Method for producing acid soil modifier by using agricultural waste

A technology for agricultural waste and acidic soil, applied in the field of producing acidic soil conditioner, can solve the problems of easy calcification of effective nutrients, damage to soil aggregate structure, adverse effects on soil, etc., and achieves low product cost, improved soil aggregate structure, and improved Effects of soil conditions and microflora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

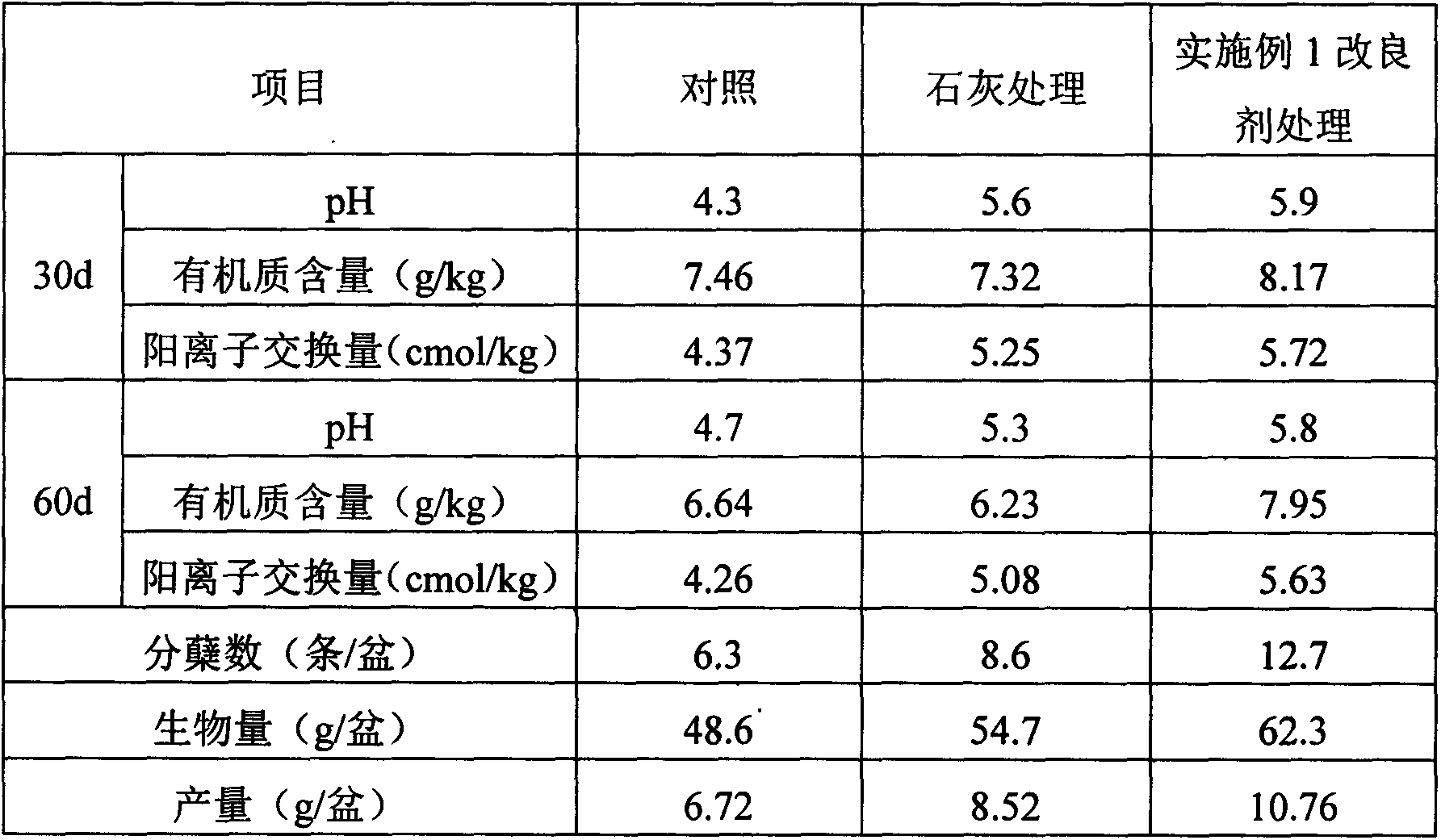

Embodiment 1

[0016] Crush the rice straw into a powder with a diameter of less than 2mm, heat 60% of it to 300°C under air-isolated conditions for 4 hours to obtain biochar powder; mix the above biochar powder and the remaining 40% rice straw powder , mix together with the limestone powder (over 40 mesh sieves) of 10% of the total volume of the above two materials, and stir evenly to get final product. Apply this product to improve acidic soil, and the application rate is 200-500kg per mu.

Embodiment 2

[0018] Crush corn stalks into powders with a diameter of less than 2mm, heat 50% of them to 400°C under air-isolated conditions for 3 hours to obtain biomass charcoal powder; , mix together with the limestone powder (through 40 mesh sieve) of above-mentioned two kinds of material total volume 20%, stir evenly and get final product. Apply this product to improve acidic soil, and the application rate is 200-300kg per mu.

Embodiment 3

[0020] Grind the dried cow dung into powders with a diameter less than 2mm, heat 70% of it to 600°C under air-isolated conditions for 2.5 hours to obtain biomass charcoal powder; dry the above-mentioned biomass charcoal powder and the remaining 30% Cow dung powder is mixed with 50% limestone powder (through a 40-mesh sieve) of the total volume of the above two substances, and stirred evenly. Apply this product to improve acidic soil, and the application rate is 50-150kg per mu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com