Ink cartridge having filtering means

A filter and ink cartridge technology, applied in printing and other directions, can solve problems such as poor ink supply, clogged recording head, loss of function, etc., and achieve the effect of preventing leakage, volatilization and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

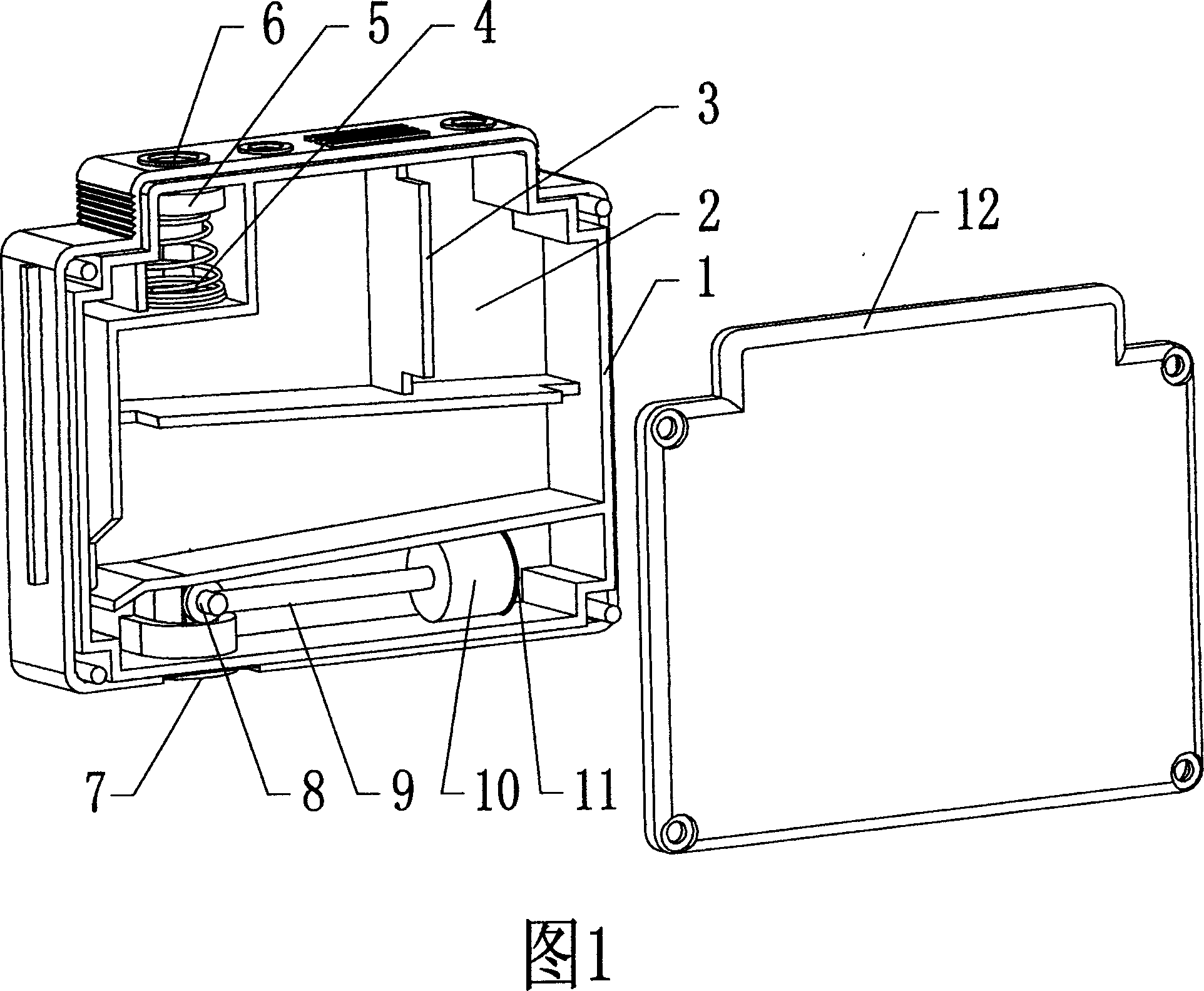

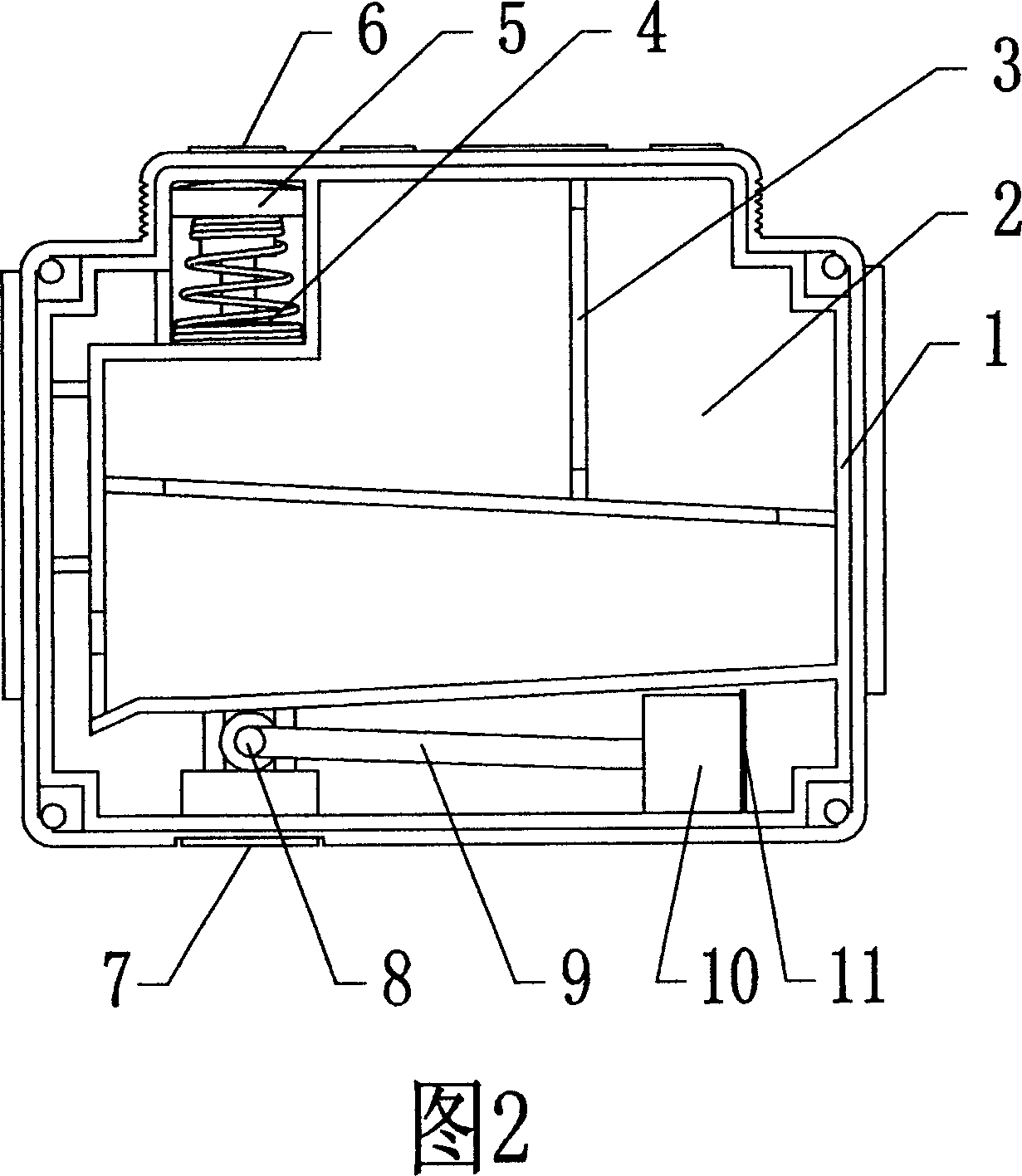

[0015] In the following, the details of the invention will be discussed based on the embodiments shown in the drawings.

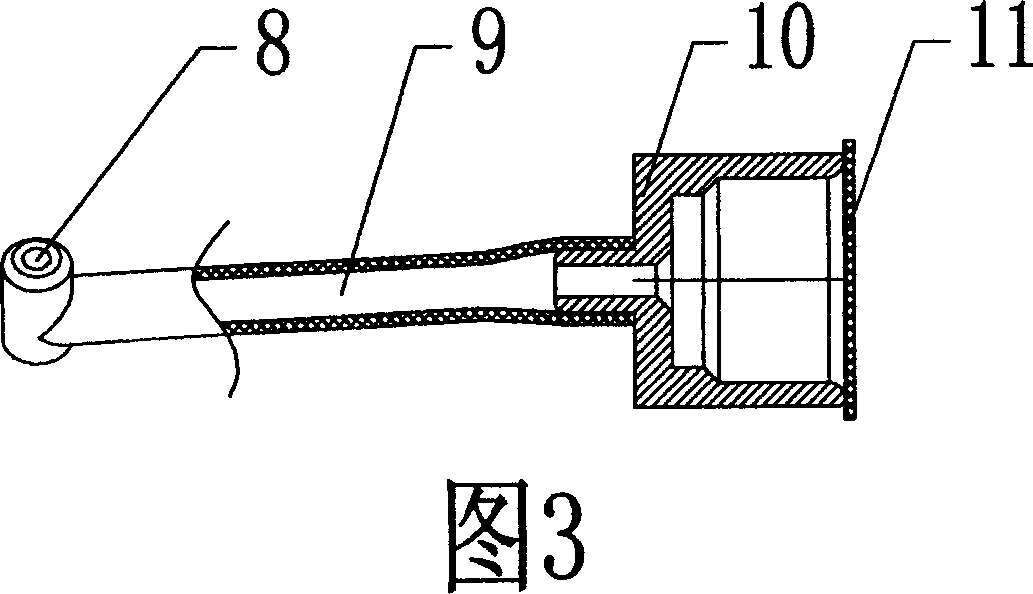

[0016] Referring to accompanying drawing 1-3, the ink cartridge of the present invention comprises a housing 1; An ink storage chamber 2; Partition plate 3 divides the ink storage chamber 2 into several parts that communicate with each other, effectively eliminates the problem caused by the ink cartridge moving back and forth with the inkjet printer character carriage. And make the ink in the ink storage cavity vibrate and produce the air bubble; One is placed on the air vent 6 of the band control valve body that is communicated with the atmosphere at the top of the ink storage cavity; Communication or isolation with the atmosphere; a filter 10 located at the bottom of the ink storage chamber 2, its inlet is equipped with a microporous filter member 11 with a pore size less than 1 micron, which can be used to prevent ink from leaking and block impurities in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com