Hot-line work removing device for branches

A technology for cleaning devices and live work, which is applied in agriculture, electric pruning saws, agricultural machinery and implements, etc. It can solve problems such as high cost and complex structure, and achieve good protection, good balance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

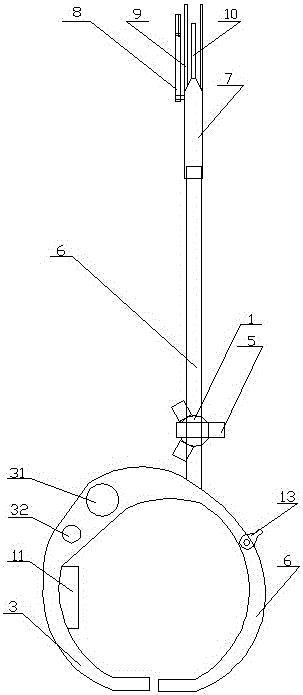

[0037] Embodiment 1: A device for cleaning branches for live work, including an operation base, a cleaning mechanism arranged on the control base, and a control mechanism arranged at the end of the cleaning mechanism. The operation base includes a support column 12, The supporting frame 1 arranged at the lower part of the supporting column 12 and the ratchet module 5 arranged at the upper part of the supporting column 12 and connected with the cleaning mechanism.

[0038] The control mechanism includes an operating handle 31 arranged at the front end of the operating arm, a processor 32 arranged in the operating arm 3 , and a power supply 11 connected to the processor 32 and arranged on the operating arm.

[0039] The cleaning mechanism includes a support arm 6 whose middle part is arranged on the ratchet module 5 and the other end is provided with a cleaning module. The front end of the support arm 6 is hinged with the cleaning module. An electric telescopic rod 14 is connect...

Embodiment 2

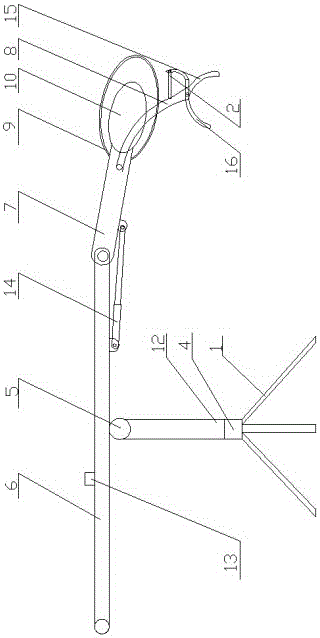

[0045] Embodiment 2: A device for cleaning branches for live work, including an operation base, a cleaning mechanism arranged on the control base, and a control mechanism arranged at the end of the cleaning mechanism. The operation base includes a support column 12, The supporting frame 1 arranged at the lower part of the supporting column 12 and the ratchet module 5 arranged at the upper part of the supporting column 12 and connected with the cleaning mechanism.

[0046] The control mechanism includes an operating handle 31 arranged at the front end of the operating arm, a processor 32 arranged in the operating arm 3 , and a power supply 11 connected to the processor 32 and arranged on the operating arm.

[0047] The cleaning mechanism includes a support arm 6 whose middle part is arranged on the ratchet module 5 and the other end is provided with a cleaning module. The front end of the support arm 6 is hinged with the cleaning module. An electric telescopic rod 14 is connect...

Embodiment 3

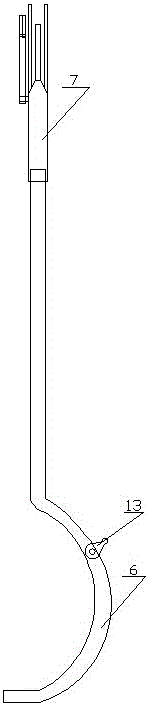

[0055] Embodiment 3: A branch cleaning device for live work, including an operation base, a cleaning mechanism arranged on the control base, and a control mechanism arranged at the end of the cleaning mechanism, the operation base includes a support column 12, The supporting frame 1 arranged at the lower part of the supporting column 12 and the ratchet module 5 arranged at the upper part of the supporting column 12 and connected with the cleaning mechanism.

[0056] The control mechanism includes an operating handle 31 arranged at the front end of the operating arm, a processor 32 arranged in the operating arm 3 , and a power supply 11 connected to the processor 32 and arranged on the operating arm.

[0057] The cleaning mechanism includes a support arm 6 whose middle part is arranged on the ratchet module 5 and the other end is provided with a cleaning module. The front end of the support arm 6 is hinged with the cleaning module. An electric telescopic rod 14 is connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com