Device and method for desalination of tubular biocathode microbial desalination fuel cell

A microbial desalination and bio-cathode technology, which is applied in the field of cylindrical bio-cathode microbial desalination fuel cell desalination devices, can solve the problems of high cost of Pt/C, limited practical application, low desalination efficiency, etc. Effect of desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

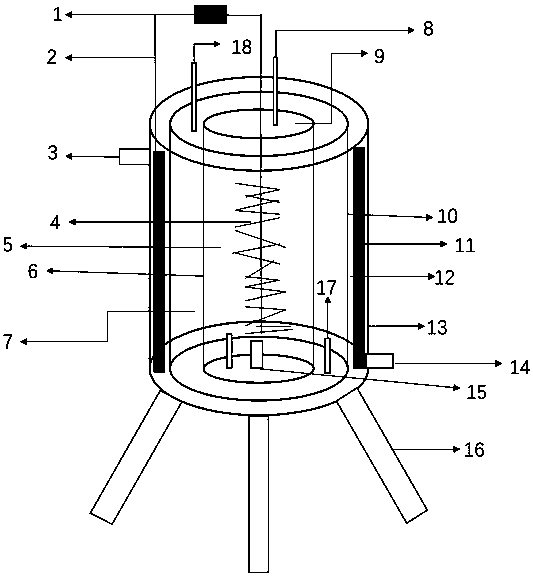

[0024] Specific implementation mode one: as figure 1 As shown, a cylindrical biocathode microbial desalination fuel cell desalination device, the device includes an external resistance 1, an external circuit 2, an anolyte outlet 3, a cathode and a cathode biofilm 4, a catholyte 5, and a cation exchange membrane 6 , desalination chamber 7, catholyte water inlet 8, catholyte water outlet 8a, cathode chamber top cover 9, anion exchange membrane 10, anode and anode biofilm 11, anolyte 12, tubular reactor shell 13, anolyte water inlet 14. Aeration head 15, bracket 16 (made of plexiglass material), water inlet 17 of desalination chamber (made of plexiglass material), water outlet 18 of desalination chamber (made of plexiglass material);

[0025] The reactor is a sleeve-shaped structure, the bottom end of the reactor is a closed end, and the top end is an open end. The reactor is made of a cylindrical reactor shell 13 (made of plexiglass, with a thickness of 5 mm), and a cation excha...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 1 As shown in the specific embodiment 1, the cylindrical biocathode microbial desalination fuel cell desalination device, the resistance value of the external resistance 1 at startup is 500~2000Ω, and the resistance value at the operation stage is 10~200Ω.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 As shown, the device for desalination of the tubular biocathode microbial desalination fuel cell described in the specific embodiment one or two, the composition and proportioning of the catholyte 5 are NaHCO 3 2 g / L, KH 2 PO 4 4.4 g / L, K 2 HPO 4 •3H 2 O 3.4 g / L, NH4 Cl 1 g / L, MgCl 2 •6H 2 O 0.1 g / L, CaCl 2 • 2H 2 O 0.1 g / L, yeast extract 0.1 g / L and trace metal solution 10 mL; the composition and proportioning of the trace element metal solution are: NiCl 2 ·6H 2 O0.024 g / L; Na 2 WO 4 2H 2 O 0.025 g / L; Na 2 MoO 4 0.025 g / L; FeSO 4 ·7H 2 O 0.1 g / L; CaCl 2 2H 2 O 0.1 g / L; CoCl 2 ·6H 2 O 0.1 g / L; CuSO 4 ·5H 2 O 0.01 g / L; KAl(SO 4 ) 2 12H 2 O 0.01 g / L; Boric acid 0.01 g / L; Zinc chloride 0.13 g / L; Manganese sulfate 0.5 g / L; Nitrilotriacetic acid 2.0 g / L; Magnesium sulfate 3.0 g / L;

[0028] The composition and proportioning ratio of the anolyte are: sodium acetate 1.64 g / L, KH 2 PO 4 4.4g / L, K 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com