Patents

Literature

52results about How to "Not clogged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurizing method using soda waste liquid and calcium carbide waste residue

InactiveCN101306304AHigh desulfurization rateQuick responseDispersed particle separationLiquid wasteSlag

The invention discloses a method for removing SO2 by utilizing soda ash waste liquid and carbide waste slag. CaCl2 in the soda ash waste liquid is utilized to react with the SO2 in flue gas, white CaSO3 settlement is generated, HCl is released and dissolved in water to form hydrochloric acid with very low concentration; Ca(OH)2 in the carbide waste slag is used for neutralizing HCl and generating CaCl2 and water, and CaCl2 is recycled. The desulphurization process mainly consumes Ca(OH)2 in the carbide waste slag. If no local soda ash waste liquid, calcium chloride dehydrate (CaCl2*2HO) produced by the soda ash waste liquid can be purchased for preparing CaCl2 solution. The carbide waste slag can be replaced by lime. The process is characterized by one high, two low and three points of environmental protection. The process firstly has high desulphurization rate, secondly has low fixed-asset investment and low running costs and thirdly utilizes the waste liquid and the waste slag to reduce the environmental pollution. Compared with all prior desulphurization processes, the process has great advantages.

Owner:康仁

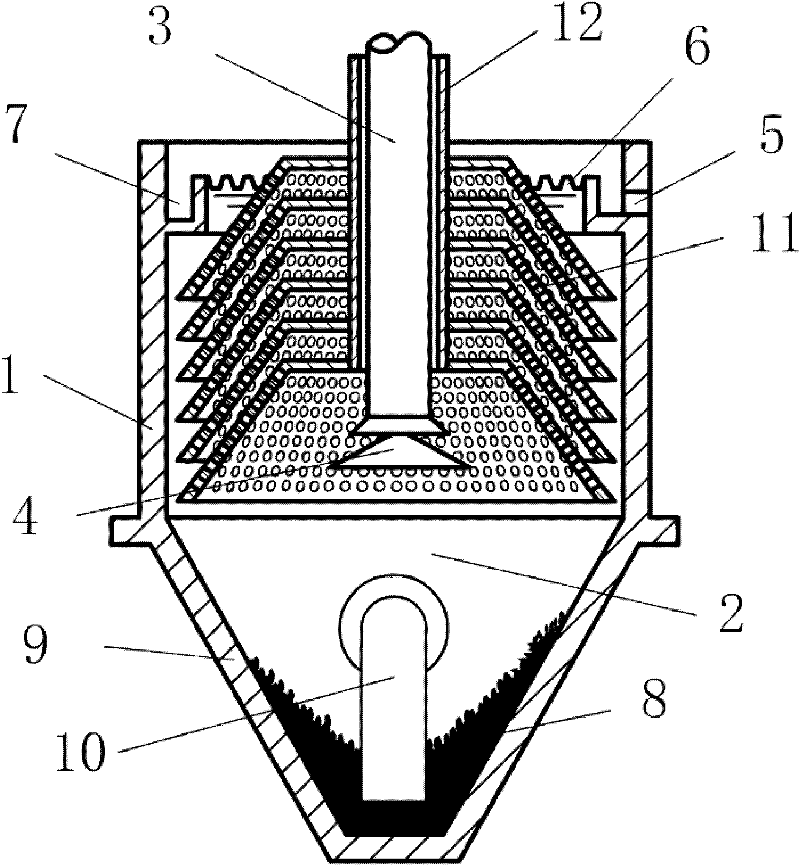

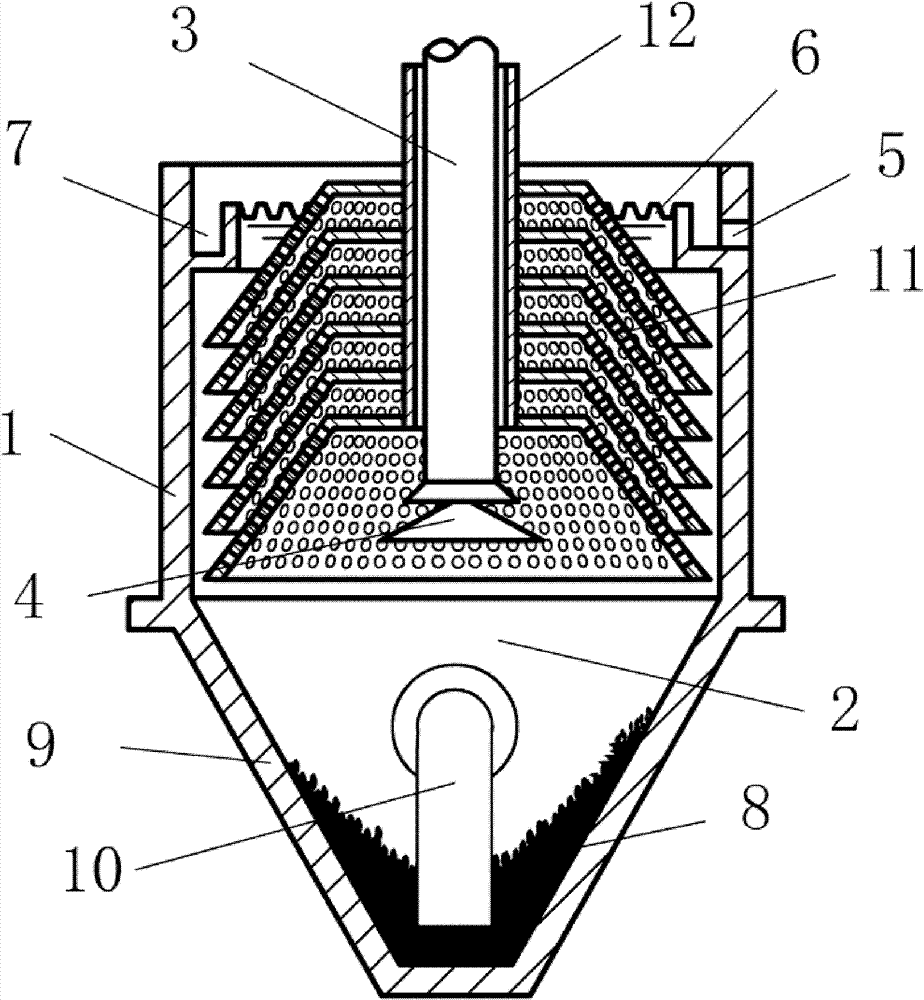

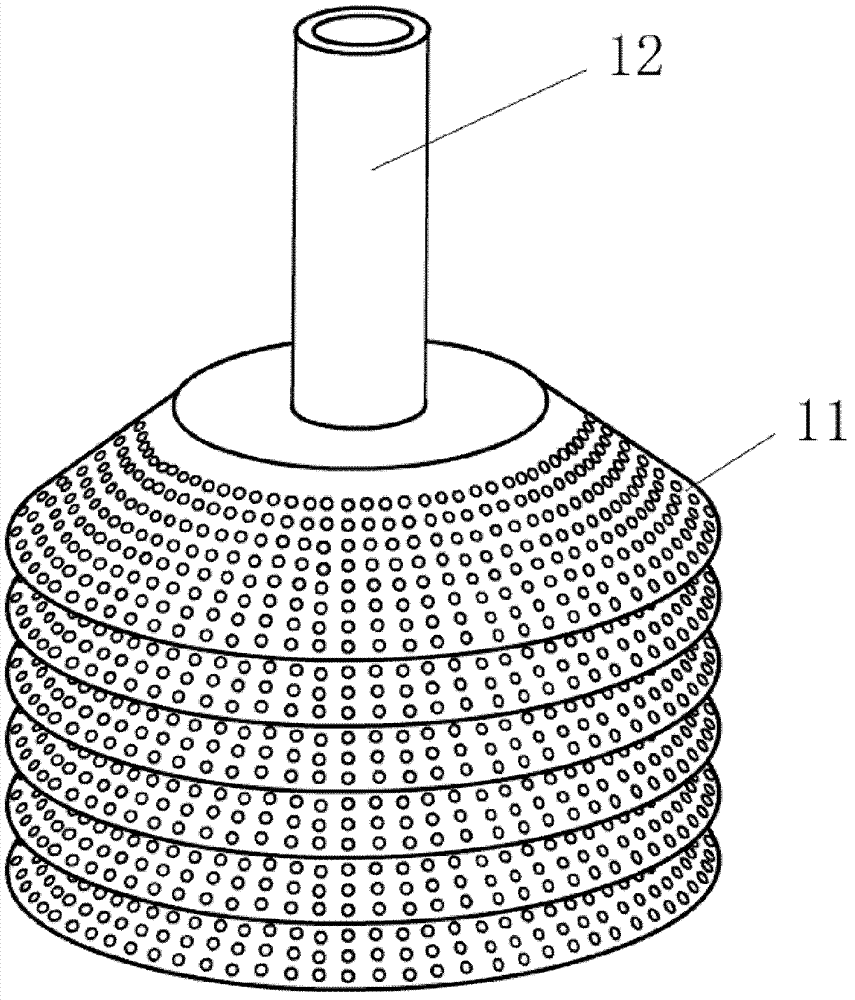

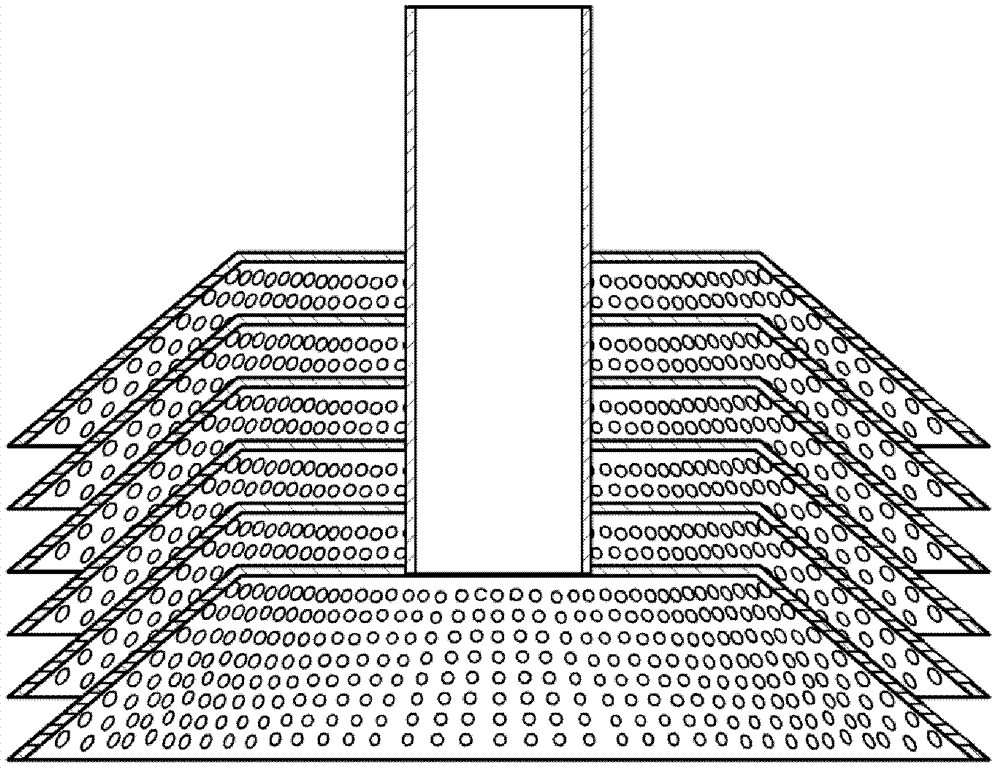

Sewage filter

InactiveCN102228759AImprove purification efficiencySS reductionFiltration separationSedimentation settling tanksFlocculationWater flow

The invention provides a sewage filter, which synthesizes a shallow tank theory, a dynamic coagulation theory, an accelerated coagulation theory and an inclined plate technology, effectively solves the problem of easiness in blockage of the traditional inclined plate. The sewage filter is used for subdividing raw motion water through by using filter masks and a plurality of through hole structures; and the raw water forms stable eddies at rear edges of plate holes of filter mask bodies. Under the entrainment action of the eddies, non-fluidic substances in the raw water are collected at centers of the eddies and get in continuous contact and collision with one another in eddy cores to undergo a flocculation reaction, and slides down along the mask bodies under the gravity action to settle into a mud collecting hopper, so that the purposes of removing suspended substances in the raw water and cleaning a water body are achieved. The sewage filter can rotate around an axis of a rotating shaft; and a strongly turbulent shear flow is formed through left and right repeated quick rotation to scour an inclined plate at a high speed and to clean deposits and blockages very conveniently.

Owner:韦志锋 +1

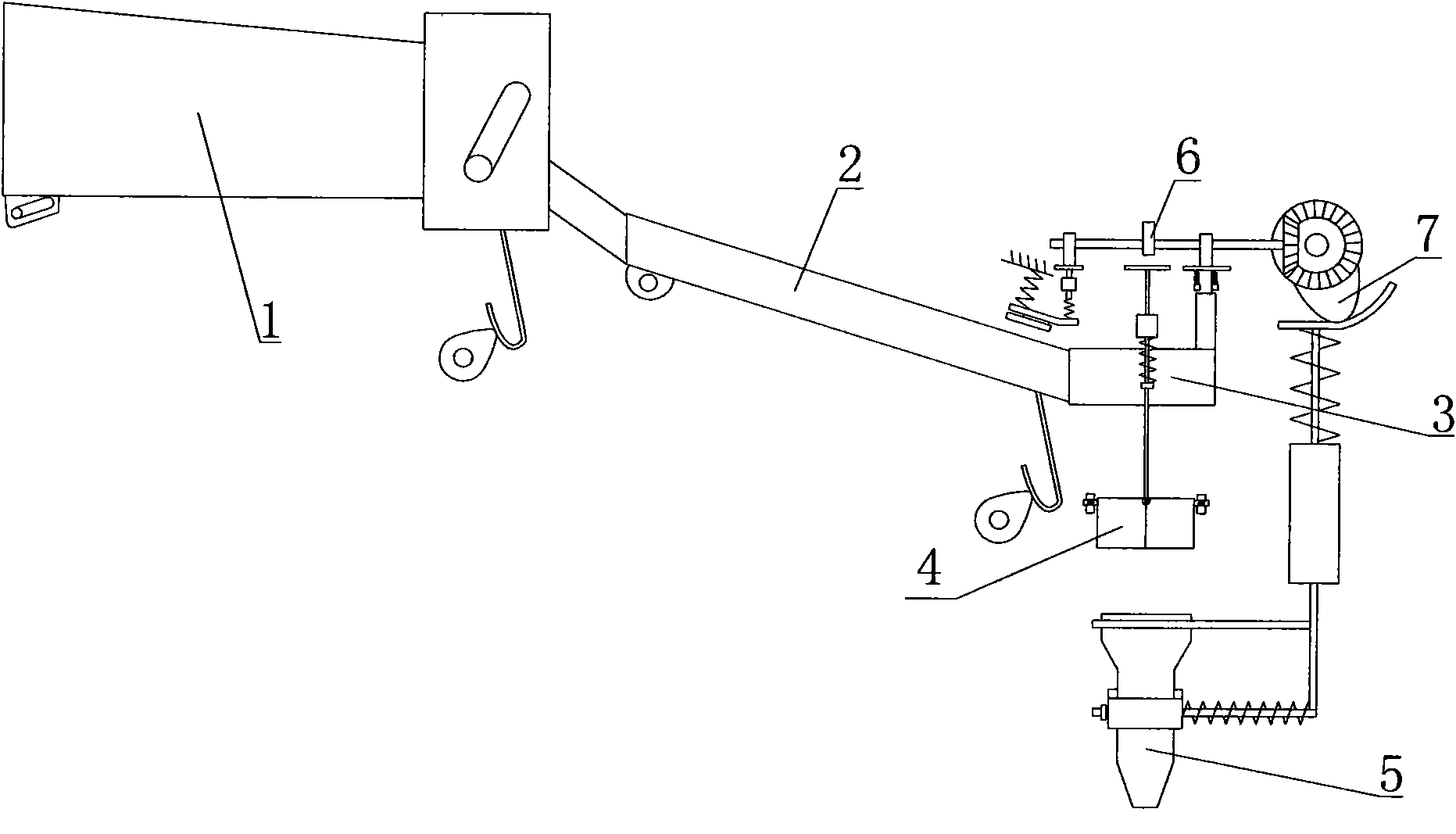

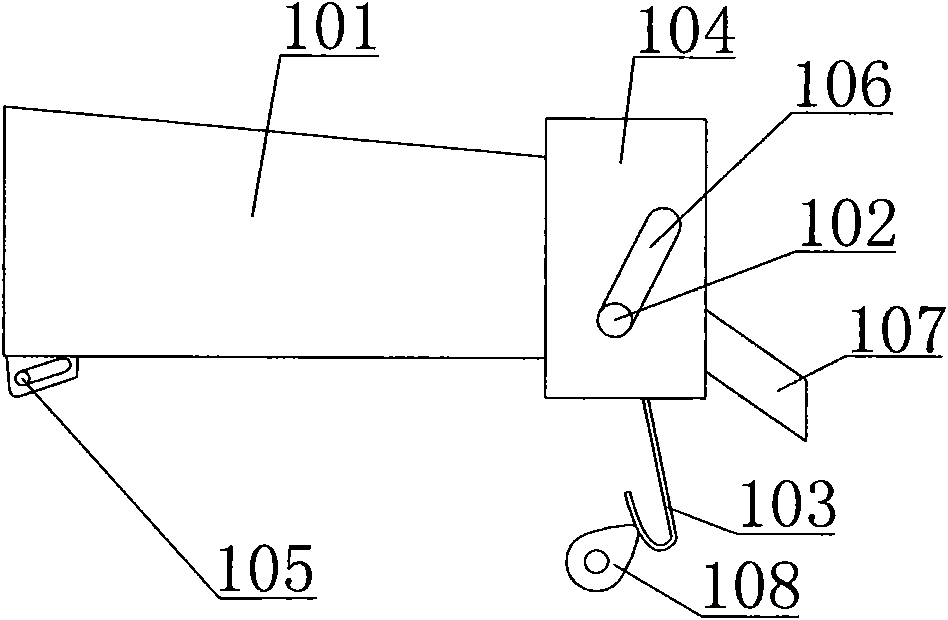

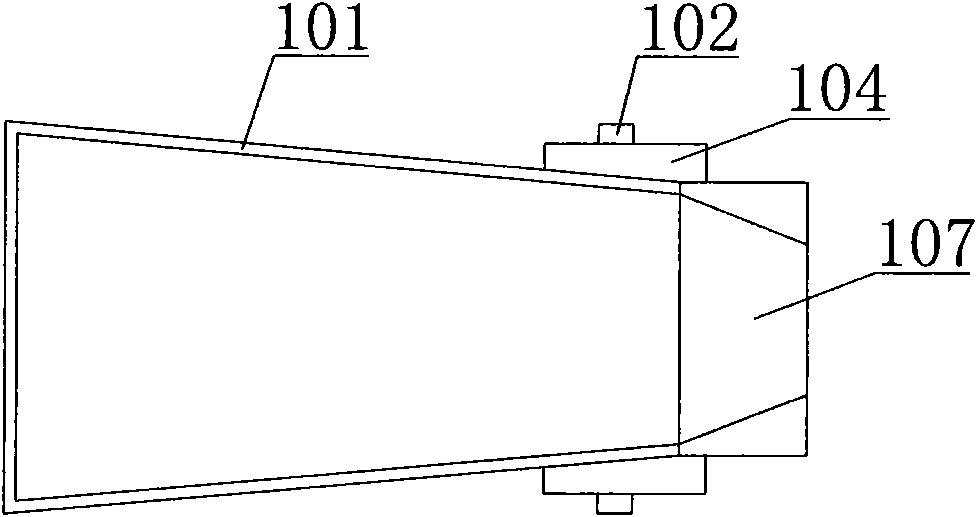

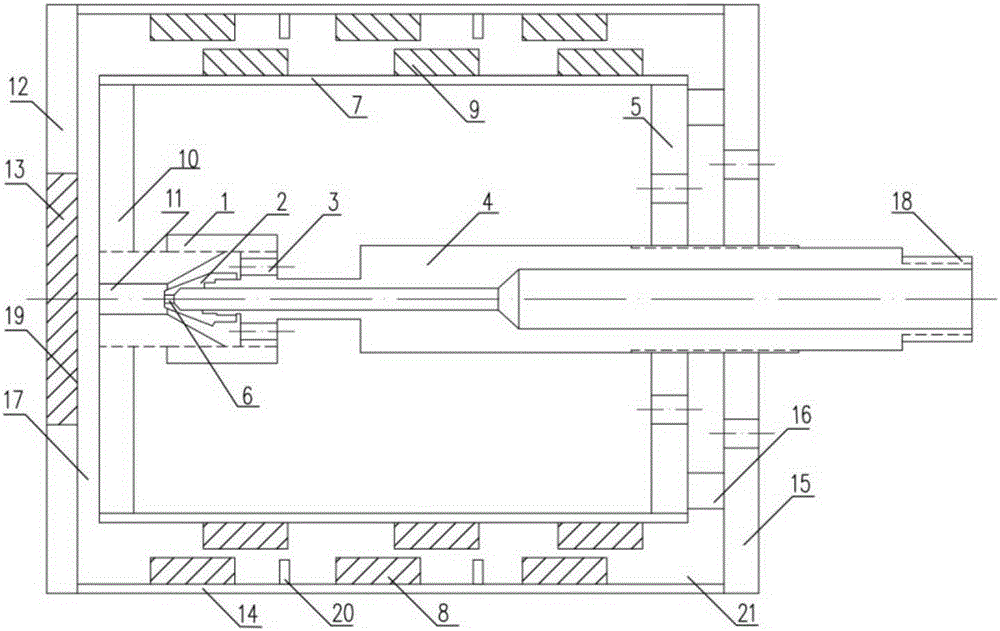

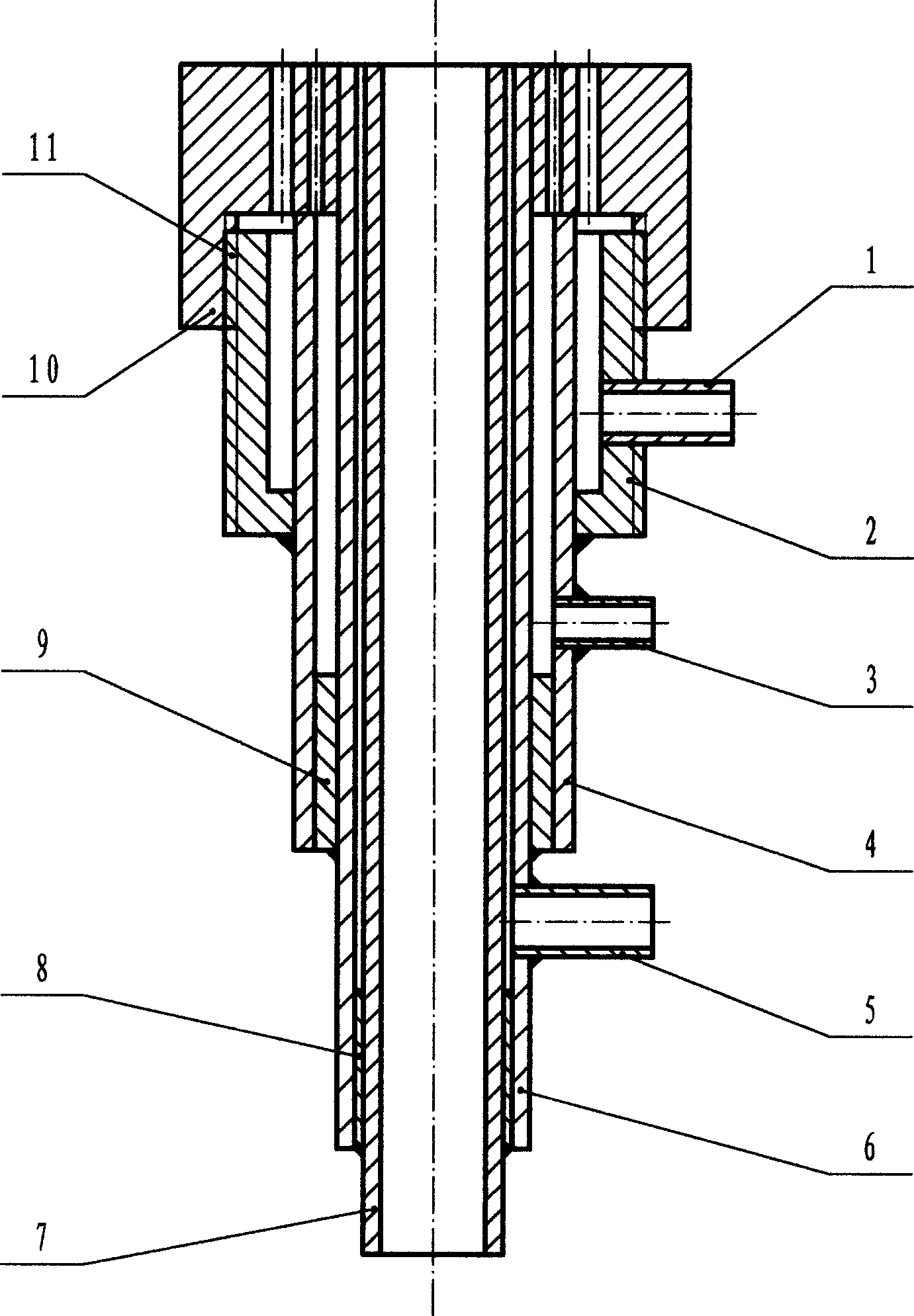

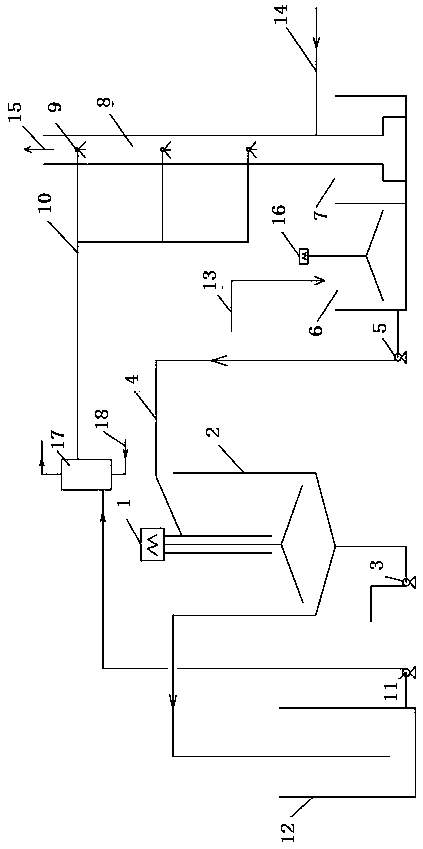

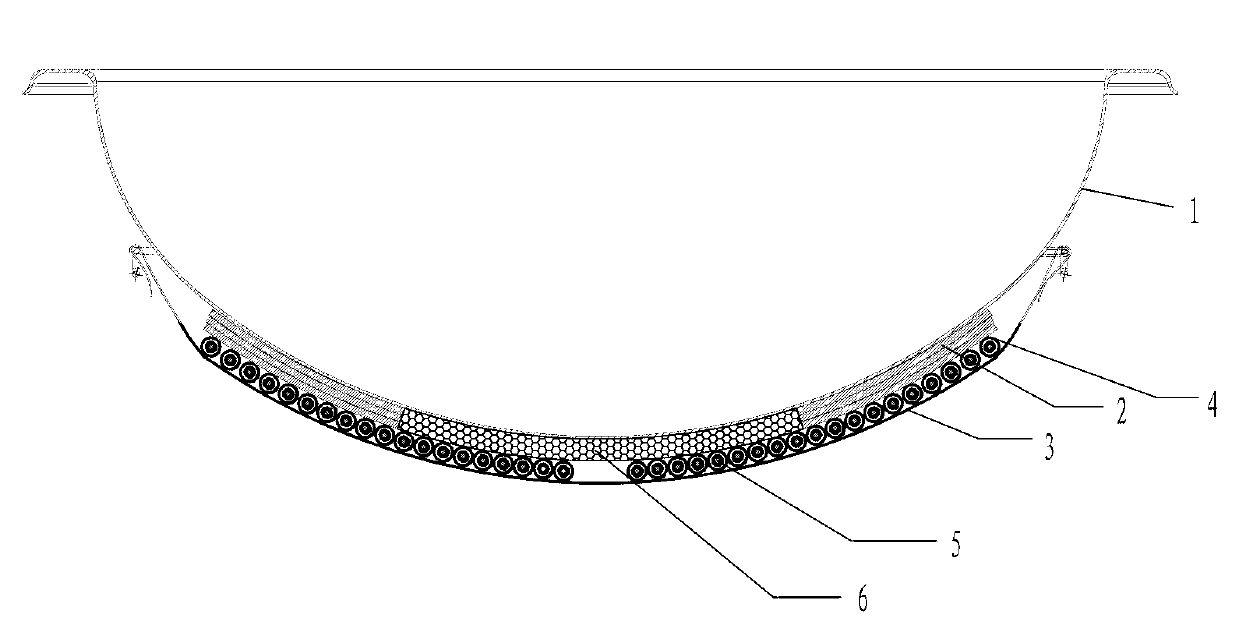

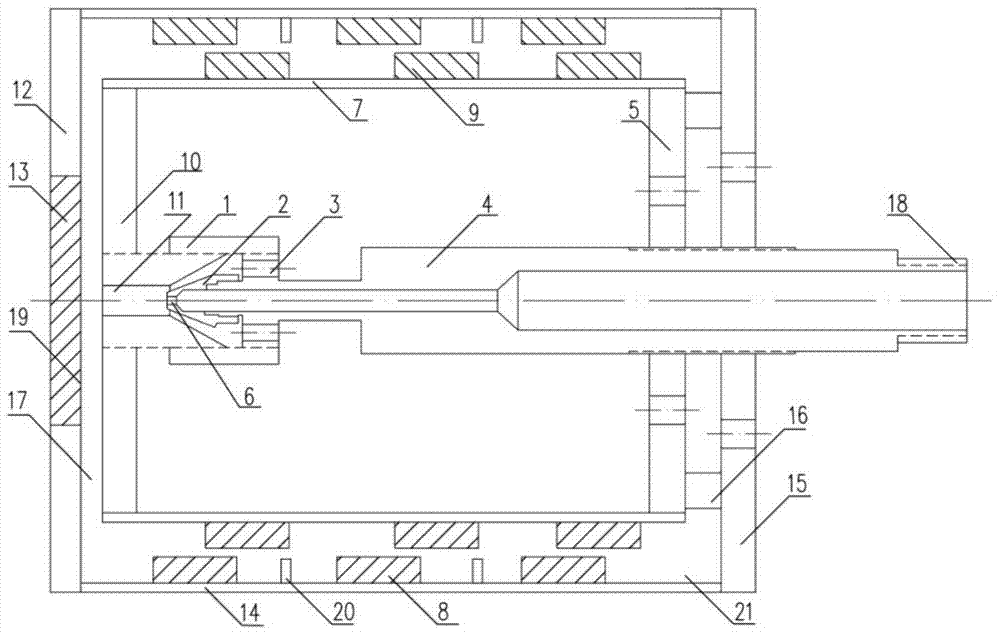

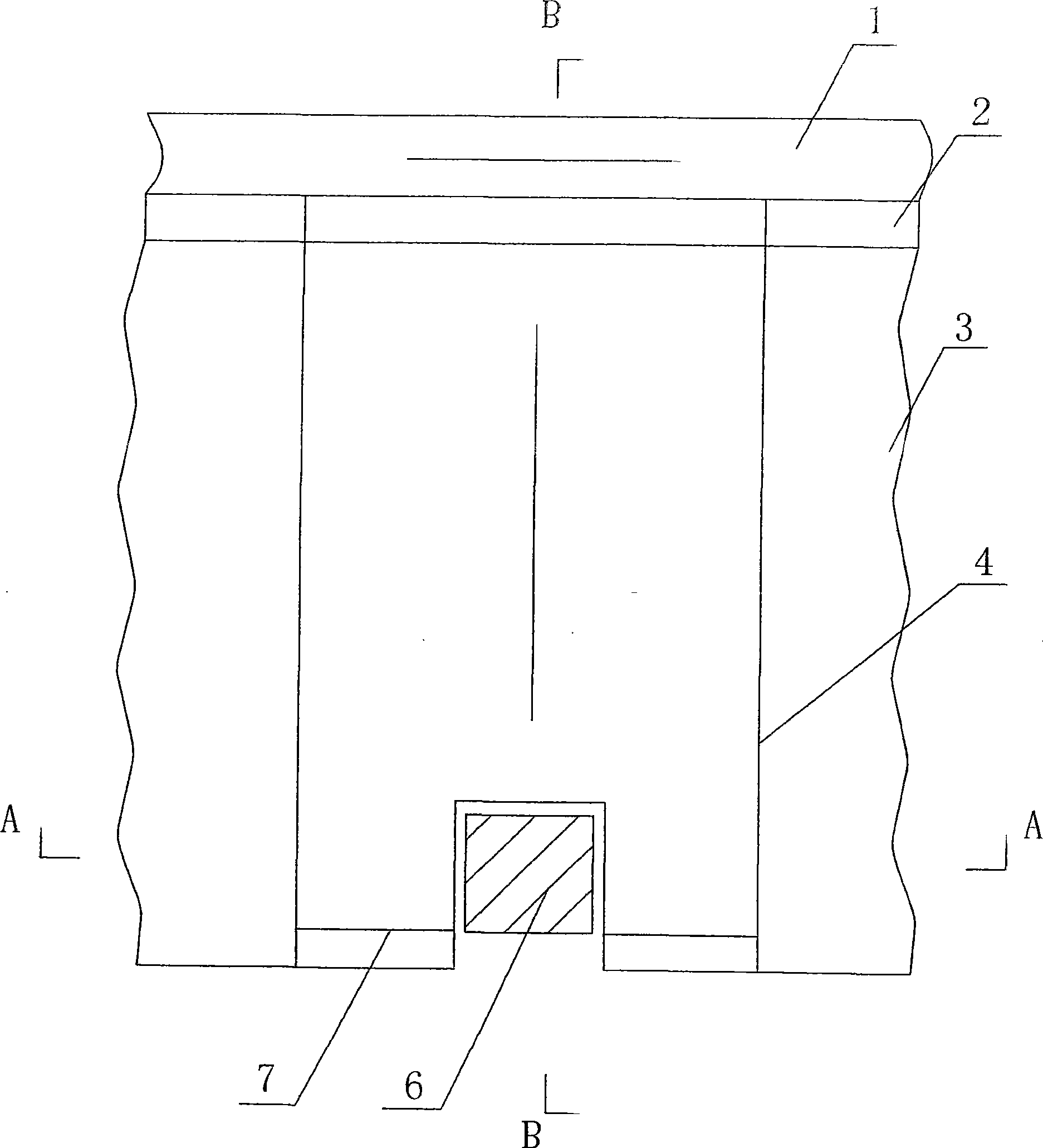

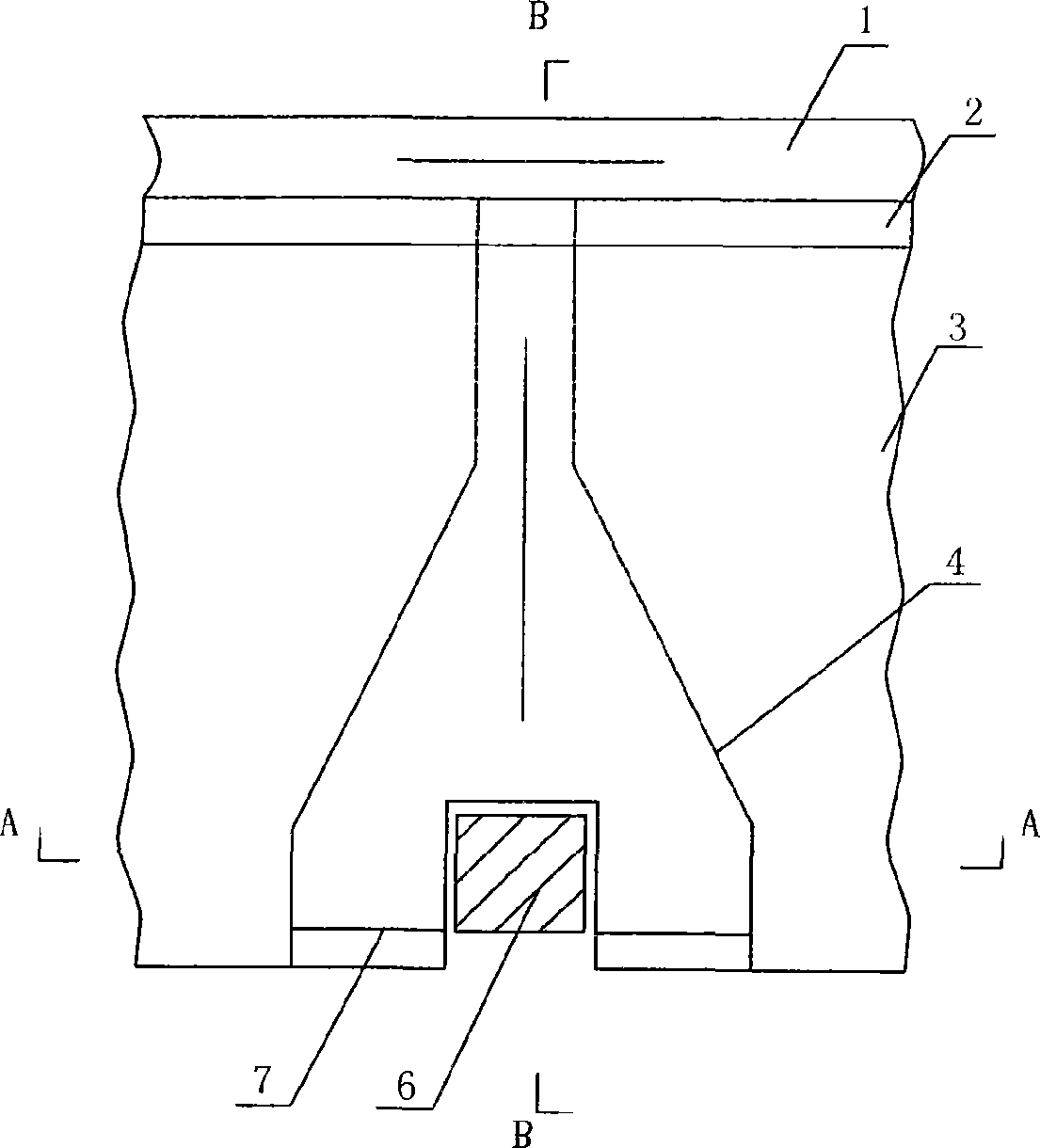

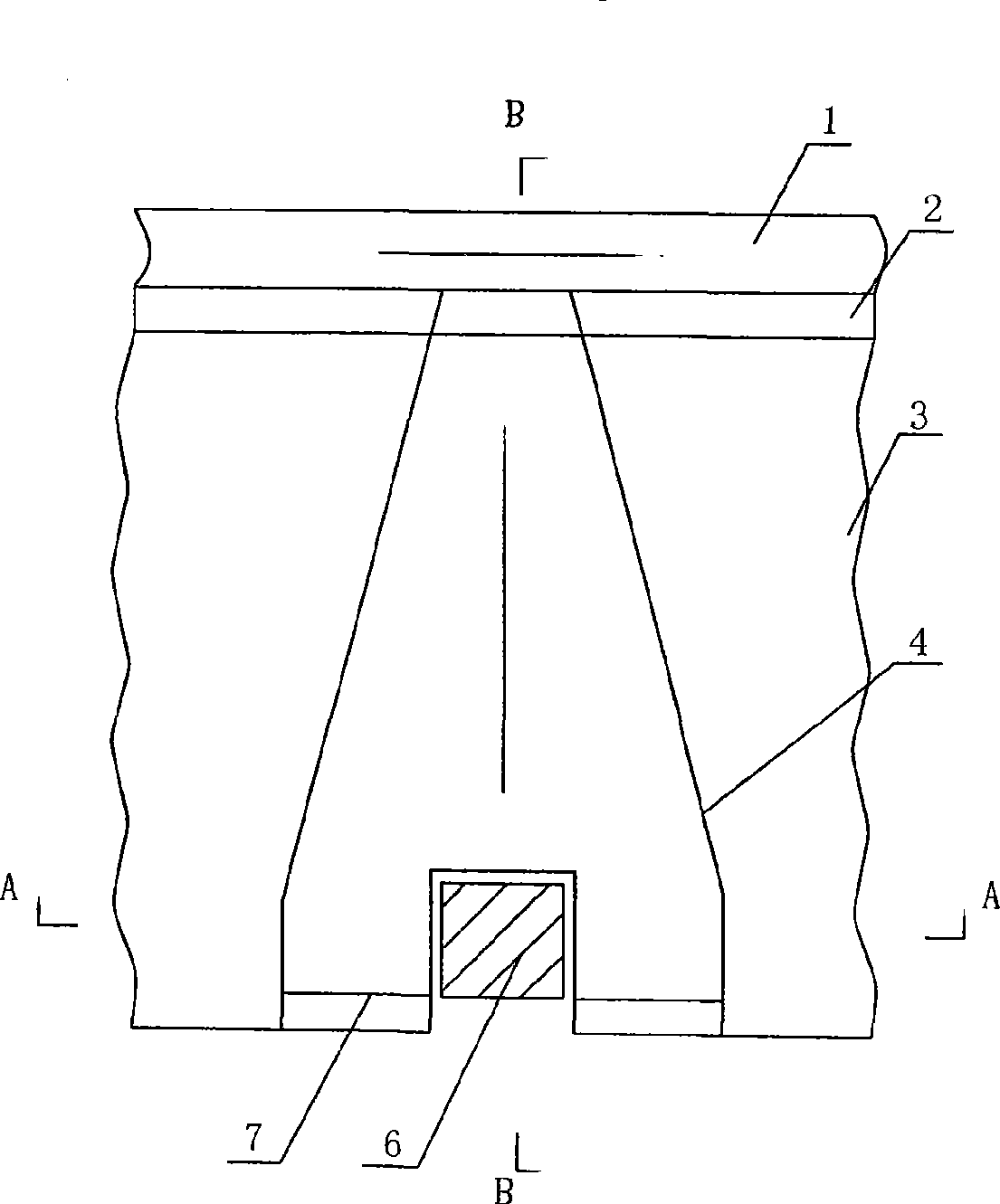

Full-automatic garlic planter capable of adjusting head and back of garlic

InactiveCN101878687ANot cloggedNo damageSeed depositing seeder partsSingle grain seedersEngineeringAutomation

The invention discloses a full-automatic garlic planter capable of adjusting the head and back of garlic. The full-automatic garlic planter comprises a power transmission mechanism and a rack, the full-automatic garlic planter is characterized in that a shaking seed feeding tank (1), a clove-by-clove separation seed feeding plate (2), an overturning-opening type garlic clove flat dropper (3), a garlic clove head / back adjuster (4) and a garlic clove vertical planter (5) with the inlets and outlets thereof sequentially corresponding to each other are arranged on the rack; and the overturning-opening type garlic clove flat dropper (3), the garlic clove head / back adjuster (4) and the garlic clove vertical planter (5) are respectively driven and controlled by a cam assembly (6) for controlling the garlic cloves to sequentially drop and an actuating cam assembly (7) for controlling the planting process. The garlic planter is capable of preventing the garlic cloves from being blocked and damaged in the unloading process and allowing the garlic cloves to be sequentially unloaded clove by clove in rows; the adjustment of head and back and the vertical planting process of the garlic can ensure that the back direction of the garlic seeds is identical with the seeding direction thereof, thus increasing the per-mu yield of the garlic, reducing the labor intensity, improving the labor efficiency and ensuring the high automation level. Therefore, the invention is widely applicable in seeding garlic.

Owner:魏传水

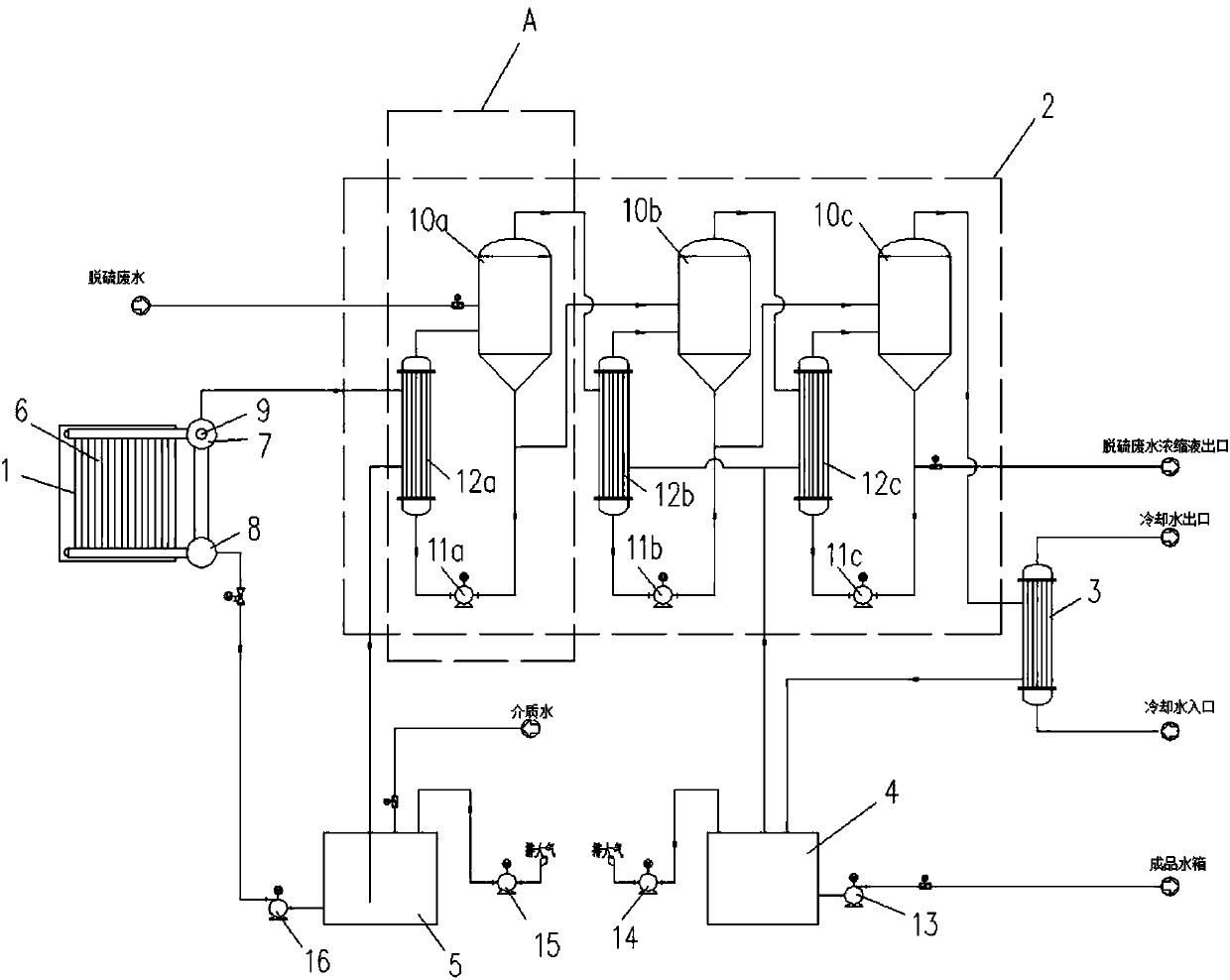

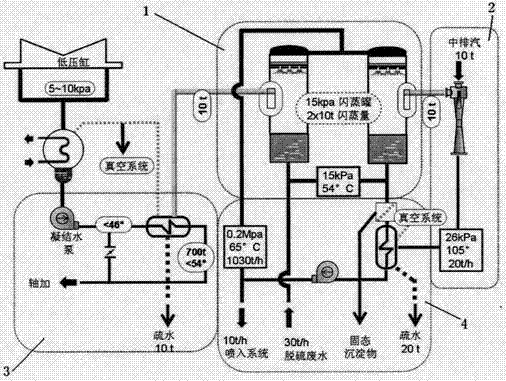

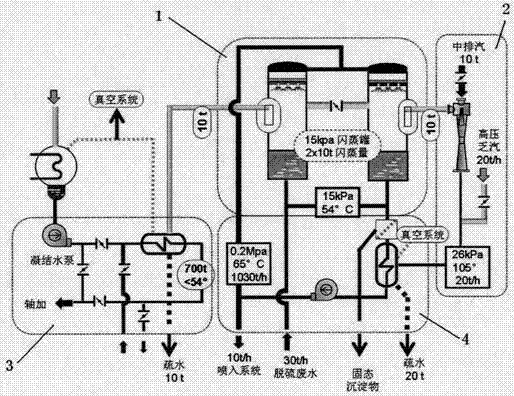

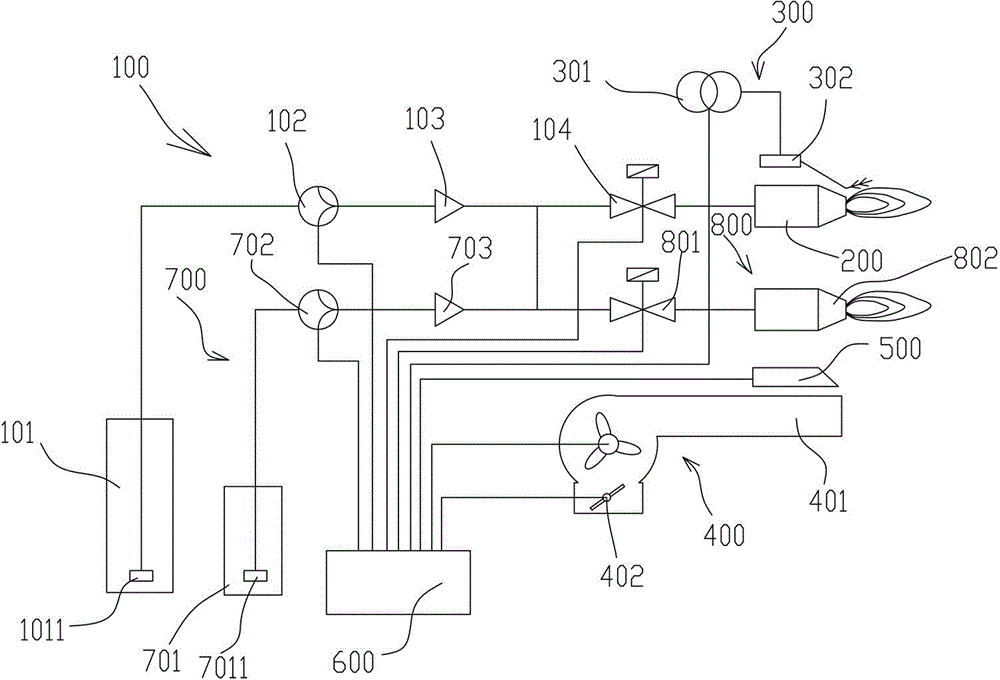

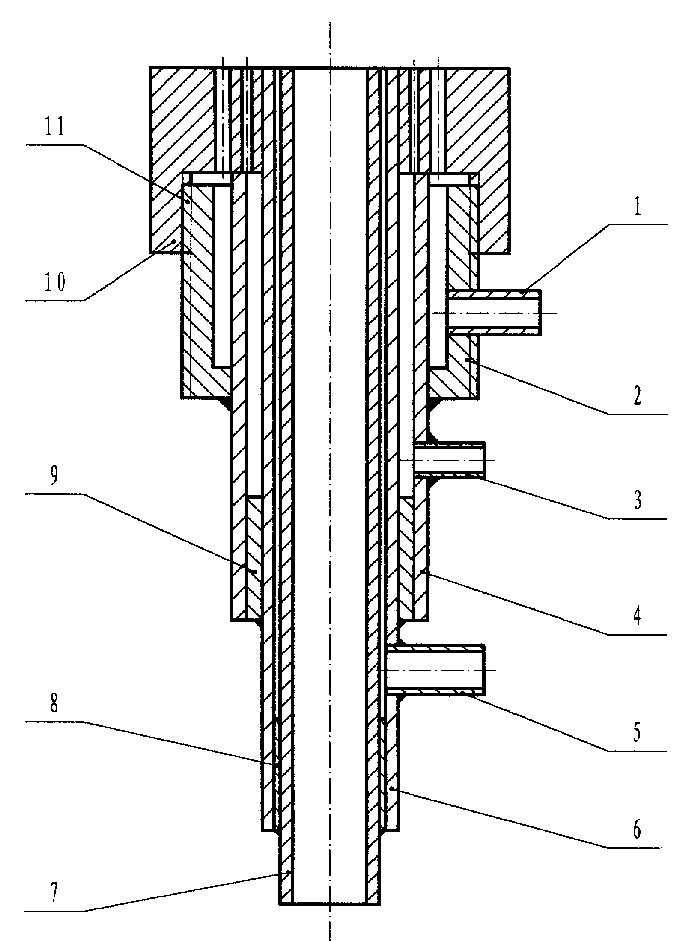

Concentrated solution drying system utilizing smoke waste heat to concentrate desulphurization waste water

PendingCN107792909ARealize ladder utilizationIncrease profitWaste water treatment from gaseous effluentsWater/sewage treatment by heatingWastewaterExhaust fumes

The invention relates to a concentrated solution drying system utilizing smoke waste heat to concentrate desulphurization waste water. The concentrated solution drying system comprises a flue heat exchanger, an evaporator group, a tail gas condenser, a tail gas condensation tank and a desulphurization waste water drying system, wherein a desulphurization waste water pipeline and a flue heater areconnected with the evaporator group, steam treated by the evaporator group successively enters the tail gas condenser and the tail gas condensation tank, and the desulphurization waste water concentrated solution treated by the evaporator group enters the desulphurization waste water drying system; the flue heat exchanger utilizes the smoke waste heat to heat the desulphurization waste water in the evaporator group; the evaporator group separates impurities from the desulphurization waste water in an evaporation manner; the tail gas condenser cools and condenses the evaporated steam; the tailgas condensation tank stores the condensed water and sends the condensed water into a finished product water tank; and the desulphurization waste water concentrated solution in the desulphurization waste water drying system is sprayed into a drying space to be mixed with flying ash to form solid powder to be collected. By adopting the concentrated solution drying system, no waste solid, waste water and waste gas is generated in the technological process, the condensed water evaporated by the waste heat of the smoke is completely recycled, the investment expense is low, and the maintenance costis low.

Owner:北京尤科恩环保工程有限公司

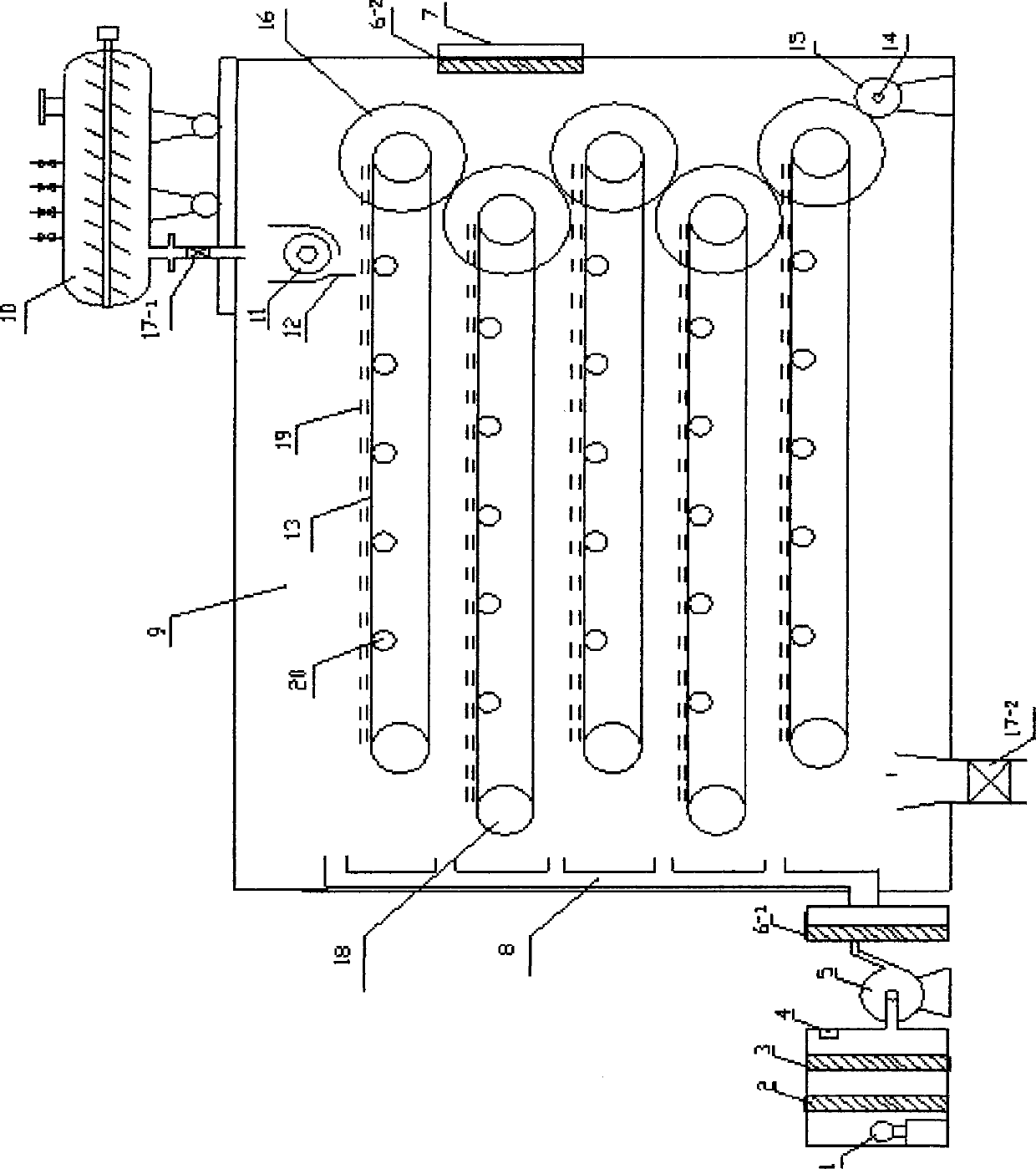

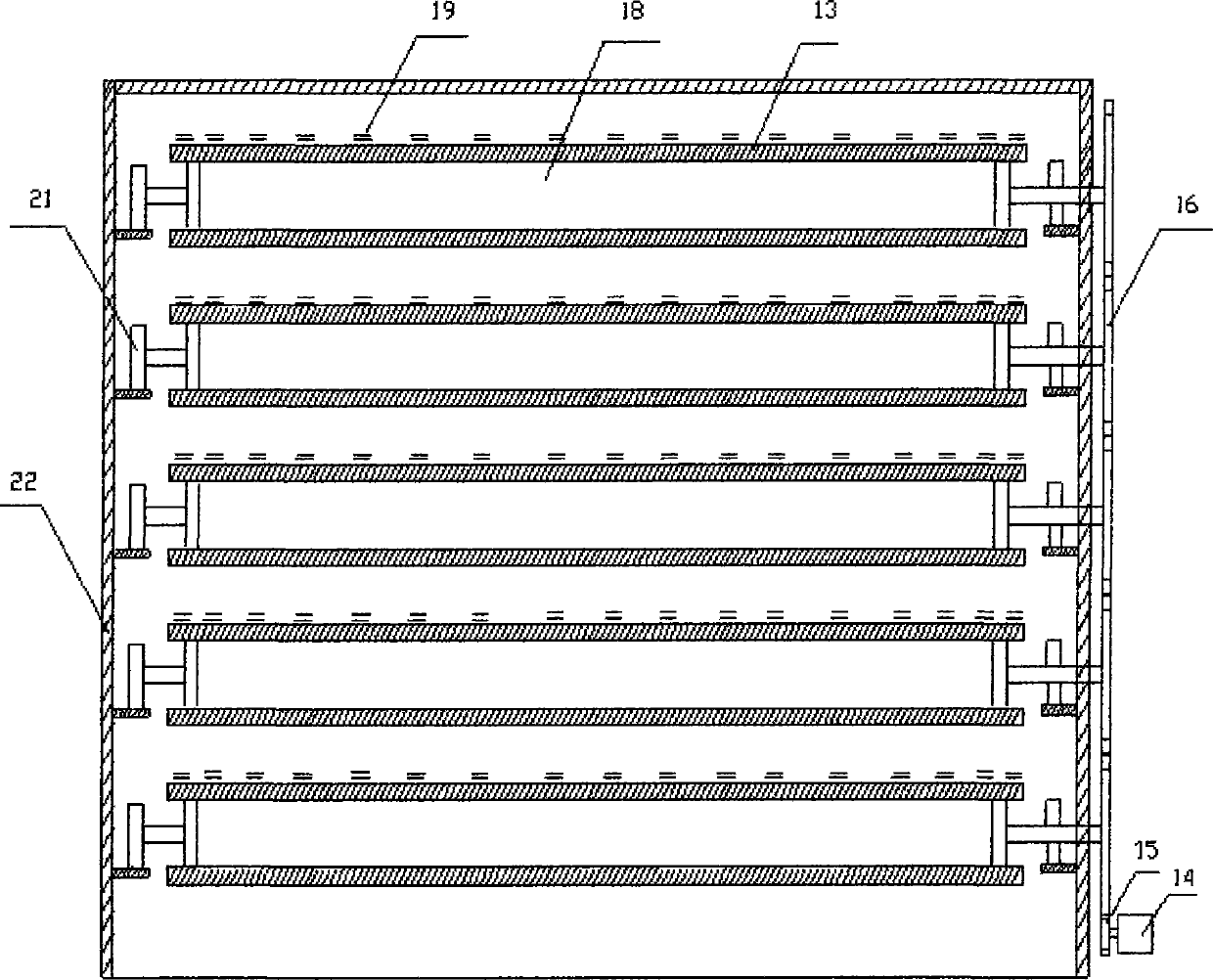

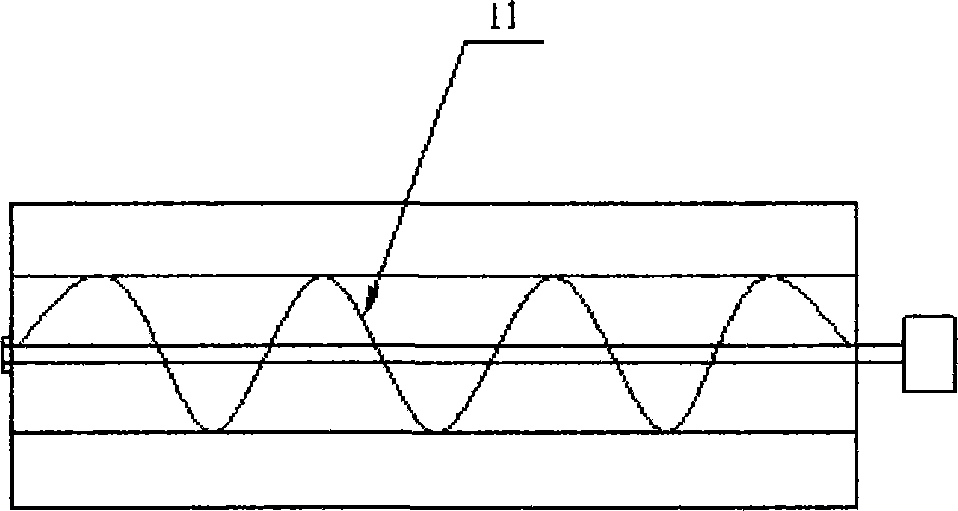

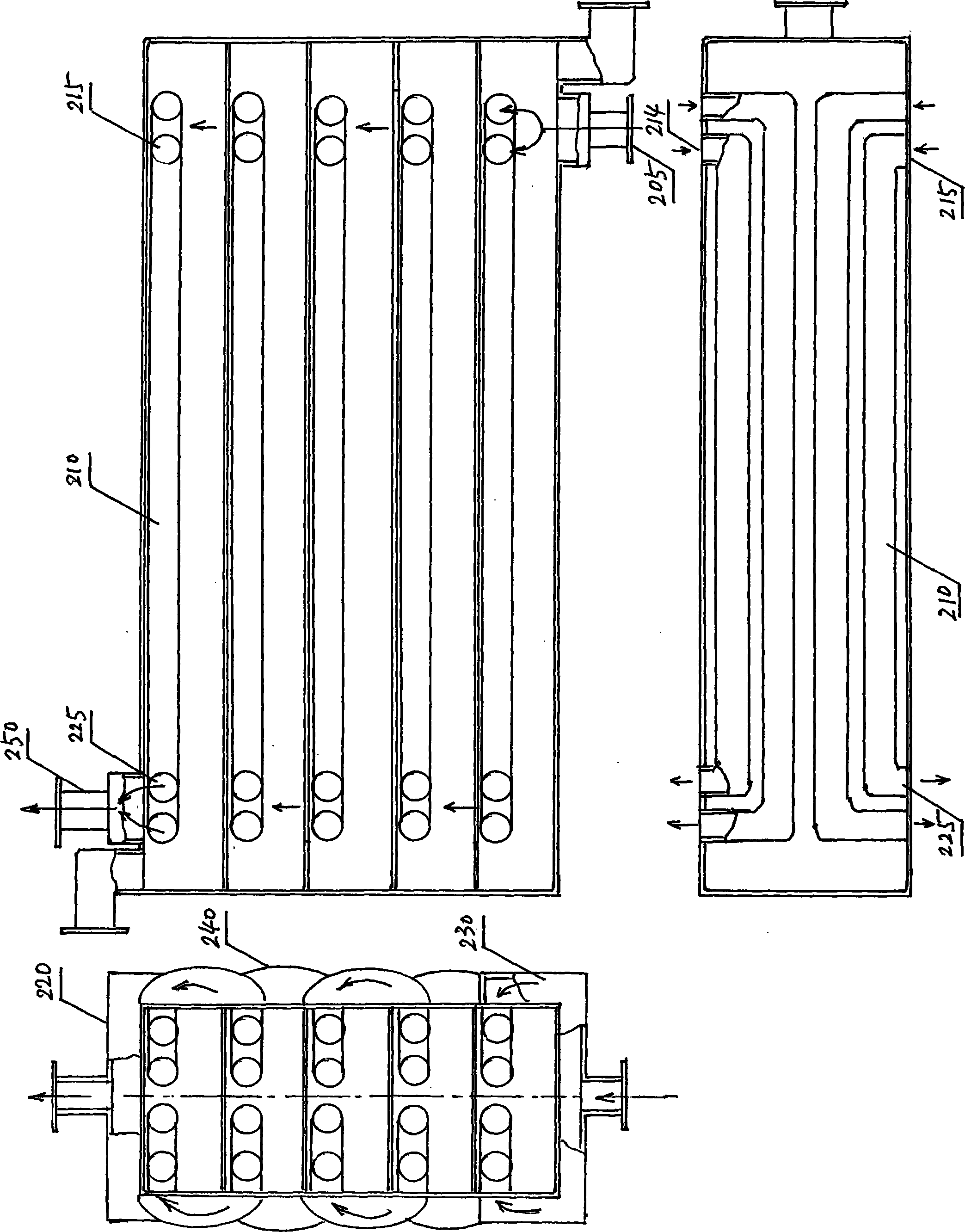

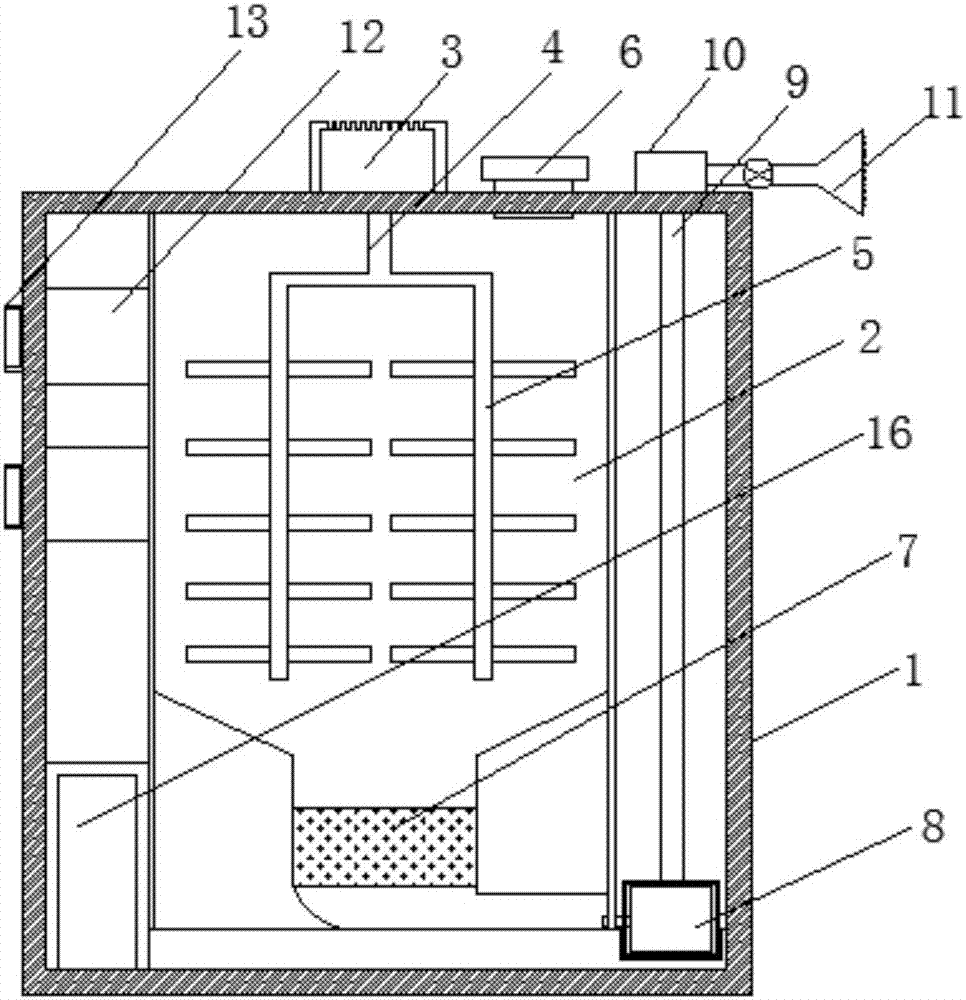

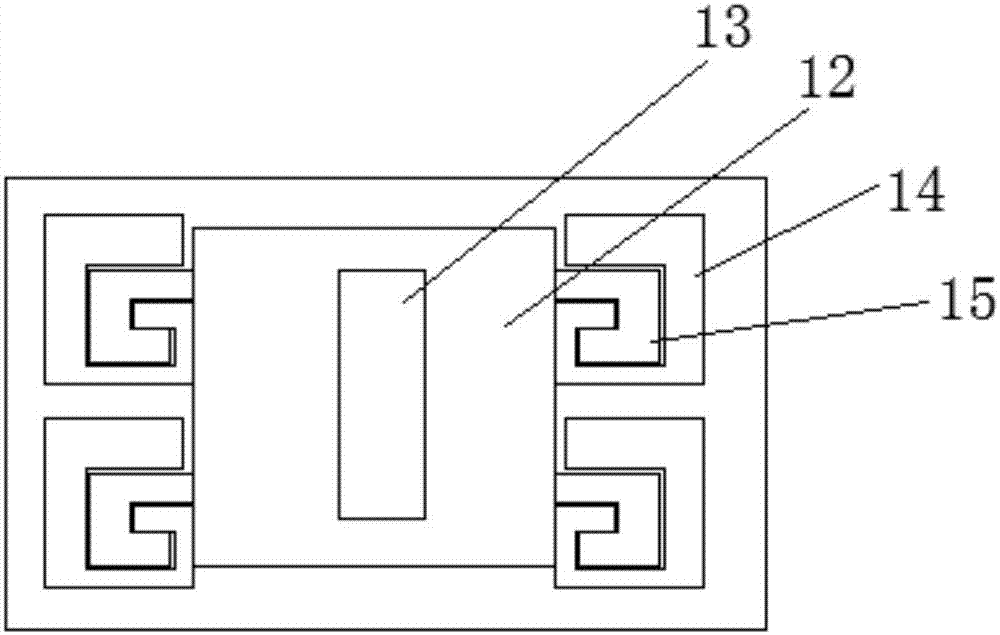

Thin-layer self-control static solid fermentation integrated optimizing method and device thereof

InactiveCN103966084ALarge capacityIncrease the areaBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlAir volume

The invention relates to a thin-layer self-control static solid fermentation integrated optimizing method and a device thereof. To solve the problems existing in the prior art, the method comprises the following steps: paving solid fermentation materials, which have been sterilized and inoculated, on a multi-layer movable slat fermentation bed in a sterile fermentation room to form a thin layer at a time, automatically controlling the sterile air volume, temperature and humidity to carry out solid fermentation according to the different fermentation phases, starting the driving device of the multi-layer movable slat fermentation bed to move the materials out of the fermentation room after the fermentation of the solid materials is finished, and finally carrying out a product post-treatment. The device comprises a sterile air adjusting system, a movable bacterium sterilizing and inoculating tank, a spiral paving machine, a multi-layer movable slat fermentation bed, and a sterile fermentation room. The method and device have the following advantages: (1) the hyphae of zymocyte are not easy to break, the growth of zymocyte is good, and the device is especially good for the enzyme-producing and enzymolysis solid fermentation; (2) the massive production bottleneck of thin-layer static solid fermentation is broken down, the industrial scale-production degree is high, the equipment investment is little, and the production efficiency is high.

Owner:徐少云

A low-temperature evaporation treatment system for desulphurization waste water

ActiveCN107473301AZero emissionWill not cause secondary pollutionWaste water treatment from gaseous effluentsWater/sewage treatment by heatingSalt freeEvaporation

A low-temperature evaporation treatment system for desulphurization waste water is disclosed. The system includes a waste water heating system, a waste water flash evaporation system, a flash evaporation steam cooling system, and a waste water heating source system. The desulphurization waste water in the waste water flash evaporation system flows through the waste water heating system and is heated, and then the waste water enters a spraying flash evaporation mechanism of the waste water flash evaporation system and is subjected to flash evaporation. Flash evaporation steam of the waste water flash evaporation system is distributed into two pipelines respectively connected to the flash evaporation steam cooling system and the waste water heating source system. The waste water heating source system provides heated steam for the waste water heating system. A desulphurization waste water circulating pipeline in the waste water flash evaporation system is connected to a flue spraying and evaporation system through a concentrated-water discharging pipe. The desulphurization waste water is subjected to heating and low-temperature flash evaporation to reduce the amount, thus achieving zero emission of the desulphurization waste water, improving running safety of an electrostatic precipitator and recovering salt-free water that is obtained through flash evaporation.

Owner:UNI RISING BEIJING TECH CO LTD

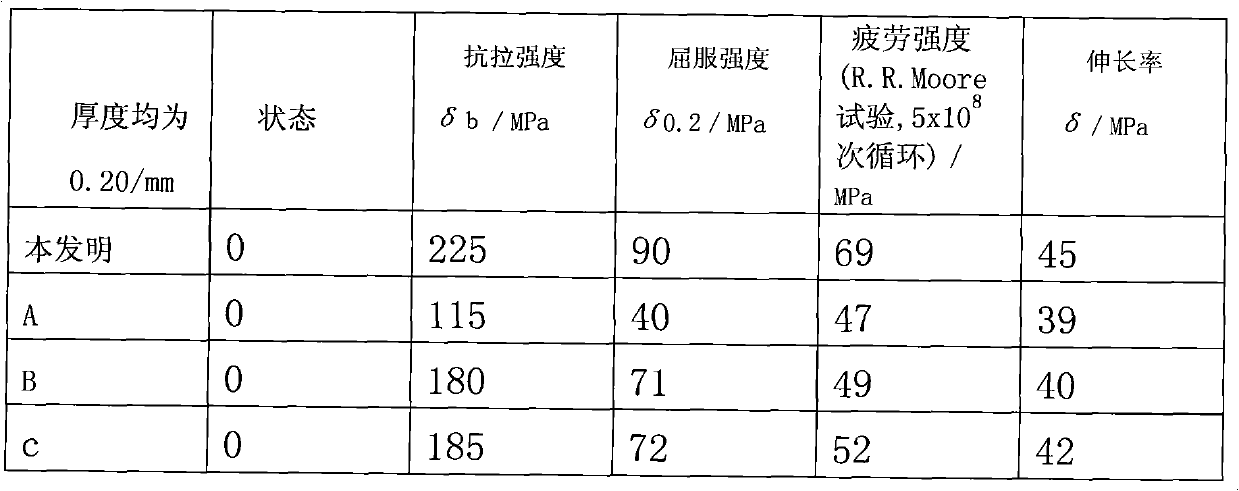

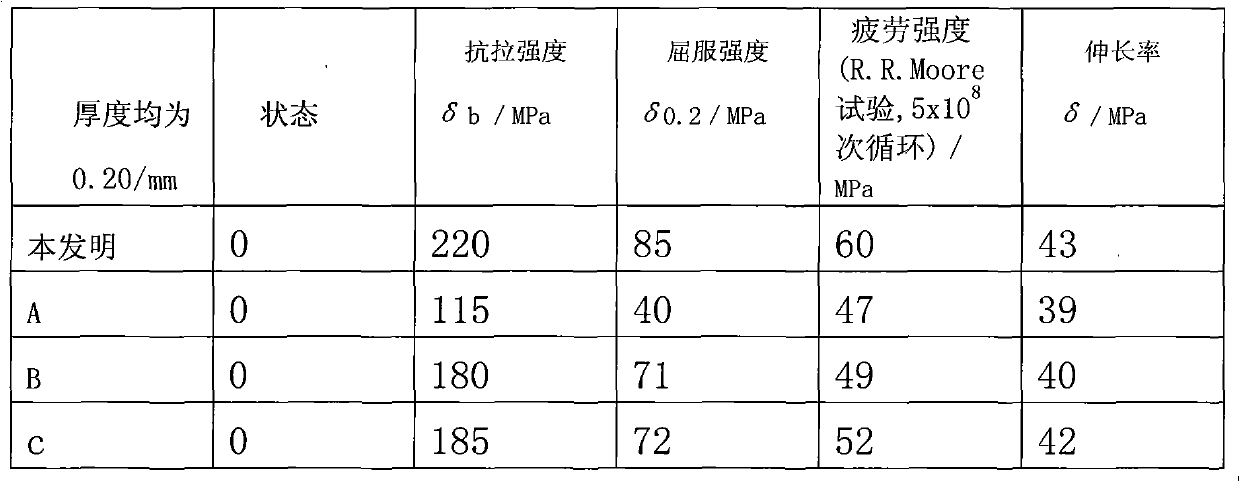

Explosion-suppressing material and preparation method thereof

InactiveCN102634703AImprove extrusion resistanceGood anti-collapseFire rescueBoring toolsChemical compositionPerformance index

The invention belongs to a preparation method of an explosion-suppressing material. The explosion-suppressing material comprises the following chemical compositions by weight percent: 0.3-0.5 percent of Si, 0.1-0.3 percent of Fe, 0.15-0.25 percent of Cu, 1.0-1.5 percent of Mn, 1.0-1.5 percent of Mg, 0.1-0.3 percent of Zn, 0.15-0.25 percent of Ti, 0.03-0.06 percent of La, 0.05-0.09 percent of Ce and the balance Al. A grain structure of the explosion-suppressing material is refined by adopting a repeated heating forging and pressing method. The explosion-suppressing material provided by the invention has excellent extrusion resistance, collapse prevention, zero dreg-falling and high-strength explosion-suppressing property. The performance indexes of the explosion-suppressing material, such as strength, plasticity, fracture toughness and fatigue resistance, are greatly increased according to the preparation method; the technology is simple and is easily performed; and the service life of the explosion-suppressing material is prolonged.

Owner:王季庄

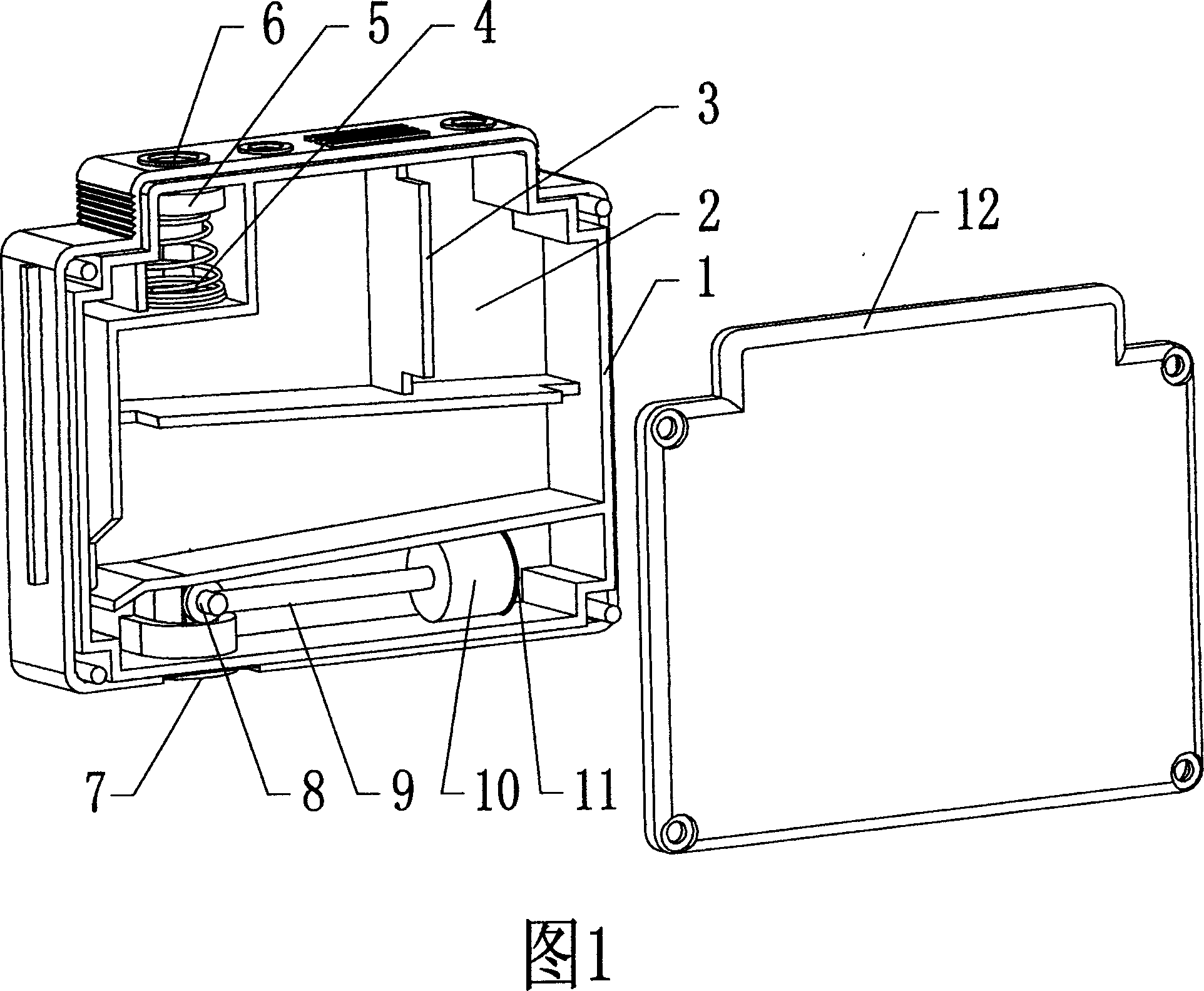

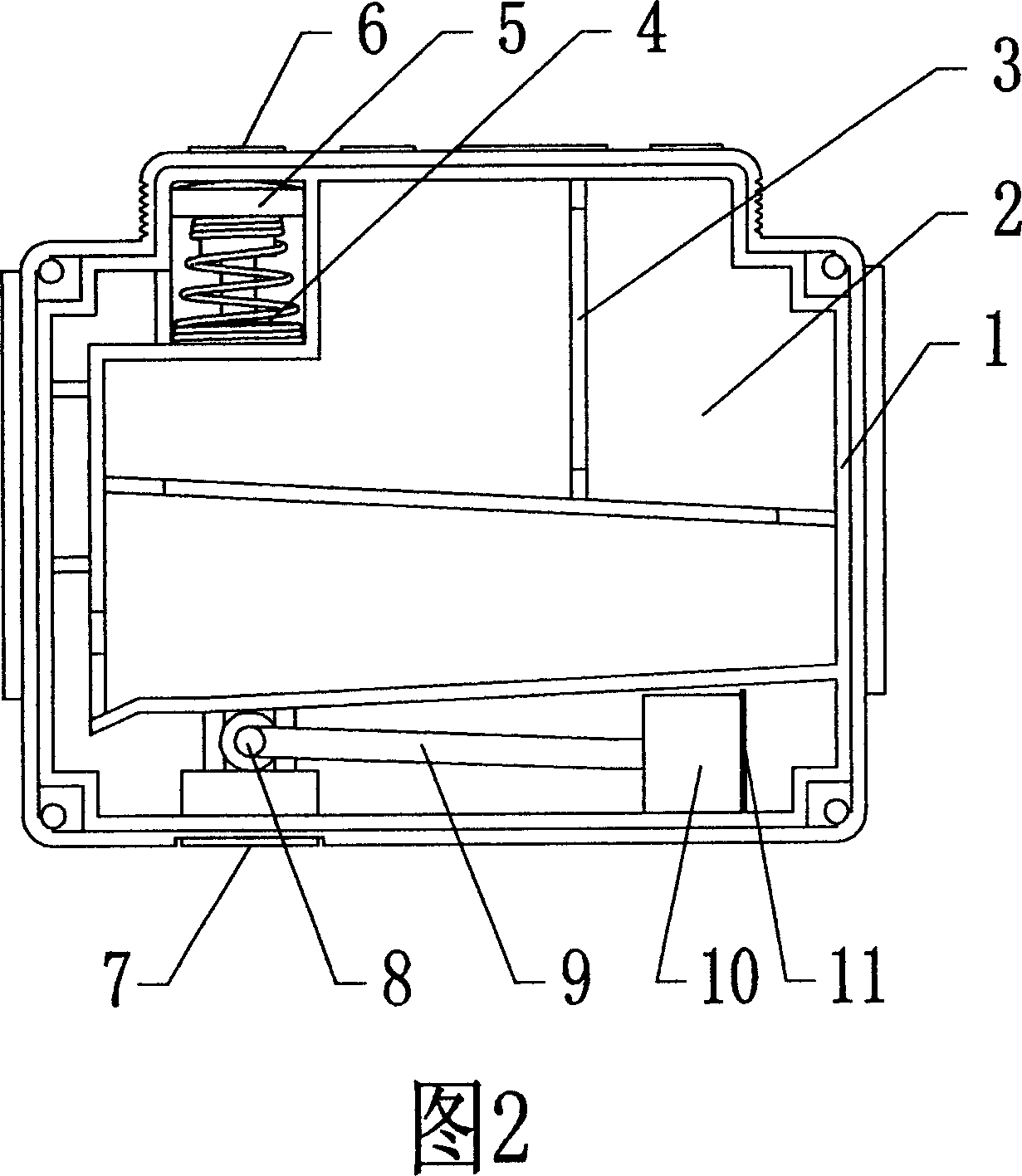

Ink cartridge having filtering means

Owner:ZHU HAI NAT RESOURCES & JINGJIE IMAGING PROD

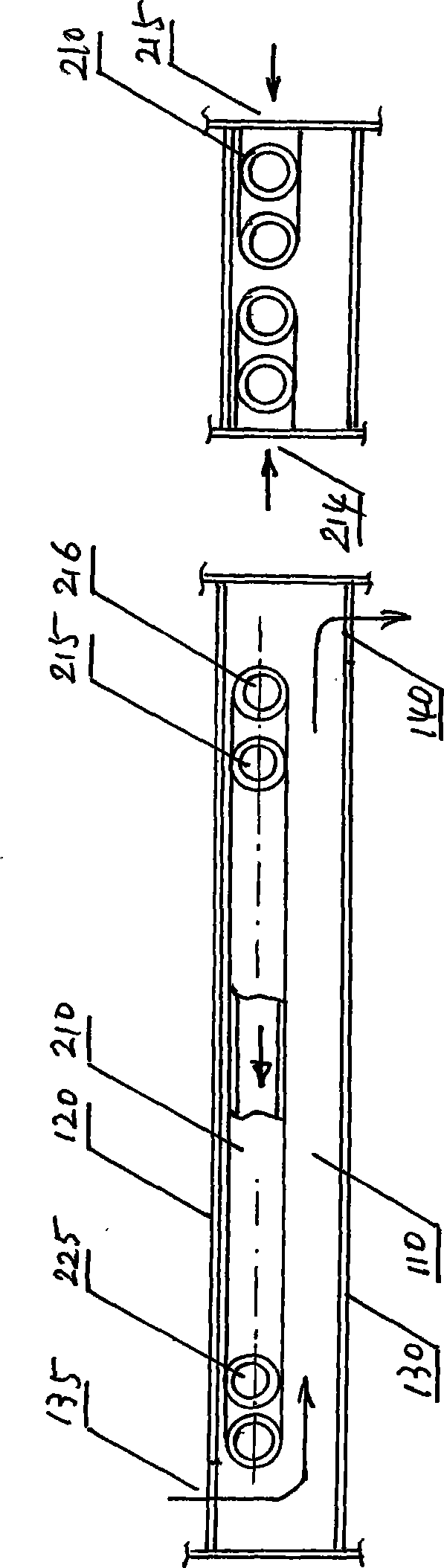

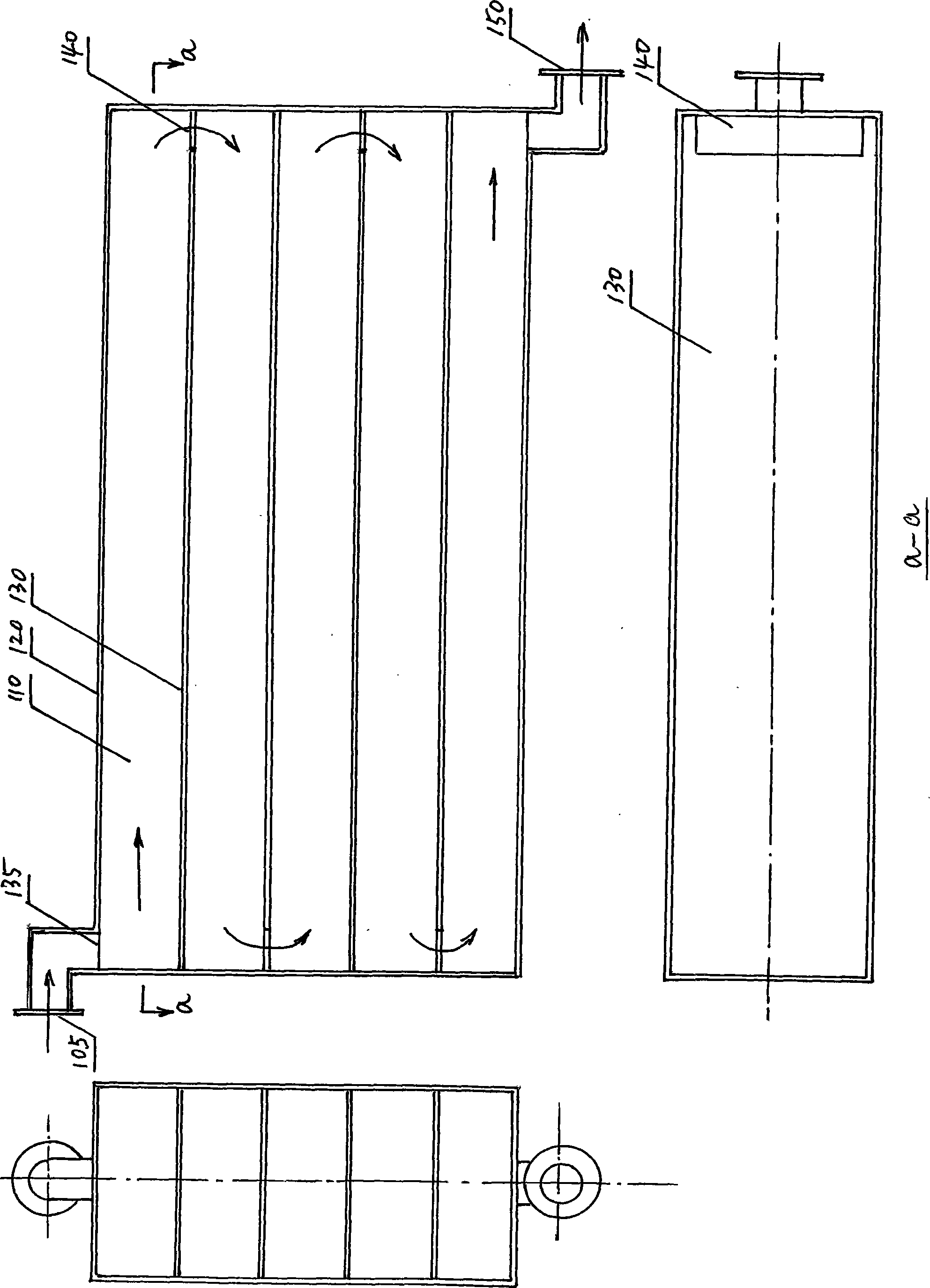

Flow passage type sewage heat exchanger

ActiveCN103134352ANo depositionNot cloggedStationary tubular conduit assembliesHeat exchange apparatusHeat transmissionWater flow

The invention provides a flow passage type sewage heat exchanger which structurally comprises a box body, a sewage flow passage, a clear water flow passage, a dirt removing door and a base. Sewage and clear water respectively flow in the flow passages arranged inside the box body and heat is exchanged through a dividing wall. The clear water flow passage is composed of a plurality of circular heat transmission tubes, arranged inside the sewage flow passage with a rectangular cross section, and tightly attached to the lower surface of a top plate of the sewage flow passage. The sewage flow passage comprises a sewage inlet, a sewage pipeline and a sewage outlet. The sewage enters the heat exchanger from the sewage inlet, enters the sewage pipeline from a water inlet at one end of the top plate of the sewage pipeline, flows out from a water outlet at the other end of a bottom plate, and finally flows out from the sewage outlet. The clear water flow passage comprises a clear water inlet, an inlet water distributive tank, clear water pipelines, a tile-shaped plate, an outlet collection tank and a clear water outlet. The clear water enters the heat exchanger from the clear water inlet, passes the inlet water distributive tank, enters the clear water pipeline, passes the tile-shaped plate, enters another clear water pipeline, and finally passes an outlet collection tank and flows out from the clear water outlet.

Owner:HIT HARBIN INST OF TECH KINT TECH

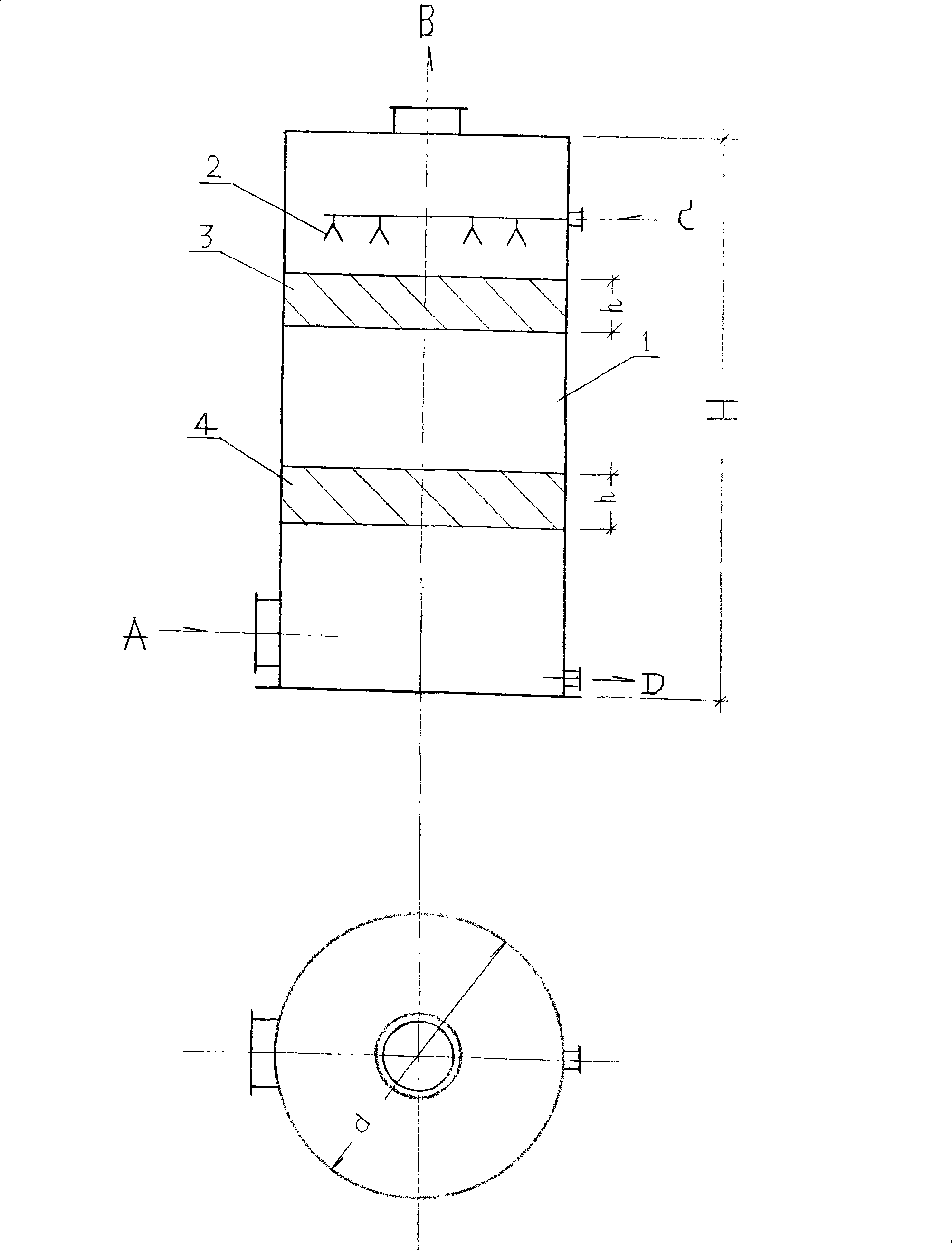

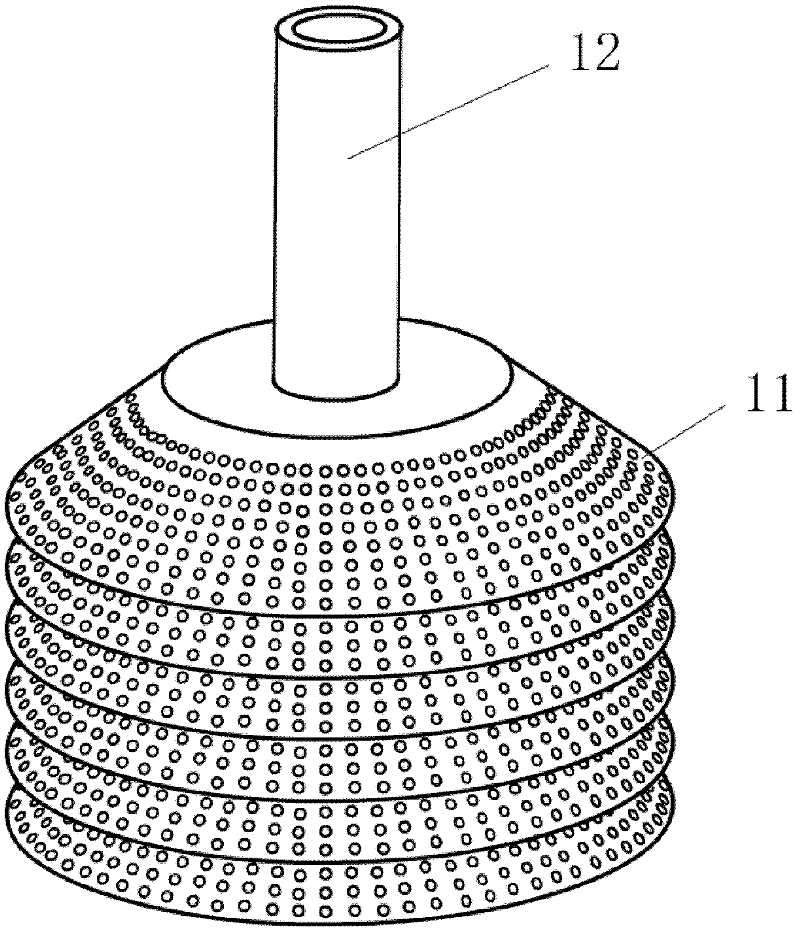

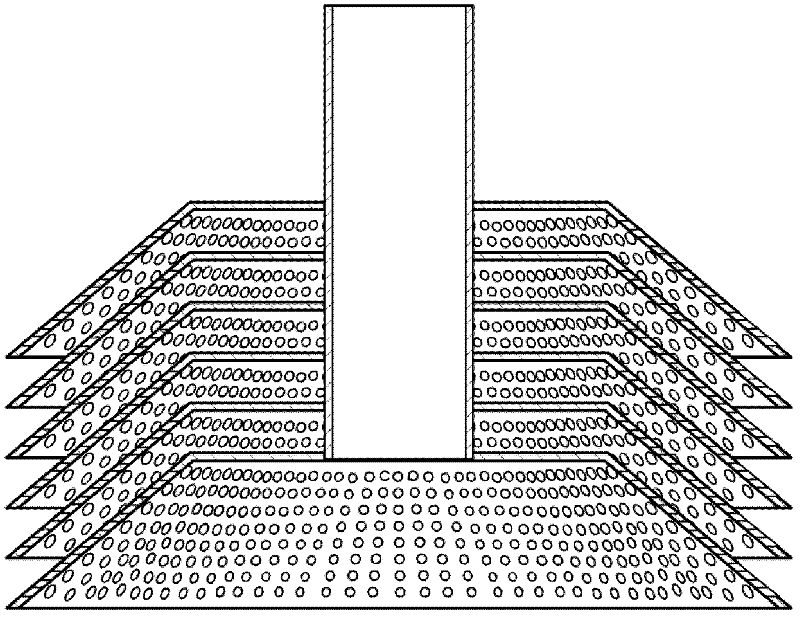

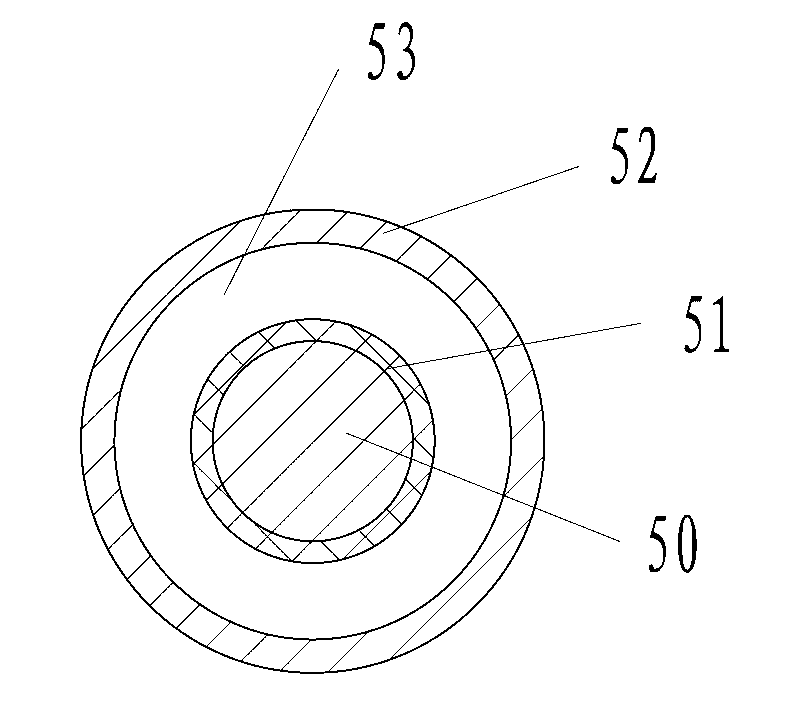

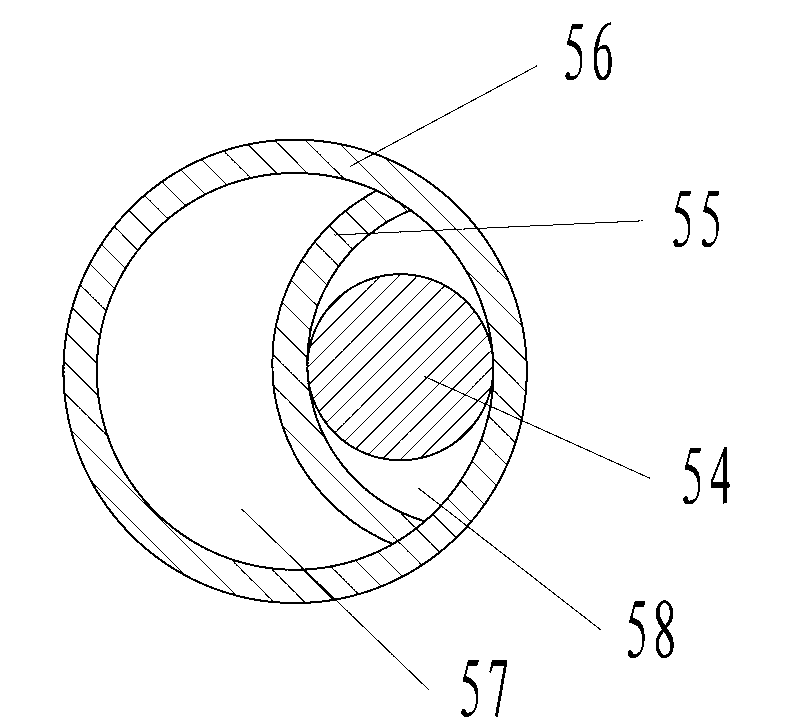

Blocking-proof micro-bubble aeration device for sewage treatment

ActiveCN105293678ASolve the blockageAvoid cloggingTreatment using aerobic processesSustainable biological treatmentMicro bubbleSewage sludge treatment

The invention relates to a blocking-proof micro-bubble aeration device, which is used for oxygen aeration of an aerobic treatment section in a sewage treatment process. The device is cylindrical, and comprises the structures of an inner barrel, an outer barrel, an air inlet pipe, an air nozzle, a water plate, a diffusing pipe and the like, wherein a crushing chamber and a snakelike waterway are formed between barrel walls of the inner barrel and the outer barrel, an air-water mixture enters the crushing chamber and the snakelike waterway via the diffusing pipe, and repetitive multi-time impact crushing and disturbing and dispersing are carried out, so that micro bubbles are generated. According to the device, the micro bubbles are not generated by extruding compressed air through micro holes in the surface of the aeration device (head), thus, the micro holes are not formed in the surface and interior of the device, and the problem of blocking is prevented from occurring.

Owner:崔杰

Identification type permeable pavement brick and preparation method thereof

The invention discloses an identification type permeable pavement brick and a preparation method thereof. The identification type permeable pavement brick comprises a permeable base layer and a luminous surface layer; the permeable base layer is prepared from the following components in parts by weight: 390 to 420 parts of cement, 10 to 30 parts of mineral powder, 750 to 850 parts of heavy slag gravel, 800 to 900 parts of heavy slag sand, 1 to 5 parts of a water reducing agent and 210 to 230 parts of water; and the luminous surface layer is prepared from the following components in parts by weight: 20 to 30 parts of film-coated color sand, 1 part of resin, 0.25 to 0.3 part of curing agent, 0.9 to 1.1 parts of light-emitting material, 0.2 to 0.4 part of light-reflecting material and 0.05 to 0.1 part of auxiliary agent. The identification type permeable pavement brick has a colorful effect in the daytime, can absorb sunlight and store light energy, releases the stored light energy in the form of visible light at night, and has good mechanical properties and water permeability.

Owner:中冶武汉冶金建筑研究院有限公司 +1

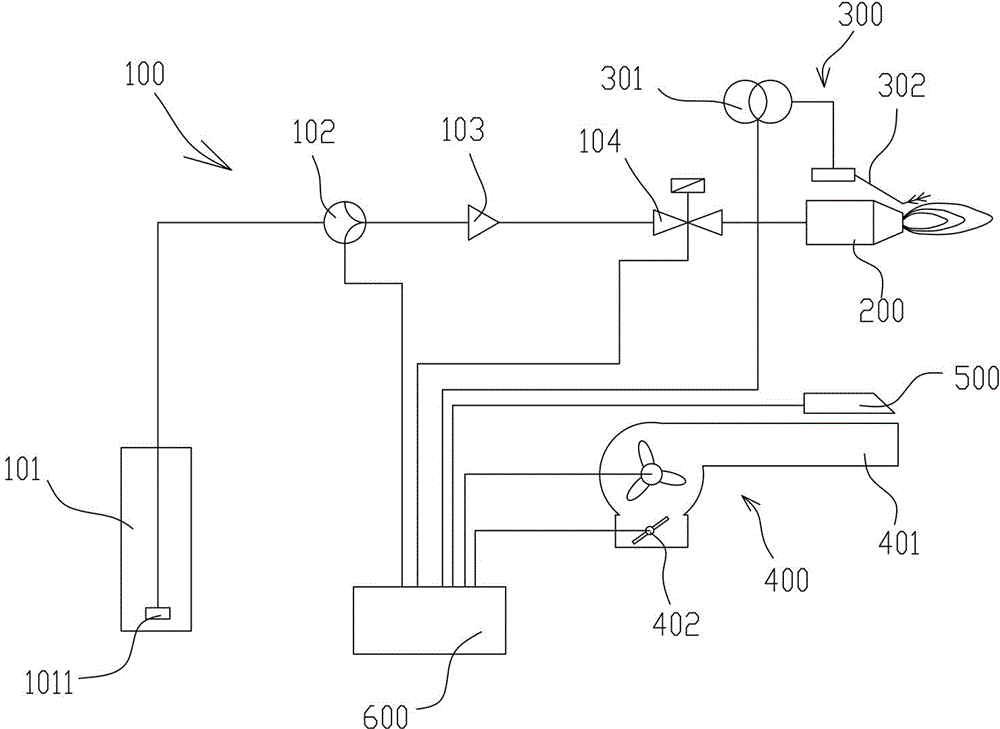

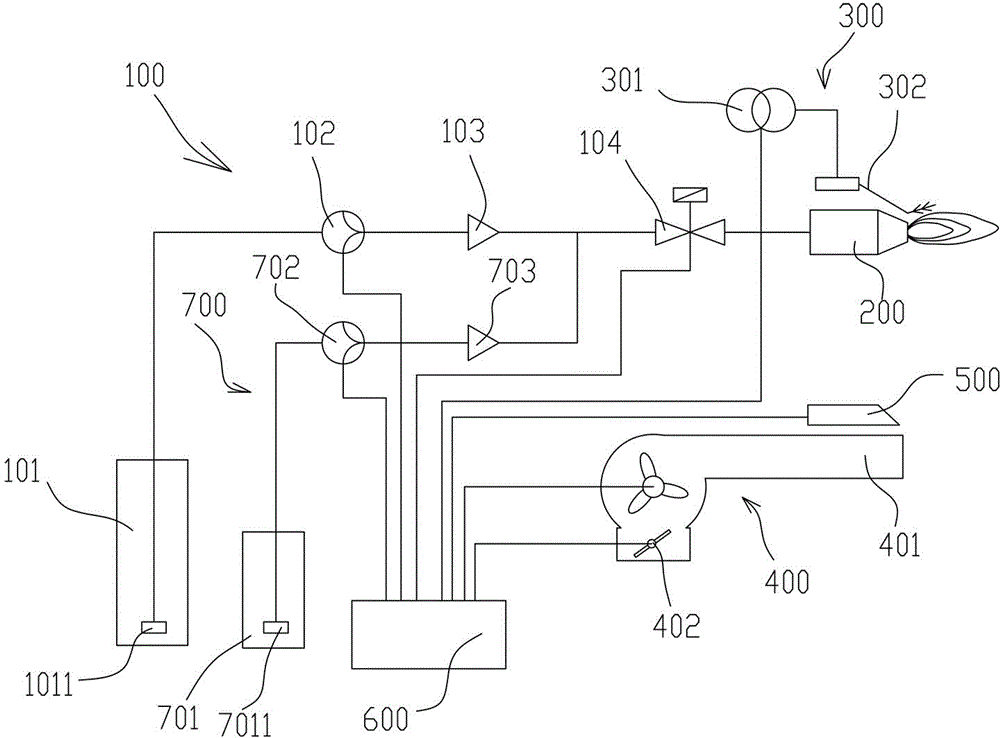

Pressure atomization burner special for high-energy carbon alcohol slurry clean industrial fuel

ActiveCN104791786ANot cloggedEfficient use ofBurnersFuel supply regulationAutomatic controlHigh energy

The invention relates to a pressure atomization burner special for high-energy carbon alcohol slurry clean industrial fuel. The pressure atomization burner comprises a fuel feed system, a first pressure atomization nozzle, an ignition system and an air supply device; the fuel feed system is used for feeding the solid-liquid-phase mixed fuel and comprises a fuel storage tank used for storing the solid-liquid-phase mixed fuel, a booster pump used for pumping out the solid-liquid-phase mixed fuel, a fuel one-way valve located on the booster pump and a first fuel flow rate adjusting valve located behind the fuel one-way valve; the first pressure atomization nozzle is located behind the fuel flow rate adjusting valve and used for supplying the atomized solid-liquid-phase mixed fuel to a burning mechanism; the ignition system comprises an ignition transformer and an ignition bar; the air supply device is used for supplying air to the burning mechanism. The pressure atomization burner has the advantages of being simple in structure, low in cost, convenient to start up and shut down and automatically controlled, and not blocking a pipeline.

Owner:ZHONGLAN ENERGY SHENZHEN CO LTD

Sewage filter

InactiveCN102228759BSS reductionIncrease surface loadSedimentation separationFiltration separationFlocculationSewage

The invention provides a sewage filter, which synthesizes a shallow tank theory, a dynamic coagulation theory, an accelerated coagulation theory and an inclined plate technology, effectively solves the problem of easiness in blockage of the traditional inclined plate. The sewage filter is used for subdividing raw motion water through by using filter masks and a plurality of through hole structures; and the raw water forms stable eddies at rear edges of plate holes of filter mask bodies. Under the entrainment action of the eddies, non-fluidic substances in the raw water are collected at centers of the eddies and get in continuous contact and collision with one another in eddy cores to undergo a flocculation reaction, and slides down along the mask bodies under the gravity action to settle into a mud collecting hopper, so that the purposes of removing suspended substances in the raw water and cleaning a water body are achieved. The sewage filter can rotate around an axis of a rotating shaft; and a strongly turbulent shear flow is formed through left and right repeated quick rotation to scour an inclined plate at a high speed and to clean deposits and blockages very conveniently.

Owner:韦志锋 +1

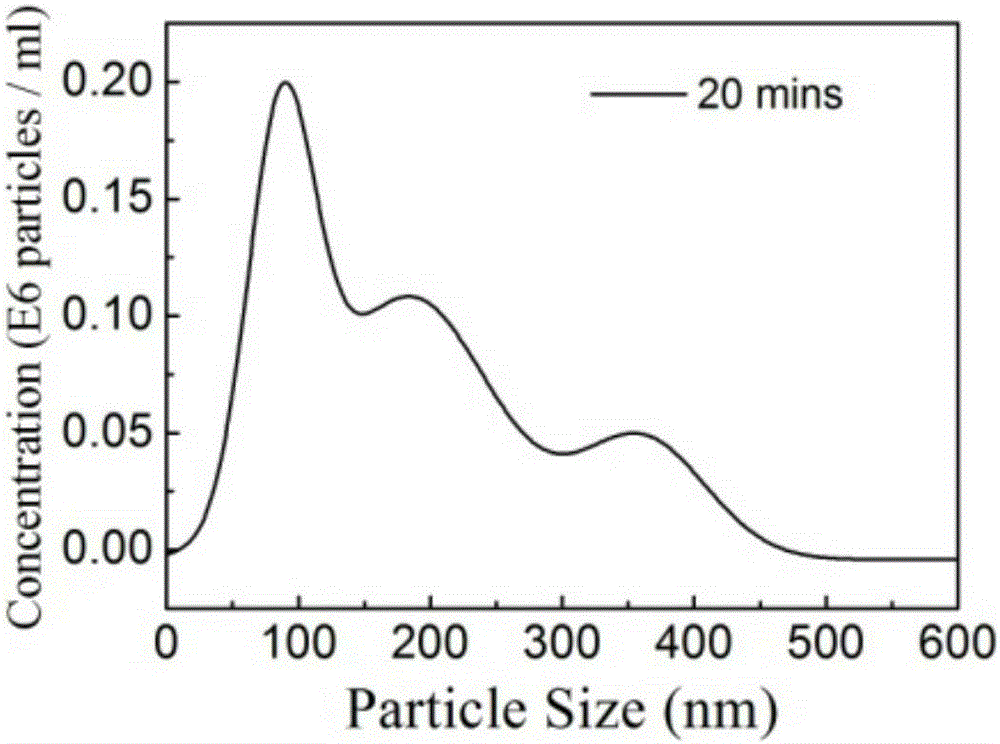

Technology for preparing nanometer ceramic particle material with industrial propane

The present invention relates to the field of new material technology, and a technique for prparing nm ceramic particle material by use of industrial propane. The present invention features the technological scheme of designing a combustion nozzle and controlling the particle for collecting temperature and pressure to prepare nanometer ceramic particle material with the flame gas phase deposition process. The present invention has simple technological process, producing nanometer ceramic particle material low cost in, high in product purity, with uniformly distributed grain sizes, high spherical degree, average grain size of 10-100 nm and controllable crystal form, etc. The nanometer ceramic particle material may find its wide application in catalyst, functional paint, functional fiber material, fine ceramic material, cosmetics, etc.

Owner:DALIAN UNIV OF TECH

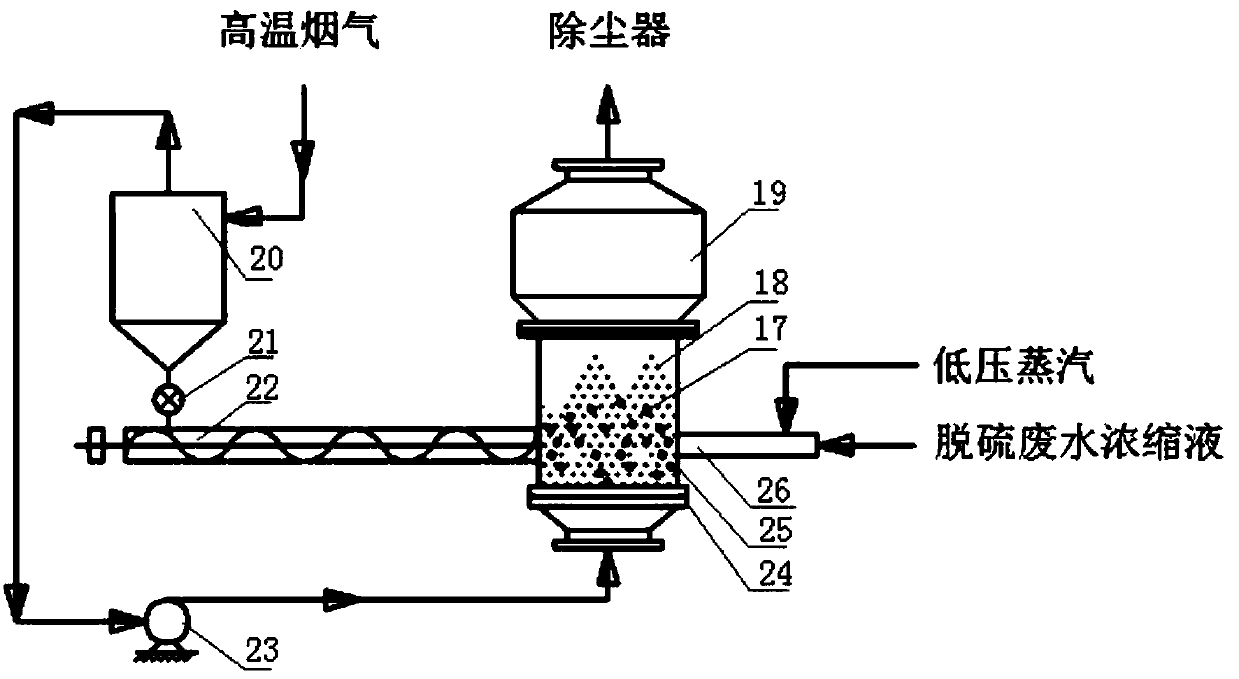

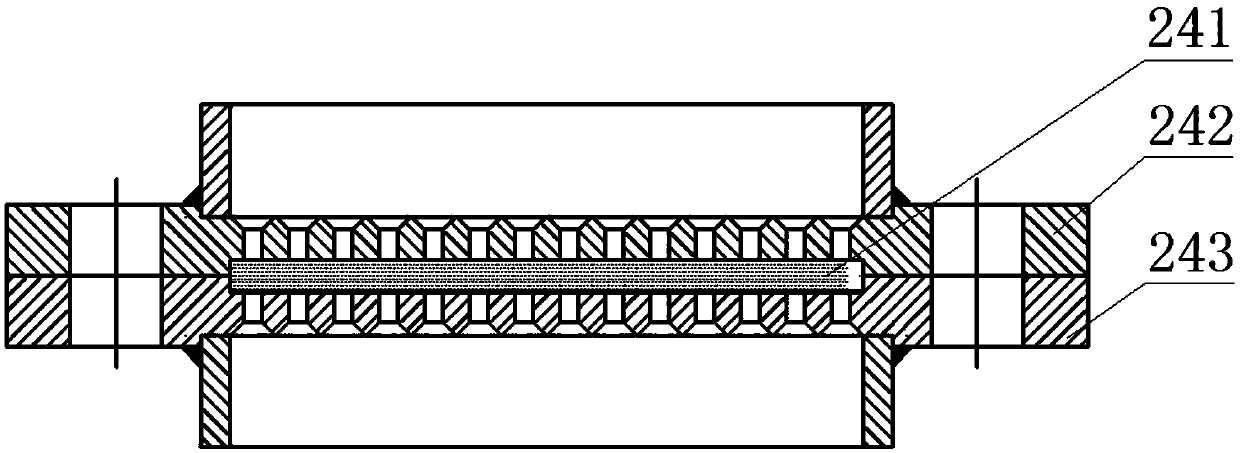

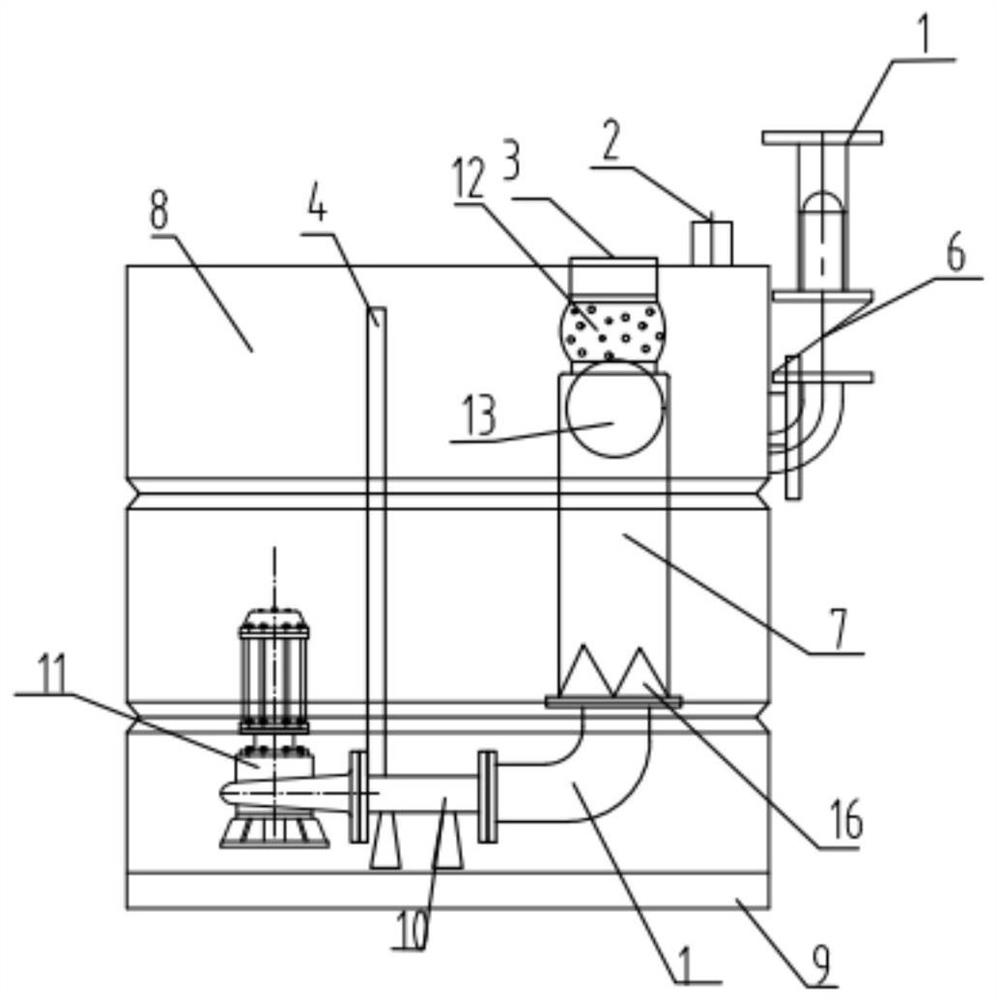

Low-temperature evaporation and concentration system for desulfurization wastewater

PendingCN107686141ANo foulingNot cloggedWaste water treatment from gaseous effluentsWater/sewage treatment by heatingWater circulationCryogenic system

The invention discloses a low-temperature evaporation and concentration system for desulfurization wastewater. The system comprises a wastewater heating system, a wastewater flash treatment system anda flash steam suction and compression system, wherein the desulfurization wastewater flows through the wastewater heating system to be heated and then enters a spray flash mechanism of the wastewaterflash treatment system to be flashed; a flash steam pipeline of the wastewater flash treatment system is connected with the flash steam suction and compression system; the flashed steam is compressedby the flash steam suction and compression system to raise the temperature, and serves as a heat source of the wastewater heating system to be connected to the wastewater heating system; a desulfurization wastewater circulating pipeline of the wastewater flash treatment system is connected with a flue spray evaporation system by virtue of a concentrated water output pipe. The desulfurization wastewater is heated and subjected to low-temperature flash reduction, the concentrated wastewater is sprayed into the flue to be evaporated, water vapor in the wastewater is discharged into atmosphere along with the flue gas, and saline materials in the wastewater are trapped by a dust remover, therefore, zero emission of the desulfurization wastewater is realized, the operating safety of an electricprecipitator is improved, and the flashed salt-free water is recycled.

Owner:UNI RISING BEIJING TECH CO LTD

Antifreezing fluid for vehicles

The invention discloses an antifreezing fluid for vehicles, which is prepared from the following raw materials in parts by weight: 11-19 parts of ethylene glycol, 1-5 parts of sodium phosphate, 2-6 parts of sodium chloride, 11-14 parts of sodium benzoate, 1-5 parts of potassium nitrate, 6-16 parts of phenol formaldehyde resin, 5-7 parts of borax, 3-6 parts of sodium molybdate, 4-7 parts of trialkylol amine phosphate, 1-5 parts of methyl tert-butyl ether, 2-8 parts of methyl benzotriazole, 5-9 parts of benzotriazole, 5-9 parts of glycine, 4-8 parts of hydroxypropyl methacrylate, 3-7 parts of methyl silicone oil and 20-40 parts of deionized water. The antifreezing fluid for vehicles has the advantages of reasonable formula, stable effect, high antifreezing property, high antirust property and high scaling resistance.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Explosion suppression material

The invention relates to an explosion suppression material. The explosion suppression material comprises the following chemical components in percentage by weight: 0.05-0.1% of Si, 0.03-0.035% of Cu, 1.0-1.1% of Mn, 1.0-1.1% of Mg, 0.2-0.3% of Cr, 0.05-0.08% of Ti, 0.08-0.12% of Fe, 0.08-0.1% of Zn and the balancing amount of Al. The explosion suppression material has an excellent corrosion-resistant property and is high ductility; in addition, the explosion suppression material is relatively high in strength and can completely meet the needs.

Owner:BEIJING PHOENIX TECH CO LTD

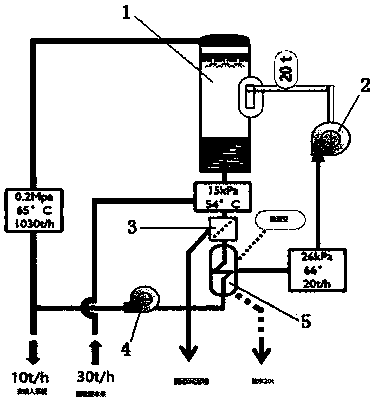

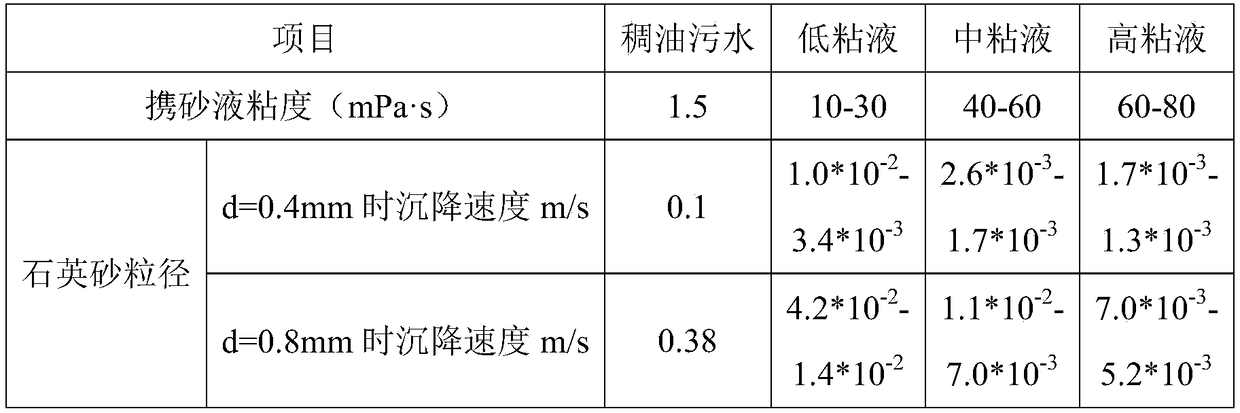

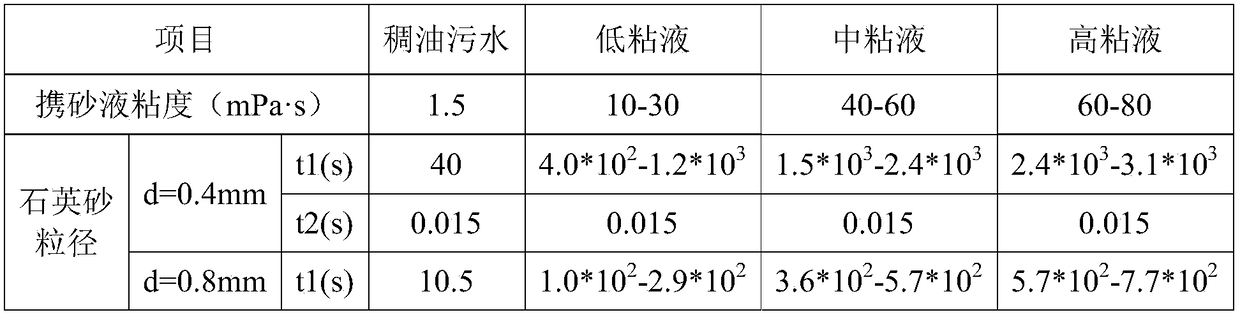

Oil deposit purification sewage sand-carrying filling sand prevention method and sand prevention pipe column

ActiveCN109236246ASuspendingReduce sedimentation velocityCleaning apparatusFluid removalChemical reactionEngineering

The invention relates to an oil deposit purification sewage sand-carrying filling sand prevention method and a sand prevention pipe column. The method comprises the following steps of 1, putting the sand prevention pipe column provided with a top packer in a predetermined position in a well, conducting packing, and opening a filling sand adding channel; 2, with oil deposit purification sewage withthe viscosity of 1.4-1.6 mPa.s as sand-carrying liquid, mixing the oil deposit purification sewage with quartz sand with the particle size of 0.4-0.8 mm according to the sand-carrying ratio of 3-15%,and afterwards, conducting positive squeezing and filling; 3, conducting releasing, and backwashing remaining sand in a pipe. According to the method, the oil deposit purification sewage with low viscosity serves as the sand-carrying liquid, the risks of sand blocking and sand burying are reduced, successful sand adding is ensured, and the construction requirement for low-sand-ration filling sandprevention is met. The sand-carrying liquid is the purified thickened oil sewage of an area where a construction well is located, has good compatibility with stratum liquid and stratum minerals, avoids the situation that chemical reactions are caused and sediments clog stratum pores, and is wide in source, cheap and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

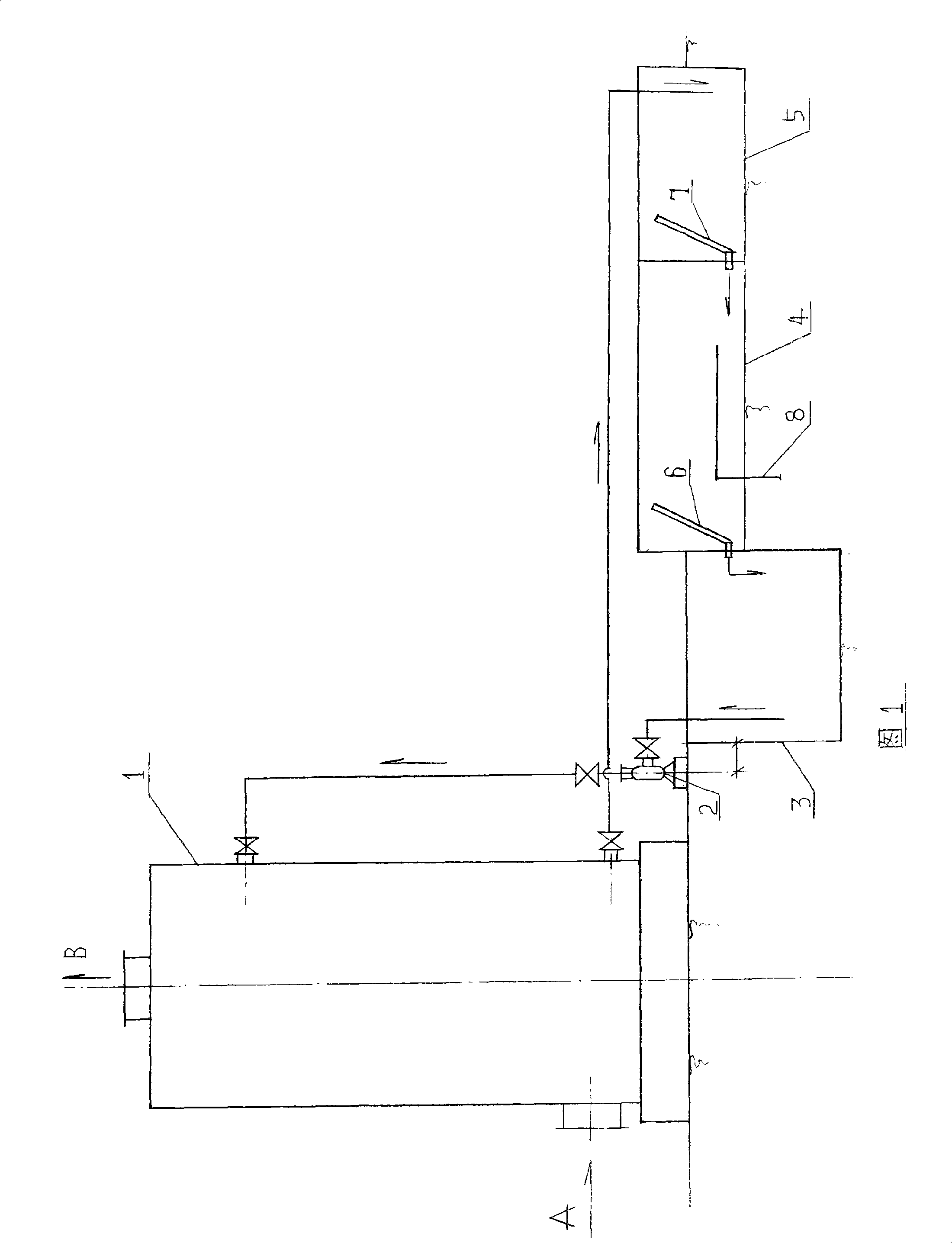

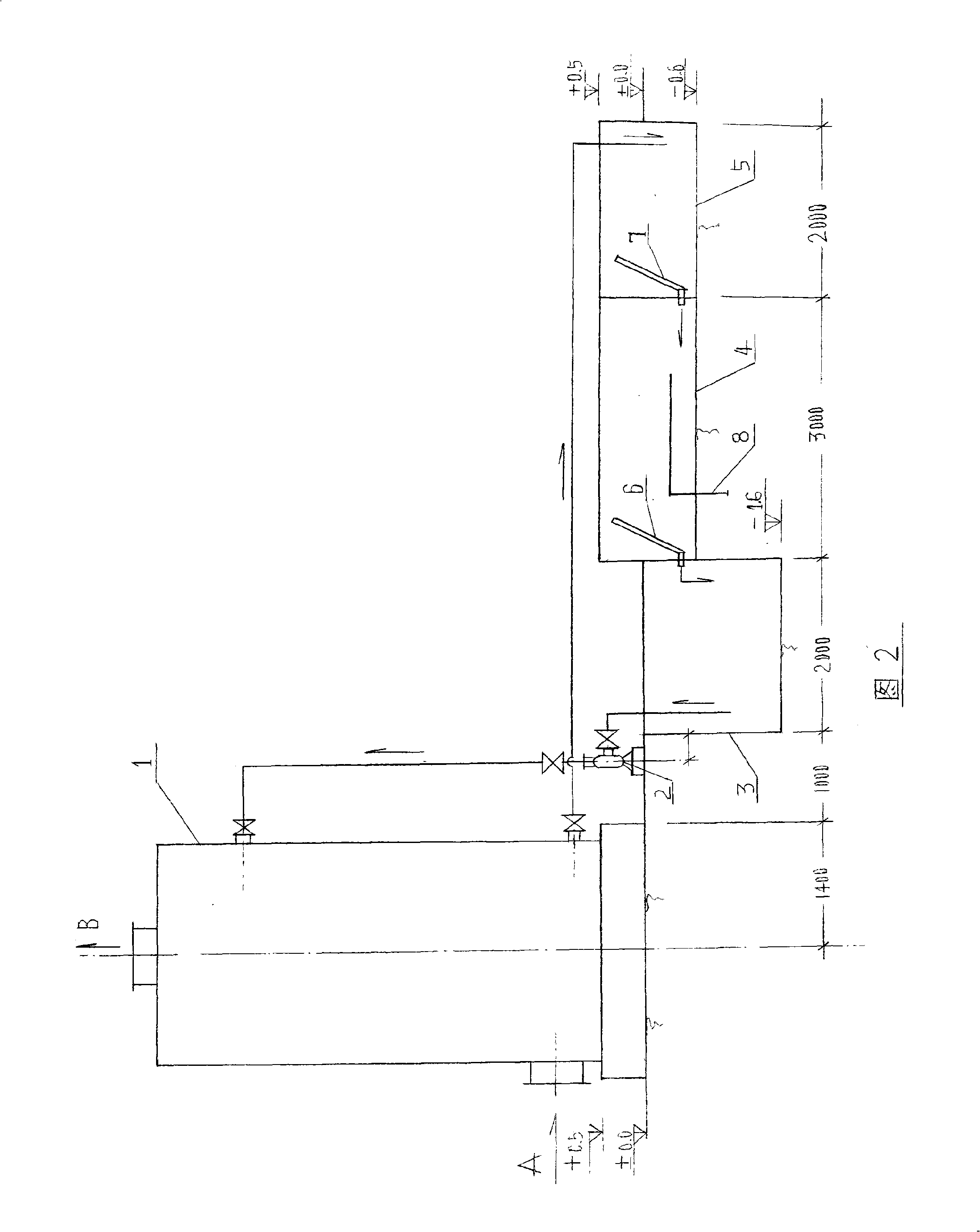

Device and method for treating tail gas by utilizing carbide slag slurry in acetylene production through indirect circulation method

ActiveCN110743351AGood rinse effectGood effect on waste gas treatmentDispersed particle separationSlagExhaust gas

The invention relates to a device and a method for treating tail gas by utilizing a carbide slag slurry in acetylene production through an indirect circulation method. According to the method, a carbide slag slurry is poured into a neutralization tank, and is conveyed into a clarification barrel by using a mortar pump; the carbide slag slurry is layered in the clarification barrel according to a sedimentation principle, wherein the solid part sinks to the bottom of the barrel, and the clear liquid rises to the top of the barrel and overflows into a clear water barrel; the slag slurry supernatant in the clear water barrel is conveyed to a leaching tower by using a leaching pump, and a leaching liquid is uniformly distributed in the leaching tower through spraying heads, and completely contacts, reacts with and absorbs acidic waste gas from a production device or waste gas capable of reacting with water to generate acidic substances; and the qualified tail gas after treatment is discharged to the atmosphere, and the neutralized leaching water enters a leaching tank, overflows into the neutralizing tank, and then is conveyed into the clarification barrel through the mortar pump so asto be recycled. The device of the invention is low in cost, convenient to control, remarkable in waste gas treatment effect and capable of continuously operating.

Owner:TANGSHAN SUNFAR SILICON IND

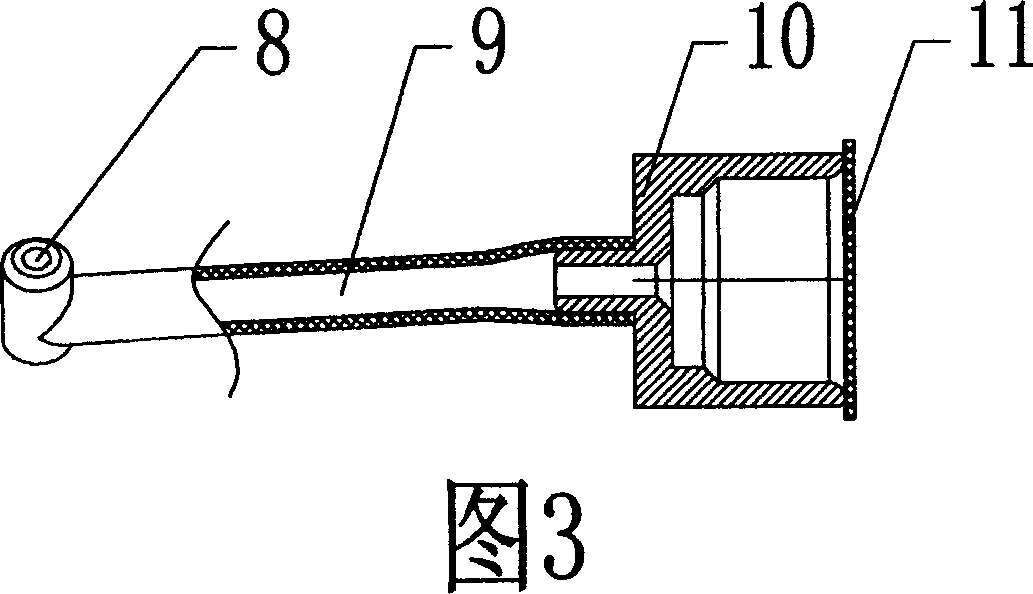

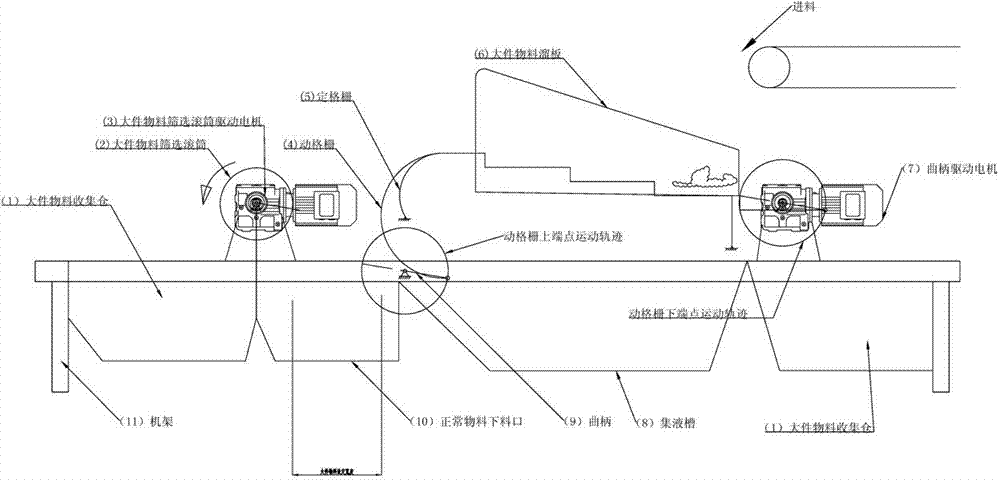

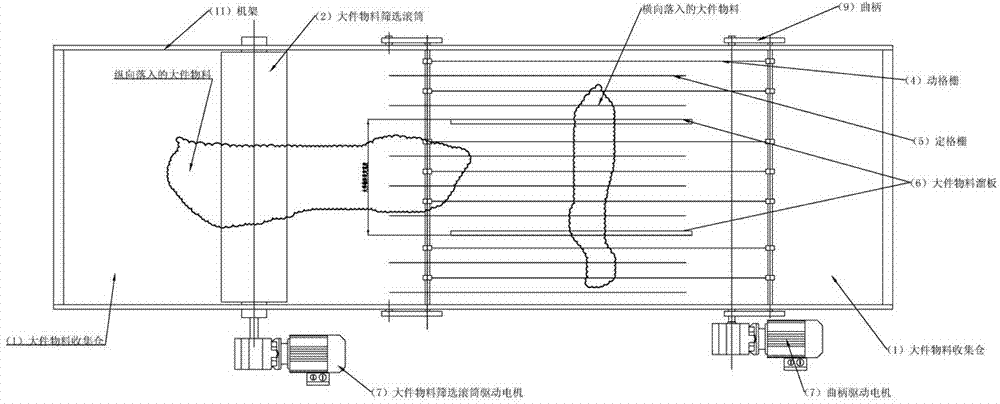

Selective garbage screening and feeding device and method

The invention relates to a selective garbage screening and feeding device and method. The selective garbage screening and feeding device comprises large-size material collection chambers (1), a large-size material screening roller (2), a large-size material screening roller driving motor (3), a movable grating (4), a fixed grating (5), a large-size material slide carriage (6), a crank driving motor (7), a liquid collection tank (8), a crank (9), a normal material discharging opening (10) and a rack (11). When being used for transporting mixed garbage, the selective garbage screening and feeding device with the method has the advantages of being capable of effectively removing large-size materials, being high in transportation capability, avoiding winding and blockage, resisting to abrasion, being capable of collecting filtrate and reducing humidity of the garbage, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

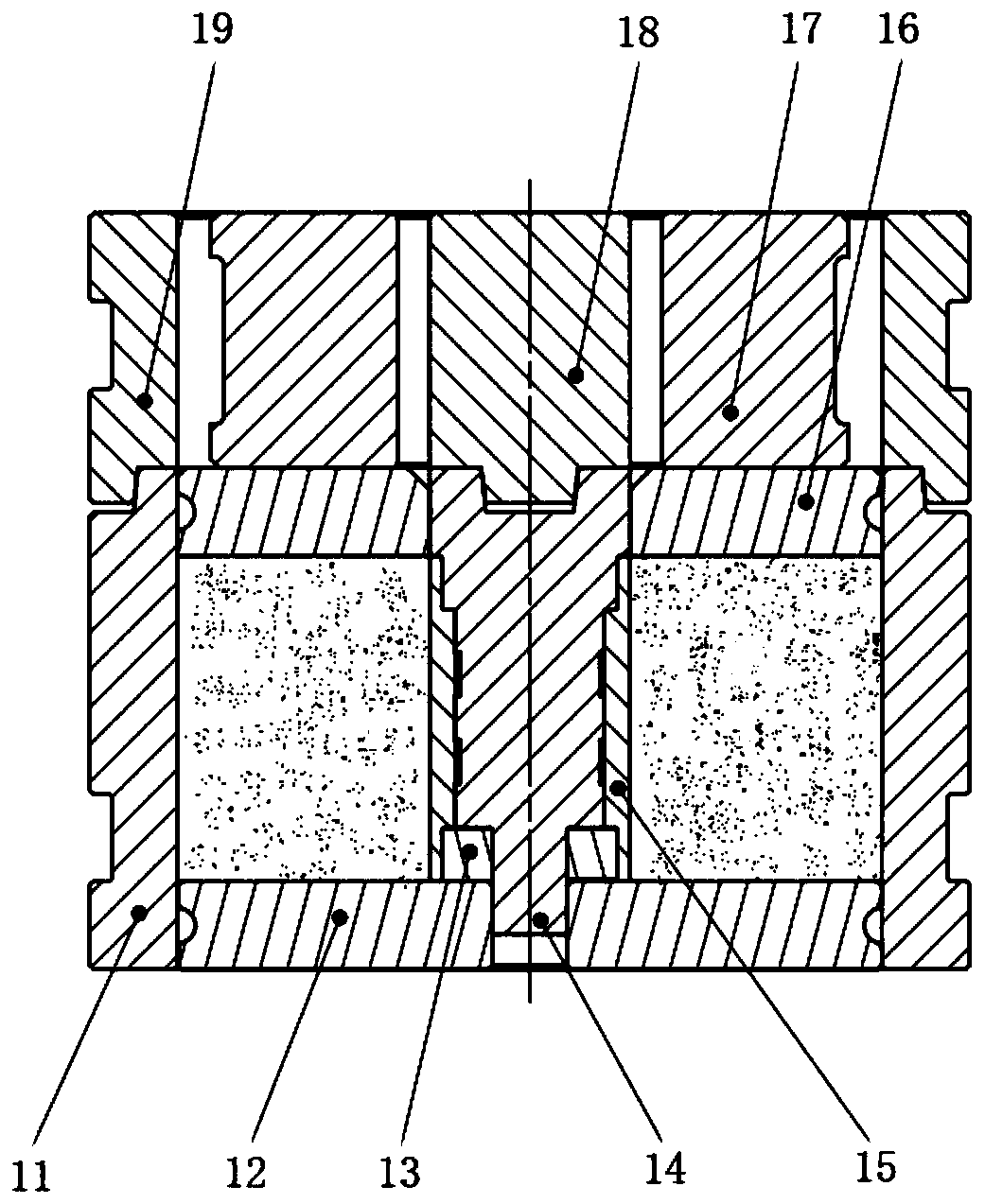

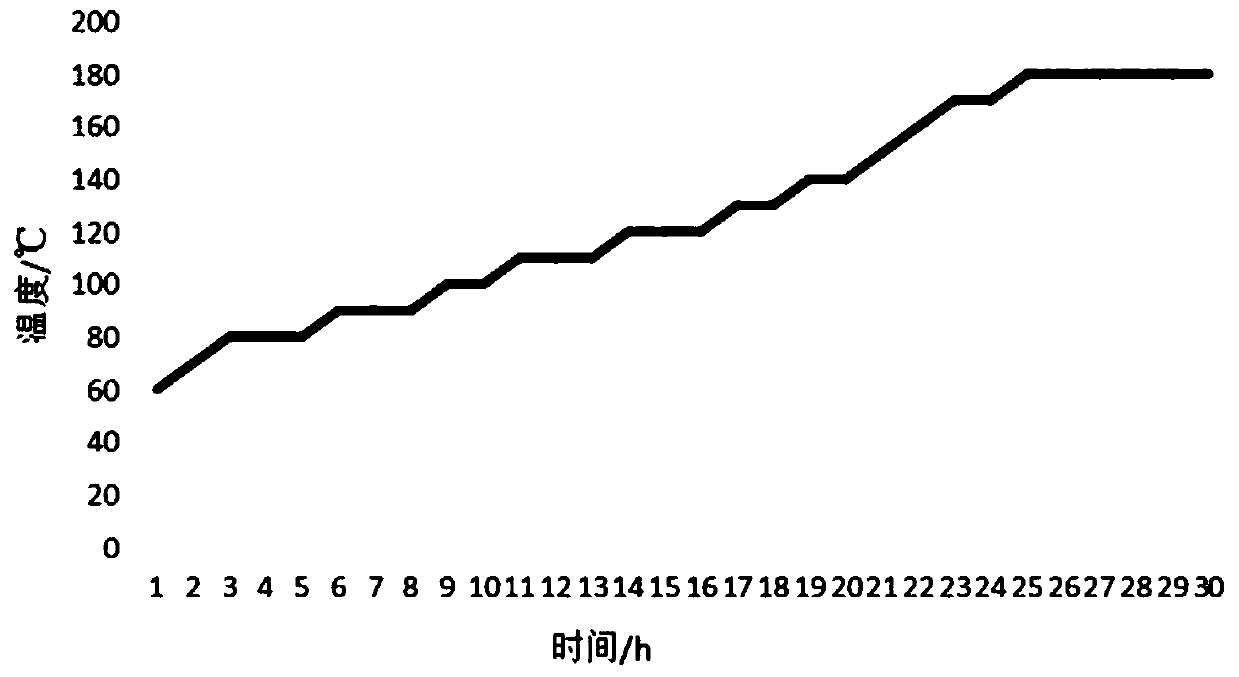

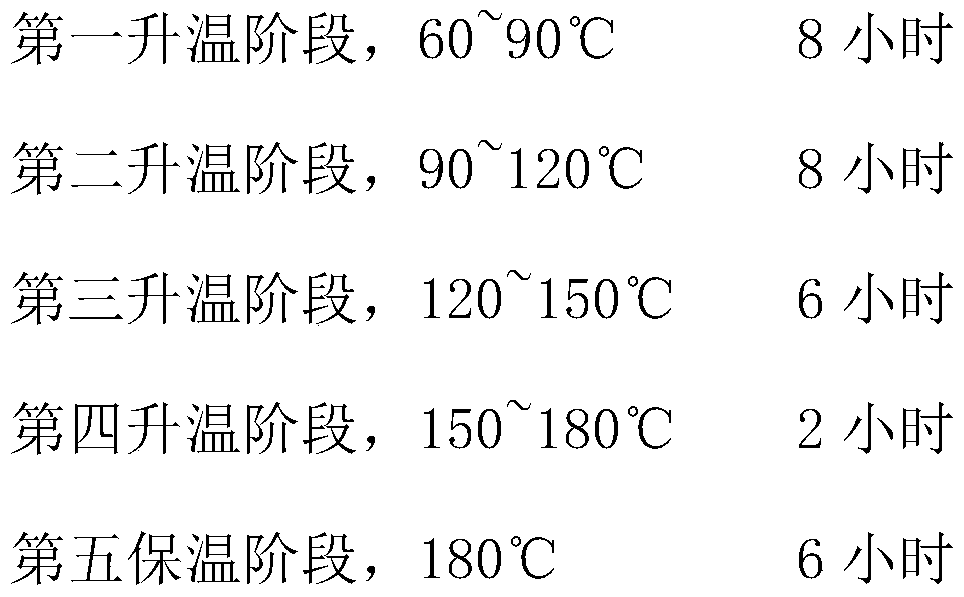

Forming process of special passive grinding wheel for high-speed grinding vehicle

ActiveCN110303439AGood self-sharpeningStrong grinding efficiencyGrinding devicesHigh-speed grindingPotassium

The invention discloses a forming process of a special passive grinding wheel for a high-speed grinding vehicle. The forming process comprises the following steps of preparing materials comprising components of, in parts by weight, 55-70 parts of combination grain size fused alumina zirconia, 5-10 parts of combination grain size brown fused alumina, 9-12 parts of mixed resin, 0.5-1 parts of silanecoupling agent, 1.5-8 parts of ferric sulfide, 1.5-5 parts of potassium cryolite, 1-3 parts of feldspar powder, 1-3 parts of barite, 1.5-3 parts of semi-hydrated gypsum powder and 2-4 parts of hollowglass beads; mixing materials; carrying out cold press molding; and hardening. Compared with the prior art, the preparation method has the positive effects that the materials are selected according to a specific formula design, cold press molding is carried out, a passive grinding wheel prepared by arranging a solidifying heating curve suitable for the cold press molding process has the advantages that the strength is high, the self-sharpening performance is high, the grinding efficiency is high, the grinding wheel is not blocked in the grinding process, the heat dissipation is rapid, a steelrail is not burnt, and the quality of the surface of the ground steel rail is good.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

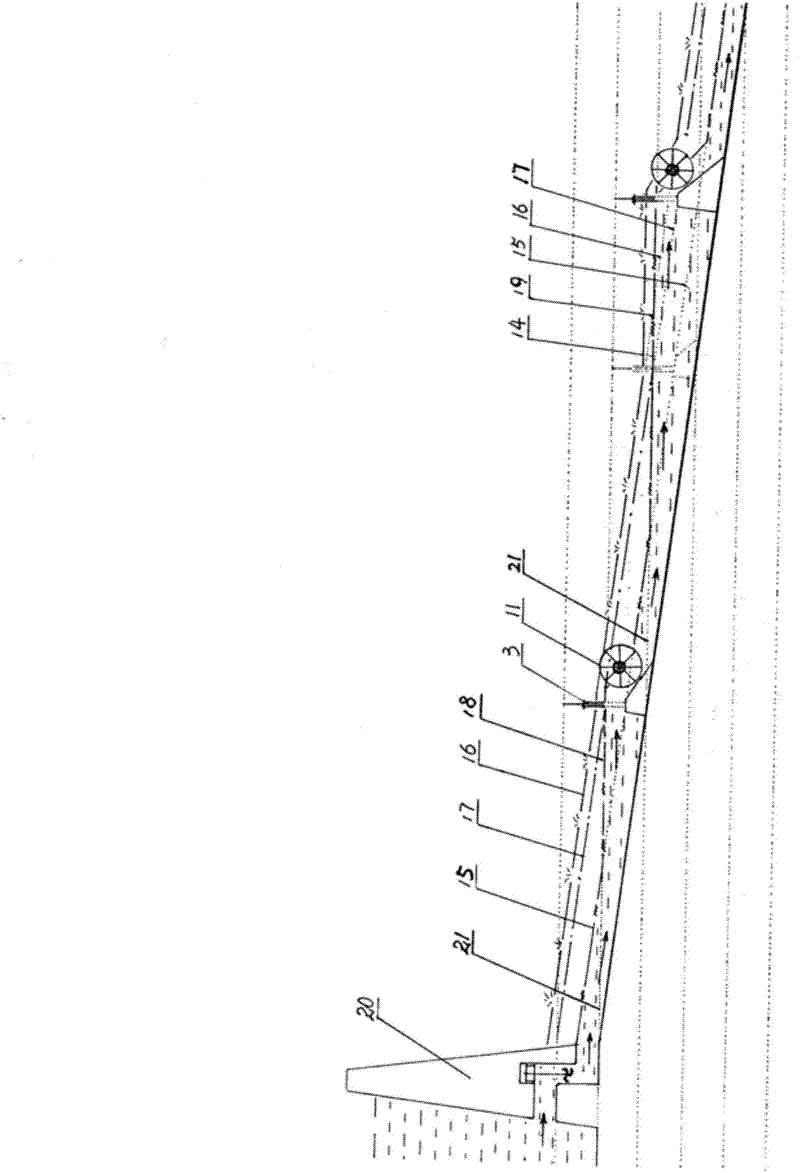

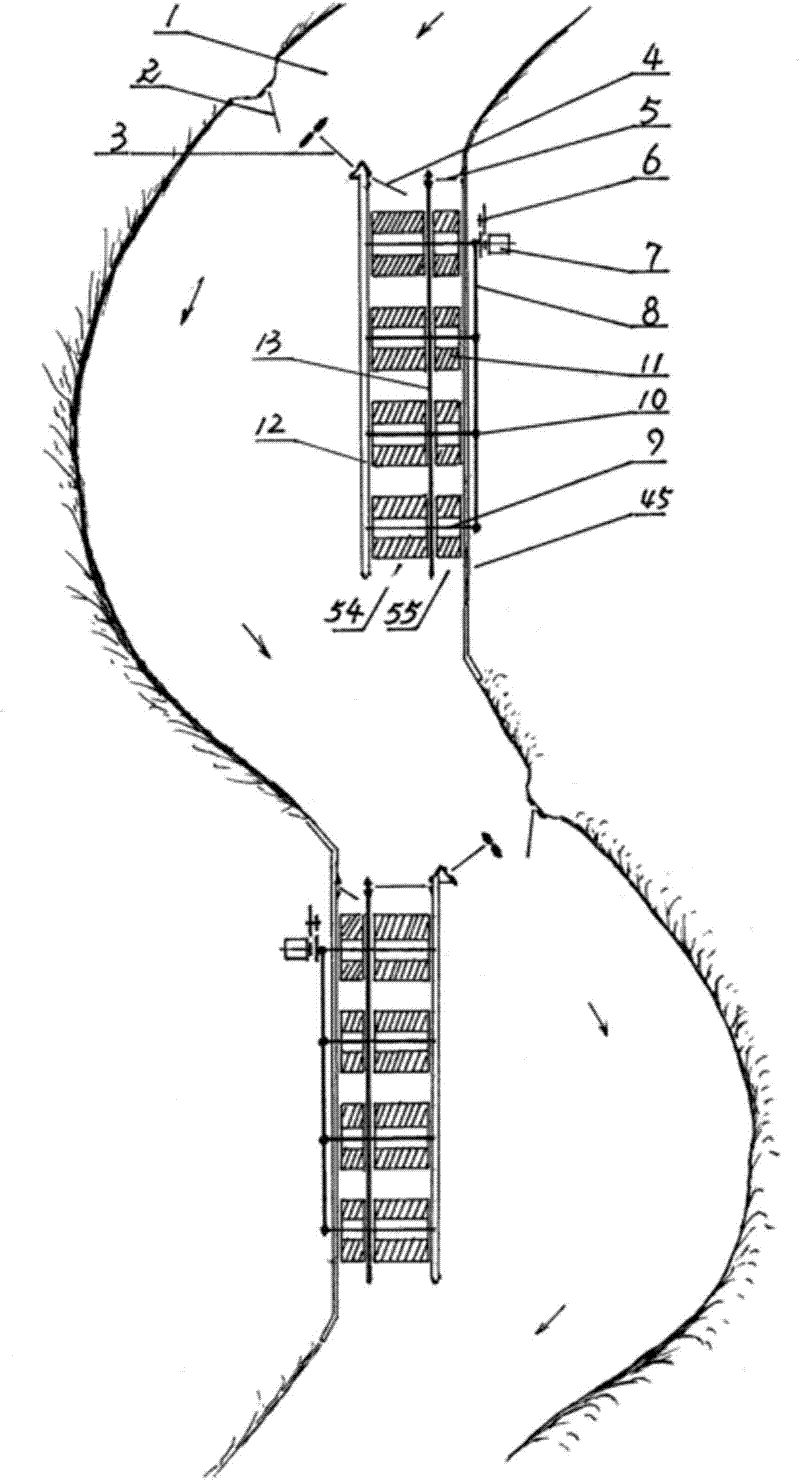

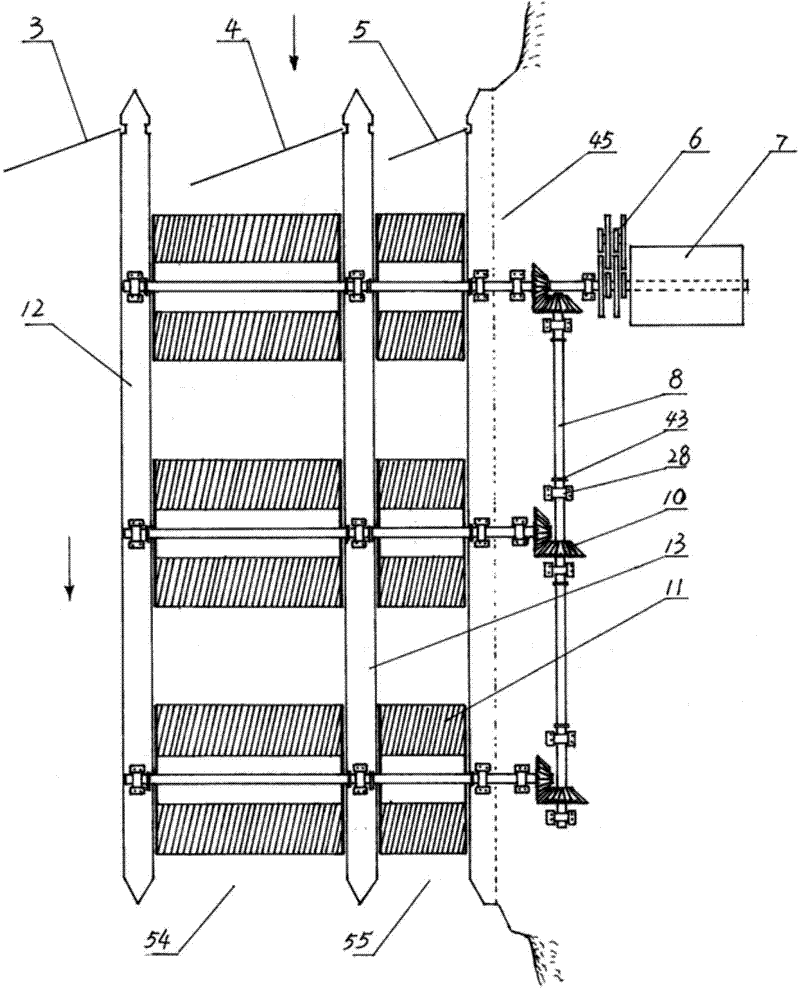

Method for densely building hydroelectric power station and hydroelectric power station capable of being densely built

ActiveCN102505670ATake advantage ofUse doubleWater-power plantsConventional hydroenergy generationPower stationRiver routing

The invention relates to a method for densely building hydroelectric power stations. The bottom line of a water outlet at a built or previous hydroelectric power station or a bottom line of a river bed as a starting line, the line is horizontally extended to a point at which a next section of a river channel and a flood-season water level line are intersected, and another hydroelectric power station can be built at the point. The hydroelectric power station capable of being densely built comprises water turbines, a generator set and a transmission mechanism which is connected with the water turbines and the generator set. The hydroelectric power station additionally comprises a first bypass gate, a second bypass gate, a first flushing gate, a second flushing gate, a first separation wall, a second separation wall, and a first flume and a second flume which are formed by the first separation wall and the second separation wall, wherein the first bypass gate, the second bypass gate, the first flushing gate and the second flushing gate are sequentially built at the upstream end in the inflow direction of a river, and the first separation wall and the second separation wall are built at the downstream ends of the first flushing gate and the second flushing gate. The water turbines are arranged in the first flume and the second flume. The transmission shafts of the transverse water turbines are mutually connected and then are connected with the transmission mechanism.

Owner:李建英

Electromagnetic heating device with water-cooling heat dissipation function

InactiveCN102997290ANoiseless cooling effectFast heat dissipationDomestic stoves or rangesCoil arrangementsWater circulationMagnet

The invention relates to an electromagnetic heating device with a water-cooling heat dissipation function. The electromagnetic heating device comprises magnet exciting coils, a drive circuit and a control circuit, wherein the magnet exciting coils are used for generating an alternating magnetic field and are matched with cookware made of ferromagnetic materials to form electromagnetic vortexes so as to heat the cookware made of the ferromagnetic materials; and the drive circuit and the control circuit are used for controlling and driving the magnet exciting coils to work. The electromagnetic heating device is characterized in that the magnet exciting coils are wound by a lead with a water-cooling sleeve to form an integral structure, the lead with the water-cooling sleeve is formed by a metal wire wrapped with an insulating layer or a paint insulating layer, a diversion pipe is externally sleeved outside the metal wire wrapped with an insulating layer or a paint insulating layer, and the diversion pipe is communicated with a water circulation cooling control system to form a water circulation loop. The electromagnetic heating device is capable of directly cooling the magnet exciting coils by virtue of water circulation, and has the advantages of good heat dissipation effect, no noise, safety and durability, and the like.

Owner:陈梓平

Noncorrosive compression-resisting explosion-suppressing material and preparation method thereof

InactiveCN102634704AImprove corrosion resistanceImprove extrusion resistanceElectrophoretic coatingsHoneycombRare earth

The invention belongs to a noncorrosive compression-resisting explosion-suppressing material and a preparation method thereof. The noncorrosive compression-resisting explosion-suppressing material comprises the following compositions: 0.03-0.08 parts of Si, 0.03-0.05 parts of Fe, 0.02-0.04 parts of Cu, 0.9-1.5 parts of Mn, 0.9-1.5 parts of Mg, 0.09-0.15 parts of Zn, 0.09-0.12 parts of Ce and the balance Al. A rare earth film layer is arranged on an outer layer of a prepared honeycomb netted explosion-suppressing material. The explosion-suppressing material provided by the invention has excellent corrosion resistance, extrusion resistance, collapse prevention, zero dreg-falling, and high-strength explosion-suppressing property. The performance indexes of the explosion-suppressing material,such as strength, plasticity, fracture toughness and fatigue resistance, are greatly increased according to the preparation method; the technology is simple and is easily performed; and the service life of the explosion-suppressing material is prolonged.

Owner:王季庄

An anti-clogging micro-bubble aeration device for sewage treatment

InactiveCN105293678BAvoid cloggingPass smoothlyTreatment using aerobic processesSustainable biological treatmentWaste treatmentOxygen

The invention relates to a blocking-proof micro-bubble aeration device, which is used for oxygen aeration of an aerobic treatment section in a sewage treatment process. The device is cylindrical, and comprises the structures of an inner barrel, an outer barrel, an air inlet pipe, an air nozzle, a water plate, a diffusing pipe and the like, wherein a crushing chamber and a snakelike waterway are formed between barrel walls of the inner barrel and the outer barrel, an air-water mixture enters the crushing chamber and the snakelike waterway via the diffusing pipe, and repetitive multi-time impact crushing and disturbing and dispersing are carried out, so that micro bubbles are generated. According to the device, the micro bubbles are not generated by extruding compressed air through micro holes in the surface of the aeration device (head), thus, the micro holes are not formed in the surface and interior of the device, and the problem of blocking is prevented from occurring.

Owner:崔杰

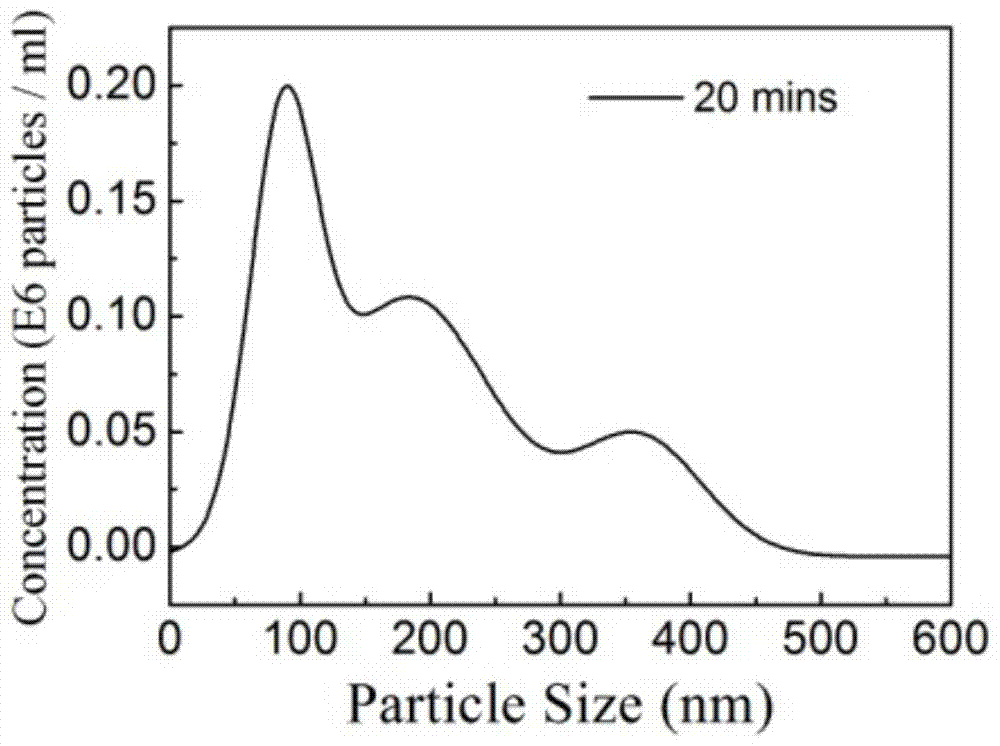

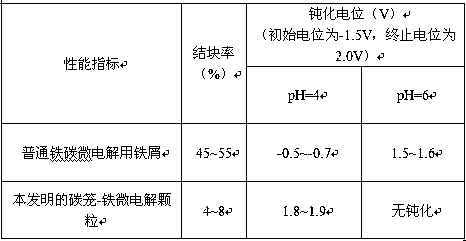

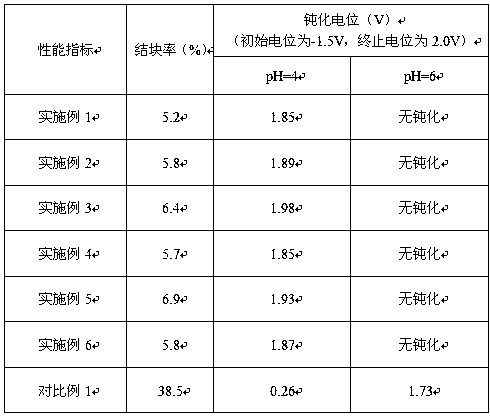

Carbon cage-iron microelectrolytic particles for acidic sewage treatment and preparation method

InactiveCN108191004AGood micro electrolytic performancePrevent compactionSpecific water treatment objectivesWater/sewage treatmentIron powderElectrolysis

The invention belongs to the technical field of sewage treatment and provides carbon cage-iron microelectrolytic particles for acidic sewage treatment and a preparation method. The method comprises steps as follows: an iron powder dispersion liquid is prepared for mist spray and condensation, iron powder agglomerated microspheres immobilized by stearic acid are prepared, then silica-chitosan composite gel is prepared, the microspheres are uniformly coated with the composite gel and then subjected to high-temperature carbonization, firm microporous cages are formed, iron powder is covered withthe cages, and the microelectrolytic particles with the iron powder covered with the carbon cages are obtained. Compared with a traditional method, the prepared carbon cage-iron microelectrolytic particles not only have good microelectrolysis performance, but also can effectively prevent the iron powder from hardening, the problem that an iron-carbon micro-electrolysis material is prone to hardening and passivating when applied to sewage treatment is solved thoroughly, the purposes of preventing scaling and blockage, realizing continuous operation and efficiently treating acidic sewage can beachieved effectively, meanwhile, the preparation process is simpler, the preparation cost is lower, and the carbon cage-iron microelectrolytic particles can be popularized for production and application.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

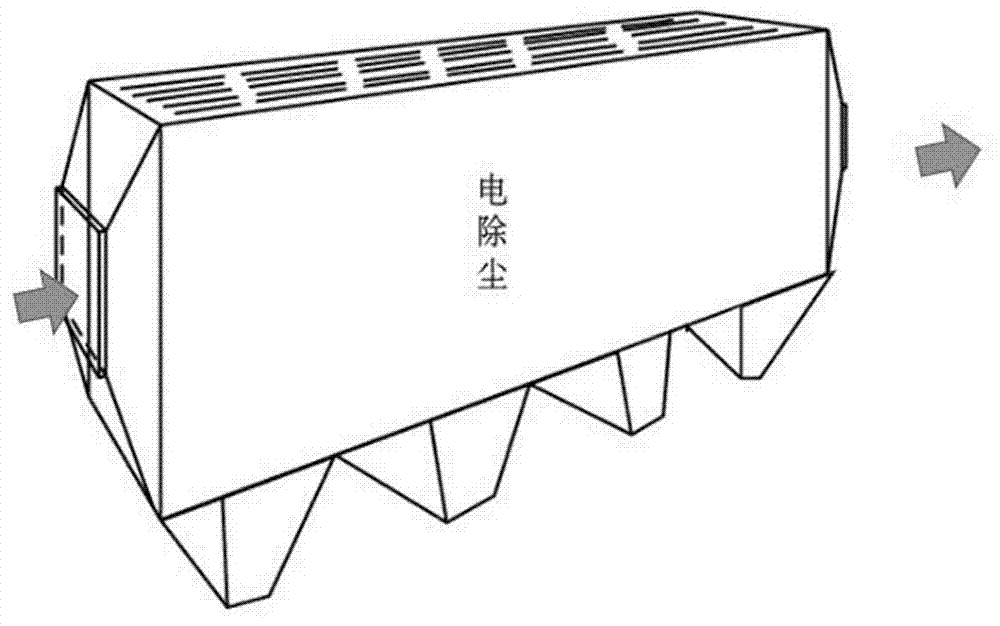

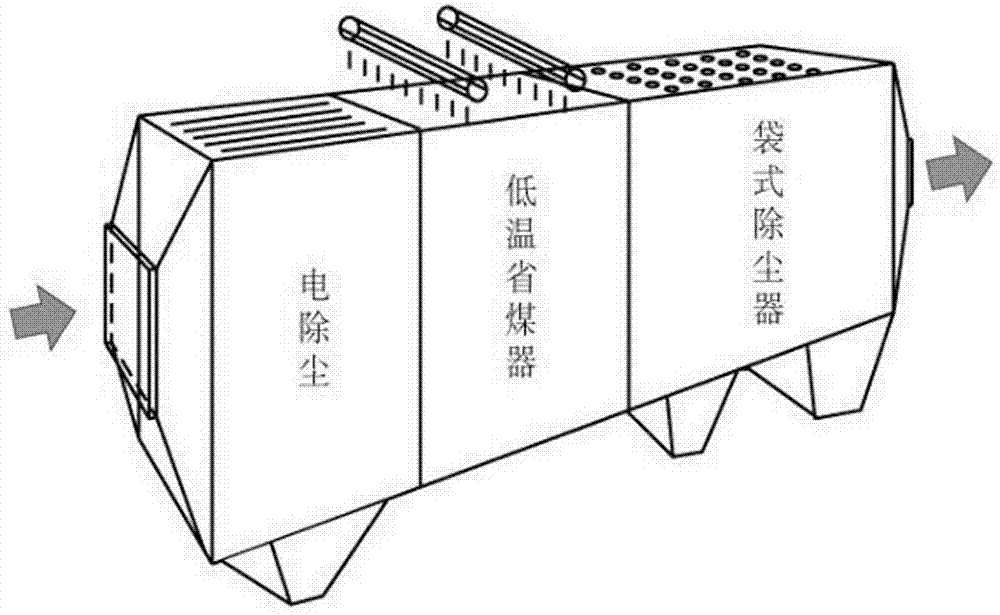

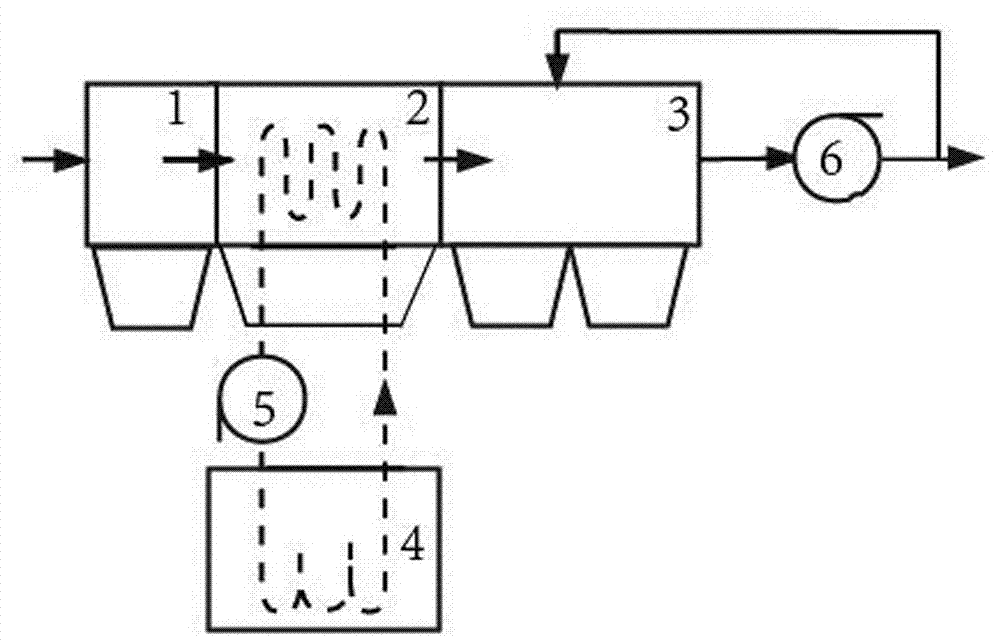

Energy-conservation, desulphurization and dust removal integrated electric-bag dust remover

The invention belongs to the technical field of pollutant purification and particularly relates to an energy-conservation, desulphurization and dust removal integrated electric-bag dust remover. The electric-bag dust remover is characterized in that an integrated electric dust remover is modified into the electric-bag integrated dust remover with an energy-conservation, desulphurization and dust removal technology and comprises an electric dust remover body, a low-temperature economizer, a bag dust remover body, an air heater and an induced draft fan, the electric dust remover body, the low-temperature economizer, the bag dust remover body and the induced draft fan are sequentially connected, the low-temperature economizer is connected with the air heater, the air heater is connected with the position of the entry of an air preheater, and the induced draft fan is connected with a desulfurizing tower. By the arrangement, flue gas temperature is reduced, the electric-bag dust remover is downsized, filtration wind speed is reduced, and dust removal efficiency of the bag dust remover body is favorably improved; through longitudinal isolation, 3-4 channels are longitudinally isolated respectively from the entry to the exit, leakage can be isolated if available, and preparation is ready for online isolation for online overhaul; the energy-conservation, desulphurization and dust removal integrated electric-bag dust remover is mainly applied to thermal flue gas treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

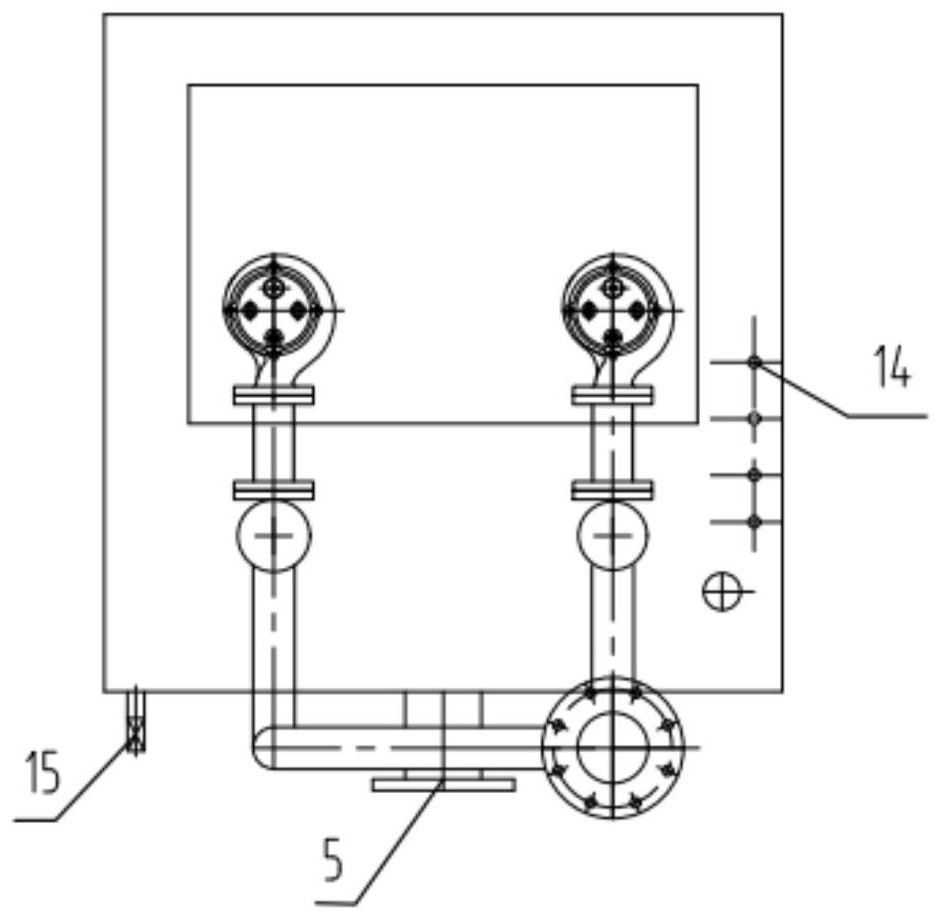

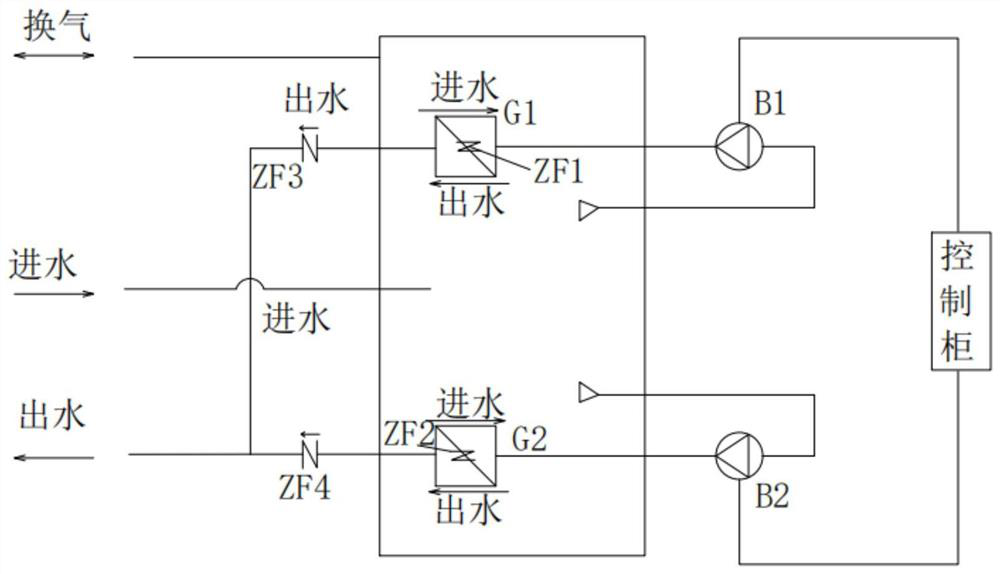

Backwashing sewage lifter and use method thereof

PendingCN112282035ASolve the problem of timely clearingExtended service lifeFatty/oily/floating substances removal devicesSewerage structuresOutfallCheck valve

The invention discloses a backwashing sewage lifter and a use method thereof. The backwashing sewage lifter comprises a closed water collecting tank and a control cabinet; at least two sewage liftingcircuits are arranged in the water collecting tank; each sewage lifting circuit comprises a terminal main pump and a lifting channel; one end of each lifting channel is connected with the output end of the main pump, and the other end of each lifting channel is communicated with a water inlet and a water outlet; water inlet check valves are arranged between the water inlets and the lifting channels, and water outlet check valves are arranged between the water outlets and the lifting channels; when the water level in the water collecting tank reaches the starting water level of one of the mainpumps, the control cabinet controls one of the main pumps to start to discharge water, back washing is carried out on the corresponding sewage discharge lifting circuit, water inflow is stopped or water inflow is carried out from the other sewage discharge lifting circuit; and when the water level is reduced to be lower than the starting water level of one main pump, the control cabinet controls one main pump to stop running. Compared with a traditional sewage pool and a lifting device, the backwashing sewage lifter has the beneficial effects of no blockage, no precipitation, no cleaning and no pollution, and the reduction of the occupied area.

Owner:上海双解泵业制造有限公司

Electric sprayer for castanea mollissima planting

InactiveCN107494504AImprove pollutionEasy to pull outRotary stirring mixersTransportation and packagingBiochemical engineeringSprayer

The invention discloses an electric sprayer for castanea mollissima planting. The electric sprayer comprises a tank body, wherein a stirring chamber is arranged inside the tank body; a placing box is arranged at the upper end of the tank body; a rotating motor is arranged in the placing box; a water inlet is also formed in the upper end of the tank body; a rubber piston is inserted into the water inlet; a rotating rod is connected to the driving end of the rotating motor; one end, away from the rotating motor, of the rotating rod, penetrates through the side wall of the tank body and is symmetrically connected with two extension rods; connecting rods are separately and fixedly connected to the lower ends of the two extension rods; a plurality of stirring blades are arranged on two sides of the two connecting rods. According to the electric sprayer for the castanea mollissima planting, disclosed by the invention, by arrangement of drawers for placing insecticide or fertilizer and remained garbage bags or bottles, centralized treatment of rubbish is favorably realized and the pollution to environment is avoided; in addition, water, the insecticide and the fertilizer are mixed more sufficiently by stirring, and the condition that insecticidal or fertilizing effect is affected due to non-uniform mixing is avoided; besides, the electric sprayer is driven by electric power and has the advantages of high working efficiency, simple structure as well as convenience and practicality.

Owner:长兴丰收园茶叶专业合作社

Sealing method and device for anode rod of aluminum cell

The invention provides a method for sealing aluminium cell anode rods. The method is characterized in that a device capable of producing negative pressure is installed around each rod; and the flue gas originally overflowing through the clearance between the rods and a housing plate is reversely absorbed into a flue of an aluminum cell. The invention also correspondingly provides an anode rod sealing device specially designed for executing the method. The sealing device comprises side plates, a front end plate and a top plate and is characterized in that the sealing device consists of two side plates, the top plate and the front end plate and is a cavity device surrounding the anode rods from three faces; wherein (1) a grid structure is adopted on the front end of the device enclosing the anode rods from three faces; (2) the tail part of the device is welded with a plate-web girder and is communicated with a horizontal flue; and (3) the device is arranged on a horizontal housing plate and takes the horizontal housing plate as the bottom plate of the device. The sealing device can greatly reduce the leaked flue gas, thereby improving the working environment of an electrolysis shop, and creating good social and economic benefits.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com