Unfavorable taste-masking drug granule, chewable formulation and preparation process thereof

A technology of taste-masking granules and preparation process, which can be used in pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc. It can solve the problems of difficult matrix materials and obvious bitterness, and avoid equipment or processes, and avoid inclusion efficiency not high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

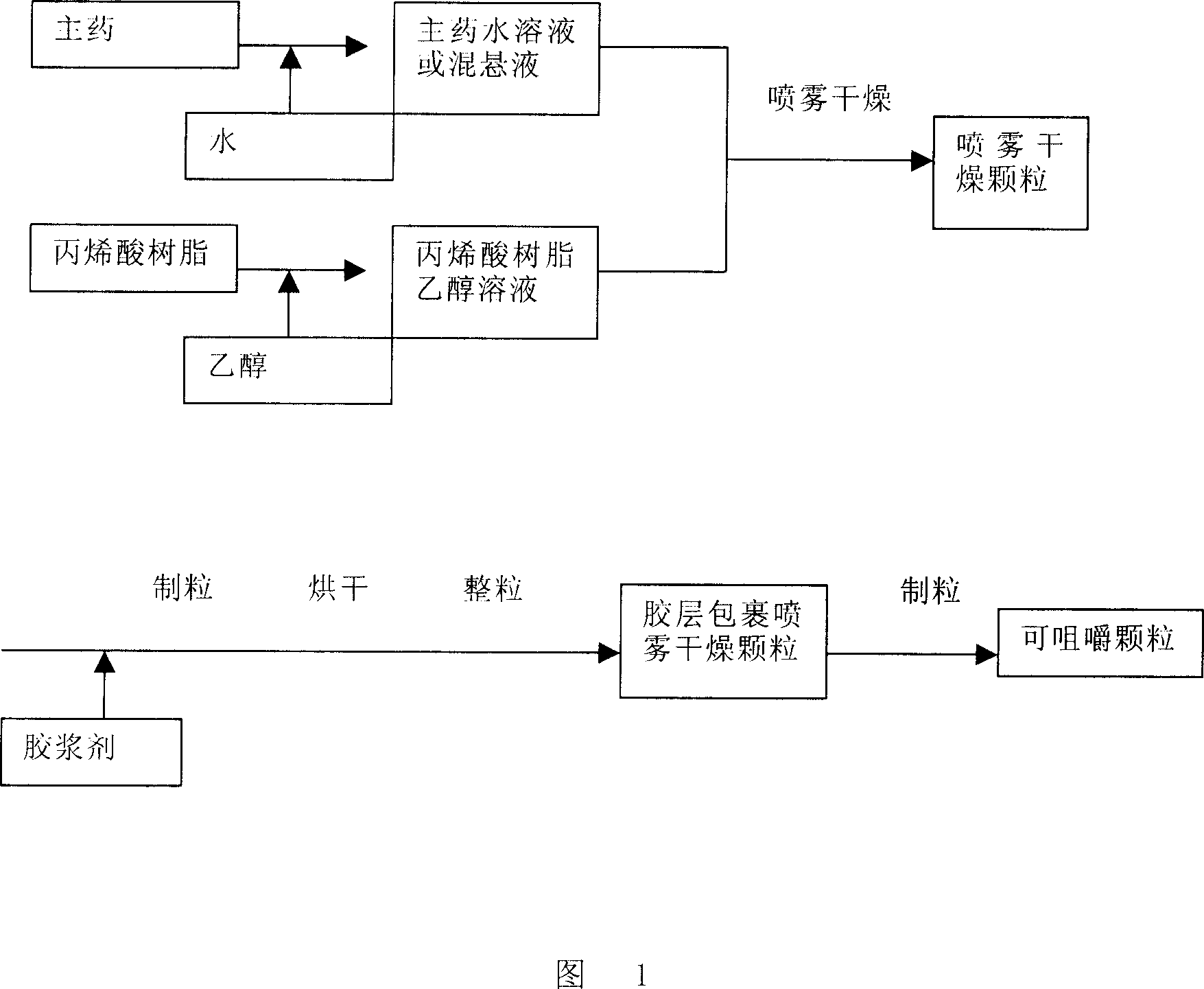

Image

Examples

Embodiment 1

[0040] Acrylic resin No. 4 375g (Degussa company, Eudragit E-100) is dissolved in dehydrated alcohol 1300g, is mixed with the ethanol solution of acrylic resin, berberine 25g (Hainan Pharmaceutical Factory Co., Ltd.) is dispersed in the water of 320g, obtains For the suspension of berberine, the two solutions are mixed uniformly and heated to 50 degrees Celsius to obtain a solution. The solution is sprayed into a spray dryer for spray drying, the rotating speed is adjusted to 300HZ, and the drying temperature is set to 115-120 degrees Celsius. After collection and drying, 60-120 mesh particles are obtained and sieved. Prepare 800 g of aqueous solution of xanthan gum (Shandong Jinsu Biological Products Co., Ltd.) with a concentration of 1%, add 5 g of sucralose to dissolve to obtain a glue, and pour 400 g of the spray-dried particles into the glue to stir and disperse evenly at 55 degrees Celsius Dried, tested for moisture, sieved to obtain xanthan gum-wrapped granules, added s...

Embodiment 2

[0053] Acrylic resin No. 4 15g (Degussa company, Eudragit E-100) is dissolved in absolute ethanol 100g, is mixed with the ethanol solution of acrylic resin, 15g of dextromethorphan hydrobromide (Shanghai Xinya Pharmaceutical Co., Ltd.) is dispersed In 20g of water, the solution of dextromethorphan hydrobromide was obtained, and the two solutions were mixed uniformly to obtain the solution. The solution is sprayed into a spray dryer for spray drying, the rotating speed is adjusted to 300HZ, and the drying temperature is set to 115-120 degrees Celsius. After collection and drying, 60-120 mesh particles are obtained and sieved. Prepare 100 g of an aqueous solution of gum arabic (Shandong Runyuan Industrial Co., Ltd.) with a concentration of 10%, add 2 g of sucralose to dissolve to obtain a glue agent, pour 20 g of spray-dried particles into the glue agent, stir and disperse evenly, and dry at 55 degrees Celsius , test moisture, sieve to get Arabic gum-wrapped granules after passi...

Embodiment 3

[0065] Acrylic resin No. 4 750g (Degussa company, Eudragit E-100) is dissolved in absolute ethanol 3000g, is mixed with the ethanol solution of acrylic resin, paracetamol 150g (Shanghai Xinya Pharmaceutical Co., Ltd.) is dispersed in 600g The solution of paracetamol was obtained in the water, and the two solutions were mixed uniformly to obtain the solution. The solution is sprayed into a spray dryer for spray drying, the rotating speed is adjusted to 300HZ, and the drying temperature is set to 115-120 degrees Celsius. After collection and drying, 60-120 mesh particles are obtained and sieved. Prepare 500g of an aqueous solution of gum arabic (Shandong Runyuan Industrial Co., Ltd.) with a concentration of 10%, add 20g of sucralose to dissolve to obtain a glue agent, pour 500g of spray-dried particles into the glue agent, stir and disperse evenly, and dry at 55 degrees Celsius , test moisture, sieve to get Arabic gum-wrapped granules after passing the test, add fillers such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com