Carbon cage-iron microelectrolytic particles for acidic sewage treatment and preparation method

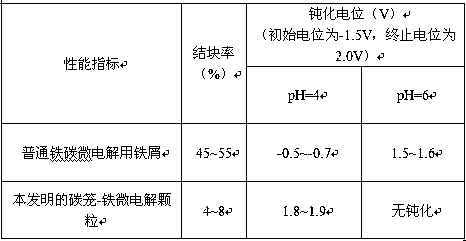

A technology of acidic sewage and micro-electrolysis, applied in water/sewage treatment, water/sludge/sewage treatment, special treatment targets, etc. Solve the effects of easy hardening and passivation, good micro-electrolysis performance and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Heat 36kg of carbonyl iron powder, 1kg of stearic acid and 63kg of glyceryl tristearate to 85°C, stir and mix for 18 minutes to form an iron powder dispersion, then spray and condense to form an average particle size fixed by stearic acid. 300μm iron powder agglomerated microspheres; add 10kg of nano-silica powder, 35kg of chitosan, and 1kg of glutaraldehyde into 54kg of deionized water, and stir at 68°C for 50 minutes to obtain a silica-chitosan composite gel; Finally, add 40kg of iron powder agglomerated microspheres into 60kg of silica-chitosan composite gel, so that the surface of the microspheres is uniformly coated with the composite gel, and then heated to 500°C in a high-temperature furnace for carbonization for 75 minutes to form a firm microporous cage , the iron powder is networked in the cage, and the micro-electrolytic particles of the iron powder networked by the carbon cage are prepared.

[0033] testing method:

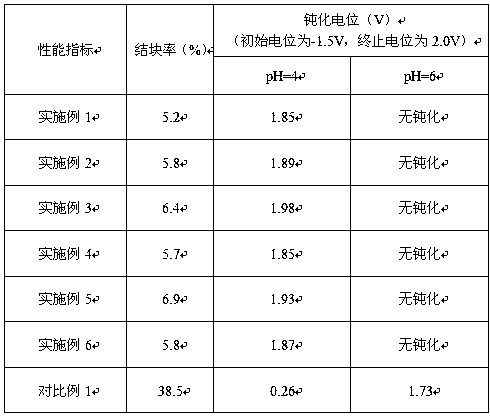

[0034] After sieving the prepared electr...

Embodiment 2

[0037]Heat 32kg of carbonyl iron powder, 1kg of stearic acid and 67kg of vinyl bisstearamide to 80°C, stir and mix for 20 minutes to form an iron powder dispersion, then spray and condense to form an average particle size fixed by stearic acid. 200μm iron powder agglomerated microspheres; 8kg nano-silica powder, 30kg chitosan, and 1kg formaldehyde were added to 61kg deionized water, and stirred at 60°C for 60min to obtain a silica-chitosan composite gel; finally Add 35kg of iron powder agglomerated microspheres to 65kg of silica-chitosan composite gel, so that the surface of the microspheres is uniformly coated with the composite gel, and then heated to 400°C in a high-temperature furnace for 90 minutes of carbonization to form a firm microporous cage. The powder is networked in the cage to make micro-electrolytic particles of iron powder networked by carbon cages.

[0038] The test method is consistent with Example 1, and the obtained data are shown in Table 2.

Embodiment 3

[0040] Heat 40kg of carbonyl iron powder, 2kg of stearic acid and 58kg of stearic acid monoglyceride to 90°C, stir and mix for 15 minutes to form an iron powder dispersion, then spray and condense to form an average particle size fixed by stearic acid. 400μm iron powder agglomerated microspheres; add 12kg nano-silica powder, 40kg chitosan, 2kg methylenebisacrylamide into 46kg deionized water, stir at 75°C for 40min to prepare silica-chitosan composite Gel; finally, add 45kg of iron powder agglomerated microspheres into 55kg of silica-chitosan composite gel, so that the surface of the microspheres is evenly covered with the composite gel, and then heated to 600°C in a high-temperature furnace to carbonize for 60 minutes to form a firm gel. Microporous cage, iron powder is networked in the cage, and micro-electrolytic particles made of iron powder networked by carbon cage.

[0041] The test method is consistent with Example 1, and the obtained data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com