Dual ion desalting electrode and preparation method thereof

A dual ion and desalination technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of complex pore structure, low effective surface area, and poor desalination efficiency, and achieve high effective surface area, high desalination rate, and desalination capacity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

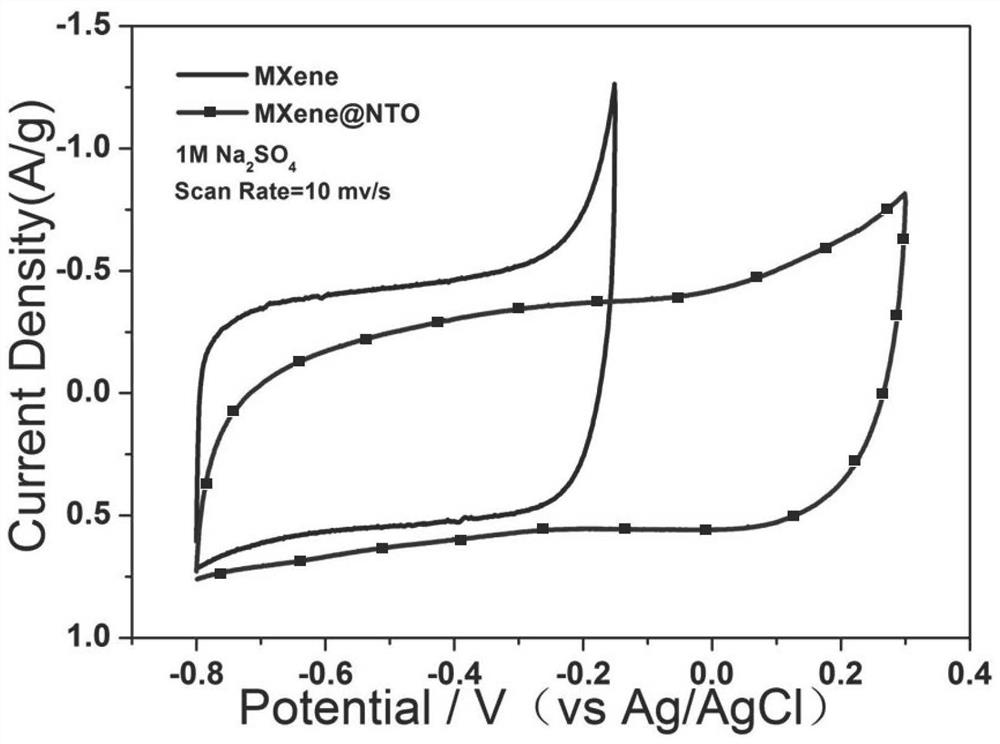

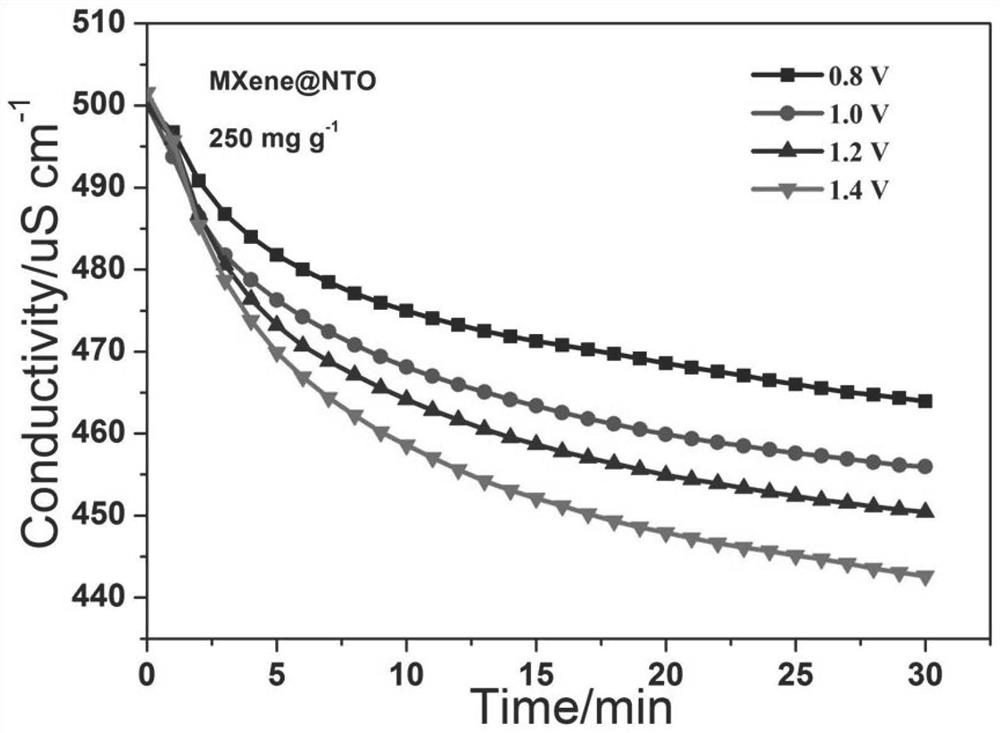

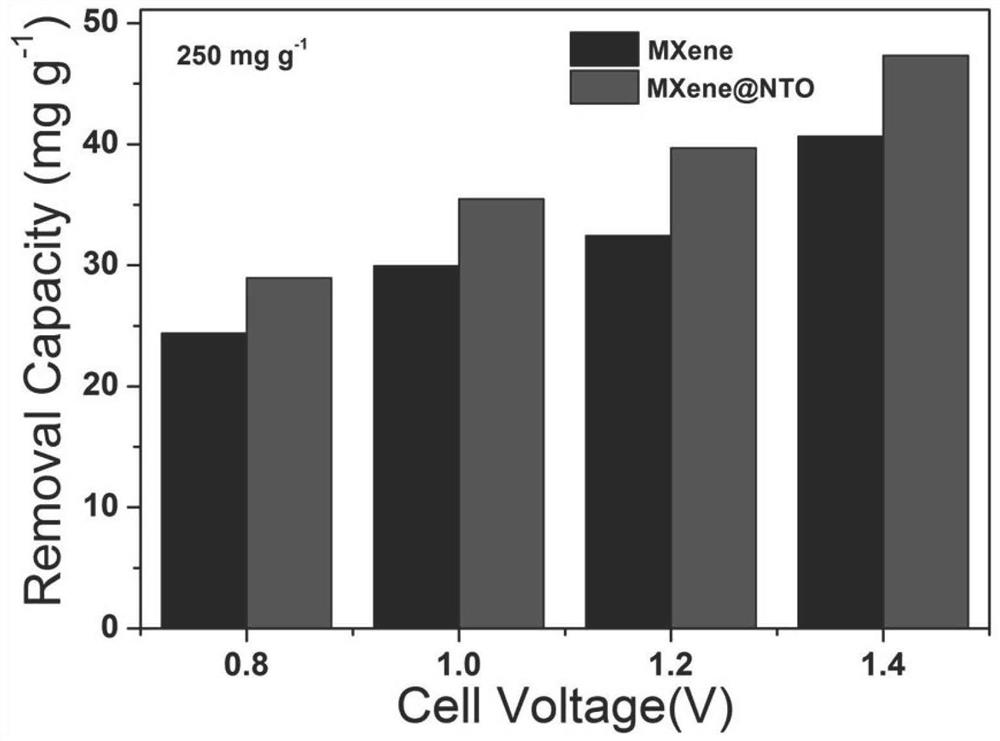

[0032] The MXene@NTO composite material is used as the negative electrode material, and the NiCo-Ox@graphene composite material is used as the positive electrode material.

[0033] Preparation of MXene@NTO composite material: According to the amount of adding at least 10 ml of NaOH solution per 0.1 g of MXene, MXene was added to NaOH solution with a concentration of 2 mol / L, hydrothermally reacted at 300 °C for 3 h, and left to cool naturally to room temperature; after the obtained reaction product was filtered, washed with deionized water at least twice, and vacuum-dried at 60°C for at least 10 hours to obtain the MXene@NTO composite material.

[0034] Preparation of NiCo-Ox@graphene composite material: Weigh nickel chloride hexahydrate, cobalt chloride hexahydrate and hexamethylenetetramine according to the molar ratio of 10:5:32 and dissolve them in 30 ml deionized water, stir them magnetically 15 min; add graphene oxide to the mixture, the amount of graphene oxide added pe...

Embodiment 2

[0037] The MXene@NTO composite material is used as the negative electrode material, and the NiCo-Ox@graphene composite material is used as the positive electrode material.

[0038] Preparation of MXene@NTO composite material: According to the amount of adding at least 10 ml of NaOH solution per 0.1 g of MXene, MXene was added to NaOH solution with a concentration of 4 mol / L, hydrothermally reacted at 260 °C for 6 h, and left to cool naturally to normal temperature; after the obtained reaction product was filtered, washed with deionized water at least twice, and vacuum-dried at 50 °C for at least 10 h to obtain the MXene@NTO composite material.

[0039] Preparation of NiCo-Ox@graphene composite material: Weigh nickel chloride hexahydrate, cobalt chloride hexahydrate and hexamethylenetetramine according to the molar ratio of 10:5:32 and dissolve them in 30 ml deionized water, stir them magnetically 15 min; add graphene oxide into the mixture, the amount of graphene oxide added p...

Embodiment 3

[0042] The MXene@NTO composite material is used as the negative electrode material, and the NiCo-Ox@graphene composite material is used as the positive electrode material.

[0043] Preparation of MXene@NTO composite material: According to the amount of adding at least 10 ml of NaOH solution per 0.1 g of MXene, MXene was added to NaOH solution with a concentration of 6 mol / L, hydrothermally reacted at 220 °C for 5 h, and stood for natural cooling to room temperature; after the obtained reaction product was filtered, washed with deionized water at least twice, and vacuum-dried at 30-50 °C for at least 10 h to obtain the MXene@NTO composite material.

[0044] Preparation of NiCo-Ox@graphene composite material: Weigh nickel chloride hexahydrate, cobalt chloride hexahydrate and hexamethylenetetramine according to the molar ratio of 10:5:32 and dissolve them in 30 ml deionized water, stir them magnetically 15 min; add graphene oxide into the mixture, the amount of graphene oxide add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com