Device and method for enhancing desalting battery performance by using ion exchange mixed bed

An ion exchange and battery performance technology, applied in the field of electrochemical desalination, can solve problems such as rising internal resistance of batteries, and achieve the effects of reducing internal resistance, improving ionic conductivity, and increasing desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

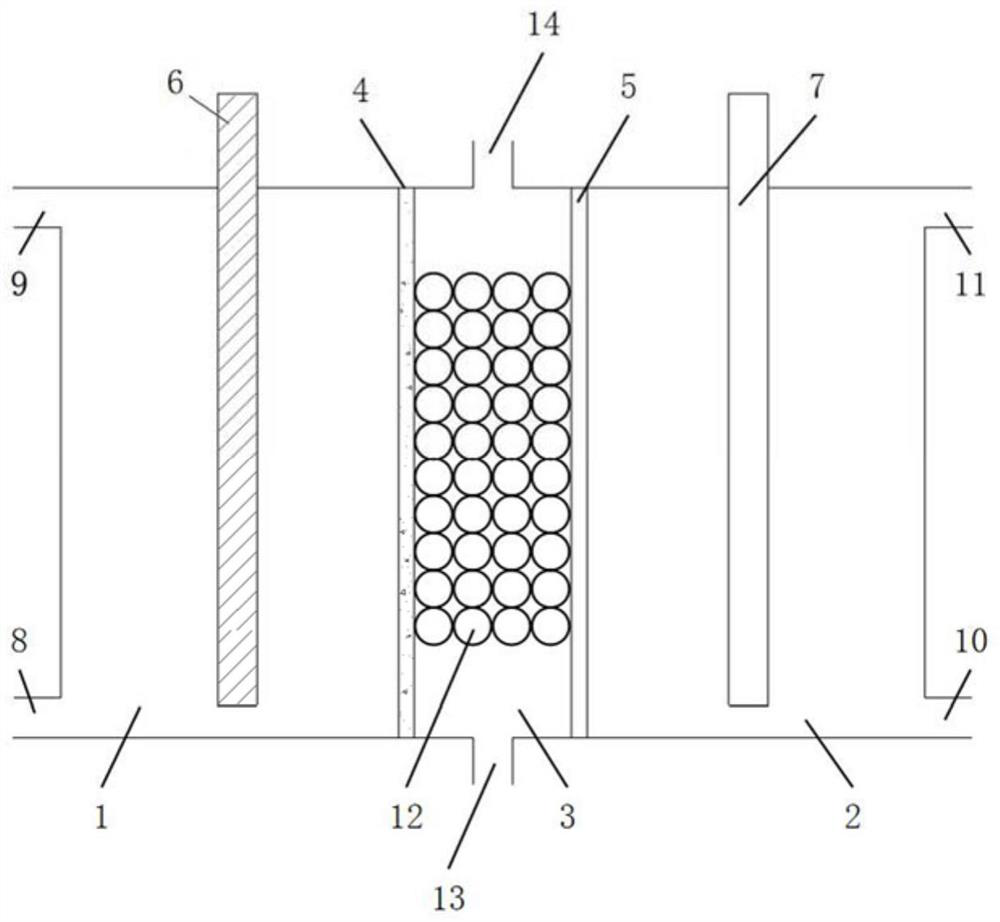

[0039] (1) Assembly figure 1 The structure of the flow desalination battery shown.

[0040] (2) Prepare 5 g / L, 4 g / L, 3 g / L, 2 g / L, 1 g / L, 0.8 g / L, 0.6 g / L, 0.4 g / L, 0.2 g / L respectively NaCl solution is used as the feed liquid, so that the feed liquid chamber is filled with the NaCl solution with the above-mentioned concentration gradient, and the two electrode chambers are filled with anion electrolyte and cation storage electrolyte respectively, and the electrolyte and feed liquid are kept static, and the two ends of the electrodes are connected to a double constant potential The internal resistance of the battery was analyzed by impedance spectroscopy, and the specific results are shown in Table 1.

[0041] (3) Select 5 g / L NaCl solution as the feed liquid for desalination. The amount of feed liquid is 50 mL, which is circulated by a peristaltic pump; the anion storage electrolyte and cation storage electrolyte are each 100 mL, which are circulated by a peristaltic pump; ...

Embodiment 2

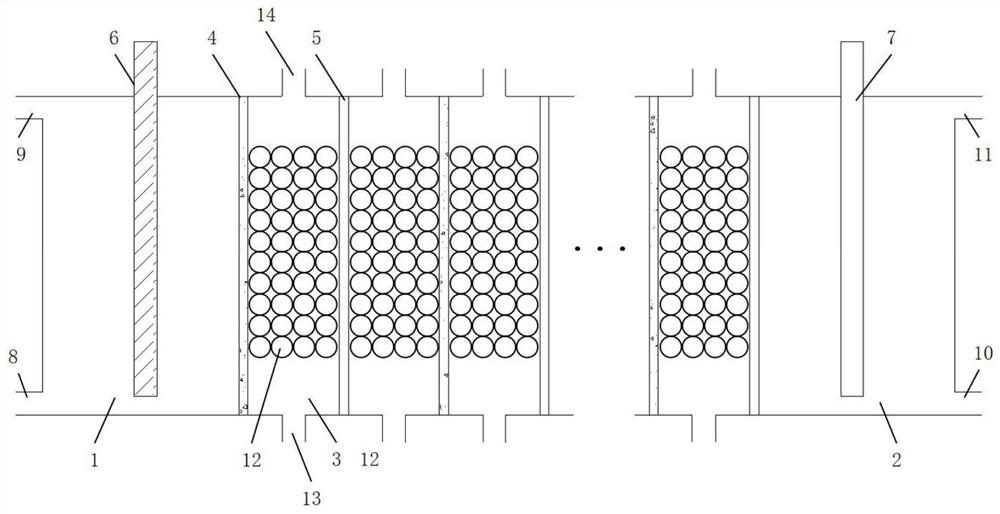

[0052] (1) Assembly Figure 5 The structure of the flow desalination battery shown.

[0053] (2) Through a suitable pipeline connection method, the cation-storing electrolyte enters the electrode chamber 2 from the electrolyte inlet 10, fills the electrode chamber 2, and then flows out from the electrolyte outlet 11, and enters the electrode chamber 1 from the electrolyte inlet 8, Then flow out through the electrolyte outlet 9, and use a peristaltic pump to circulate this process. The amount of electrolyte for storing cations is 100 mL; the feed liquid is 10 g / L NaCl solution, and the first feed liquid chamber is filled with the feed liquid, and the feed liquid The liquid inlet and outlet are sealed, and the feed liquid in it is kept still as concentrated water, and the dosage is about 10 mL; the feed liquid in the second feed liquid chamber is circulated by a peristaltic pump, and the dosage is 50 mL, which is used as desalination water, that is, recovered The ratio is set t...

Embodiment 3

[0061] (1) Assembly figure 1 The structure of the flow desalination battery shown.

[0062] (2) Prepare NaCl solutions of 35 g / L, 20 g / L, 10 g / L, 9 g / L, 8 g / L, 7 g / L, 6 g / L, and 5 g / L respectively as the feed liquid , let the feed liquid chamber be filled with the NaCl solution with the above-mentioned concentration gradient, the two electrode chambers are filled with anion electrolyte and cation storage electrolyte respectively, keep the electrolyte and feed liquid static, connect the two ends of the electrodes to a bipotentiostat, and use impedance spectroscopy The internal resistance of the battery was analyzed by the analytical method, and the specific results are shown in Table 2.

[0063] (3) Select 35 g / L NaCl solution as the feed liquid for desalination. The amount of feed liquid is 50 mL, which is circulated by a peristaltic pump; the anion-storage electrolyte and cation-storage electrolyte are each 100 mL, and the peristaltic pump is used for circulation; Charge an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com