Mineral fluid high-pressure delivery pump

A technology of high-pressure transportation and minerals, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, which can solve the problems of crankshafts such as huge mass, mass, bulky, and inconvenient transportation, and achieve volume reduction and The effect of weight, compact and simple structure, convenient start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

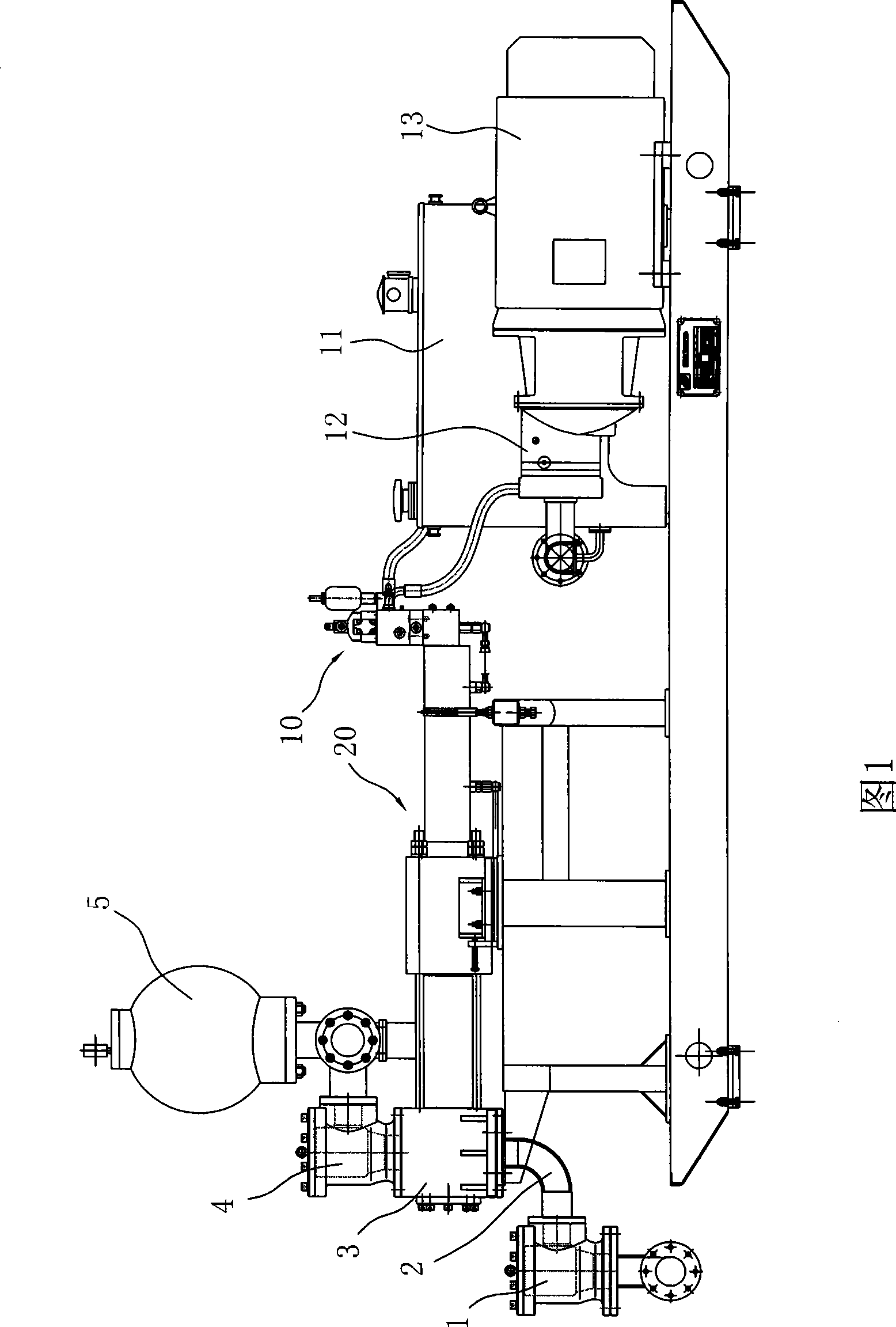

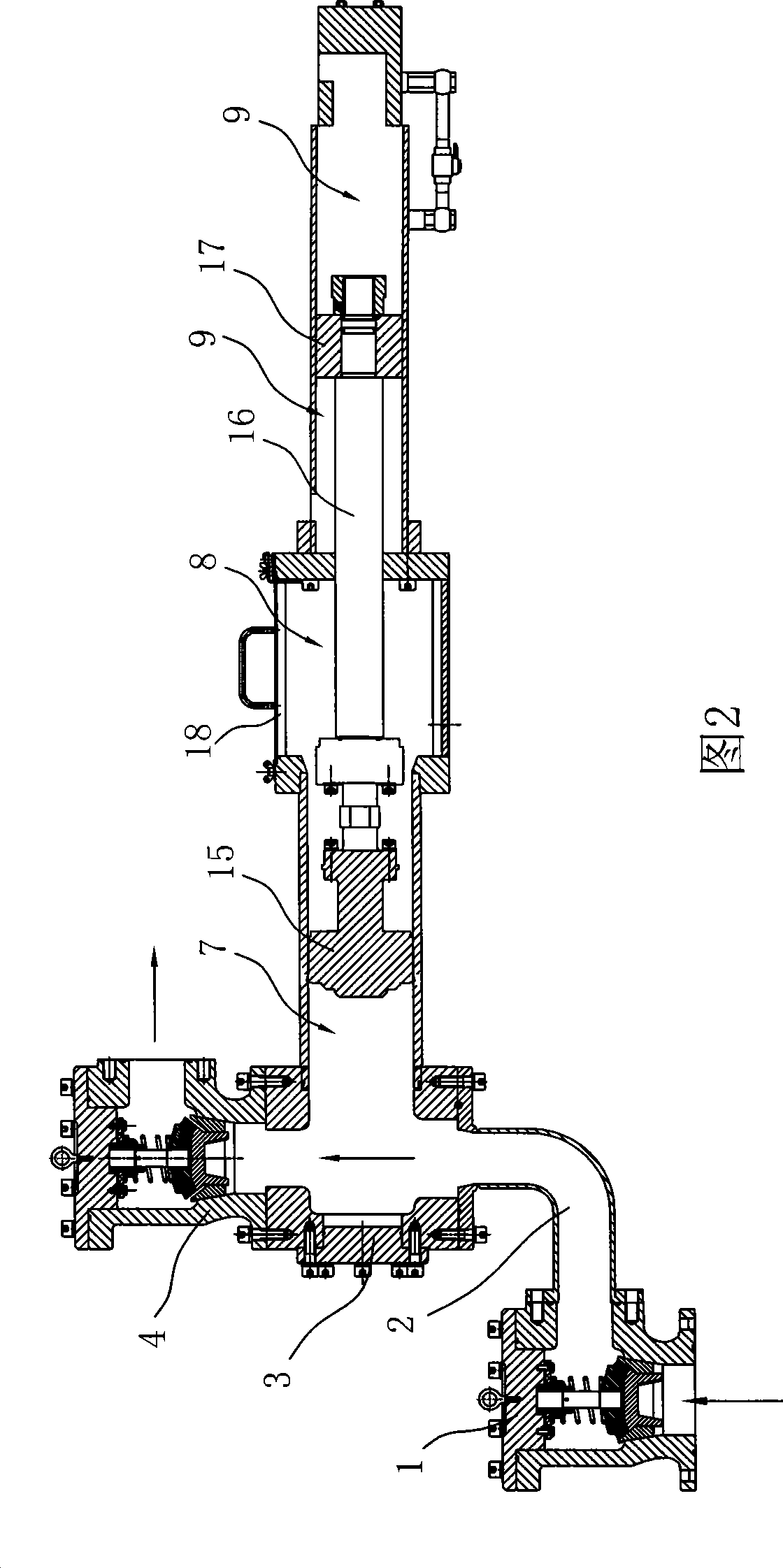

[0015] Embodiment: mineral fluid high-pressure delivery pump, as shown in Figure 1 and Figure 2, it comprises pump body 20, is located at the piston 15 in the pump body 10, and the delivery cylinder 7 that cooperates with piston 15, is connected with piston 15 Piston drive shaft 16, the drive mechanism for driving the action of the piston drive shaft 16, is characterized in that the pump body 20 is provided with a drive cylinder 9 that matches the drive mechanism, and the drive cylinder 9 is provided with a drive cylinder that is connected to the piston drive shaft 16. Piston drive shaft driver 17, a washing cooling chamber 8 is provided between the delivery cylinder 7 and the driving cylinder 9, one end of the piston driving shaft 16 is detachably connected to the piston 15, and the other end passes through the washing cooling chamber 8 and enters the driving cylinder 9 is connected with the piston drive shaft driver 17. The driving mechanism is a hydraulic driving mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com