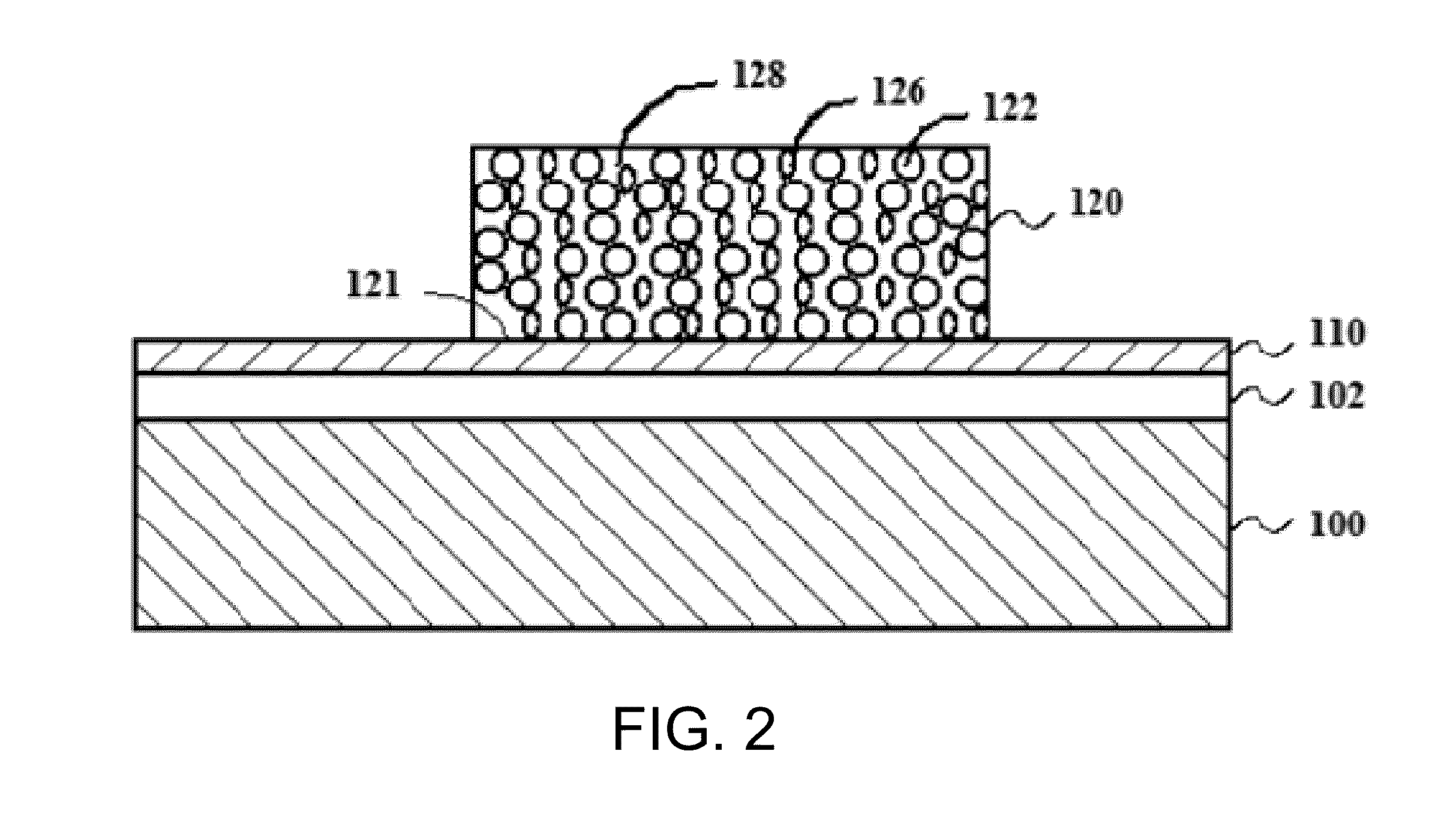

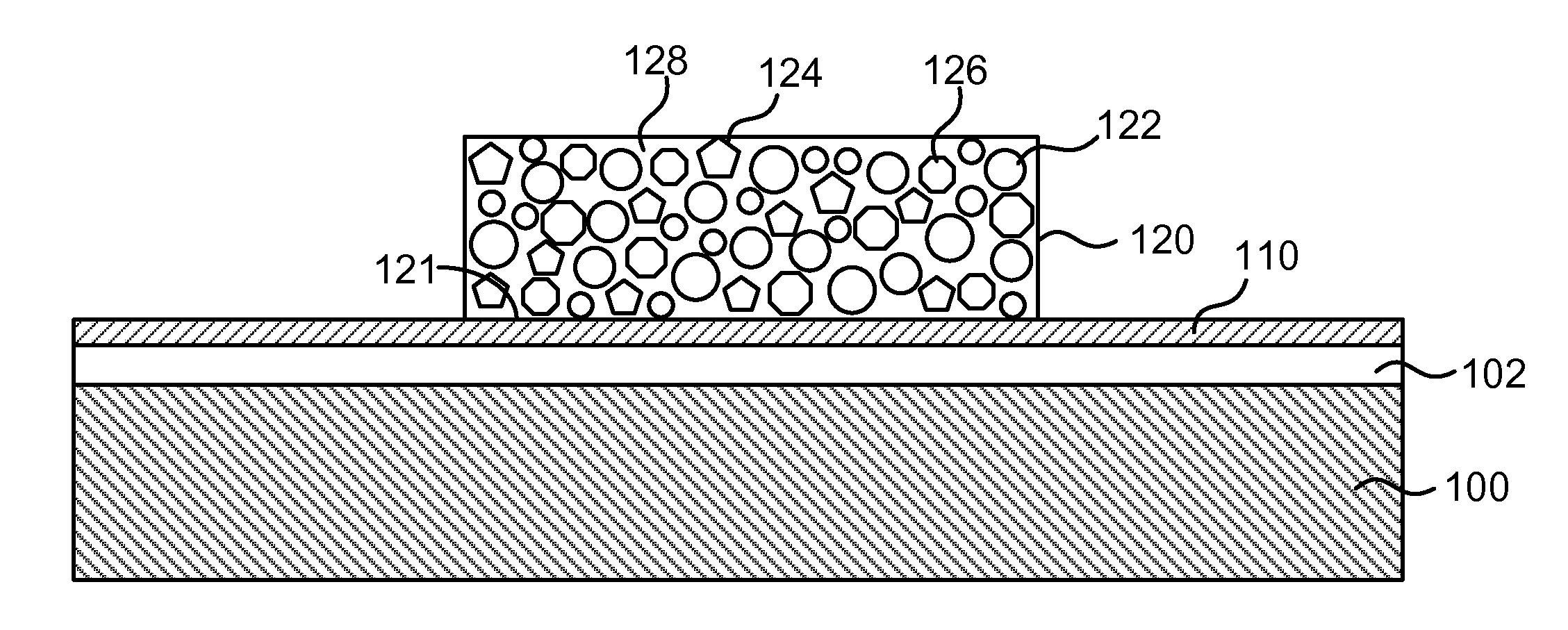

Conductive paste for front electrode of semiconductor device and method of manufacturing thereof

InactiveUS20140220732A1Low viscosityContactConductive materialSemiconductor/solid-state device manufacturingMetallic electrodeDevice material

The present invention provides a conductive paste characterized by a crystal-based corrosion binder being combined with a glass frit and mixed with a metallic powder and an organic carrier. Methods for preparing each components of the conductive paste are disclosed including several embodiments of prepare Pb—Te—O-based crystal corrosion binder characterized by melting temperatures in a range of 440° C. to 760° C. and substantially free of any glass softening transition upon increasing temperature. Method for preparing the conductive paste includes mixture of the components and a grinding process to ensure all particle sizes in a range of 0.1 to 5.0 microns. Method of applying the conductive paste for the formation of a front electrode of a semiconductor device is presented to illustrate the effectiveness of the crystal-based corrosion binder in transforming the conductive paste to a metallic electrode with good ohmic contact with semiconductor surface.

Owner:SOLTRIUM ADVANCED MATERIALS TECH LTD SHENZHEN

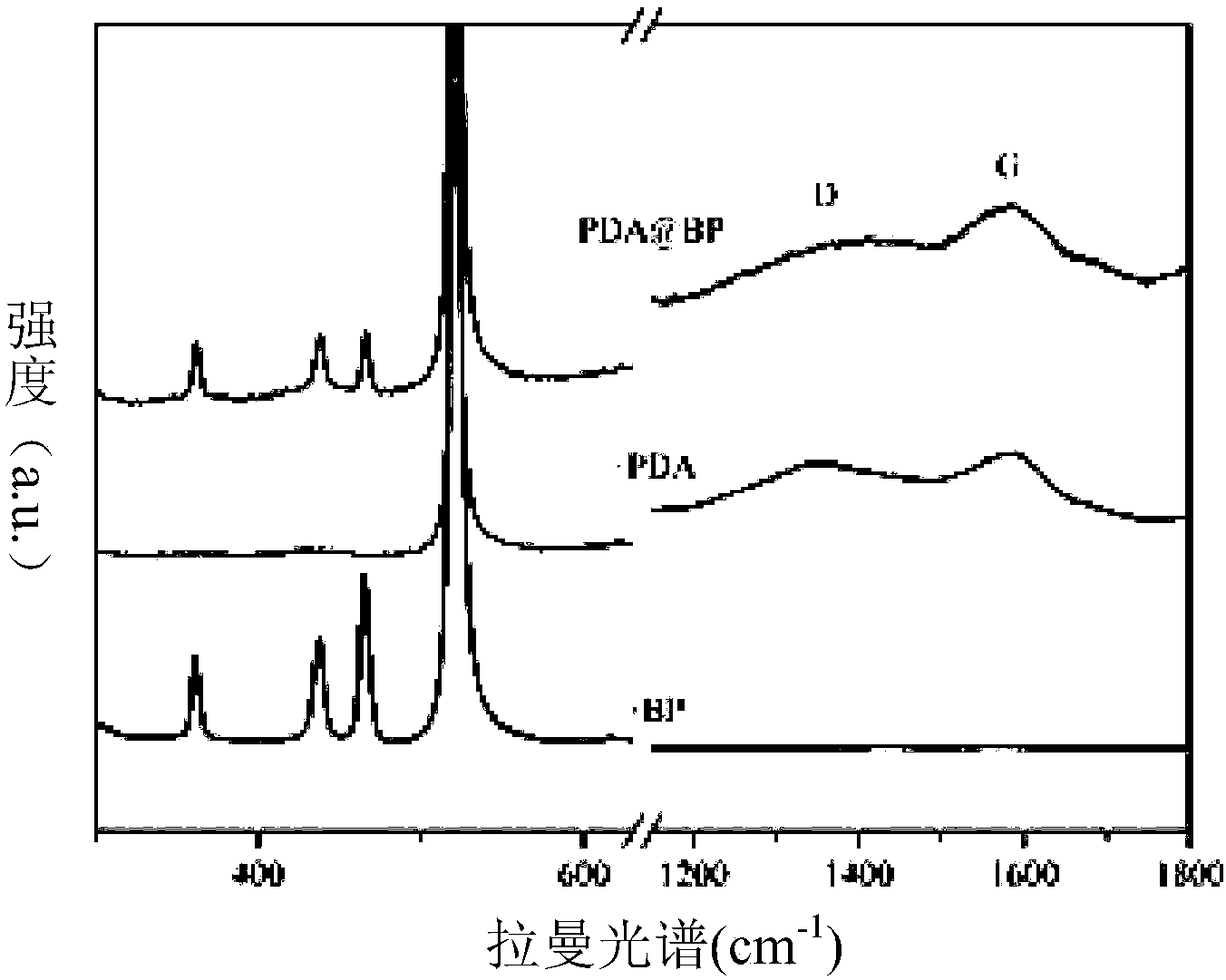

Polydopamine modified black phosphorus, and preparation method and applications thereof

InactiveCN108373145AStrong stickinessGood biocompatibilityInorganic non-active ingredientsPhosphorusWater vaporBiocompatibility Testing

The invention discloses a polydopamine modified black phosphorus, and a preparation method and applications thereof. The polydopamine modified black phosphorus comprises black phosphorus and polydopamine attached to the surface of the black phosphorus. The black phosphorus is coated with a uniform layer of polydopamine, so that the black phosphorus is isolated from oxygen and water vapor completely, and the black phosphorus stability is increased. The polydopamine modified black phosphorus possesses relatively excellent photothermal conversion performance and biocompatibility, is promising tobe applied in the fields such as photoelectric field and biological medical science. The invention also provides a preparation method of the polydopamine modified black phosphorus; the preparation method is simple; yield is high; the polydopamine modified black phosphorus is friendly to the environment; and low cost large scale production can be realized.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Microcapsule essence and its preparation method

ActiveCN101283774APrevent oxidationPrevent volatilizationChewing gumOral careSolubilityAqueous solution

The invention provides microcapsule essence, which comprises microcapsule wall and capsule core which is essence, wherein the microcapsule wall is Pullulan, and the essence has an amount of 1% to 80% that of Pullulan. The liquid essence can be well embedded in the microcapsule essence without addition of other auxiliaries according to the good film-forming property, viscosity and solubility of Pullulan, so that the microcapsule essence has the advantages of simple formula, high microencapsulation ratio, long perfume resistance time, good solubility and fast perfume release. The invention also provides the method for preparing the microcapsule essence, which comprises following steps: dissolving Pullulan in water to obtain a water solution with a certain concentration, adding essence, emulsifying uniformly, and spray-drying to obtain the final product. The preparation method has no special requirement for process parameters, easy control and good embedding effect of the product.

Owner:广东富味健康科技有限公司

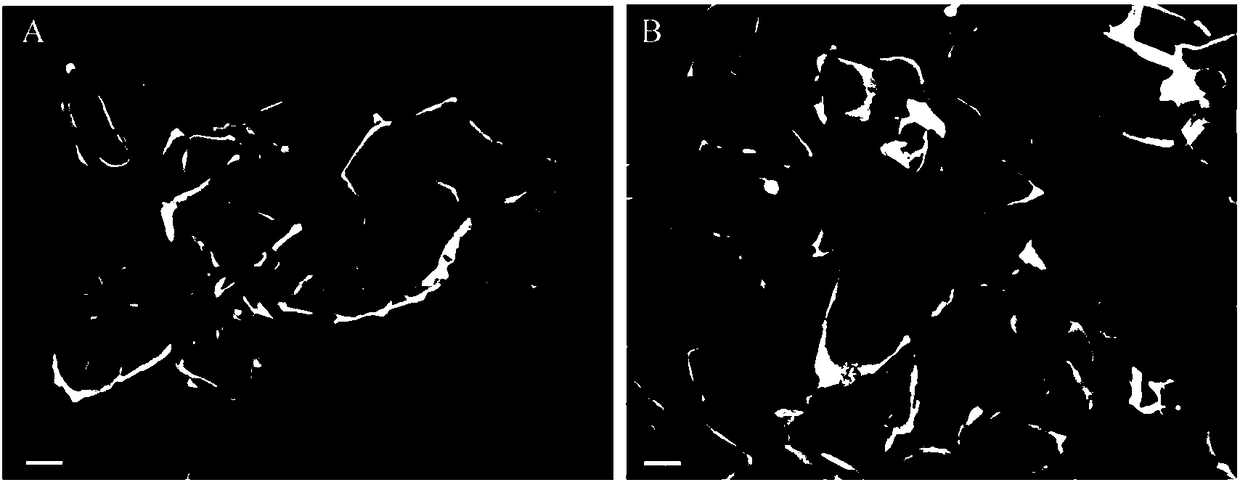

Latex Adhesives Derived From Ionic Strength Induced Soy Protein Complexes

InactiveUS20080287635A1Easy to operateHigh strengthPeptide preparation methodsFiberProtein molecules

Macro hydrophobic clusters and complexes of soybean globular proteins were observed using TEM (Transmission Electron Microscope). Upon unfolding, hydrophobic groups of the proteins became exposed toward the surface of the protein and actively interacted with other hydrophobic groups of other protein molecules, thereby forming hydrophobic bonding. The hydrophobic bonding resulted in hydrophobic protein clusters, the formation of which was affected by the degree of protein unfolding, protein structure, and hydrophobic components. Such hydrophobic clusters followed the global minimum free energy theory and formed spherical like structures with diameters ranging from 100 nm to 3000 nm. Such an understanding lends applicability to many uses in adhesives, molding composites, surfactants for oil-water systems, bio-based interior construction paints and paper coatings, fiber production, and metal powder molding applications.

Owner:SUN XIUZHUI +2

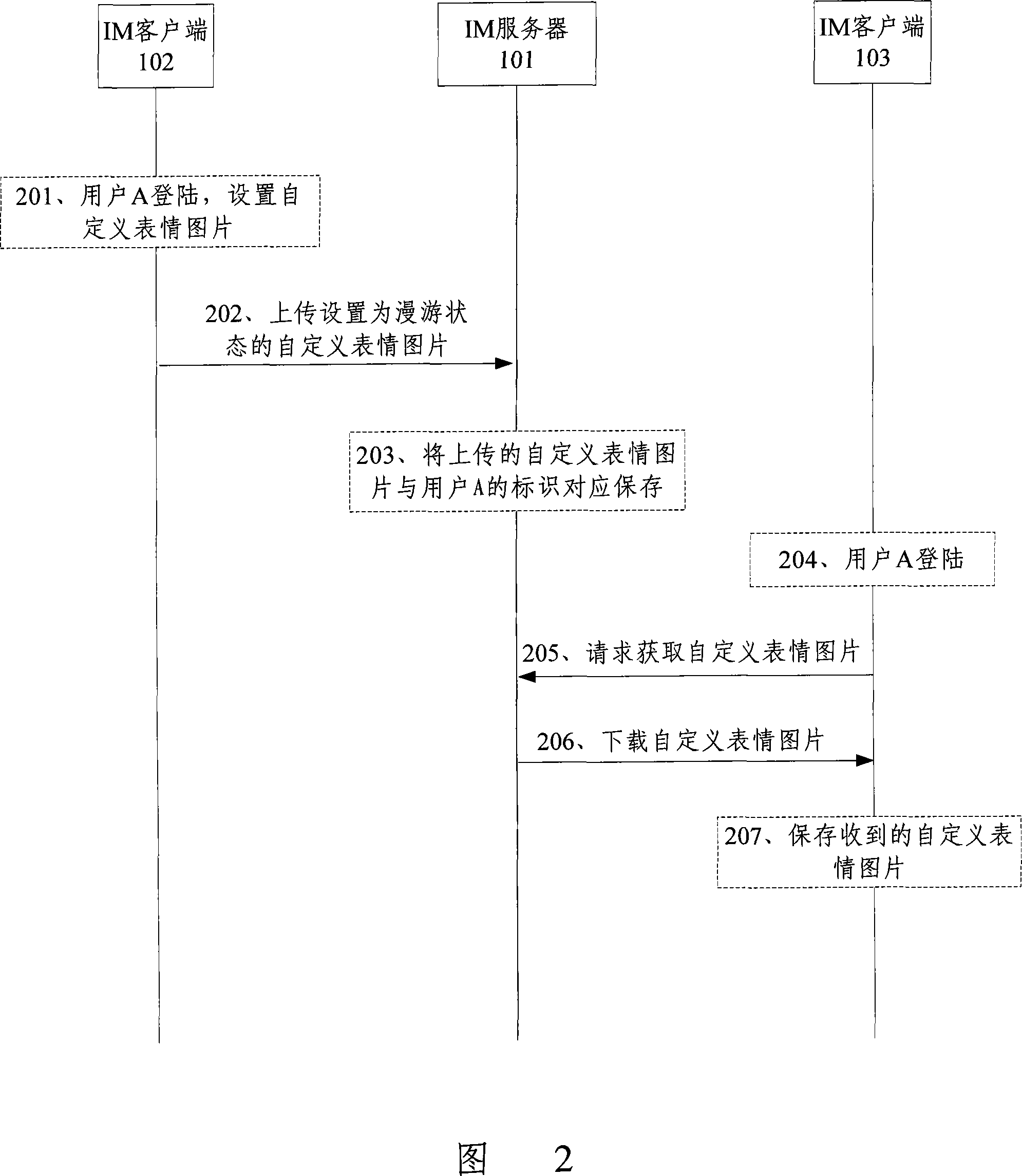

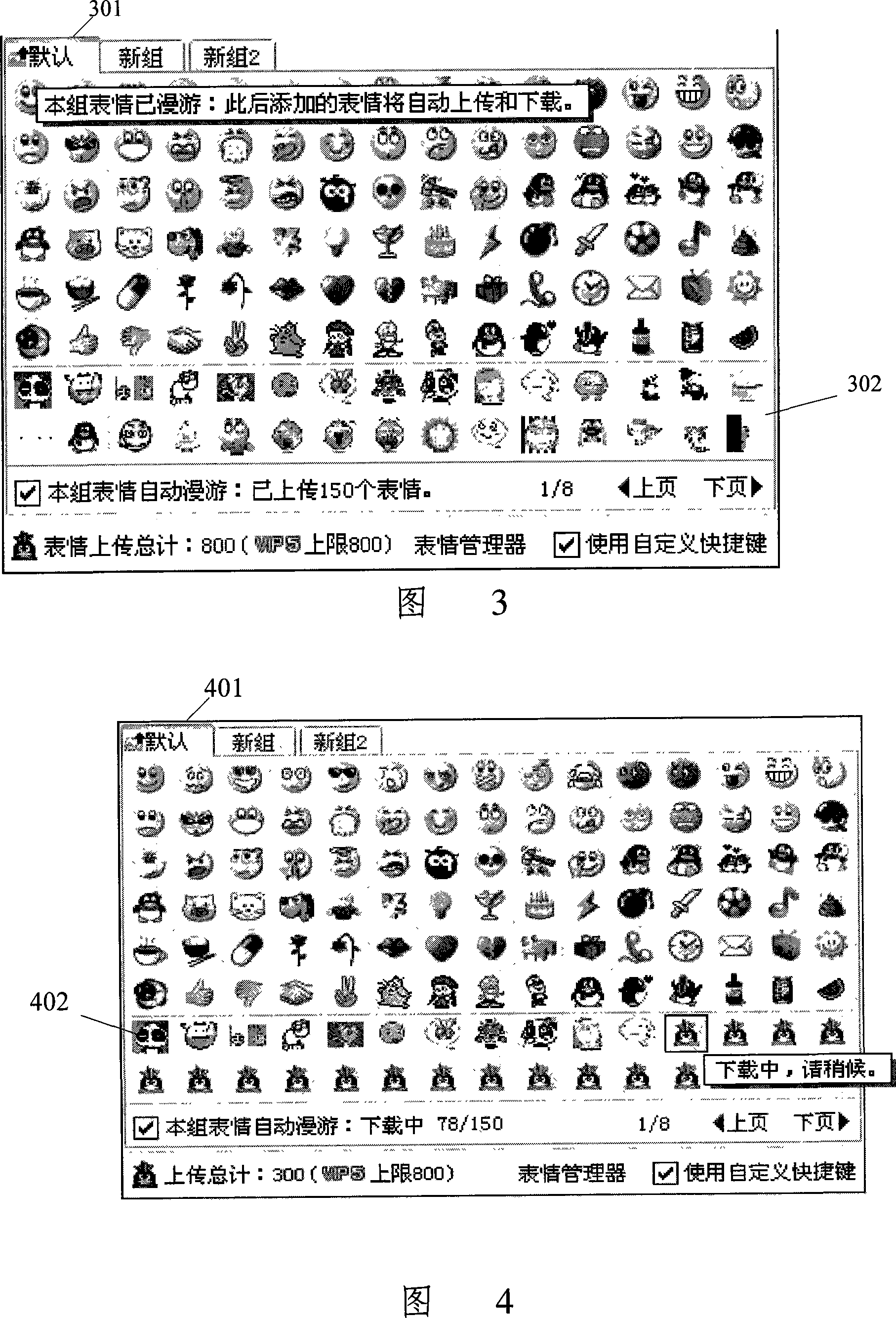

An instant communication system and transmission method of self-defined information

ActiveCN101123568AEasy instant messagingSave time and energyStore-and-forward switching systemsClient-sideCommunications system

The present invention discloses a transmission method of the customized information in an instant message (IM) system and an IM system, and the method includes three steps. Firstly, a local IM client receives and stores the customized information configured by a user; secondly, the local IM client uploads the customized information configured by the user to an IM server for storage; thirdly, when the user logs on to an IM client at a different location, the IM client at the location obtains and stores the corresponding customized information of the user from the IM server. By utilizing the present invention, the roaming function of the customized information can be realized, therefore a user can still use the customized information configured on a local IM client on an IM client at a different location, and as a result, the user can conveniently use the customized information to carry out the instant communication.

Owner:TENCENT TECH (SHENZHEN) CO LTD

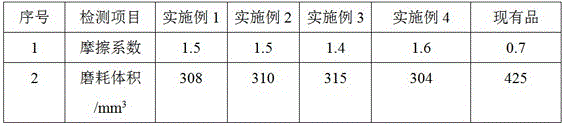

High-anti-slippery abrasion-resistant material for shoes and preparation method thereof

ActiveCN105778172AIncrease internal resistanceImprove mechanical propertiesSolesCarbide siliconOrganosilicon

The invention discloses a high-anti-slippery abrasion-resistant material for shoes and a preparation method thereof.The high-anti-slippery abrasion-resistant material is prepared from, by weight, 20-40 parts of natural rubber, 20-40 parts of styrene-butadiene rubber, 20-40 parts of butadiene rubber, 15-25 parts of halogenated butyl rubber, 20-30 parts of nanometer calcium carbonate, 10-20 parts of rubber oil, 10-20 parts of white carbon black, 3-8 parts of an activator, 3-5 parts of silicon carbide, 2-4 parts of organic siloxane, 1-5 parts of an accelerant, 1-3 parts of an antiager, 1-3 parts of sulfur and 0.5-1.5 parts of stearic acid.The raw materials required by the prepared high-anti-slippery abrasion-resistant material for the shoes are low in price and easy to obtain, the preparation process is simple, the strength is high, the anti-slippery performance is good, the abrasion-resistant performance and processing performance are excellent, the friction coefficient is 1.4-1.6, the friction volume is 304-315 / mm<3>, and the material can be used for production of high-anti-slippery abrasion-resistant shoe soles and other auxiliary materials.

Owner:QUANZHOU JIYOU SHOES CO LTD

Composition of waterborne laminating adhesive and method for preparing same

The invention relates to a composition of waterborne laminating adhesive and a method for preparing the same. The waterborne laminating adhesive comprises the following components in percentage by weight: 10 to 20 percent of soft monomer, 25 to 30 percent of hard monomer, 2 to 4 percent of functional auxiliary agent, 0.5 to 2 percent of emulsifier, 0.08 to 0.3 percent of initiator, 0.2 to 0.6 percent of Ph buffer regulator and 0.5 to 1.2 percent of functional assistant and 45 to 55 percent of softened water. Because a waterborne medium is used, so that no pollution is caused in the production process, damages caused by organic solvents to production persons and users are eliminated, and the fire risks in production and use processes are greatly reduced. The waterborne laminating adhesive has the advantages of higher bonding force, bonding strength, water resistance and solvent resistance, complete water base, no organic solvents such as benzene and ethylene dioxide, no toxin nor harmlessness, high product applicability, unnecessary modification of the original equipment, the complete replacement of the solvent-type laminating adhesive, no metachromatism with gold powder, the suitability for production of high-grade products, easily bought raw materials, simple production process, easy operation and the like.

Owner:CHANGZHOU INST OF CHEM

Glue used for adhering insects, and its prepn. method

An insect-adhering adhesive for preventing and controlling pests is prepared from rosin, castor seed oil and paraffin wax through proportional mixing. It has high and durable adhesion.

Owner:天津市园林绿化研究所

Self-heating-type fragrant hot compress paste

ActiveCN103876882AStrong stickinessFragrant and pleasantMedical devicesTherapeutic coolingEngineeringEssence oil

The invention relates to a self-heating-type fragrant hot compress paste which effectively solves the problems that according to an existing self-heating disposable warm paste, due to the fact that raw materials are easily moved, the paste is not flat, the comfort level is affected, and clothes are polluted. A raw material layer is installed in a ventilation bag composited by a non-woven fabric layer and the non-adhesive face of a piece of pressure sensitive adhesive tape, the ventilation bag is vacuumized, a piece of release paper is stuck to the adhesive tape face of the pressure sensitive adhesive tape, and heating materials are composed of reduced iron powder, expanded vermiculite, wormwood powder, activated carbon, fragrant essential oil, industrial salt, water and ethyl alcohol. The reduced iron powder, the activated carbon, the wormwood powder and the expanded vermiculite are taken to be fully mixed in the sealed bag to obtain a mixture. The industrial salt is taken to be dissolved into the water, the ethyl alcohol and the essential oil are added, stirred and dissolved into the water with the industrial salt, and the water with the industrial salt, the ethyl alcohol and the essential oil is evenly mixed with the mixture in the self-sealing bag. The self-heating-type fragrant hot compress paste is safe, non-toxic, fragrant, pleasant, convenient to use, low in cost, stable in heating and durable in heat availability.

Owner:HENAN LINGRUI PHARMA

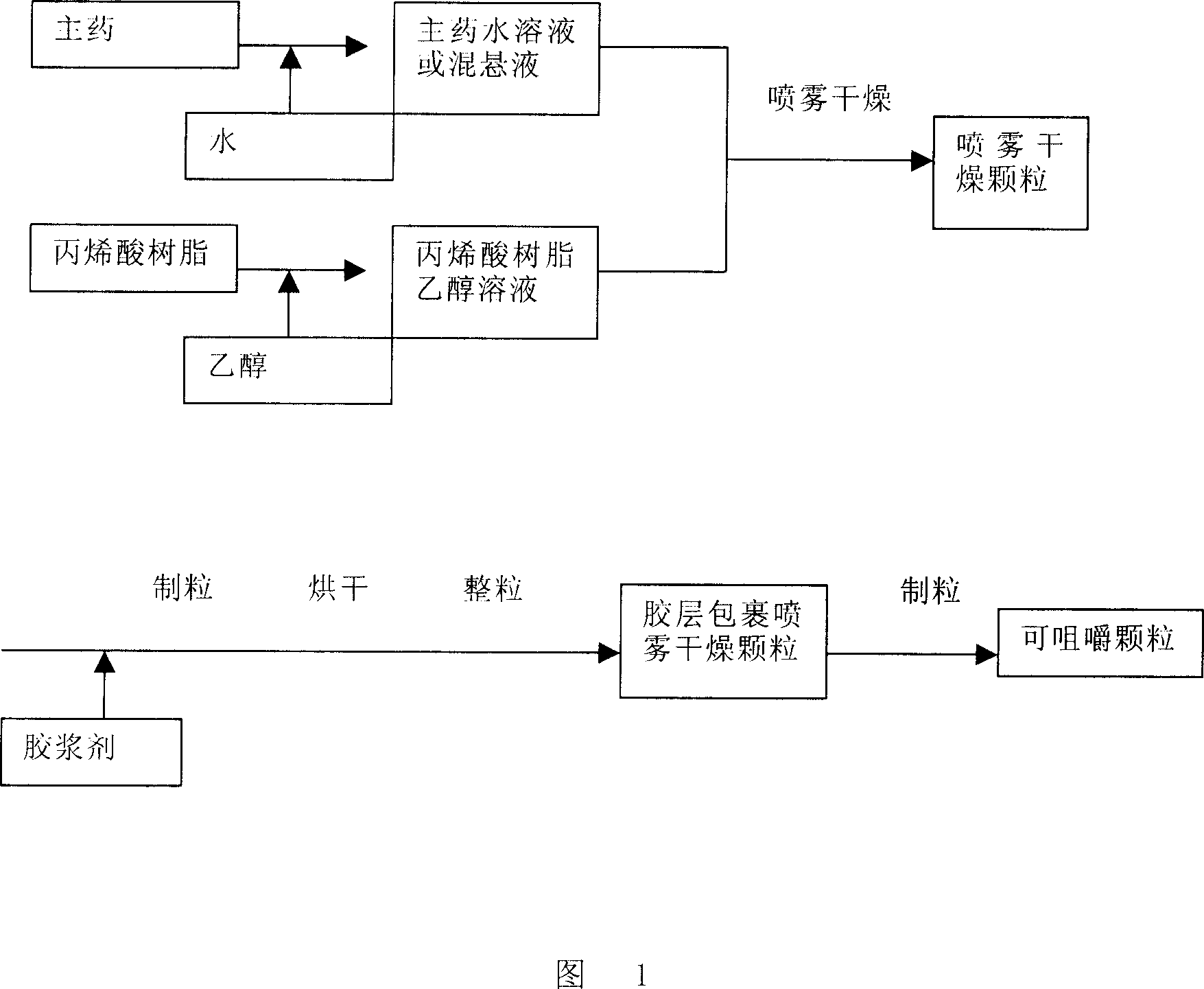

Unfavorable taste-masking drug granule, chewable formulation and preparation process thereof

InactiveCN1994468AStrong stickinessAvoid destructionPharmaceutical non-active ingredientsPill deliveryRotary evaporatorAcrylic resin

The invention relates to a particles used to shade bad taste of drug, wherein it is formed by corn element with active component and continuous polymer dress; the corn element is formed by active component and acrylic resin at 1:0.5-1:20 mass ratio; the dress is soluble gel slurry; and the drug is soluble in acid solution with bad taste. And the production comprises that: dissolving drug and soluble base material into solvent; using atomizing drier or rotation evaporator to obtain dry particles; then graining them at neutral condition via gel material; forming dress that separates drug and taste bud on the surface of particles; preparing oral agent via general method. The invention can avoid releasing bad taste in mouth but release drug in stomach.

Owner:牛祝琴 +2

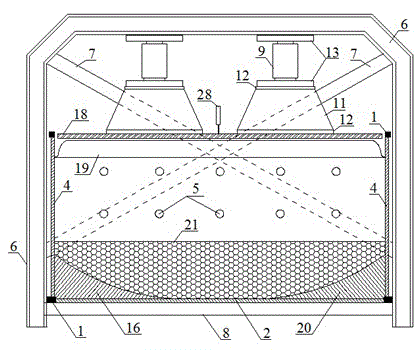

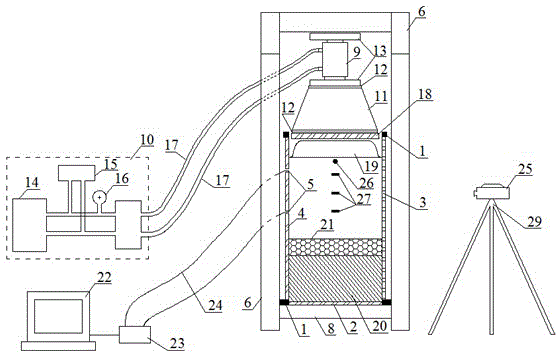

Test platform of rock-fill dam mask impervious structure model on deep overburden layer

InactiveCN103604617ASimple preparation processStrong stickinessStructural/machines measurementData acquisitionEngineering

The invention discloses a test platform of a rock-fill dam mask impervious structure model on a deep overburden layer. The platform is formed by a model box, a counter force frame, a loading system, a water pressure simulation device, a flexural deformation simulation device and a test system. The model box is arranged in the counter force frame. The flexural deformation simulation device is located at the bottom of the model box so as to simulate an impervious structure bottom deflection displacement boundary condition. The loading system applies vertically downward pressure through the counter force frame and transmits a flexible pressure load to the top surface of an impervious structure model. A testing system is formed by an earth pressure sensor, a strain, a displacement meter and a data collection instrument which are arranged in the structure model and a high-definition digital camera at a side of the model box together carries out real-time monitoring on the structural state. The platform can be used for the model test research of force deformation characteristics and failure mechanism of a deep overburden layer rock-fill dam mask impervious structure in the condition of surface water pressure load and large bottom deflection.

Owner:HOHAI UNIV

Processing method for preparing bricks by utilizing urban domestic sludge

InactiveCN101570429AStrong stickinessMeet emission standardsCeramic materials productionClaywaresSmokeSludge

The invention discloses a processing method for preparing bricks by utilizing urban domestic sludge, which relates to the processing and the utilization of the urban domestic sludge. The processing method comprises the following steps: granulating and drying the sludge for aging; uniformly mixing aged granular materials with shale or clay or coal slag or building rubbish according to the proportion by weight; after the mixing, adding an amount of water for preparing brick blanks and continuing stirring and mixing; preparing the blanks; sintering the blanks; and preserving heat and cooling the blanks to obtain the bricks. The invention greatly saves resources and provides an active sludge processing and utilizing scheme. Some of the strength indexes of the prepared bricks even exceed those of the bricks prepared by ordinary processes. During roasting, for the condition that tail gas generated in the process of roasting the sludge bricks contain more sulfur and chlorine ingredients, a combined desulphurizing and deodorizing technology inside and outside a furnace is used, namely, the limestone is added in to a burning furnace, and water is sprayed to the tail gas under a sealing condition, thus a desulphurizing reactor does not need to be arranged on a tail part so as to ensure that smoke gas reaches an emission standard.

Owner:王明根

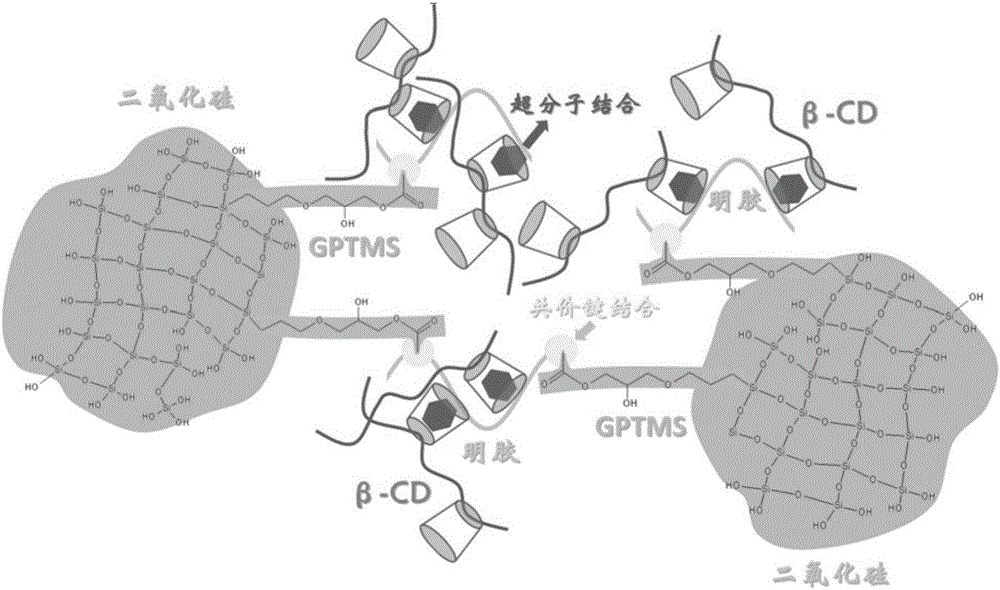

Injected supermolecule hydrogel and preparing method thereof

InactiveCN105664245AStrong adhesionStrong injectabilityTissue regenerationProsthesisSupramolecular hydrogelsGelatin

The invention belongs to the technical field of hydrogel and provides injected supermolecule hydrogel and a preparing method thereof. The injected supermolecule hydrogel comprises beta-cyclodextrin, gelatin and a coupling agent. Beta-cyclodextrin and a benzene ring in gelatin are combined in a subject and object mode by means of the hydrophobicity effect. The coupling agent is a silane coupling agent containing amino and / or epoxy bonds. Gelatin and the end, containing amino or epoxy bonds, of the coupling agent form covalent cross linking. The other end of the coupling agent is subjected to self-crosslinking to form a silicon dioxide network.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Ultrafine fried corn flour and production method thereof

The invention discloses ultrafine fried corn flour and a production method thereof. The content of corn in the ultrafine fried corn flour is 100 percent, and the fineness is greater than 200 meshes. The production method of the fried corn flour comprises the following steps of: (1) cleaning corn, peeling and degerming; (2) smashing and sieving with a 150-mesh sieve to obtain ultrafine raw corn flour; (3) adding 30 percent of water into the raw flour, stirring uniformly, extruding, curing into corn noodles, and airing or drying; and (4) smashing dry corn noodles into corn flour over 200 meshes. The ultrafine fried corn flour is yellow in color, has high viscosity after being added with water, and can be prepared into special flour with strong corn flavor such as noodle flour, dumpling flour, biscuit flour, steamed bread flour, full-moon dumpling flour and the like after being mixed with ultrafine raw corn flour and a small amount of wheat flour or buckwheat flour, rice flour and sticky rice flour. The production method has the advantages of easiness, high yield and capability of keeping the original color and nutritional ingredients of corn.

Owner:周耀英

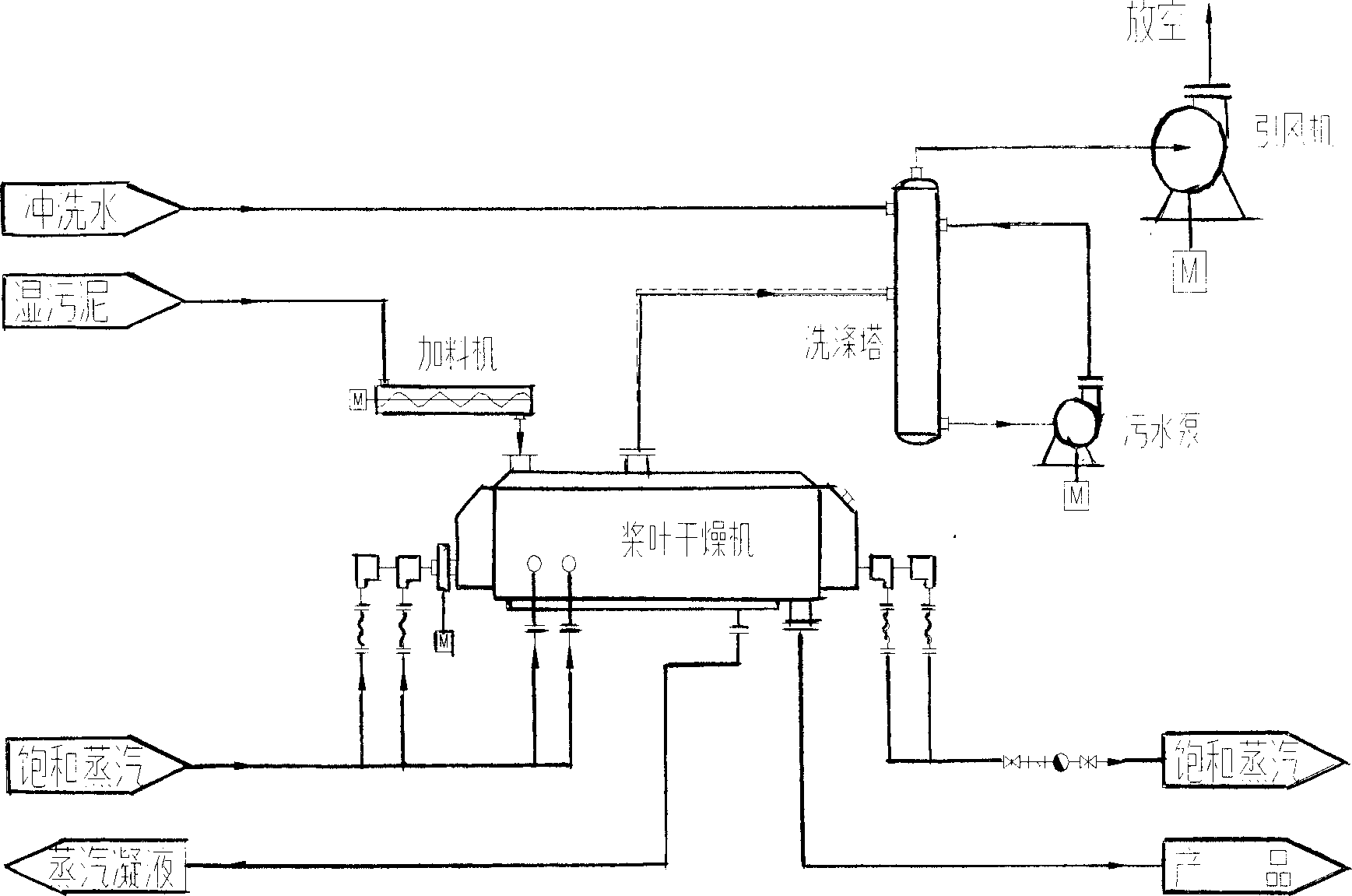

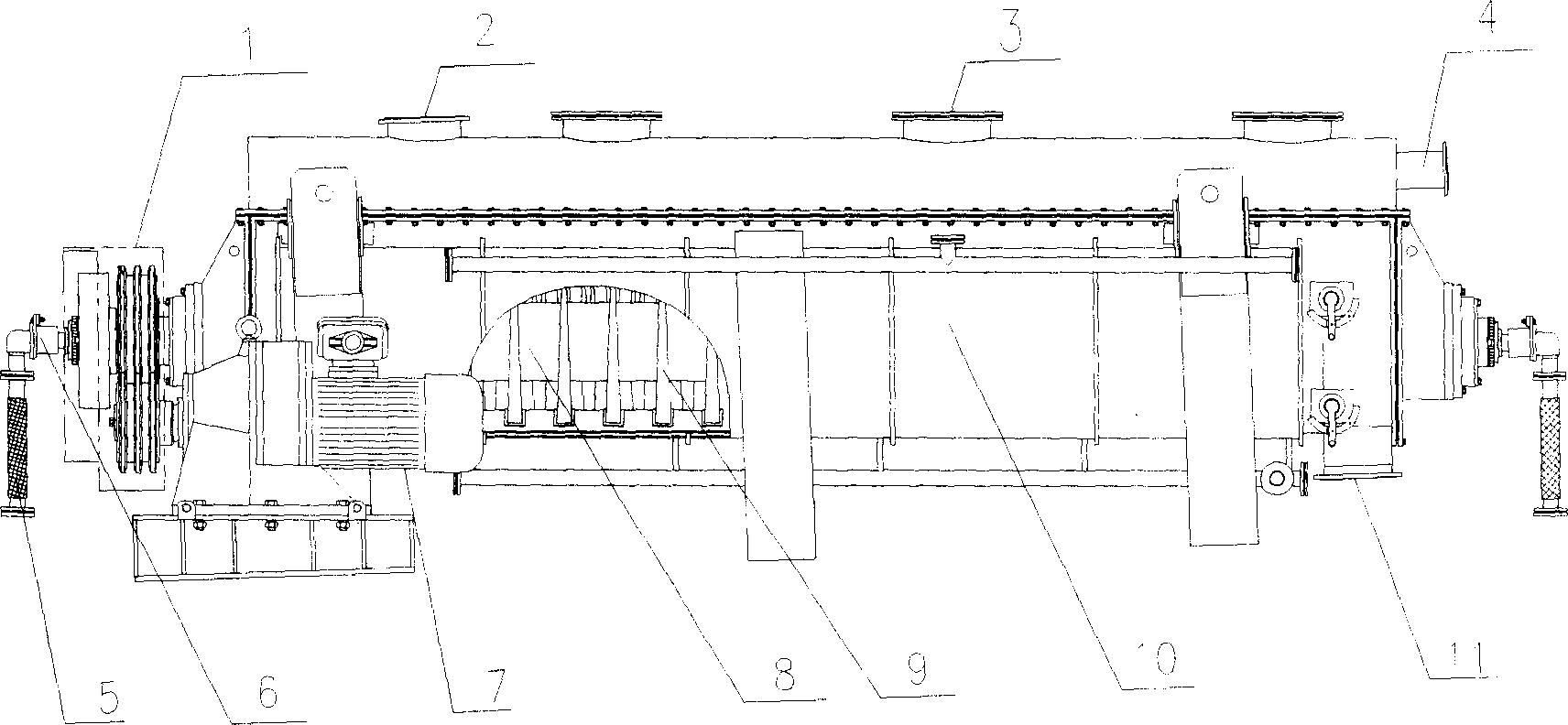

Method for drying sludge by blade drier

InactiveCN1843985ADry fitStir wellSludge treatment by de-watering/drying/thickeningEmission standardSimultaneity

The invention provides a sludge paddle desiccation method, which comprises the following steps: loading wet sludge into a paddle desiccator with a charger, indirectly heating materials through a hollow blade heating shafts and a shell jacket with thermal medium, the heating shafts intermeshied and rotating, with squeezing and relaxation alternative action, materials dried and moving to a discharge door simultaneity. The wet share evaporated in drying process is carried and discharged with carrying gas, and the carrying gas can enter from a carrying gas inlet or the discharge door, and is ejected from exhaust outlet. The heating shafts of the desiccator can be two shafts, or four shafts. The wet share discharged from the desiccator is washed, dedusted and deodorizated with a washing tower to reach the emission standard, and evacuation with a induced fan. The invention has the characters such as small energy consumption, low operating cost, small equipment plot area and equipment investment, big operating flexibility, stable and reliable operation, little entrained dust and material depletion. The invention settles the technical roadblock of huge dedusting equipment, high operating cost of hot-air sludge desiccator or short periodic motion caused by frequently sticking wall in other sludge desiccation. The invention not only make drying in allusion to the characters of high moisture content and high viscosity of sludge, but also is suitable to dry industrial sludge such as oil sludge, catalytic sludge, chemical sludge, biochemistry sludge, and domestic sludge.

Owner:LANZHOU RUIDE DRYING TECH

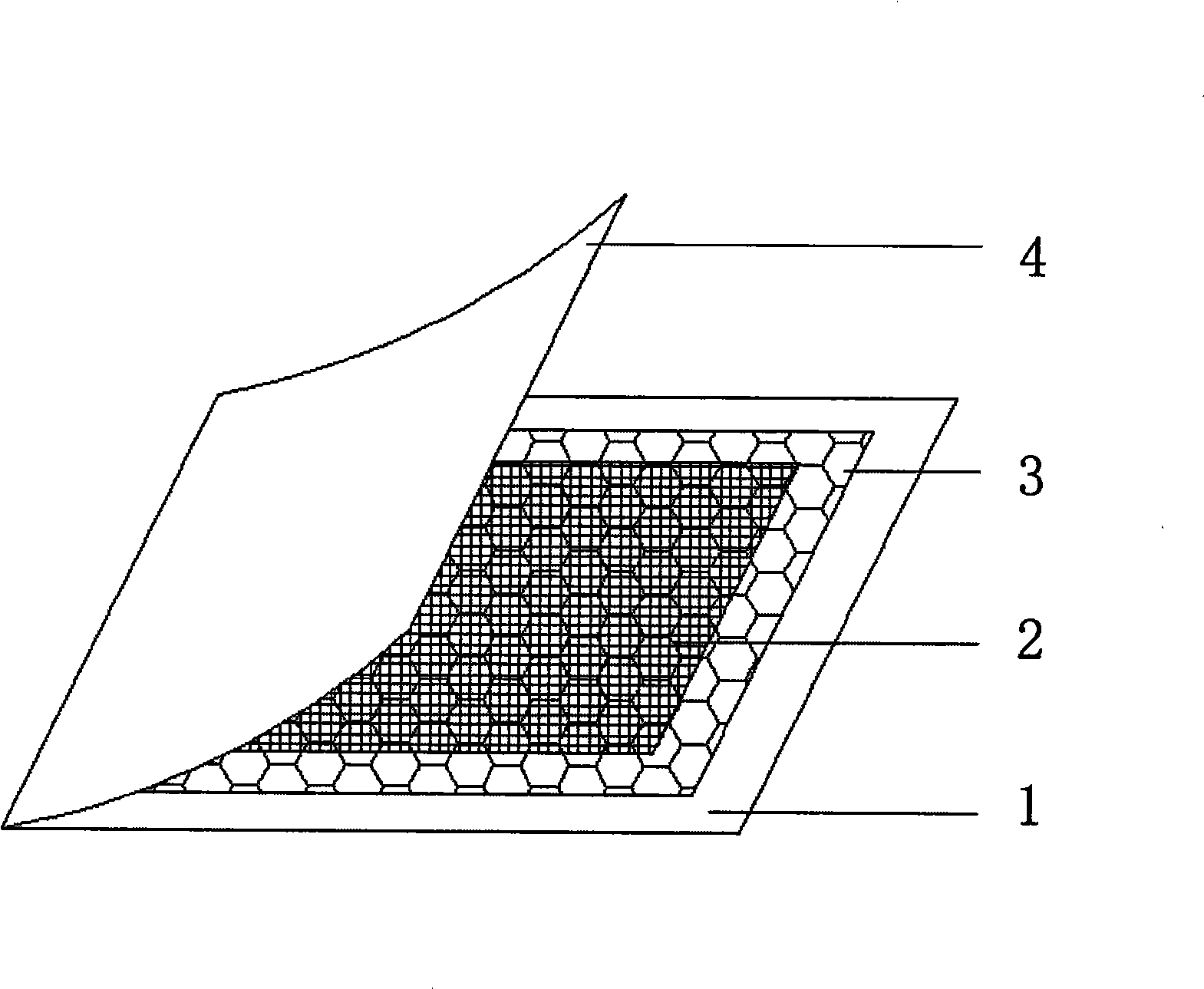

Patch capable of effectively preventing and treating apple-tree canker and production method thereof

InactiveCN101507435ALow costEasy to makeBiocidePlant growth regulatorsSodium BentonitePolyvinyl alcohol

The invention relates to a patch for effectively controlling apple tree canker and a preparation method thereof. The patch for effectively controlling the apple tree canker is a novel formulation which integrates the functions of disinfection, growth promotion, prevention and protection, and has the advantages of simple preparation, long drug effect period, low cost, simplicity, convenience and easiness, and less pollution. The patch for effectively controlling the apple tree canker comprises the following raw material compositions in percentage by weight: 0.2 percent of diniconazole, 20 percent of polyvinyl alcohol, 1.0 percent of bentonite, 2.5 percent of high fat film, 2.0 percent of peregal, 2.4 percent of potassium sorbate, and plant growth regulatory hormone (0.005 percent of rhodofix and 0.001 percent of gibberellin). The preparation method comprises the following steps: sticking multilayered gauze in the center of a waterproof adhesive plaster; covering a nylon net of which the area is slightly larger than that of the gauze on the gauze and sticking the nylon net on the adhesive plaster; using a hair brush to apply medicines and penetrating the medicines into the gauze; and using waterproof paper to be adhered to the adhesive plaster, on the basis of pesticides which are processed into cream.

Owner:NORTHWEST A & F UNIV

Adhesive Liner

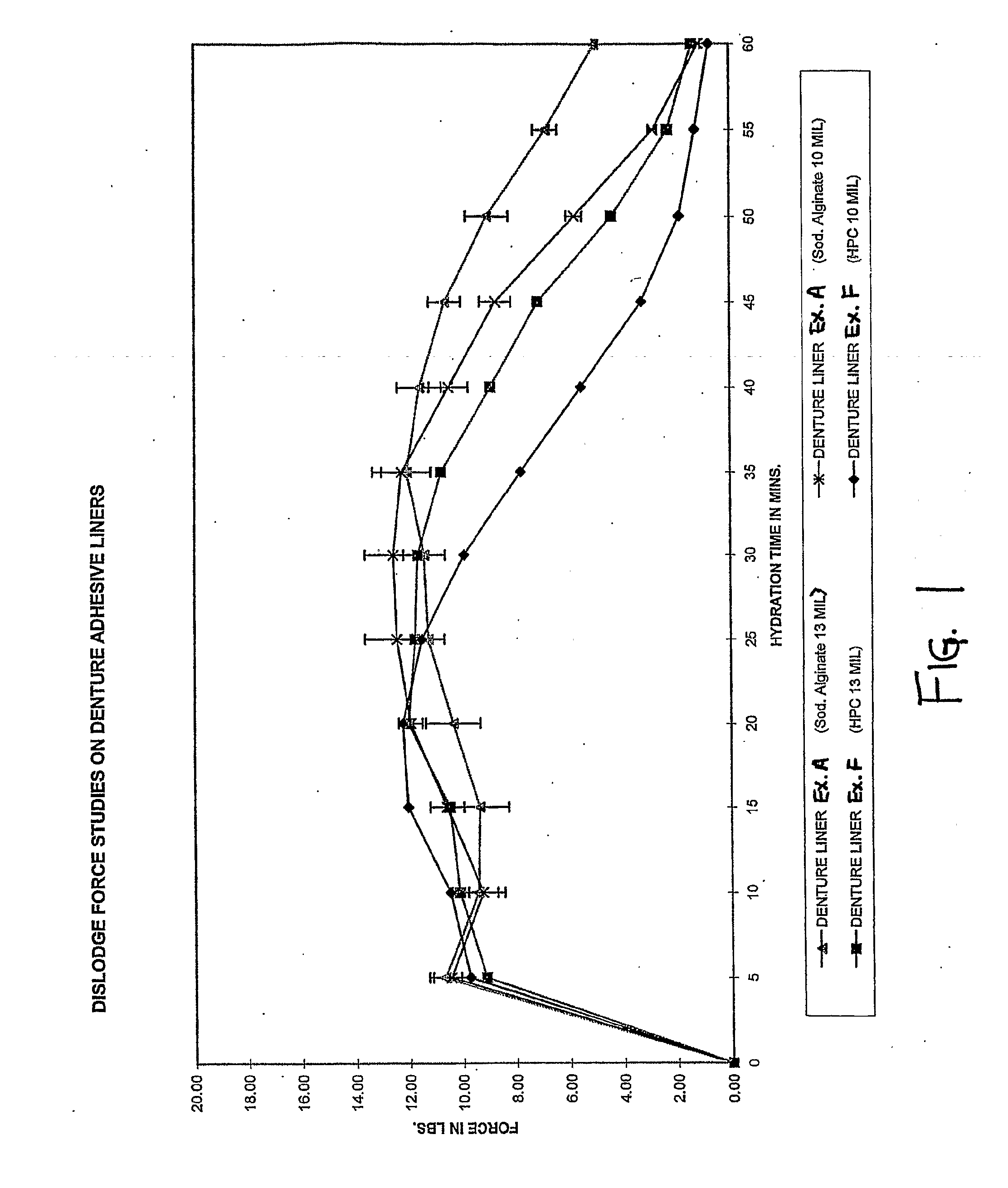

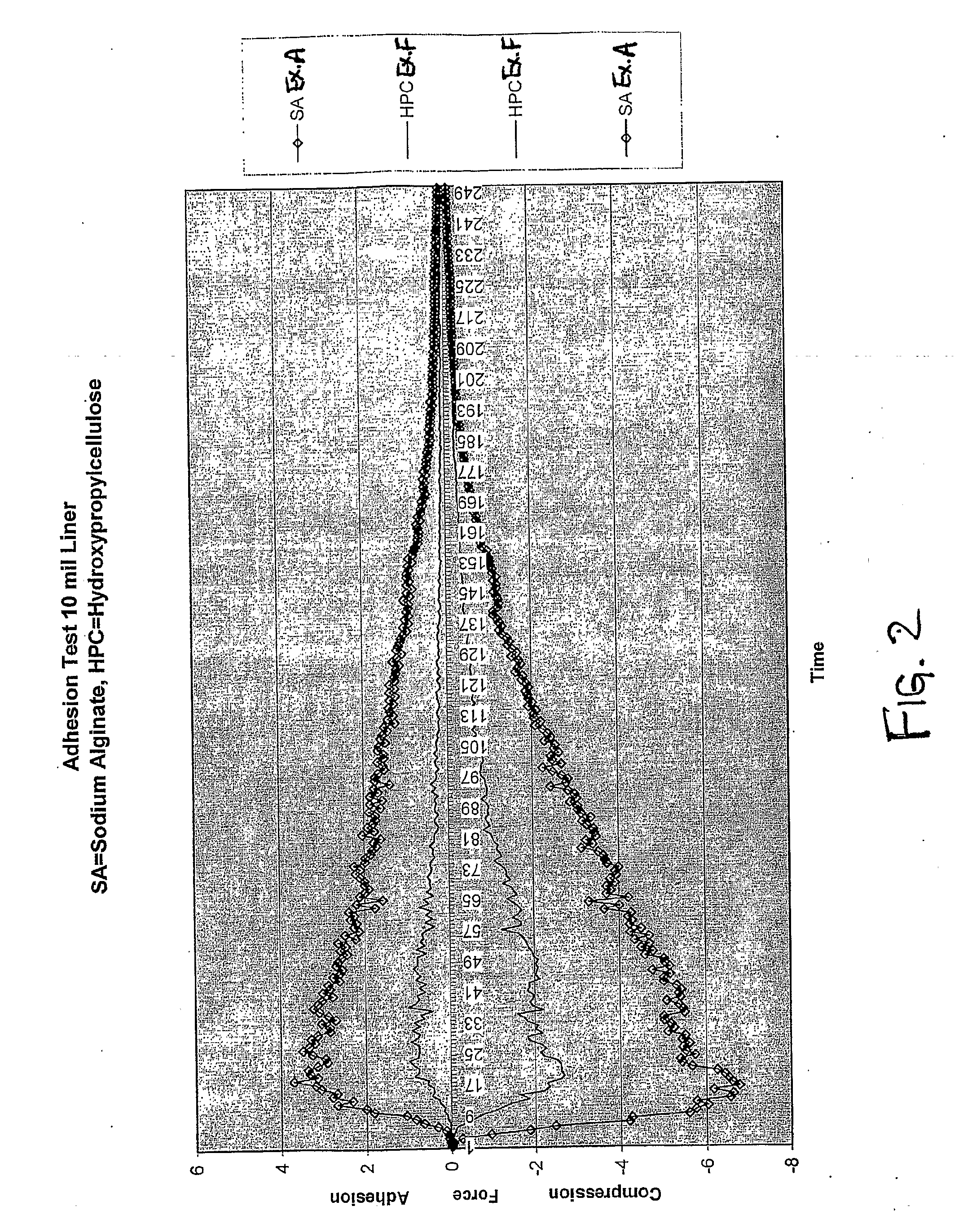

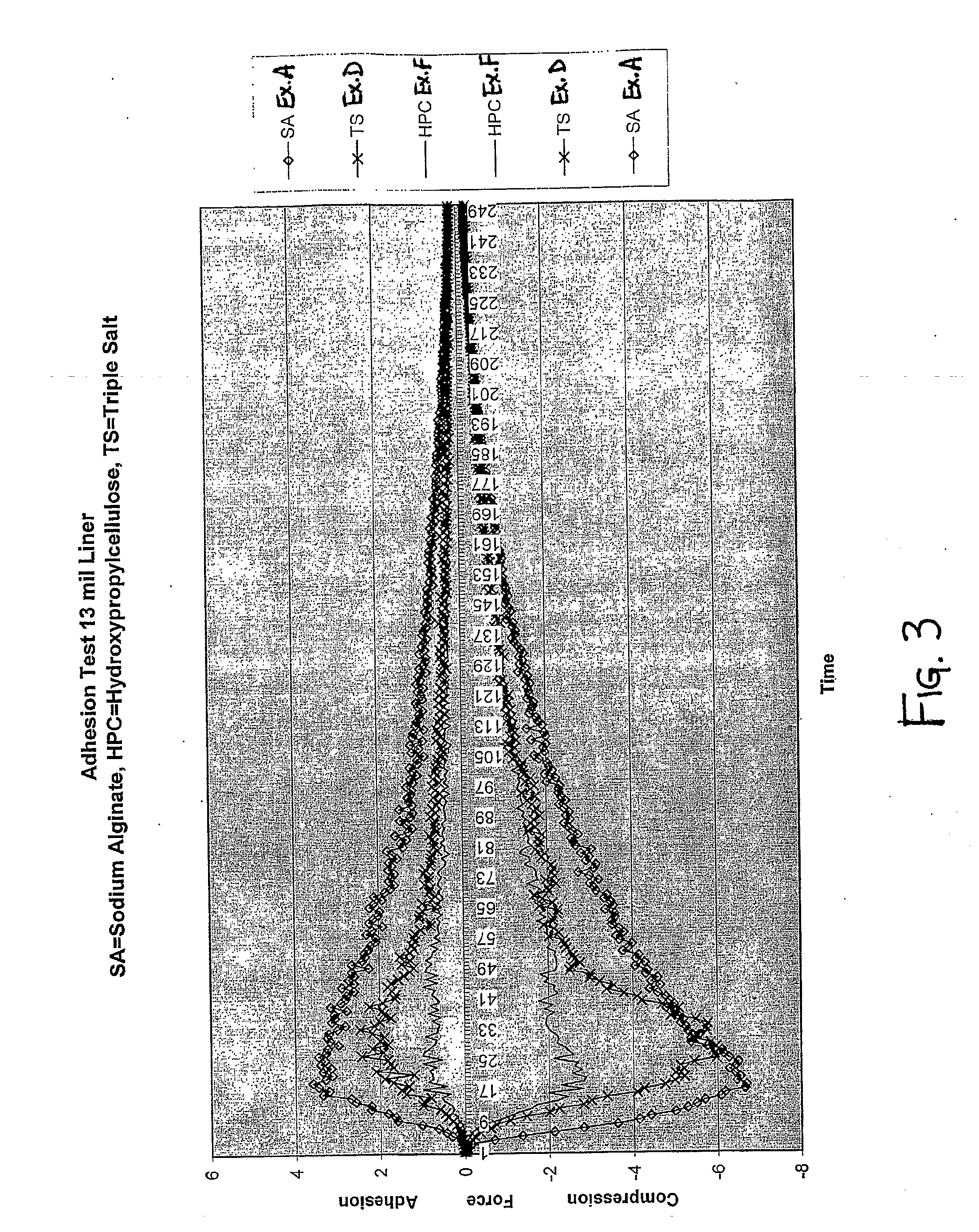

InactiveUS20080293015A1Efficient preparationStrong stickinessCosmetic preparationsImpression capsThermoplastic elastomerPlasticizer

The present invention provides a denture adhesive liner in the form of an extruded film or sheet, comprising a denture adhesive effective amount of alginate; thermoplastic polymer; and plasticizer, wherein said composition is extrudable into a film that is capable of adhering to a wet mucous surface. The present invention also provides a method for preparing a denture adhesive liner comprising the steps of: preparing a composition of a denture adhesive effective amount of alginate; thermoplastic polymer; and plasticizer; and forming a denture adhesive liner from the composition.

Owner:SMITHKLINE BECKMAN CORP

Tile paving method

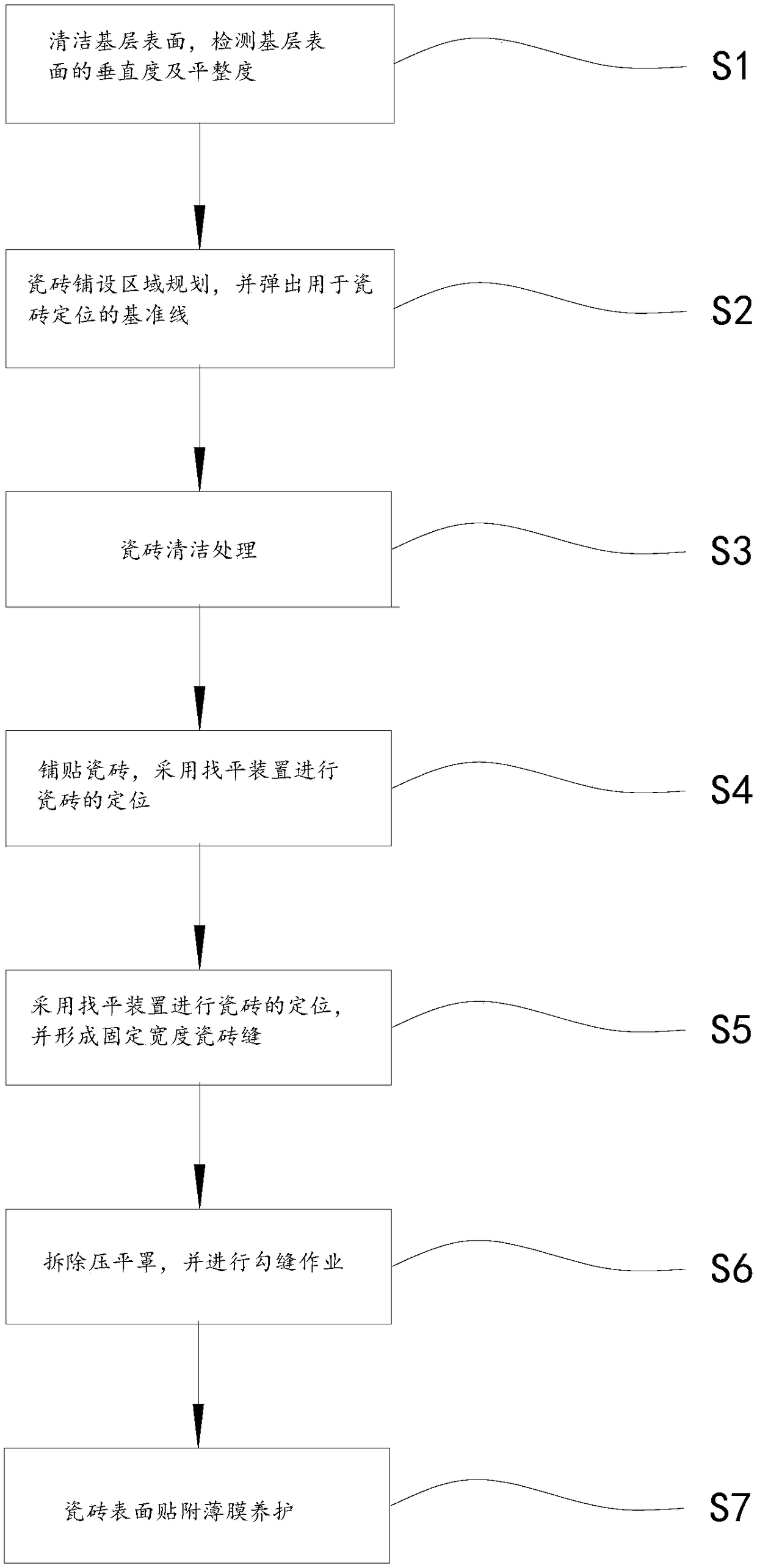

InactiveCN108222450AAvoid misalignmentGuaranteed aestheticsBuilding constructionsDislocationCivil engineering

The invention provides a tile paving method. The tile paving method comprises the following steps that the base surface is cleaned, and the perpendicularity and flatness of the base surface are detected; planning is carried out according to an area needed to be tiled, and the vertical and horizontal datum lines used for tile positioning are popped up; tiles are cleaned, and it is ensured that corners and the two surfaces of the tiles are free of oil fouling; the tiles are paved, the tiles are positioned using a leveling device, the tiles are leveled using the leveling device, and the tile seamwidth formed between every two adjacent tiles is 1.5-3 mm; after mortar is solidified, a flattening cover is removed, and pointing operation is carried out; and after the pointing is completed, a thin film is attached to the surface of the tiles after paving for conserving for 5-10 days. According to the tile paving method, dislocation phenomenon of the tiles is avoided during leveling, gaps between the tiles are controlled to be reasonable, and the beauty and practicability of the tiles after paving are enhanced.

Owner:广州炬隆卫浴制品有限公司

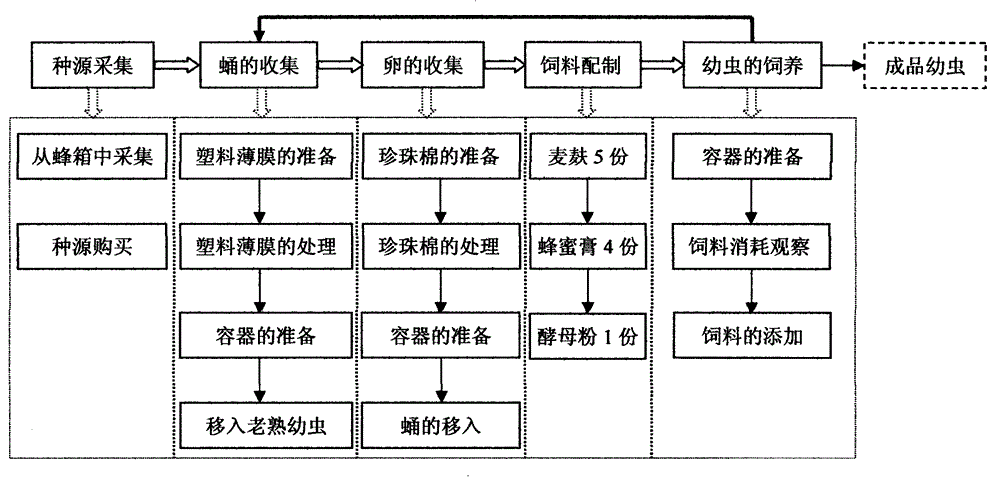

Indoor large-scale breeding and feeding method for greater wax moth

The invention relates to an indoor large-scale breeding and feeding method for greater wax moth, which belongs to the field of indoor breeding and feeding technology for resource insects. The method comprises the following steps: collecting robust and matured larva individuals as breed sources and putting the larva individuals into a container equipped with a pupation device for pupation; taking out greater wax moth pupae in a week and putting the greater wax moth pupae into a container equipped with an egg collection device; taking out the egg collection device in a week, taking off eggs, putting the eggs and a feed into a breeding container according to a certain ratio and replenishing the feed when about 90% of the feed in the container is consumed; and taking out matured greater wax moth larvae when the matured greater wax moth larvae crawl out from the feed, selecting big matured greater wax moth larvae as breed sources for reproduction again and breeding the rest matured greater wax moth larvae in the feed or using or selling the rest matured greater wax moth larvae as test greater wax moth larvae. The objectives of the invention are to overcome the problems of consumption of considerable labor and time and incapacity of realizing anniversary and volume production in large-scale breeding of greater wax moth and to provide the indoor large-scale breeding and feeding method capable of realizing volume production of greater wax moth.

Owner:GUANGXI FORESTRY RES INST

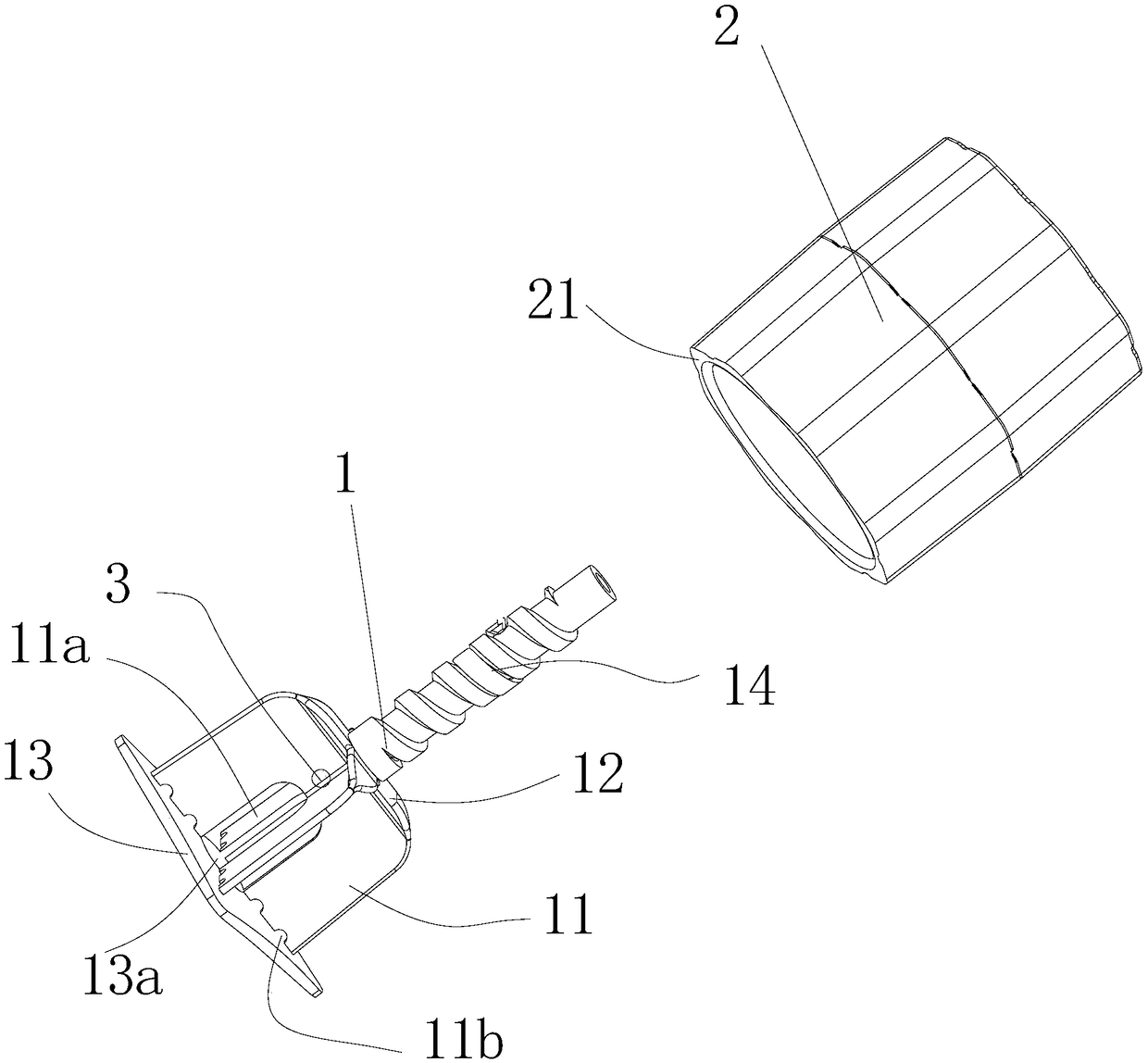

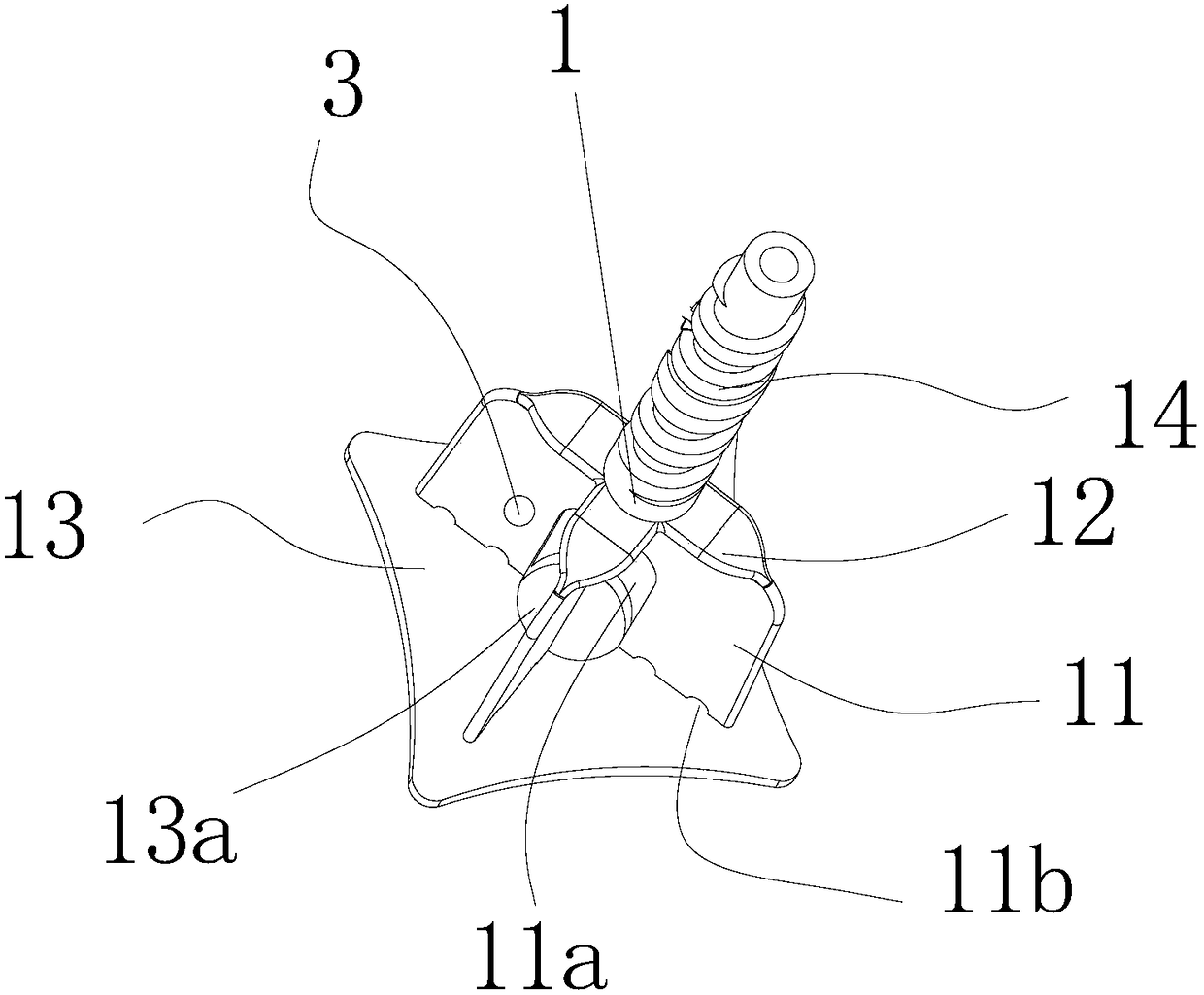

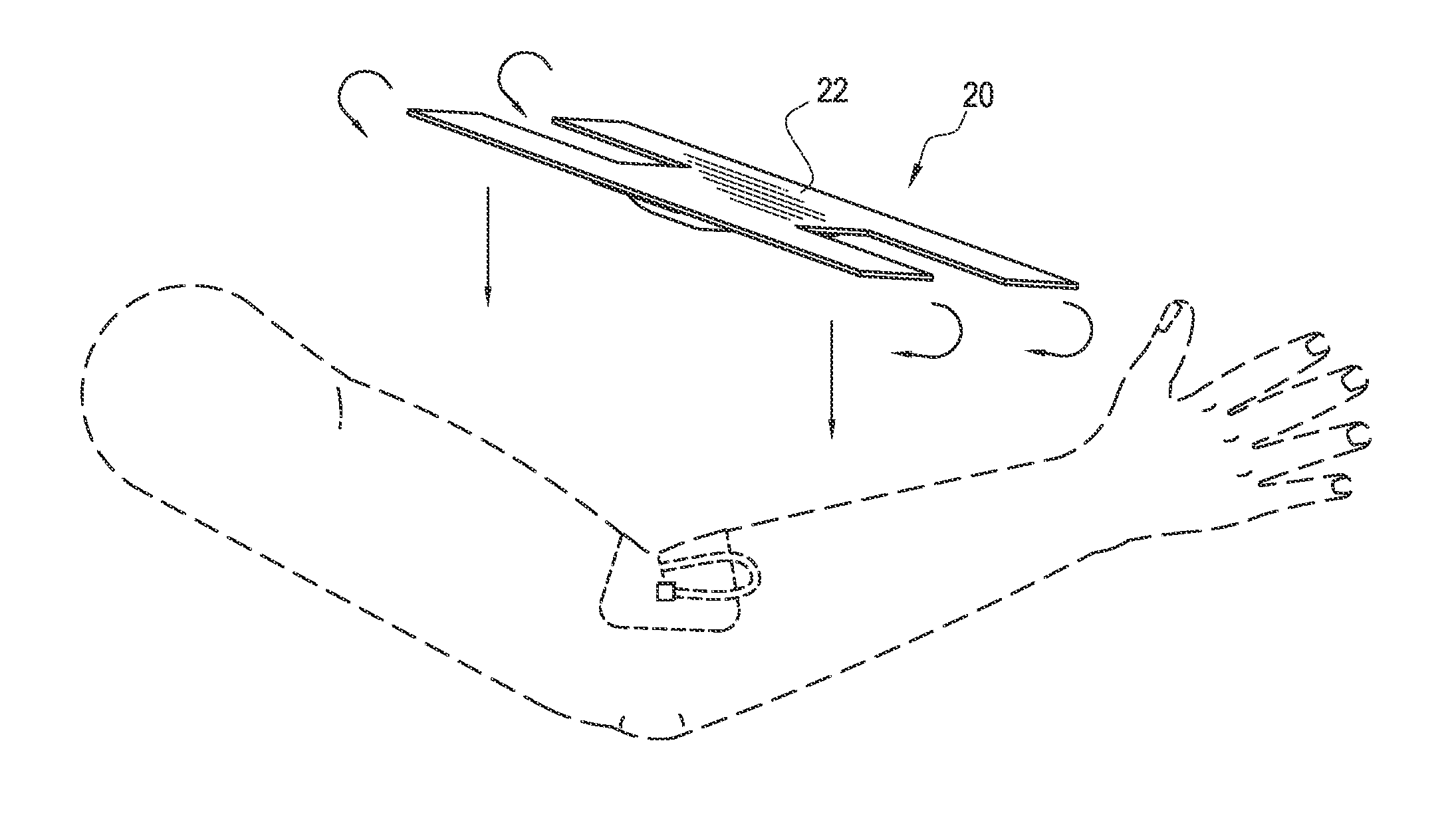

Intravenous splint cover and associated methods

InactiveUS20130204190A1Strong stickinessEasy to fixFinger bandagesCatheterEngineeringAdhesive materials

An intravenous splint cover may include a main body and a pair of opposing securing members connected to the main body. The intravenous splint cover may also include a splinting member carried by the main body to create an elevated portion of the main body. Bottom portions of the pair of opposing securing members and the main body that does not carry the splinting member may have an adhesive material applied thereto. The splinting member may extend along a medial portion of the bottom portion of the main body substantially between an entire width thereof. The intravenous splint cover according to the present invention advantageously secures an IV site of a patient while allowing the extremity of the patient with IV is located to remain mobile.

Owner:WILBORN MARIE ANDREA I

Waterproof self-adhesive coiled material prepared from butyl rubber and preparation method of coiled material

InactiveCN105585978AGood chemical stabilityImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAging resistanceButyl rubber

The invention discloses a waterproof self-adhesive coiled material prepared from butyl rubber. The coiled material is prepared from, by weight, 7-15 parts of the butyl rubber, 0.5-5 parts of carbon black, 10-16 parts of polyisobutene, 0.3-2 parts of resin, 2-8 parts of white oil, 60-80 parts of kaolin and 0.1-0.8 part of anti-aging agent. The invention further discloses a preparation method of the waterproof self-adhesive coiled material prepared from the butyl rubber. The waterproof self-adhesive coiled material prepared from the butyl rubber has the advantages of being good in chemical stability, good in aging resistance, capable of being used for a long time under the environmental condition of -40 DEG C-80 DEG C, capable of prolonging the service life, long in service life, environmentally friendly, safe, easy, convenient and rapid to use, good in air tightness and water tightness, strong in viscosity, capable of being firmly bonded with a building main structure and the like.

Owner:广州市伟能高分子材料有限公司

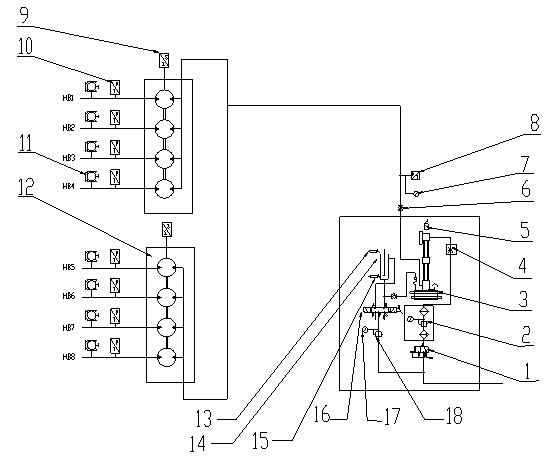

HBW grease system of composite stratum shield tunneling machine primary seal

ActiveCN103644305AEasy to start and stopAvoid damageEngine sealsTunnelsMagnetic exchangeInlet pressure

The invention discloses an HBW grease system of a composite stratum shield tunneling machine primary seal. The system comprises a grease pump and a grease pump stand column, wherein the grease pump and the grease stand column are connected with an external air compressor. A magnetic exchange valve, pneumatic FRL and a needle valve are sequentially arranged on an air inlet pipe entering the grease pump, and a grease pump approach switch is arranged on the grease pump. A pressure regulating valve, a pressure gage and a hand-operated direction valve are sequentially arranged on an air inlet pipe entering the grease pump stand column, and a high-position limit switch and a low-position limit switch are arranged on the grease pump stand column. A plurality of synchronous shunt motors and low-tension membrane pressure sensors are connected to a grease outlet pipe of the grease pump in sequence, and motor approach switches are arranged on the synchronous shunt motors. According to the HBW grease system of the composite stratum shield tunneling machine primary seal, the grease pump can be started and closed conveniently, air inlet pressure can be regulated conveniently, the rising, declining and motion speed of the grease pump stand column are operated manually, and the high-position limit switch and the low-position limit switch prevent empty beating from conducting on the grease pump and prevent a grease pump seal from being damaged.

Owner:成都中振隧道装备有限公司

Composite starch styptic powder and preparation method thereof

InactiveCN104784198AStrong water absorptionUniform particlesOrganic active ingredientsPowder deliveryCross-linkPotato starch

The invention relates to a composite starch styptic powder and a preparation method thereof. The preparation method of the composite starch styptic powder comprises the following steps: using potato starch and modified starch as raw materials, emulsifying and cross-linking the potato starch and the modified starch respectively, screening the processed potato starch and the processed modified starch respectively with 150-mesh medicinal sieves, and finally mixing the screened potato starch and the screened modified starch in a certain proportion by a dry powder blending method so as to obtain the composite starch styptic powder. The styptic powder has favorable biocompatibility, good water absorption property and high water absorption speed, can be directly used for general bleeding, deep bleeding and bleeding of parts which are difficult to reach through an operative procedure, is simple and convenient to use, and has good effect of stopping bleeding; the raw materials are free from toxicity and stimulus, wide in sources, low in cost, and simple and feasible in technology, so that the styptic powder has wide clinical application prospects.

Owner:CHONGQING LIANBAI BOCHAO MEDICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com