Sealing method and device for anode rod of aluminum cell

A technology for anode guide rods and sealing devices, which is applied in the field of aluminum electrolytic cell anodes, and can solve problems such as difficult to obtain sealing effects, inconspicuous effects, high temperature deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

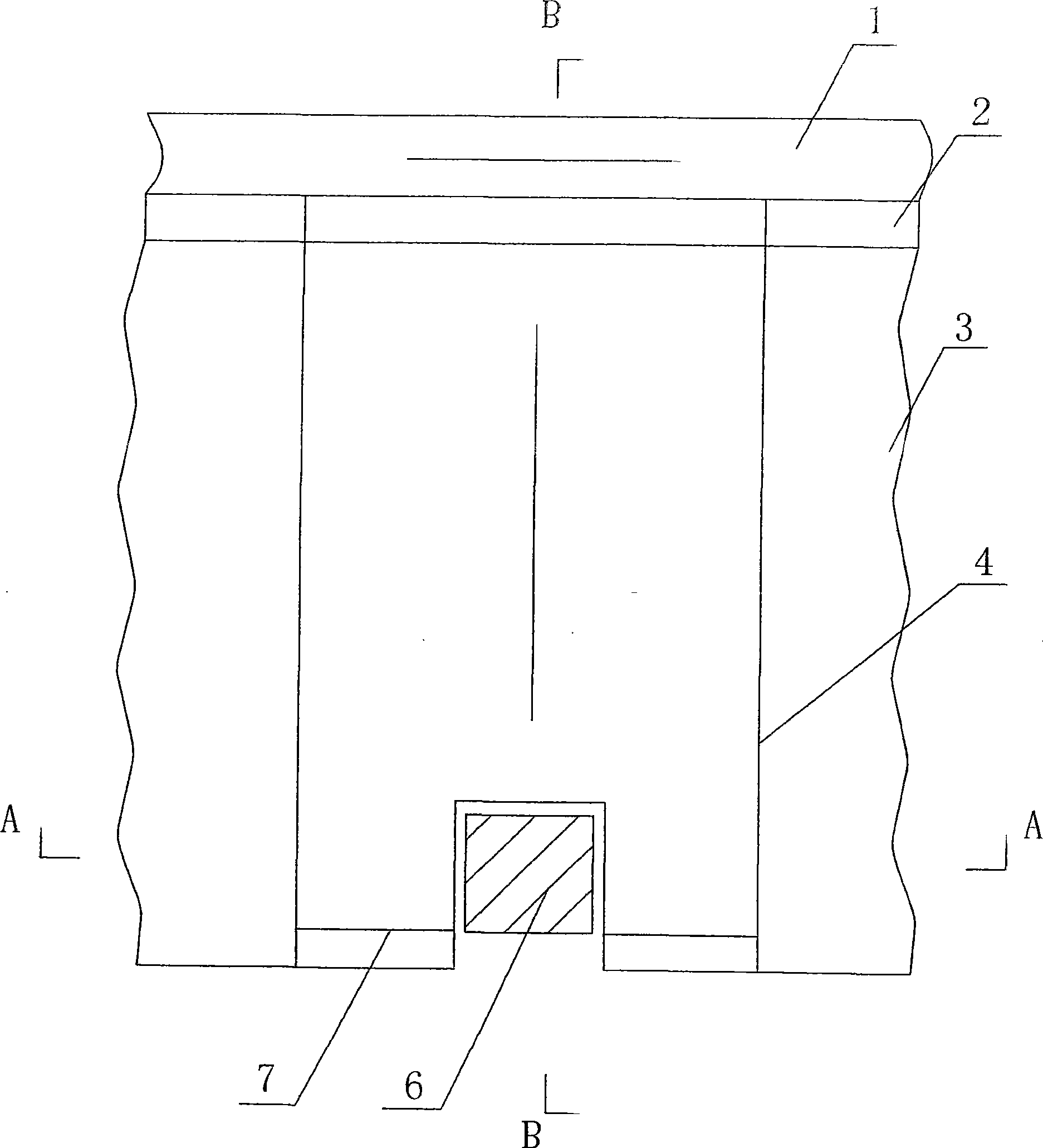

[0024] Example 1 Sealing device with front and rear equal width structures

[0025] The sealing device adopts a structure with equal width at the front and back, such as figure 1 , Figure 4 , 5 shown. The width (L=W) of the sealing device is 200 mm; the height (H) of the leading edge is 100 mm; the inclination angle (D) of the top plate is 0 degrees.

Embodiment 2

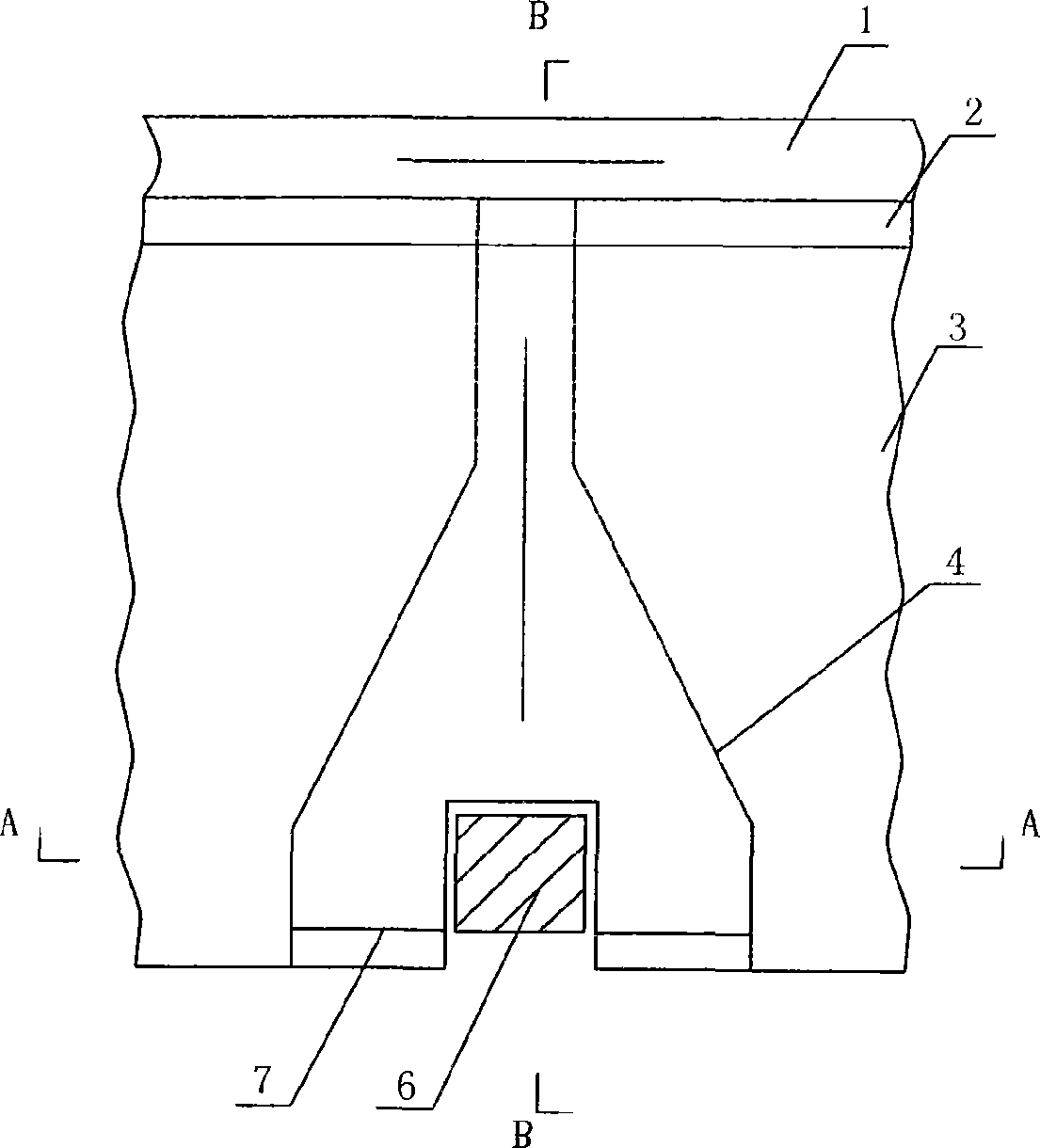

[0026] Example 2 Sealing device with wide front and narrow rear structure

[0027] The sealing device adopts a structure with a wide front and a narrow back, such as figure 2 As shown, in the top view projection, from front to back, the former seems to be composed of a horizontal rectangle with a hollowed out square, an isosceles trapezoid and a vertical rectangle. The frontal width (L) of the sealing device is 500 mm; the frontal height (H) is 80 mm; the width (W) of the sealing device corresponding to the passage of the horizontal flue interface part is 80 mm; the inclination angle (D) of the top plate is 5°.

Embodiment 3

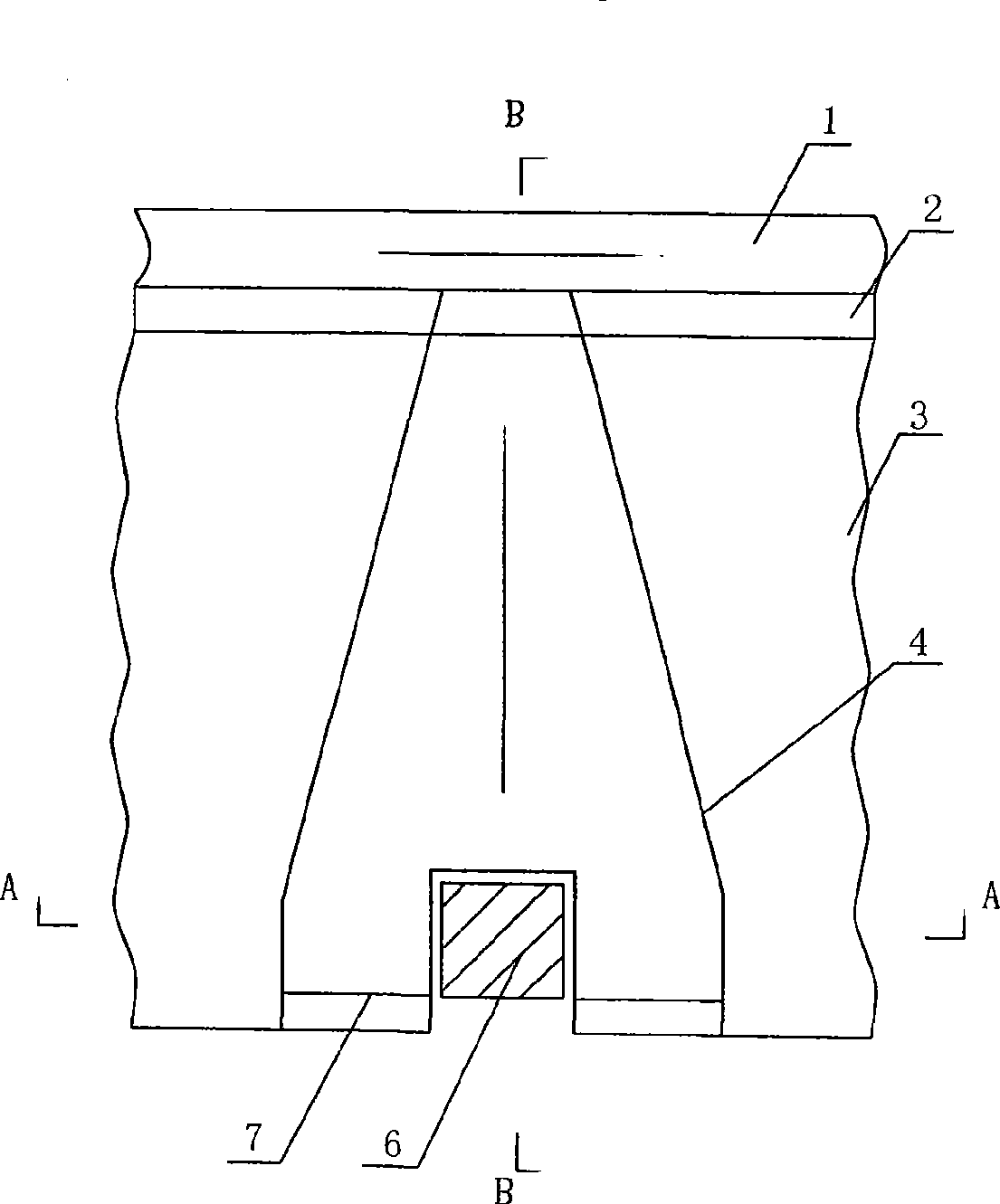

[0028] Example 3 Sealing device with wide front and narrow rear, inclined roof structure

[0029] The sealing device adopts a structure with a wide front and a narrow rear, and an inclined top plate, such as image 3 , as shown in Figure 7, its top view image is composed of a horizontal rectangle with a hollowed out square and a slender isosceles trapezoid; from the side view, its top plate has an upward sloping angle from front to back . The frontal width (L) of the sealing device is 350 mm; the frontal height (H) is 50 mm; the width (W) of the sealing device corresponding to the passage of the horizontal flue interface part is 50 mm; the inclination angle (D) of the top plate is 20°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com