An anti-clogging micro-bubble aeration device for sewage treatment

A technology of aeration device and sewage treatment, applied in aerobic process treatment, sustainable biological treatment and other directions, can solve the problem of not needing large-scale technical renovation and construction of aeration device, etc., to reduce operating costs, save costs and time, The effect of reducing electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

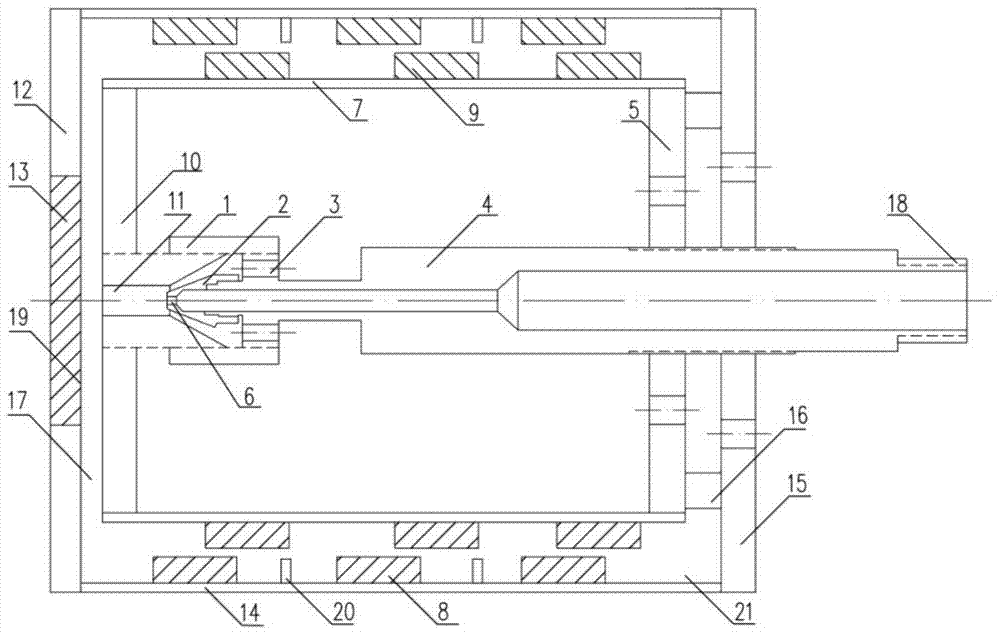

[0033]The invention has a cylindrical shape and is composed of an air inlet pipe, an inner cylinder, an outer cylinder, an air nozzle, a water pan, a diffusion pipe, a crushing chamber, a dispersion disk, a sawtooth retaining ring, a concave retaining ring, a disturbing rod and other components. The device is installed at the bottom of the aeration tank of the sewage plant to replace the existing microporous aeration device (head).

[0034] The air intake pipe 4 is connected to the existing aeration system air pipe of the sewage plant through the joint 18. The pressurized air in the air pipe enters the air intake pipe 4 and is sprayed out through the air nozzle 2 to generate high-speed rotation and be magnetized by the magnet 6. The air The polarity is more stable. The water in the aeration tank enters the inner cylinder 7 of the device through the opening on the bottom 5 of the inner cylinder and the lower cover 15 of the outer cylinder. The water pressure in the inner cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com