A low-temperature evaporation treatment system for desulphurization waste water

A treatment system and desulfurization wastewater technology, applied in the field of low-temperature flash evaporation treatment system, can solve the problems of insufficient operation safety and stability, high operating cost of filtration reduction method, etc., so as to avoid secondary pollution and adapt to the new strength with low load , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

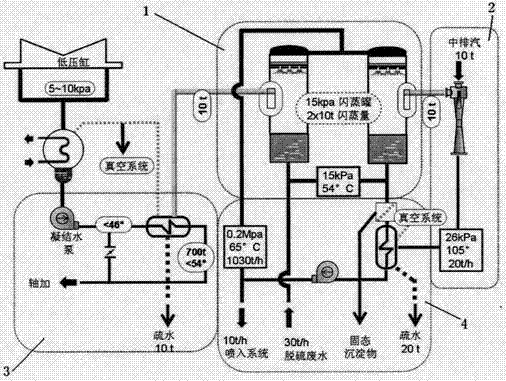

[0041] Such as figure 1 As shown, it is aimed at water-cooled units in thermal power plants. The desulfurization wastewater low-temperature evaporation treatment system includes a wastewater heating system, a wastewater flash treatment system, a flash steam cooling system, and a wastewater heating heat source system.

[0042] The upper part of the first flash tank and the second flash tank is equipped with a spray flash mechanism, and the lower part is a desulfurization wastewater tank, and the intermediate space forms a flash working area. An opening is set on the tank body of the flash working area of the first flash tank, which is connected to the first condenser through a pipeline, and an opening is set on the tank body of the flash working area of the second flash tank, which is connected to the first condenser through a pipeline. Turbocharger suction port. The wastewater outlet of the desulfurization device is connected to the first flash tank and the second flash ...

Embodiment 2

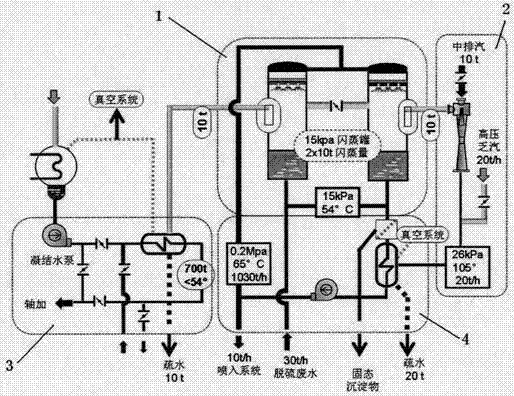

[0051] Such as figure 2 As shown, it is aimed at air-cooled units in thermal power plants (or high back pressure operation of water-cooled steam turbines).

[0052] The difference between this implementation case and Example 1 lies in the setting of the waste water heating heat source system. For thermal power plant air-cooled units or water-cooled steam turbines operating at high back pressure, the steam in the wastewater heating system can also be boosted and heated without passing through the injector, and directly connected to the pipeline to use the normal high back pressure operation of the air-cooled steam turbine or the high back pressure of the water-cooled steam turbine After operation, the exhaust steam (exhaust steam) of the steam turbine, as a heat source, enters the heating condenser to heat the waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com