Efficient energy-saving environment protective beige frying kitchen range

A high-efficiency and energy-saving technology for frying beige, which is applied in the field of frying stoves and frying stoves for frying balsamic vinegar and beige, can solve the problem of reducing production efficiency and utilization of thermal energy of coal combustion, affecting the economic benefits of vinegar manufacturers, and difficult to master the quality of fried beige. and other problems, to achieve the effect of eliminating heat loss, being conducive to environmental protection and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

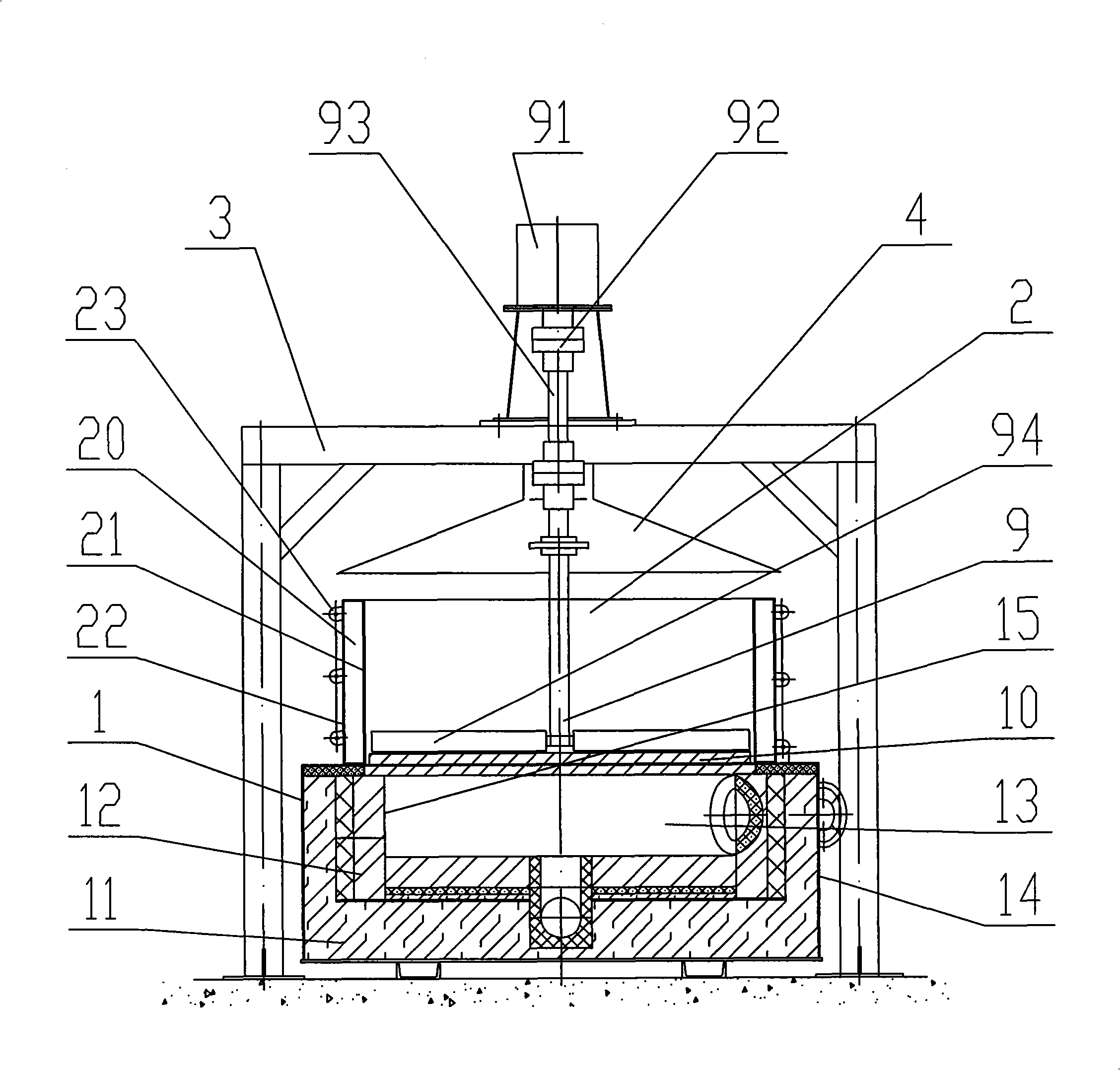

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

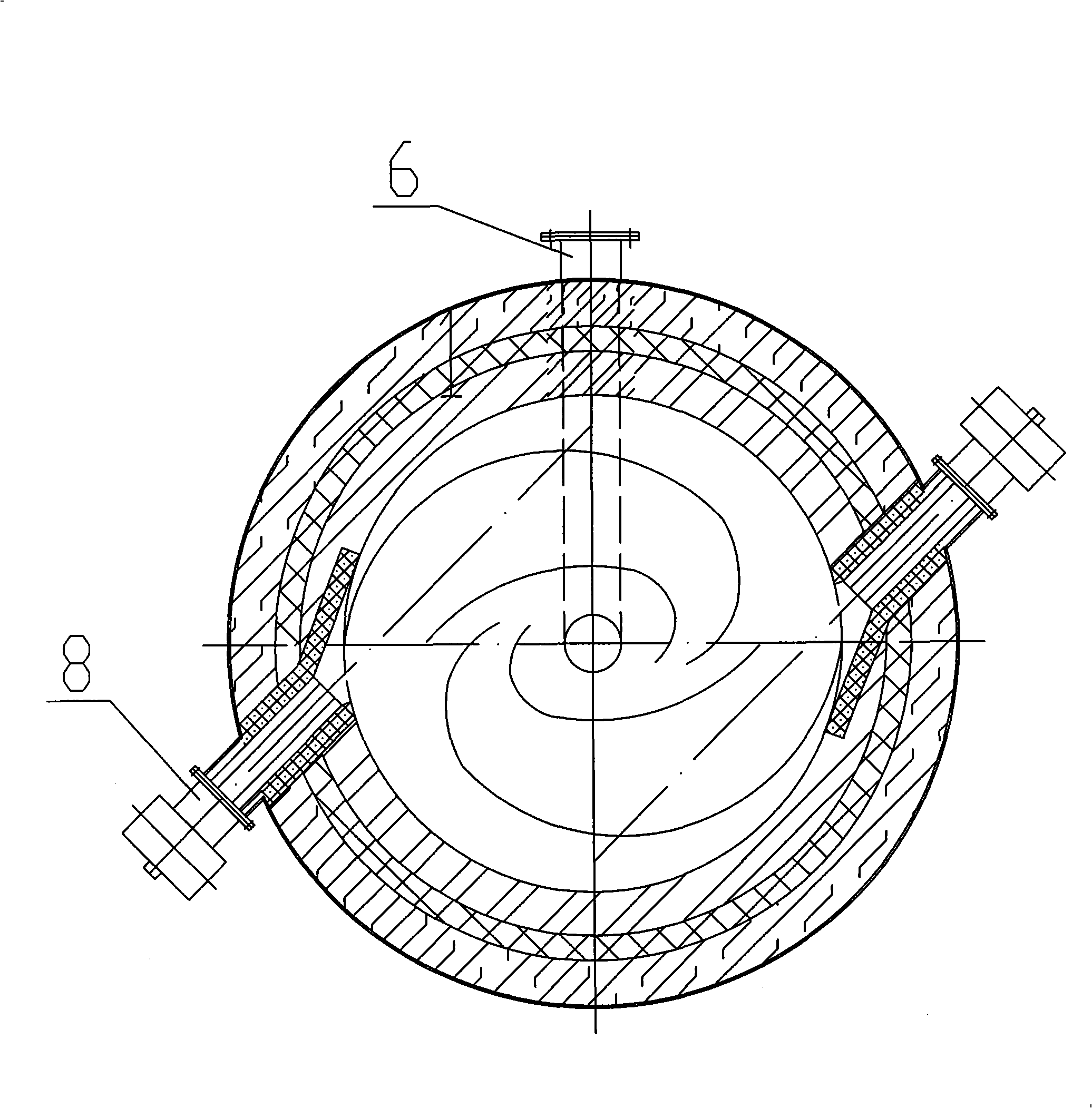

[0025] As shown in the figure, in order to solve the above-mentioned technical problems, the high-efficiency, energy-saving and environment-friendly frying beige cooker of the present invention includes a frying pan 10 and a furnace body 1, wherein the furnace body 1 includes a furnace wall 15, a circular furnace 13, and the circular furnace 13 is a thermal insulation Layer 11 and refractory layer 12 are composed. The refractory layer 12 is made of high-alumina refractory bricks or other refractory materials, and the thermal insulation layer 11 is made of aluminum silicate fiber or other thermal insulation materials. In order to enhance the sealing effect, a zigzag seal can be used at the connection between the frying pan 10 and the furnace wall 15, which can prevent the leakage of high-temperature flue gas; the furnace chamber 13 is provided with two burners 8, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com