HBW grease system of composite stratum shield tunneling machine primary seal

A technology of composite formation and shield machine, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of cumbersome maintenance, many components, inability to effectively detect the pressure of the sealed cavity, etc., to prevent pipeline blockage, prevent Effects of partial overvoltage or undervoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

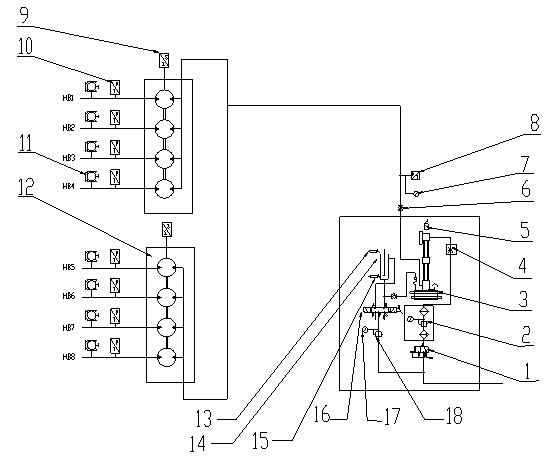

[0047] Such as figure 1As shown, a HBW grease system for the main seal of the formation shield machine includes a grease pump 3 connected to an external air compressor and a grease pump column 15, the grease pump 3 is connected to the grease pump column 15, and the external air compressor The compressed air supplied by the machine is divided into two routes, one of which enters the grease pump 3 through the intake pipe, and the other enters the grease pump column 15 through the intake pipe. On the intake pipe entering the grease pump 3, an electromagnetic reversing valve 1 and a pneumatic valve 1 are sequentially arranged. Triple piece 2 and needle valve 4, the grease pump 3 is provided with a grease pump proximity switch 5 for recording the cumulative flow of the grease pump outlet, used to record the cumulative flow of the grease pump outlet, and provide accurate information for the grease consumption of each ring in shield tunneling construction. Based on this, it is more r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com