Sectional three-dimensional structure for fast desalting and soil improvement of saline-alkali soil of new tidal marsh reclamation area

A technology of three-dimensional structure and saline-alkali land, which is applied in the fields of soil preparation methods, climate change adaptation, agricultural machinery and tools, etc., can solve the difficulty of increasing the desalination and alkali treatment of saline-alkali land in new reclamation areas, reduce the rate of drainage and desalination of dark pipes, and the effect of fast desalination of dark pipes In order to achieve the effect of improving soil infiltration capacity, improving soil porosity and preventing surface soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

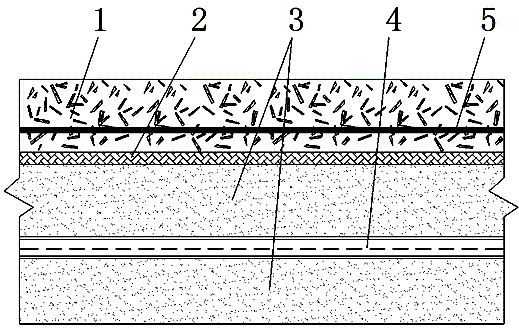

[0022] Such as figure 1 As shown, the present invention is applied to the saline-alkali land in the new reclamation area of the tidal flat. First, the hidden pipe is buried in the saline-alkali soil layer 3 section to be desalted at a depth of 90 cm to form a hidden pipe drainage layer 4. The inclination angle of the dark pipe to the water outlet direction is 2°. The embedding distance is 20m; dig out the 45cm soil of the surface layer of the soil layer 3 section, and pile it up in the open space next to it. Add 5cm long crushed straw to the surface soil on the side, the addition amount is 20t / hm 2 , add desulfurization gypsum at the same time, the addition amount is 10t / hm 2 , mixed evenly to form straw + gypsum mixed soil; spread 15cm thick mixed soil on the straw isolation layer, level it, and then lay infiltrating capillaries at 1.2m intervals (buried as deep as 30cm above the ground), and then spread the remaining mixed soil The soil is leveled to form a straw-gypsum...

Embodiment 2

[0025] The present invention is applied to the saline-alkali land in the new reclamation area of the tidal flat. First, the hidden pipe is buried in the saline-alkali soil layer 3 section to be desalinated at a depth of 100 cm to form a drainage layer 4 of the hidden pipe. 30m; plan the 40cm soil on the surface of the soil layer 3 section, and pile it up in the open space next to it. Add 8cm long crushed straw to the soil, the addition amount is 30t / hm 2 , while adding desulfurization gypsum, the addition amount is 20t / hm 2 , mixed evenly to form straw + gypsum mixed soil; spread 10cm thick mixed soil on the straw isolation layer, level it, and then lay infiltration capillary at 2m intervals (buried as deep as 30cm above the surface), and then spread the remaining mixed soil And leveled to form straw gypsum mixed tillage layer (seepage irrigation layer).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com