Patents

Literature

33results about How to "Suspending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-fat health-care chicken meat balls prepared from complex hydrophilic gel and chicken skin instead of fat and method thereof

The invention provides a method for preparing low-fat health-care chicken meat balls prepared from combinational hydrophilic gel and chicken skin instead of fats, which belongs to the technical field of poultry deep processing. The method takes chicken meat and mixed fat as main raw materials, and MTGase, the complex hydrophilic gel, compound phosphate, and soy isolated protein as auxiliary materials. The preparation procedure comprises: pickling, enzyme liquid pretreatment, hydrophilic gel pretreatment, chopping and mixing, forming, reaction, and boiling. The method has simple production process, wide raw materials and low cost, and solves the problem of quality reduction caused by low fat. Meanwhile, based on the low-fat chicken meat balls, the method can also develop series of low-fat health-care chicken meat ball products with various tastes and nutritions.

Owner:FUZHOU UNIV

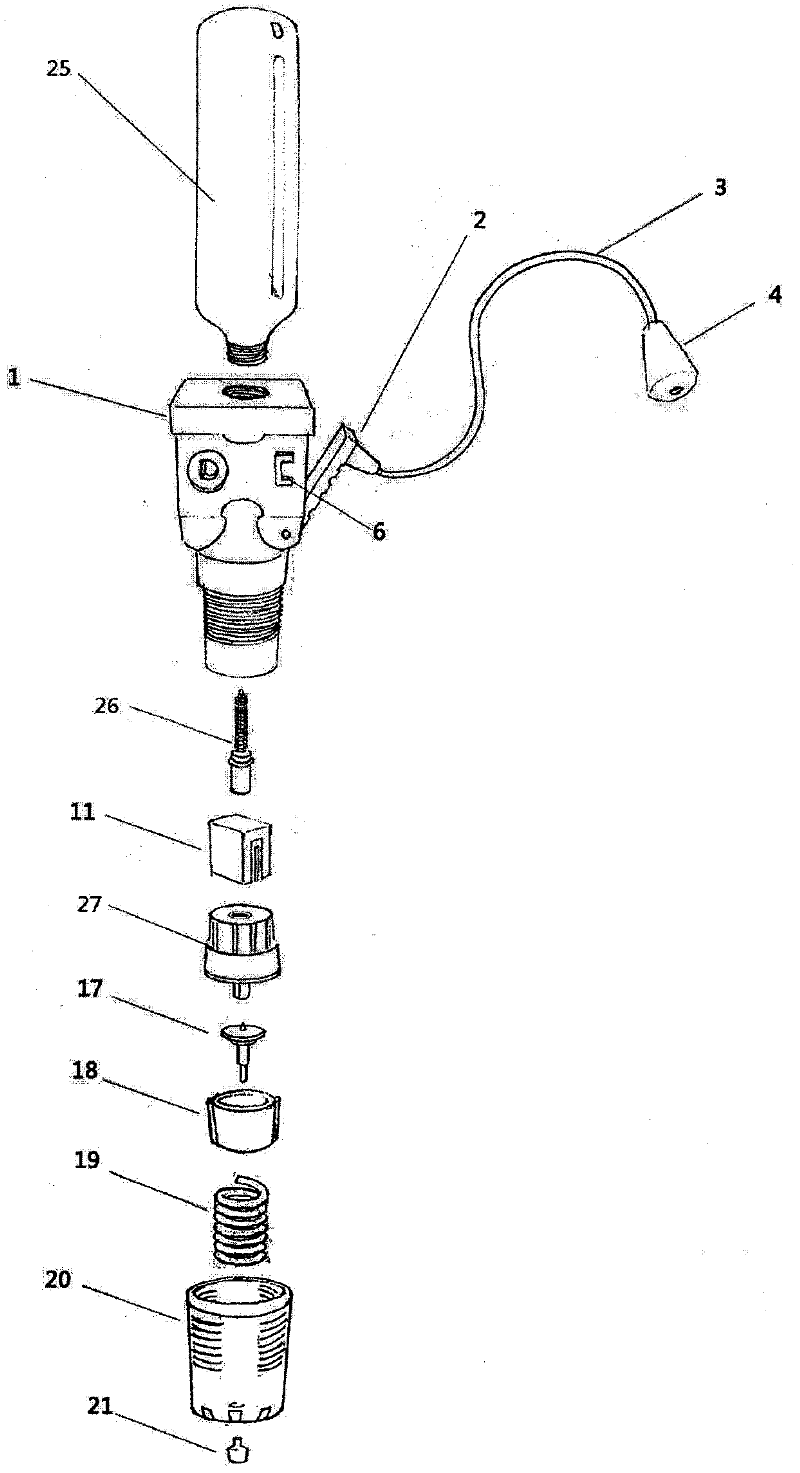

Biotrickling filter for treating volatile organic waste gas

InactiveCN101125280AEvenly distributedAvoid wall flowDispersed particle separationAir quality improvementVoltage dropEngineering

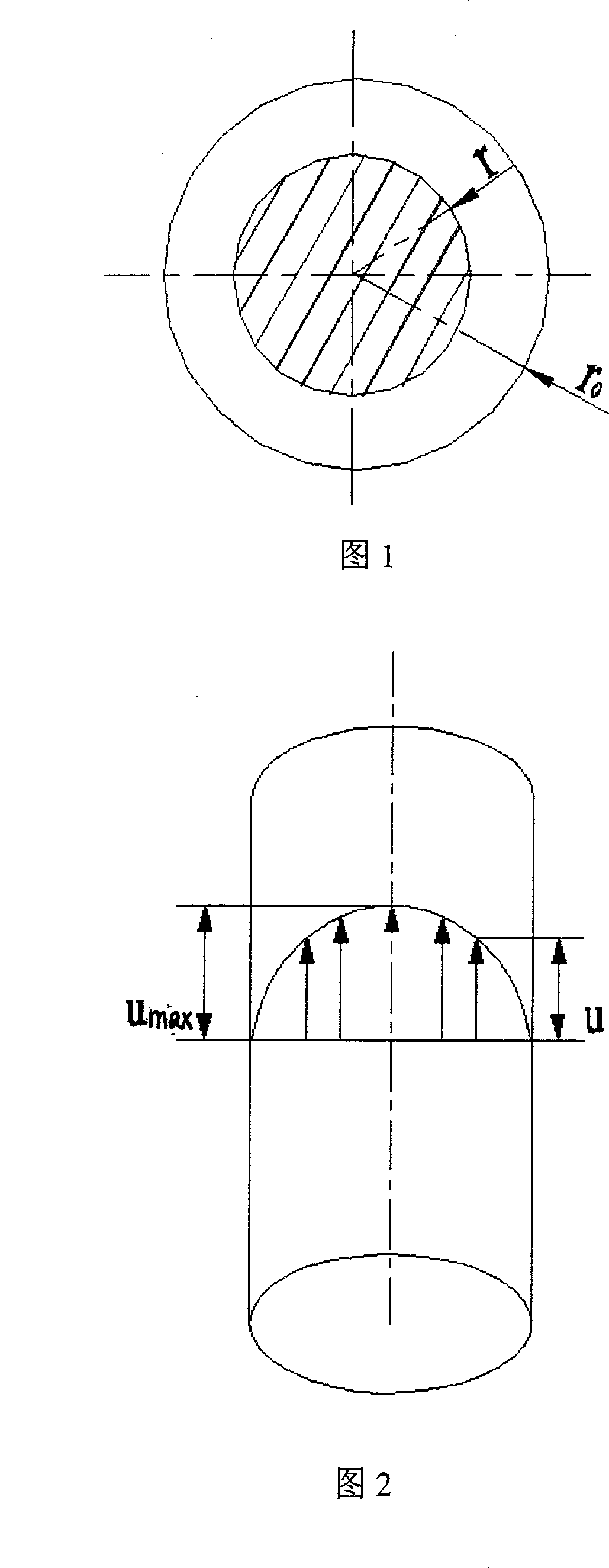

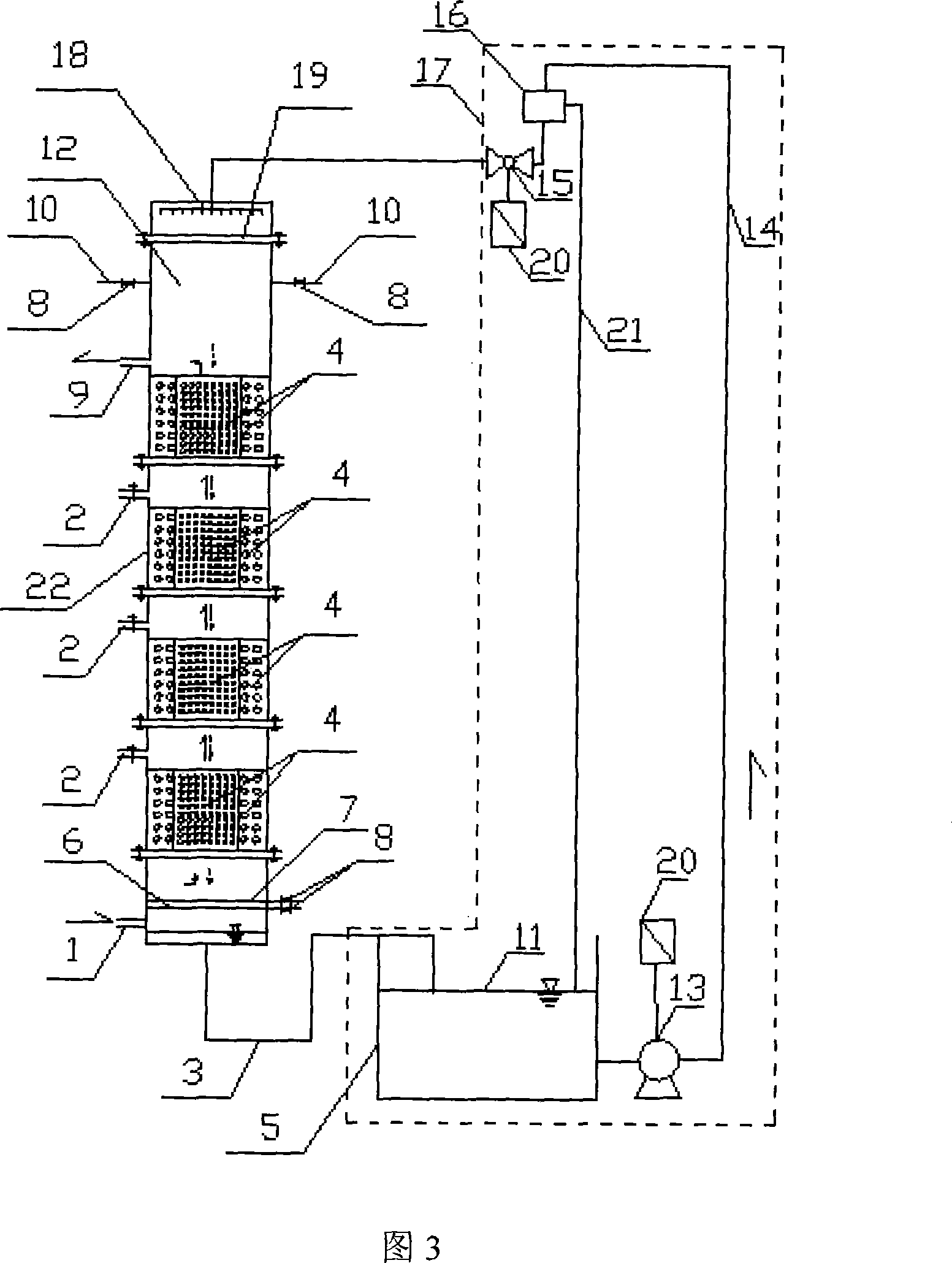

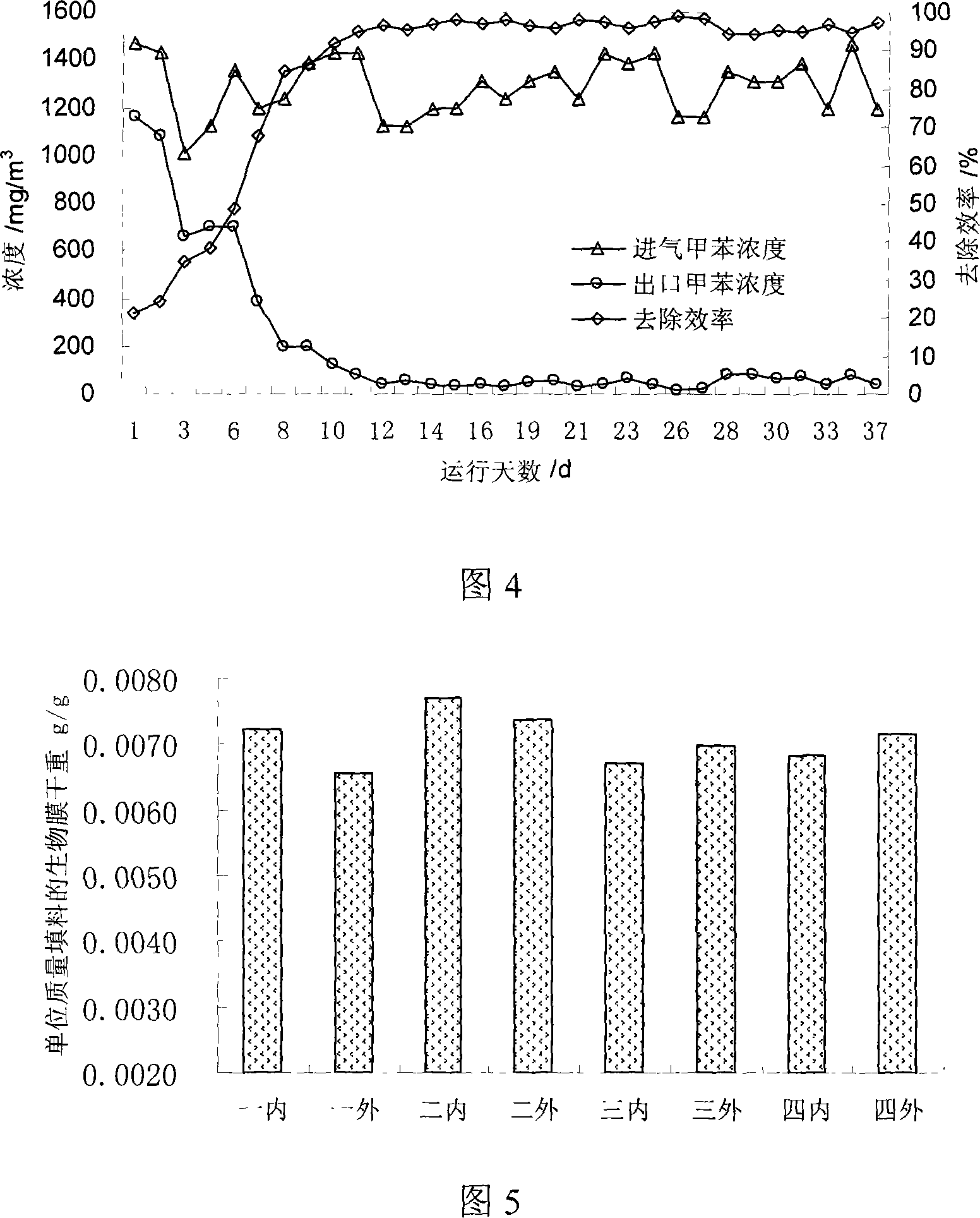

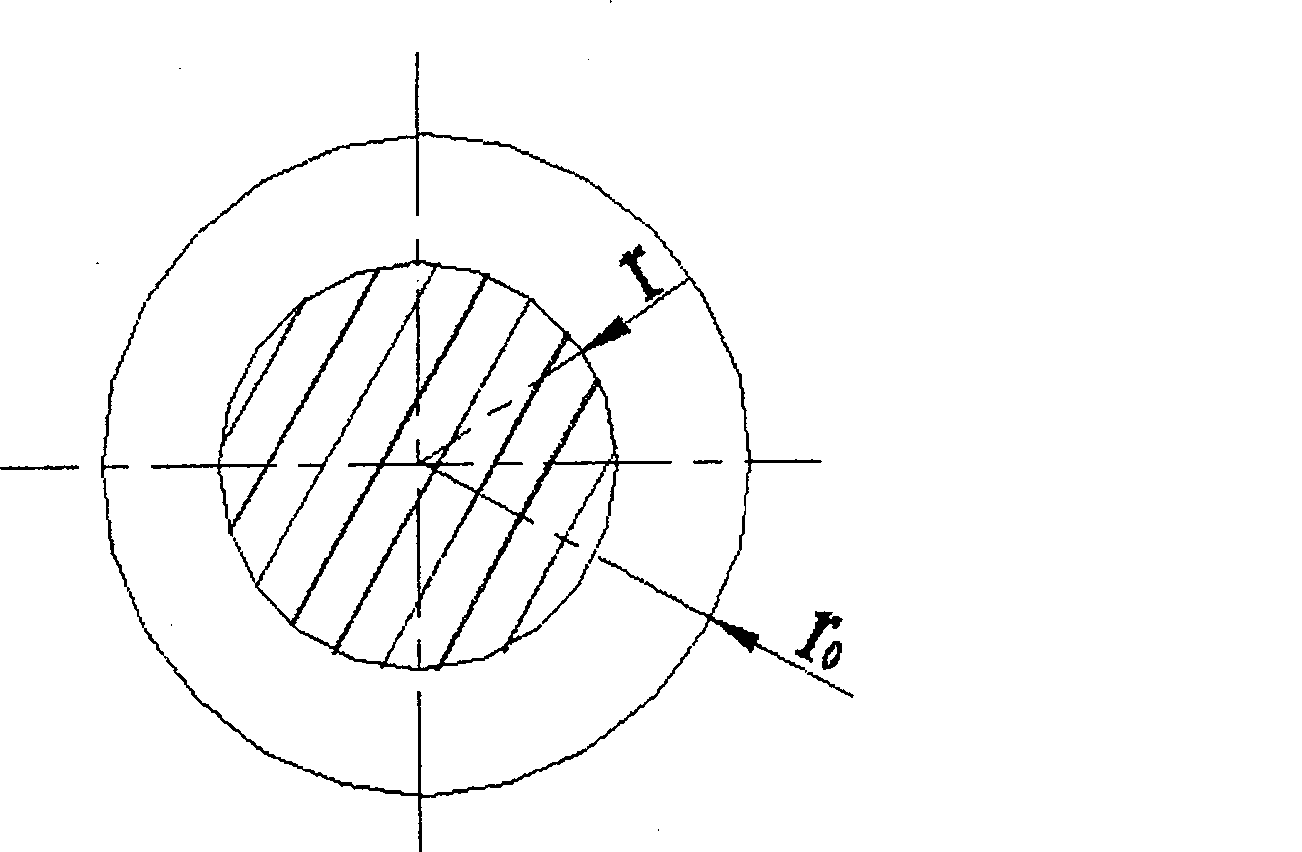

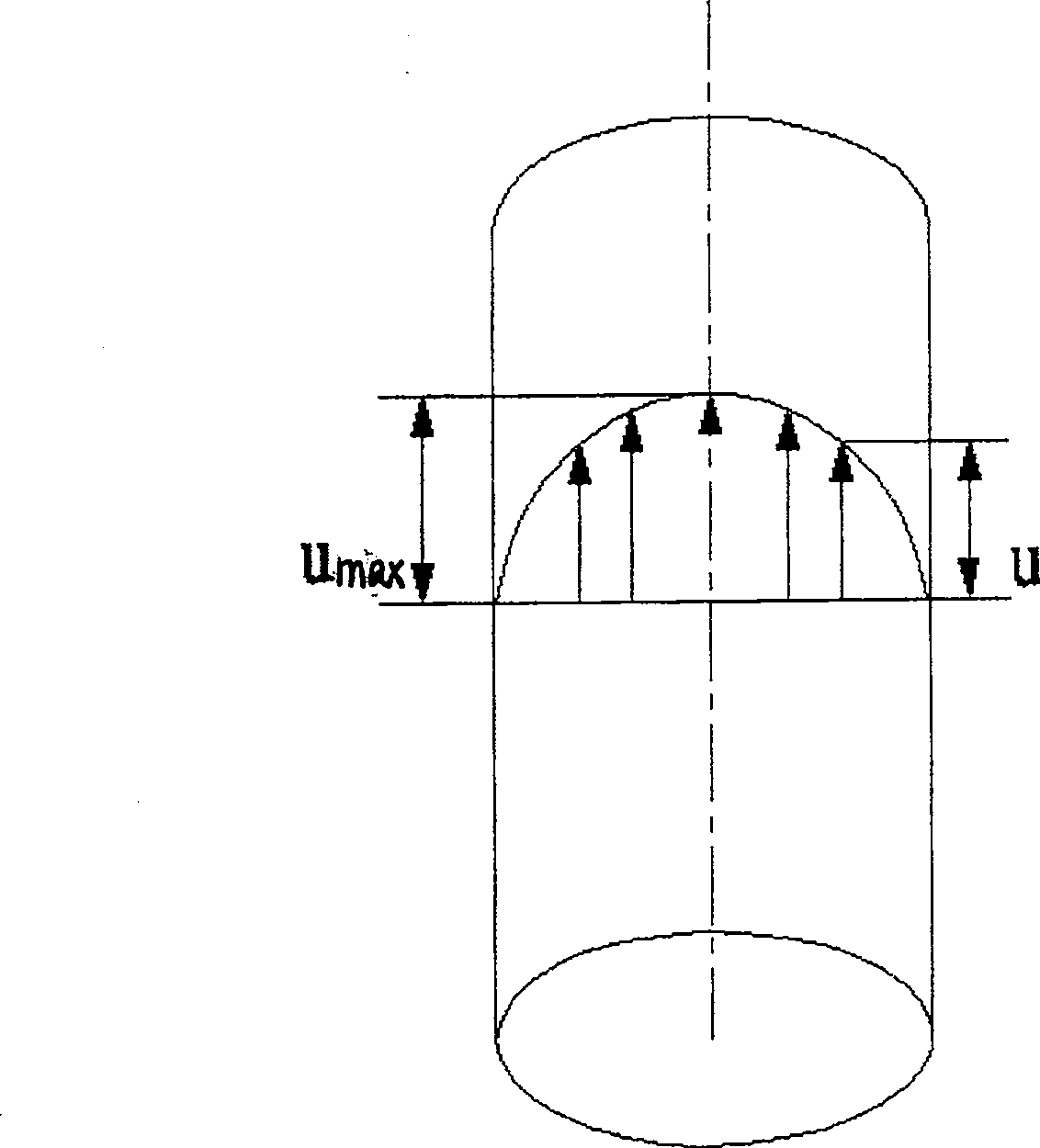

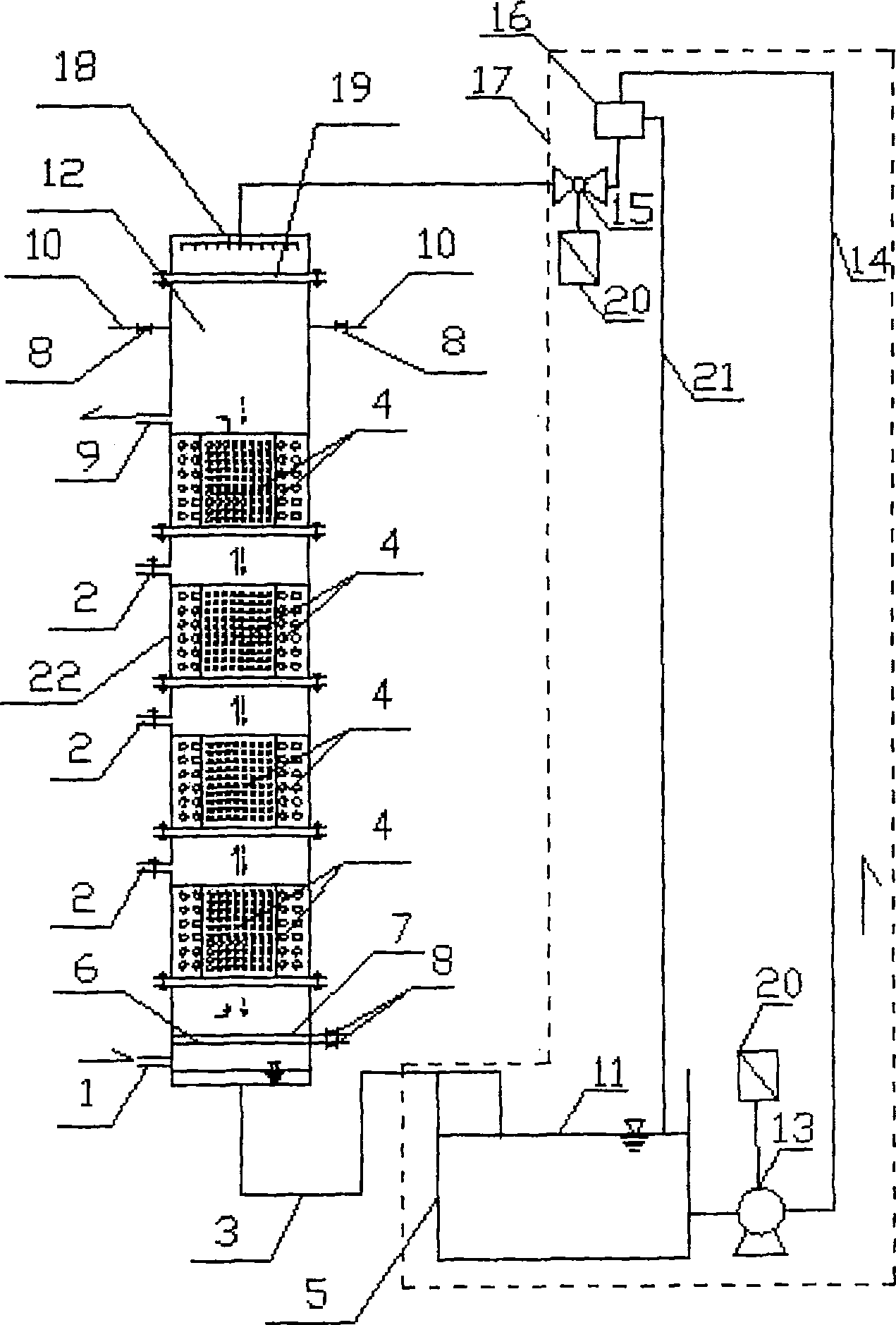

The present invention relates to a BTF used for dealing with the volatile waste gas, belonging to the field of treatment of the volatile waste gas, which aims at solving the problems that the prior BTF has uneven air flow distribution and biomass distribution, high center gas speed and voltage drop, and the prior BTF is easy to be blocked. The technic proposal is that: the volatile waste gas passes through an intake pipe (1) and then comes into a biofilter (22), and then being drained away by an exhaust pipe (9) after having the processes of degradation and purification; a nutrient solution (11) comes into the biofilter (22) through a nutrient solution shower (18) and a dropwise adding distributor device (19) having fixed quantities at fixed time; the present invention is characterized in that adopting a light and cheap packing (4) with different grain diameters, the biofilter (22) takes a homocentric column shape sleeve structure , the grain diameters of the filled packing (4) from the center to the edge are distributed from small to big, the centre area is filled with the packing (4) with small grain diameters, the ring area of the around close walls is filled with the packing (4) of big grain diameters. The present invention makes the distribution of the biomass in the biofilter even, thereby fully utilizing the useful space of the biofilter.

Owner:BEIJING UNIV OF TECH

Novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials and preparation method thereof

The invention provides a novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials, which belongs to the technical field of deep processing of poultry. The novel chicken block taking the hydrophilic compound gel and the soybean protein as the functional auxiliary materials takes chicken and chicken skin as main raw materials; and the auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, molding, reaction, rebaking, tabletting, battering and breading, and frying. The novel chicken block has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the quality of products produced by chicken raw materials. At the same time, serial chicken block products with various tastes and various nutritions can also be developed based on the novel chicken block.

Owner:FUZHOU UNIV

Low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and method thereof

The invention provides a low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and a method thereof, which belong to the technical field of deep processing of poultry. The low-fat health care chicken sausage prepared by utilizing the compound hydrophilic gel and the chicken skin to substitute the fat is characterized in that the chicken sausage takes chicken and the chicken skin as main raw materials; and auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, enema exhaust, reaction, drying and boiling. The chicken sausage has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the decrease of the quality caused by low fat. At the same time, serial low-fat health care chicken sausage products with various tastes and various nutritions can also be developed based on the low-fat chicken sausage.

Owner:FUZHOU UNIV

Method for preparing konjak weight-losing fondant

The invention belongs to the field of nutritional health food and particularly relates to a method for preparing a konjak weight-losing fondant. The fondant mainly comprises the following components:konjaku flour, milk powder, cane sugar, starch syrup and flavor. The method comprises the steps of adding water in the cane sugar, heating and dissolving the cane sugar, filtering the cane sugar to obtain a filtrate A; adding water in the konjaku flour and the milk powder, heating the mixture to the temperature of 85-90 DEG C for dissolving; simultaneously mixing and filtering the solution to obtain B; pouring the starch syrup and B into A; heating, mixing and decocting the mixture and taking out the mixture at the temperature of 114-115 DEG C; subsequently cooling the mixture to the temperature of 70 DEG C; adding the flavor and uniformly mixing the mixture to obtain C; pouring the C into a grinding tool; and pouring the C as masses; and after cooling and solidifying the masses, baking the masses for 12-24 hours under the temperature of 35-60 DEG C, and packing the masses to obtain the finished product. The prepared product has extremely low heat, strong water absorption, large viscosity and high expansion rate, can expand by 20-100 times after entering the stomach and absorbing the gastric juice, generate satiety feeling, sufficiently meet the eating sense and does not increase weight simultaneously, and does not need to diet purposely so as to achieve equilibrium dieting, thus realizing ideal weight-losing effect.

Owner:HANGZHOU LIUYI TECH

Organic-inorganic compound sewage treatment agent and preparation method thereof

ActiveCN109809519AEfficient processing effectWide variety of sourcesWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteChemical oxygen demand

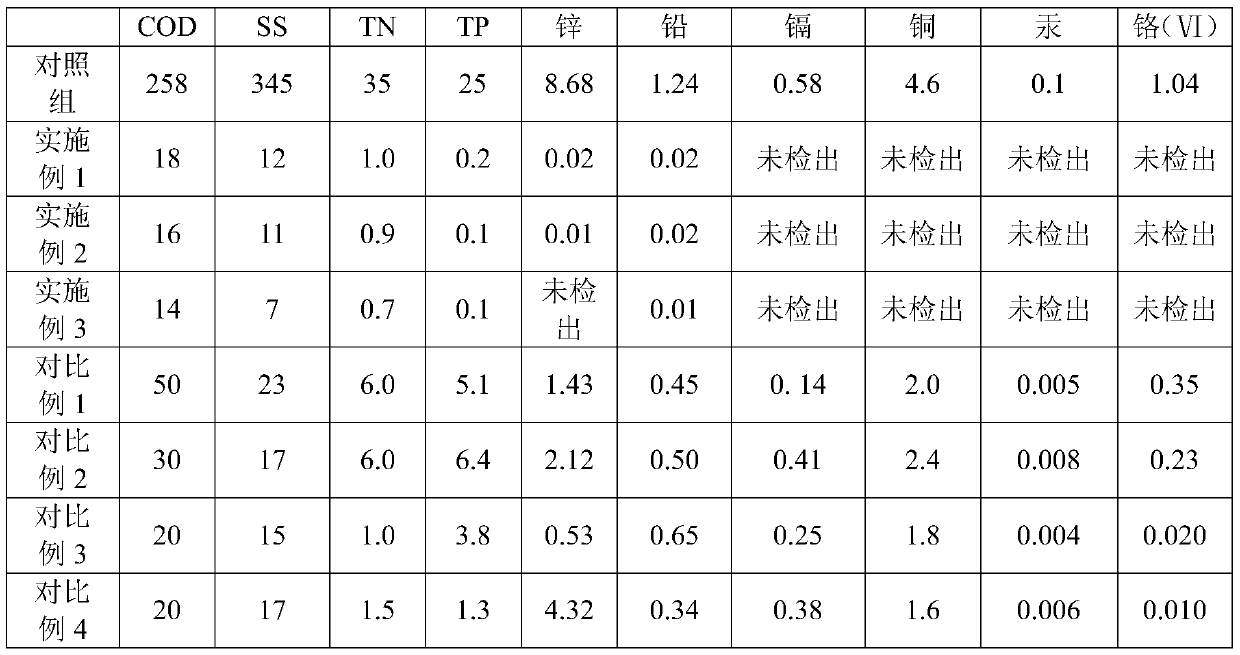

The invention discloses an organic-inorganic compound sewage treatment agent and a preparation method thereof. The compound treatment agent is prepared from the following raw materials in parts by weight: 6 to 8 parts of gelatin, 9 to 14 parts of cysteine, 9 to 24 parts of thioglycolic acid, 20 to 24 parts of sodium lignosulfonate, 22 to 26 parts of carboxymethyl chitosan, 12 to 13 parts of urea,25 to 27 parts of limestone, 14 to 16 parts of sepiolite, 28 to 30 parts of bentonite, 25 to 30 parts of fly ash, 24 to 28 parts of quick lime, 13 to 15 parts of medical stone, 13 to 15 parts of aluminum sulfate, 15 to 17 parts of ferric chloride and 12 to 14 parts of polyethyleneimine xanthic acid. The compound treatment agent provided by the invention combines advantages of an inorganic mineralabsorbent and an organic biological high polymer flocculating agent; the removing rates on heavy metal, COD (Chemical Oxygen Demand), SS (Suspended Solids), TP (Total Phosphorus) and TN (Total Nitrogen) reach 95 percent or more respectively; the content of the heavy metal, the COD, the SS, the TP and the TN in treated river channel sewage meets type IV requirements in a table 1 of National Environmental Quality Standard for Surface Water of the People's Republic of China GB3838-2002.

Owner:北水慧采(北京)科技有限公司

Plants cultivation slurry and its production method

InactiveCN1557134ASuspendingPromote growthCultivating equipmentsSoilless cultivationPlant rootsNutrient solution

The plant cultivating slurry is produced through mixing bentonite, animal excrement and other organic matter to form the material, fermentation after adding water, dilution and filtering, drying, and crushing, adding mineral fertilizer. When being used, the plant cultivating slurry is diluted via adding water to certain density. It is used as nutritive liquid for plant cultivation. The plant cultivating slurry of the present invention has the features of capacity of maintaining mineral and other nutritious components, capacity of maintaining water and air, and capacity of being transported and used in suspension state. It is sprayed to plant root so as to provide plant with rich nutrients, air and water and to provide plant with optimized growth condition.

Owner:魏勇

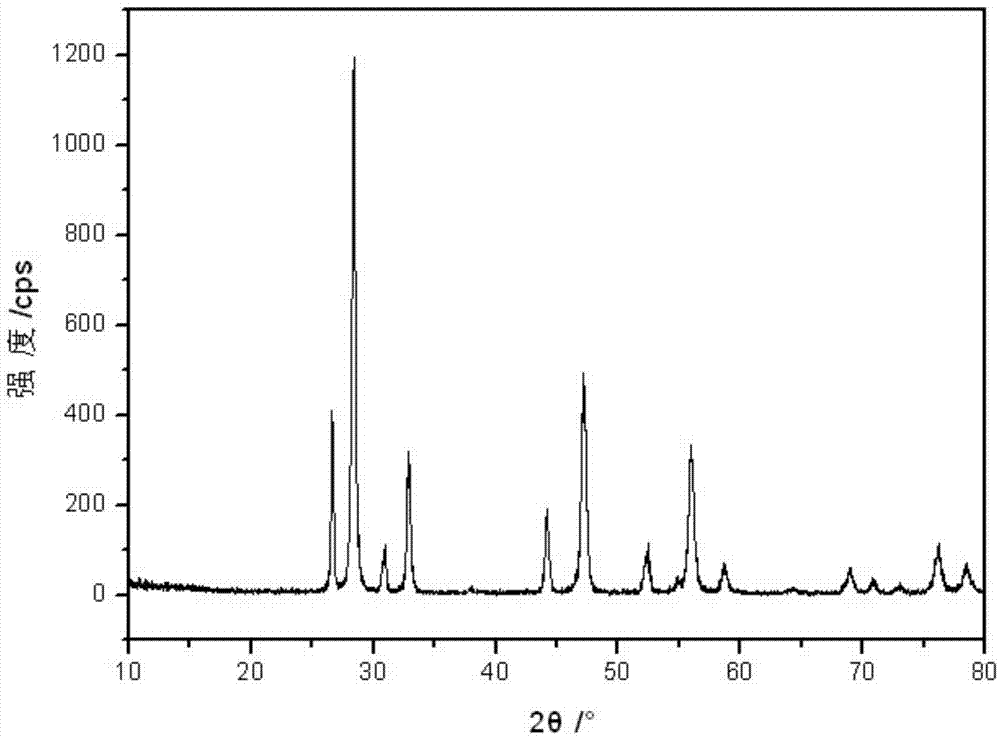

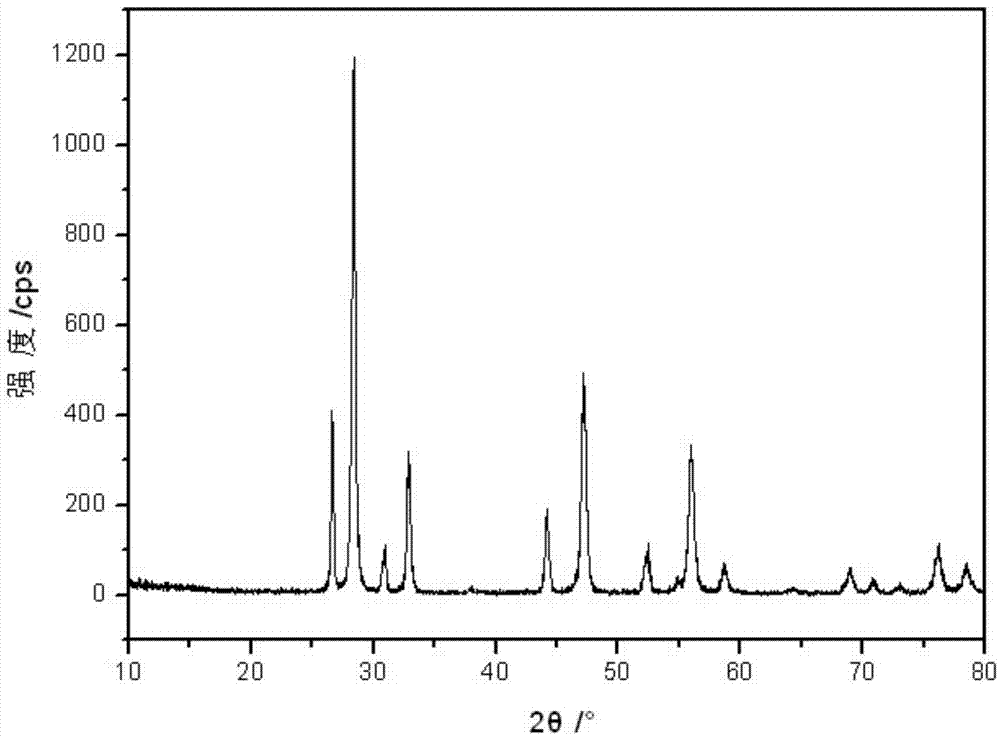

Rare-earth polishing powder and preparation method thereof

InactiveCN103756571AGood suspensionColloidalOther chemical processesPolishing compositions with abrasivesLiquid-crystal displayCerium

The invention aims at disclosing rare-earth polishing powder and a preparation method thereof. The rare-earth polishing powder comprises the following components in parts by weight: 0.5-1 part of citric acid, 1-3 parts of magnesia and the balance of cerium lanthanum oxyfluoride, wherein the sum of the mass percents of the components is 100%. Compared with an existing product, the rare-earth polishing powder has the characteristics of being good in suspension property, free of colloidal or hardened sediments and the like when the polishing powder and the water are prepared into slurry to use. The polished glass is easy to clean, so that fast polishing speed and high polishing accuracy of the polishing powder in the use procedure are ensured. The rare-earth polishing powder is applicable to surface polishing of precision instruments in optical and photoelectric information industries such as mobile phone touch glass, liquid crystal display, optical glass and the like.

Owner:上海华明高纳稀土新材料有限公司

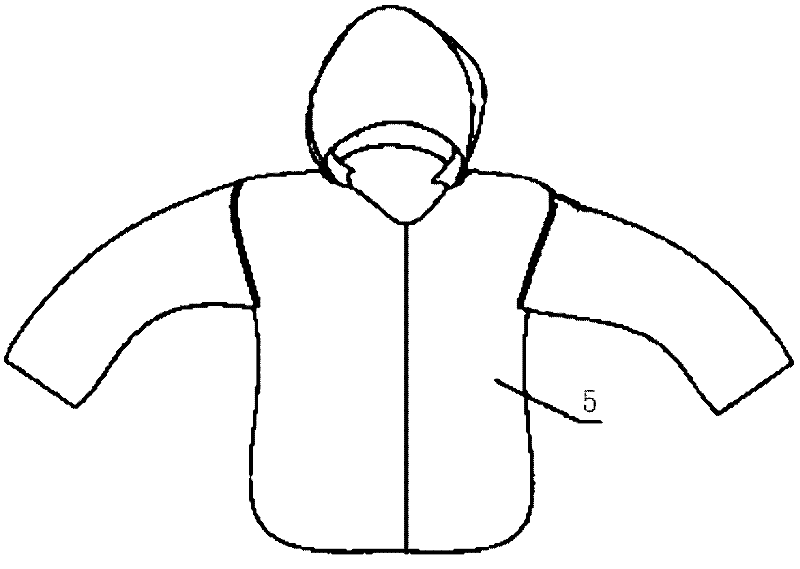

Life jacket

The invention relates to a lift jacket, comprising a shell fabric layer and a lining layer, wherein an air sac is arranged between the shell fabric layer and the lining layer, an air inlet of the air sac is connected with a compressed gas steel cylinder, and a cylinder opening of the compressed gas steel cylinder is provided with a life jacket excitation device. The cold-resistant life jacket provided by the invention is characterized in that an air sac is arranged between a shell fabric layer and a lining layer of cold weather clothes for cold resistance; when a person wears the life jacket falls into water, the excitation device is triggered when in water so as to puncture the cylinder opening of the compressed gas steel cylinder, high-pressure gas is introduced into the air sac, the air sac swells after being introduced with the gas and achieves a suspension property, and thus, the cold weather clothes has a function of the life jacket; and the cold weather clothing with the life saving function is particularly suitable for being used as work clothes in ports and wharfs.

Owner:无锡市骑安商贸有限公司

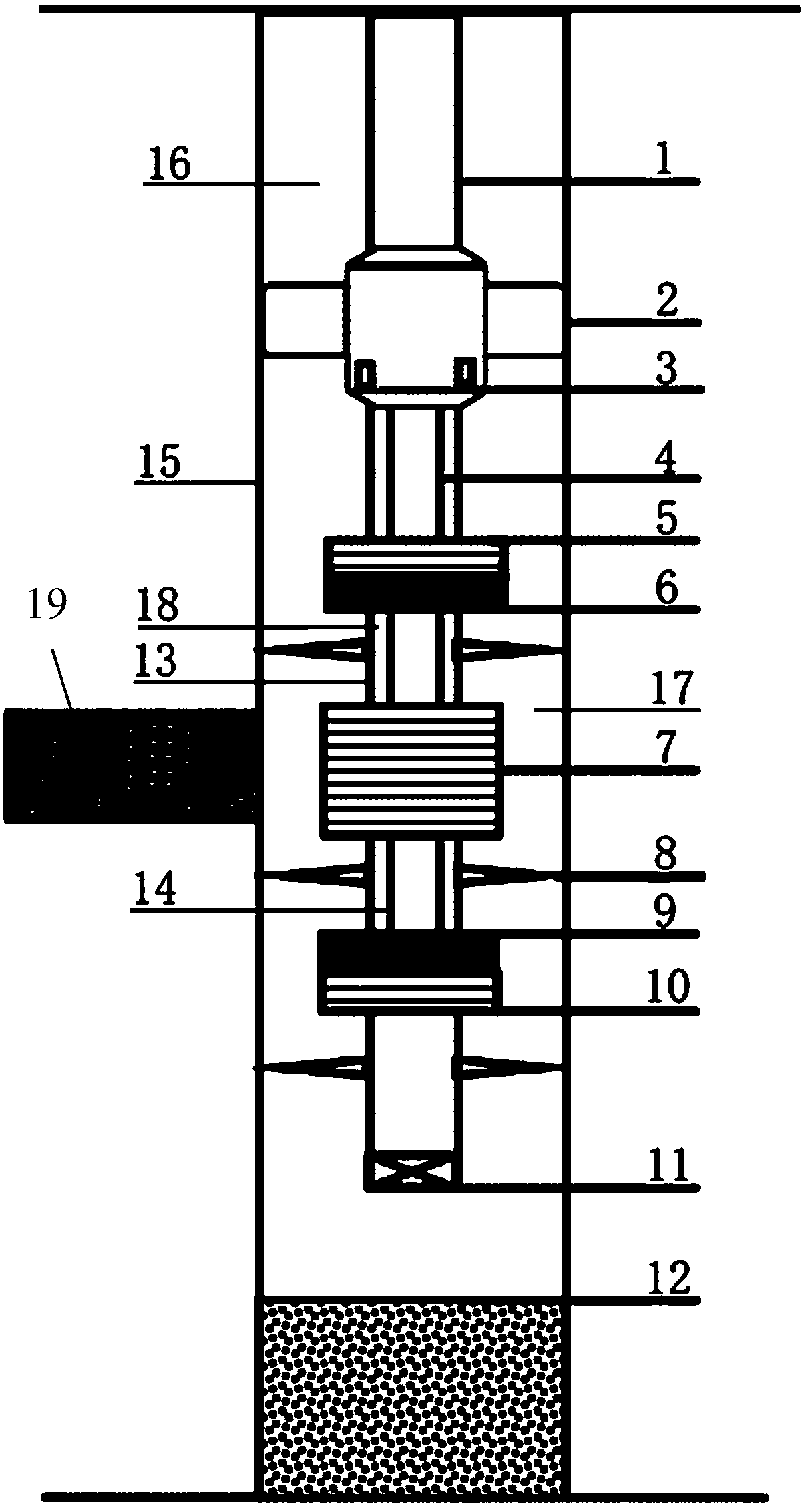

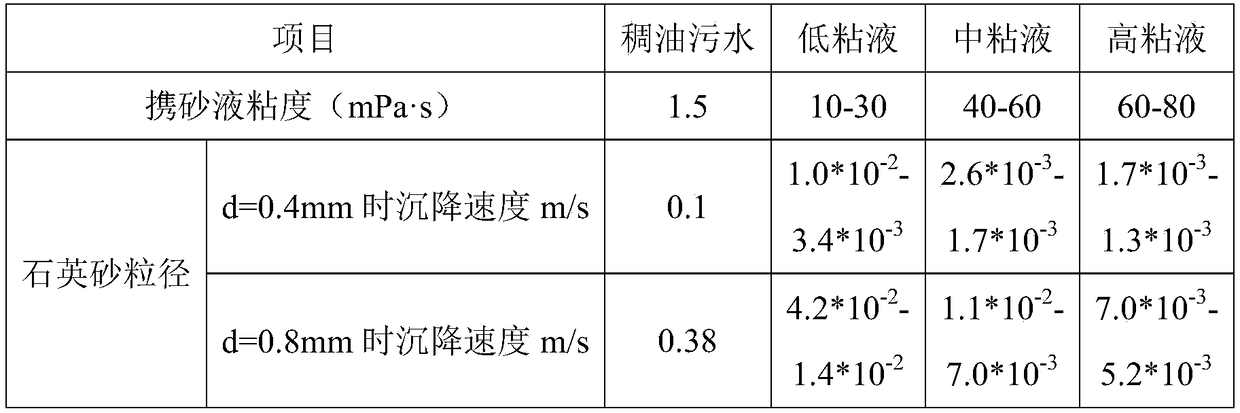

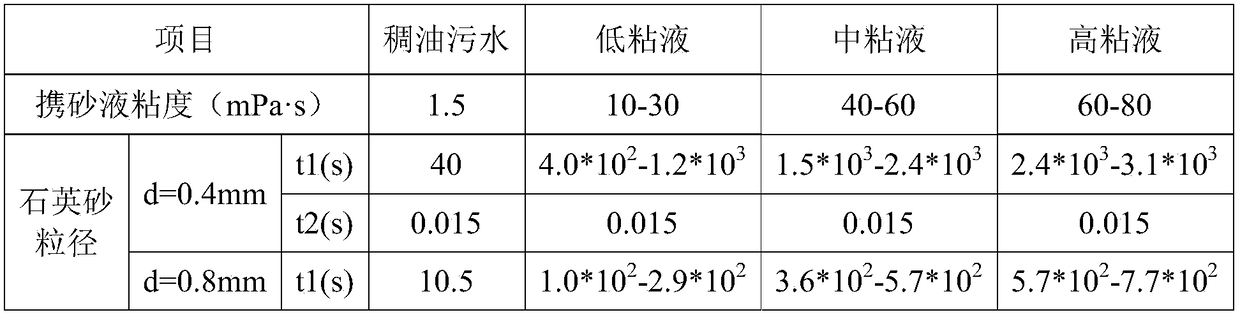

Oil deposit purification sewage sand-carrying filling sand prevention method and sand prevention pipe column

ActiveCN109236246ASuspendingReduce sedimentation velocityCleaning apparatusFluid removalChemical reactionEngineering

The invention relates to an oil deposit purification sewage sand-carrying filling sand prevention method and a sand prevention pipe column. The method comprises the following steps of 1, putting the sand prevention pipe column provided with a top packer in a predetermined position in a well, conducting packing, and opening a filling sand adding channel; 2, with oil deposit purification sewage withthe viscosity of 1.4-1.6 mPa.s as sand-carrying liquid, mixing the oil deposit purification sewage with quartz sand with the particle size of 0.4-0.8 mm according to the sand-carrying ratio of 3-15%,and afterwards, conducting positive squeezing and filling; 3, conducting releasing, and backwashing remaining sand in a pipe. According to the method, the oil deposit purification sewage with low viscosity serves as the sand-carrying liquid, the risks of sand blocking and sand burying are reduced, successful sand adding is ensured, and the construction requirement for low-sand-ration filling sandprevention is met. The sand-carrying liquid is the purified thickened oil sewage of an area where a construction well is located, has good compatibility with stratum liquid and stratum minerals, avoids the situation that chemical reactions are caused and sediments clog stratum pores, and is wide in source, cheap and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

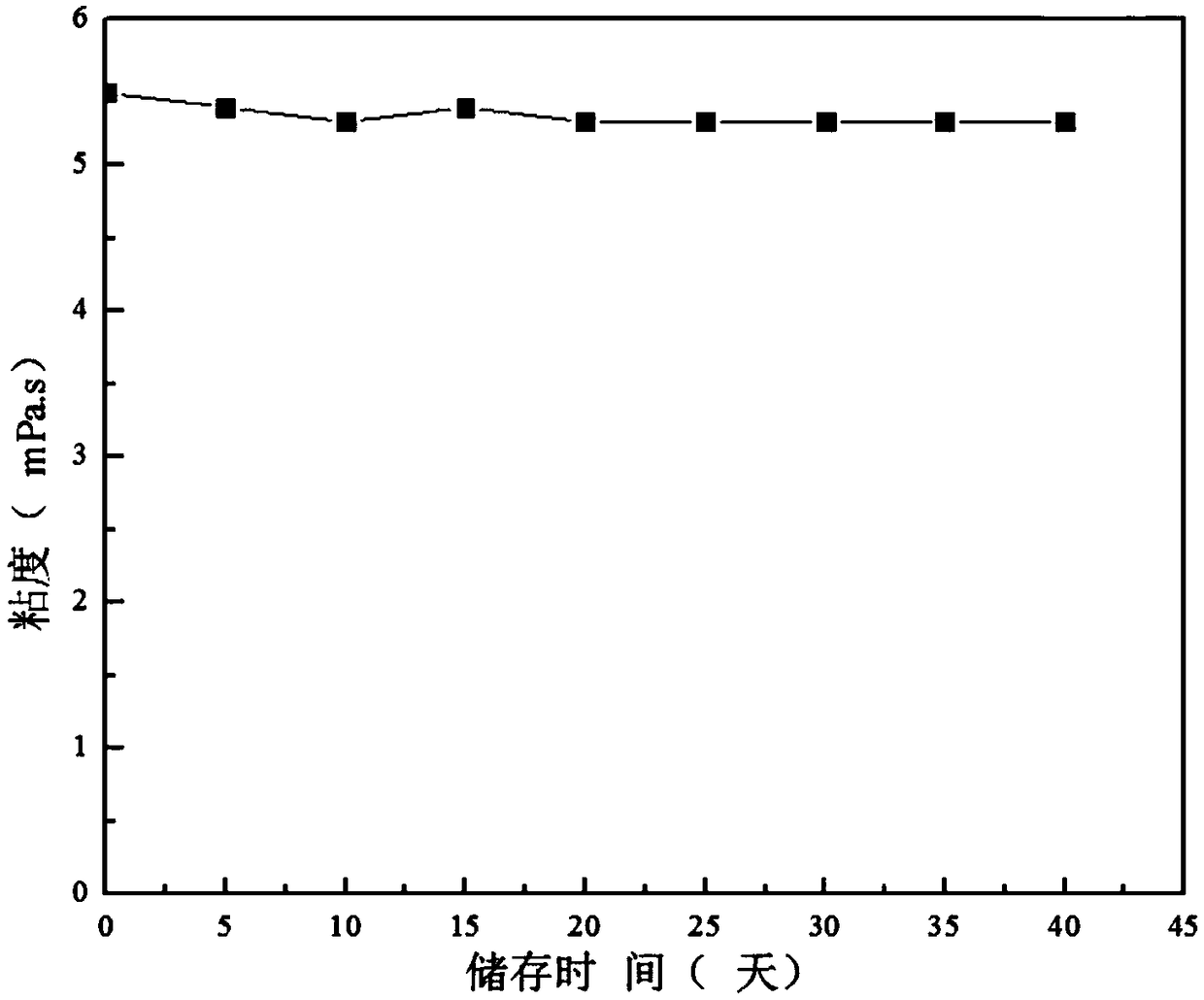

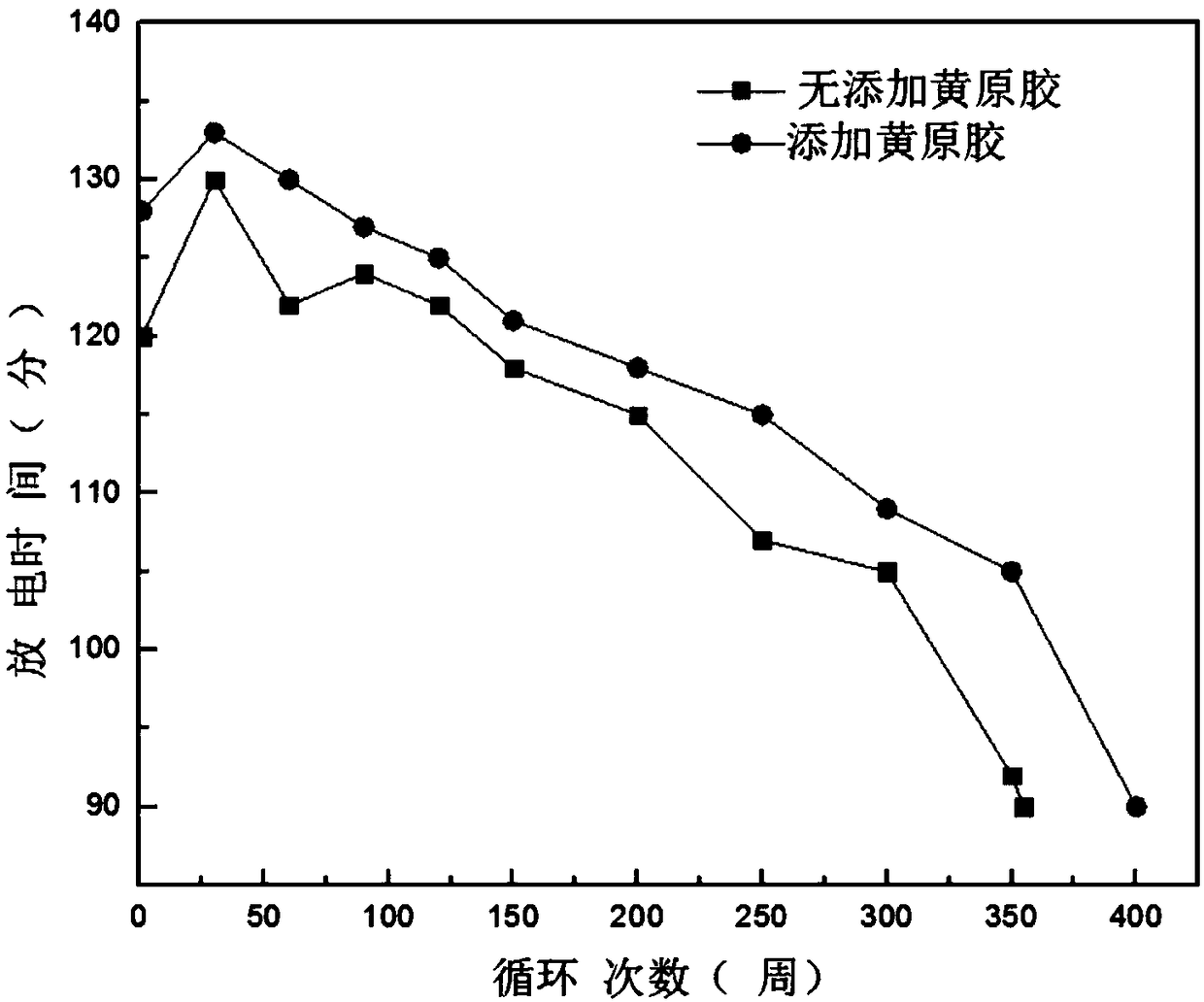

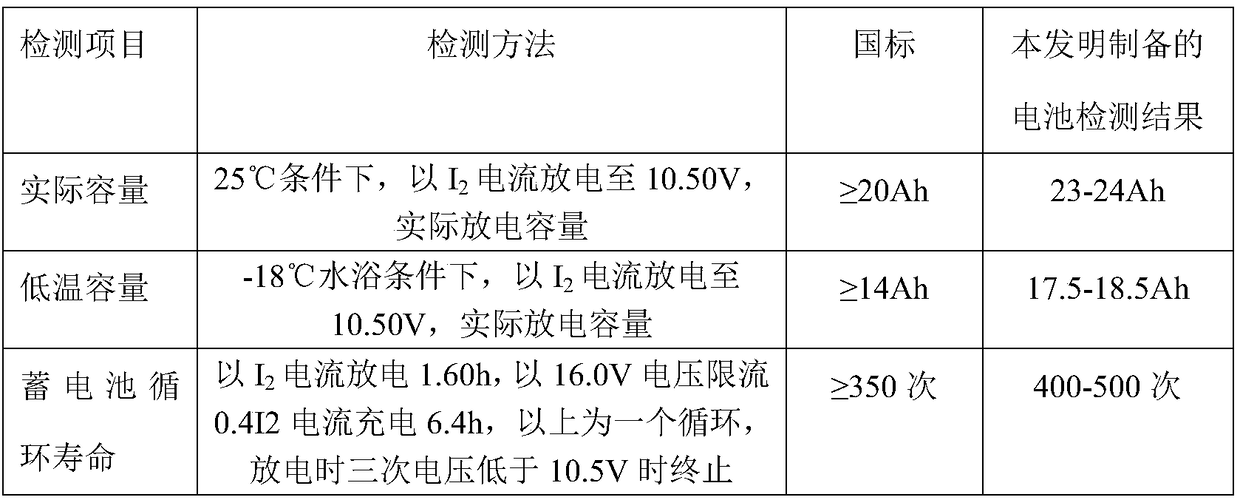

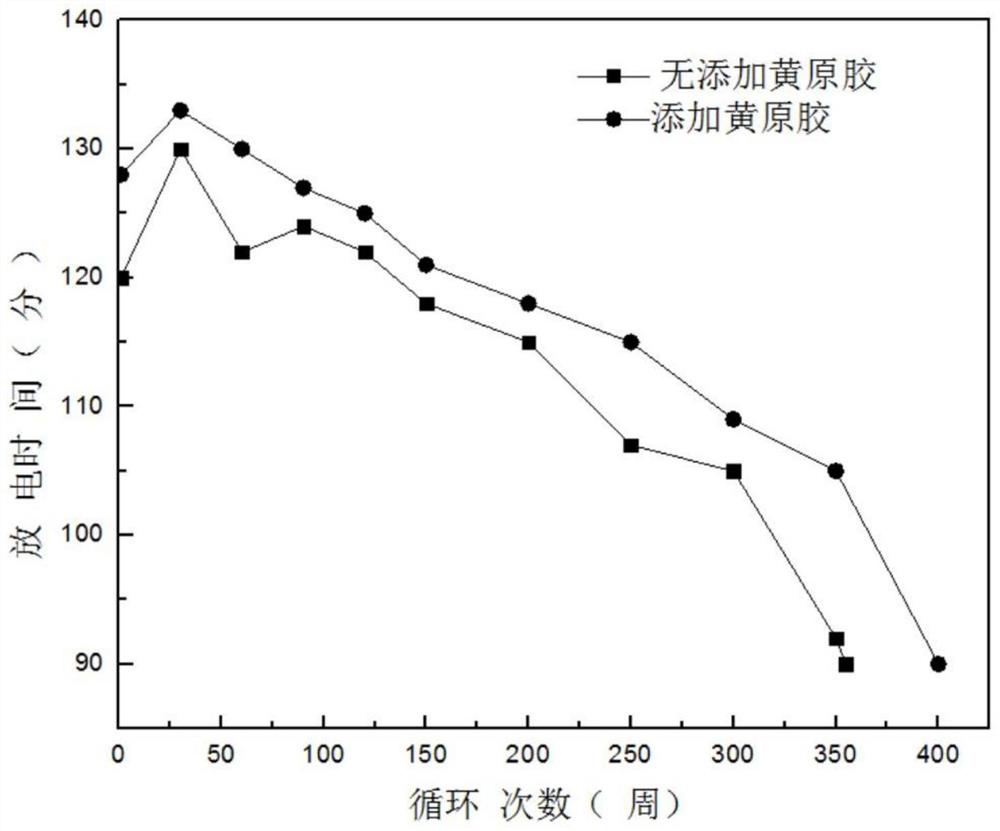

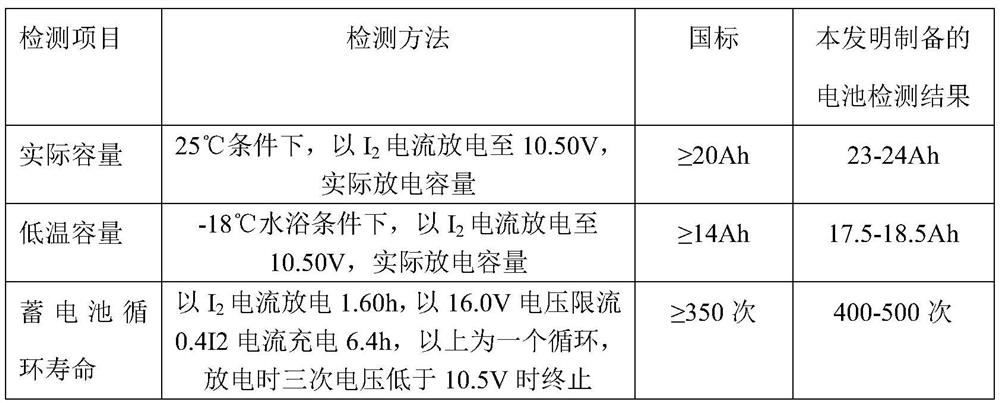

Lead-acid storage battery positive lead paste

The invention discloses a lead-acid storage battery positive lead paste. The lead-acid storage battery positive lead paste is prepared from the following raw materials in parts by weight: 70-90 partsof lead powder, 3-15 parts of sulfuric acid, 5-20 parts of water, 0.05-1 part of short fiber, 0.05-0.5 part of graphite and 0.05-0.5 part of xanthan gum. A lead-acid storage battery prepared by usingthe positive lead paste is high in initial capacity, slow in attenuation and long in cycle life, has strong large current discharge and low temperature charge and discharge performance, and ensures that the combination performance of the lead paste and a grid is significantly improved; and the problems of low initial capacity, short cycle life, easy falling off of active materials and the like inexisting lead-acid storage batteries can be effectively solved.

Owner:HENAN CHILWEE GENSHORE POWER

Yttrium-containing rare earth polishing solution and preparation method thereof

The invention discloses a yttrium-containing rare earth polishing solution. The yttrium-containing rare earth polishing solution comprises the following components by mass percentage: 10-50% of yttrium-containing rare earth polishing powder, 0.3%-1.5% of a dispersing agent, 0.5%-3% of an anti-hardening agent, 0.2%-5% of a synergist and the balance of a solvent; and a PH value of the polishing solution is 7.5-9.5. The yttrium-containing rare earth polishing solution, as a grinding material, is mainly used for polishing glass of a cover plate of a mobile phone and other optical lenses.

Owner:甘肃稀土新材料股份有限公司

Method of preparing clay/rubber nano composite by slurry blending

ActiveCN107151335AReduce water consumptionReduce raw material costsNanometreEnvironmentally friendly

The invention relates to a method of preparing a clay / rubber nano composite by slurry blending in the technical field of rubber products. The method comprises the steps of preparing clay slurry by mixing clay and water, mixing the clay slurry and rubber by mechanical blending, drying to form a clay / rubber compound, adding other rubber ingredients into the clay / rubber compound by the mechanical blending, and finally obtaining the clay / rubber nano composite by vulcanization. The preparation method of the clay / rubber nano composite is simple in technology, low in water consumption, low in cost, and environmentally friendly, and does not involve organic modification of the clay; the prepared clay / rubber nano composite has excellent mechanical properties; the clay has good dispersion in a rubber matrix.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

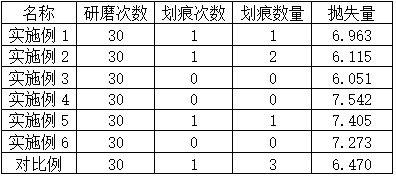

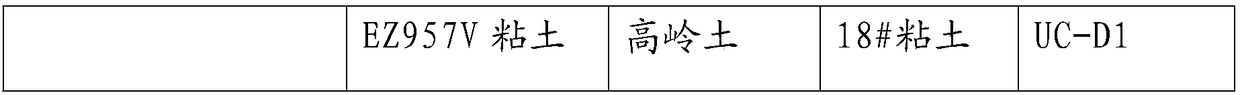

Adhesive for dye-sublimation transfer printing, and synthesis process thereof

InactiveCN106566449AImprove adhesionImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistanceAdhesive

The invention discloses an adhesive for dye-sublimation transfer printing, and a synthesis process thereof. The adhesive comprises the following components in parts by weight: 40-60 parts of bisphenol-A epoxy resin, 10-20 parts of polyurethane resin, 3-8 parts of flexibilizer, 3-8 parts of sodium acrylate, 3-10 parts of glycerol, 5-12 parts of ethylene-vinlacetate copolymer, 5-12 parts of oil-absorbing filler, 3-8 parts of organic bentonite, 4-10 parts of kaolin, 2-8 parts of antioxidant, 5-15 parts of ethylene glycol and 1-4 parts of nano-silicon dioxide. The preparation method disclosed by the invention is simple, and environment-friendly and pollution-free in preparation process; and the prepared adhesive is high in adhesion force, and excellent in high-temperature resistance and scratch resistance.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

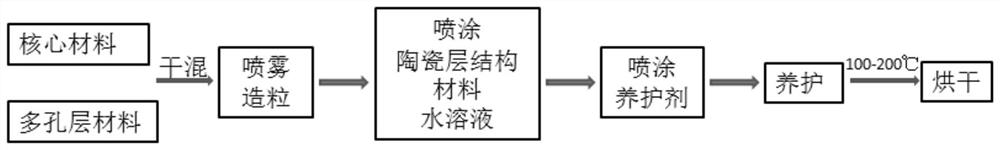

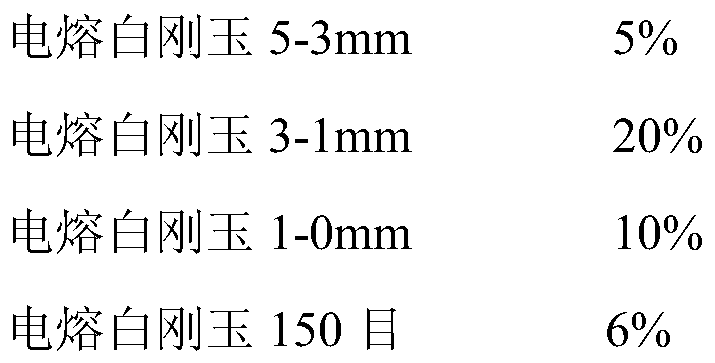

Gypsum-based plastering mortar composition

PendingCN114644498AProduct performance is stableGood construction performanceSolid waste managementGypsumCellulose

The invention belongs to the field of material preparation, and discloses a gypsum-based plastering mortar composition. The mortar composition comprises aggregate, sand, desulfurized gypsum powder, cellulose ether and auxiliaries, wherein the aggregate comprises a core material, a porous layer material and a ceramic layer structure material. The aggregate used by the gypsum-based plastering mortar composition is of a core-porous layer-ceramic layer structure, and the product performance is stable, so that the mortar composition has good construction performance.

Owner:东方雨虹砂粉科技集团有限公司

Composite chemical slurry material and preparation method thereof

The invention discloses a composite chemical slurry material. The composite chemical slurry material comprises clay and chemical slurry. The chemical slurry comprises sesbania gum, pregelatinized starch, xanthan gum, borax, sodium hydroxide and preservatives. The composite chemical slurry material has the advantages that by the composite chemical slurry material and a preparation method thereof, bentonite slurrying can be replaced, cost is low, water loss rate is extremely low, and requirements of constructors are met.

Owner:河北金丰新材料科技有限公司

Coating for metal mold casting of magnesium alloy thin-wall parts

ActiveCN102806306BImprove insulation effectHigh fire resistanceFoundry mouldsFoundry coresSodium BentoniteAlcohol

The invention discloses a coating for a metal mold casting of magnesium alloy thin-wall parts, wherein the coating consists of following components, by weight percent, 1.5 to 2.5% of diatomaceous earth, 2 to 3% of magnesia powder, 1.2 to 1.8% of titanium dioxide powder, 1 to 2% of zircon powder, 1.5 to 2.5% of bentonite, 2 to 4% of asbestos powder, 1.2 to 1.4% of silica sol and the balance of alcohol.

Owner:南京锐迈涂料科技有限公司

Low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and method thereof

The invention provides a low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and a method thereof, which belong to the technical field of deep processing of poultry. The low-fat health care chicken sausage prepared by utilizing the compound hydrophilic gel and the chicken skin to substitute the fat is characterized in that the chicken sausage takes chicken and the chicken skin as main raw materials; and auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, enema exhaust, reaction, drying and boiling. The chicken sausage has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the decrease of the quality caused by low fat. At the same time, serial low-fat health care chicken sausage products with various tastes and various nutritions can also be developed based on the low-fat chicken sausage.

Owner:FUZHOU UNIV

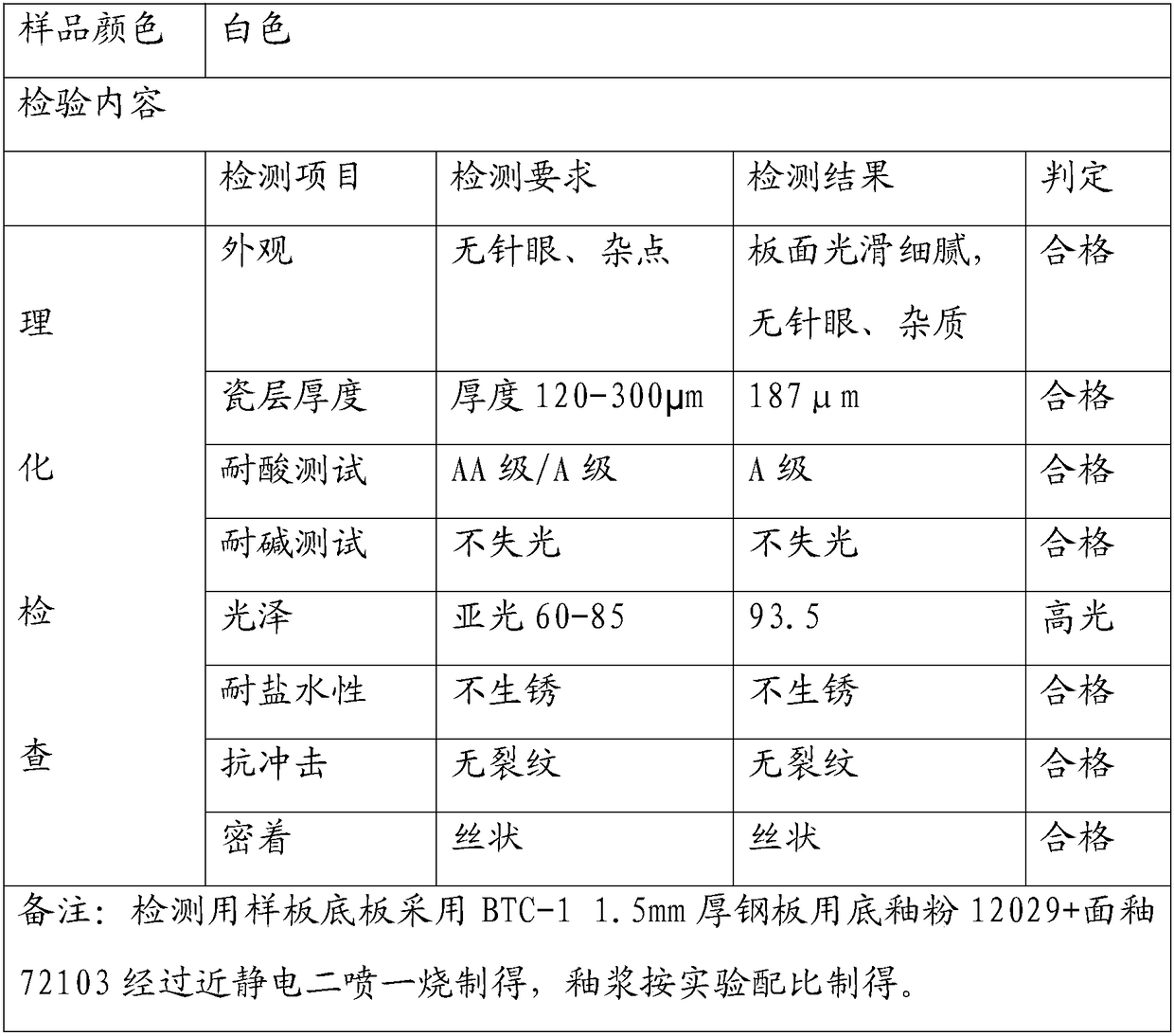

Enamel suspending agent and enamel steel plate with enamel suspending agent

The invention discloses an enamel suspending agent and an enamel steel plate with the enamel suspending agent. The enamel suspending agent is prepared from the following components in parts by weight:7.5 to 8.5 parts of a base material, 0.2 to 0.5 part of electrolyte and 40 to 50 parts of a solvent. The enamel suspending agent disclosed by the invention has the characteristics of good dispersity,high suspending rate, good dispersity in water, small particles, great surface activity, strong penetrability, no dust in a preparation process, low cost and the like; water is used as a dispersion medium and the problem that toxic and harmful substances are easily generated by an organic solvent is not caused; after the water is added to dilute the components, the suspension property is good andthe physical stability of glaze slurry can reach the optimal effect. After the enamel suspending agent disclosed by the invention and pure titanium glaze are uniformly mixed, a mixture is ground to prepare the glaze slurry; then the glaze slurry is sprayed on an enamel plate block and then the enamel plate block is fired to prepare the enamel steel plate; all performances of the prepared enamel steel plate can meet standard requirements and the construction performance is good.

Owner:ZHEJIANG KAIER NEW MATERIALS

Biotrickling filter for treating volatile organic waste gas

InactiveCN100500269CEvenly distributedMake full use of effective spaceDispersed particle separationAir quality improvementVoltage dropNutrient solution

The present invention relates to a BTF used for dealing with the volatile waste gas, belonging to the field of treatment of the volatile waste gas, which aims at solving the problems that the prior BTF has uneven air flow distribution and biomass distribution, high center gas speed and voltage drop, and the prior BTF is easy to be blocked. The technic proposal is that: the volatile waste gas passes through an intake pipe (1) and then comes into a biofilter (22), and then being drained away by an exhaust pipe (9) after having the processes of degradation and purification; a nutrient solution (11) comes into the biofilter (22) through a nutrient solution shower (18) and a dropwise adding distributor device (19) having fixed quantities at fixed time; the present invention is characterized in that adopting a light and cheap packing (4) with different grain diameters, the biofilter (22) takes a homocentric column shape sleeve structure , the grain diameters of the filled packing (4) from the center to the edge are distributed from small to big, the centre area is filled with the packing (4) with small grain diameters, the ring area of the around close walls is filled with the packing (4) of big grain diameters. The present invention makes the distribution of the biomass in the biofilter even, thereby fully utilizing the useful space of the biofilter.

Owner:BEIJING UNIV OF TECH

A kind of positive lead paste of lead-acid storage battery

ActiveCN108400304BImprove cycle lifeSuspendingLead-acid accumulatorsCell electrodesFiberPhysical chemistry

Owner:HENAN CHILWEE GENSHORE POWER

Coating for metal mold casting of magnesium alloy thin-wall parts

ActiveCN102806306AImprove insulation effectHigh fire resistanceFoundry mouldsFoundry coresAlcoholMetal mold

The invention discloses a coating for a metal mold casting of magnesium alloy thin-wall parts, wherein the coating consists of following components, by weight percent, 1.5 to 2.5% of diatomaceous earth, 2 to 3% of magnesia powder, 1.2 to 1.8% of titanium dioxide powder, 1 to 2% of zircon powder, 1.5 to 2.5% of bentonite, 2 to 4% of asbestos powder, 1.2 to 1.4% of silica sol and the balance of alcohol.

Owner:南京锐迈涂料科技有限公司

Novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials and preparation method thereof

The invention provides a novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials, which belongs to the technical field of deep processing of poultry. The novel chicken block taking the hydrophilic compound gel and the soybean protein as the functional auxiliary materials takes chicken and chicken skin as main raw materials; and the auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, molding, reaction, rebaking, tabletting, battering and breading, and frying. The novel chicken block has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the quality of products produced by chicken raw materials. At the same time, serial chicken block products with various tastes and various nutritions can also be developed based on the novel chicken block.

Owner:FUZHOU UNIV

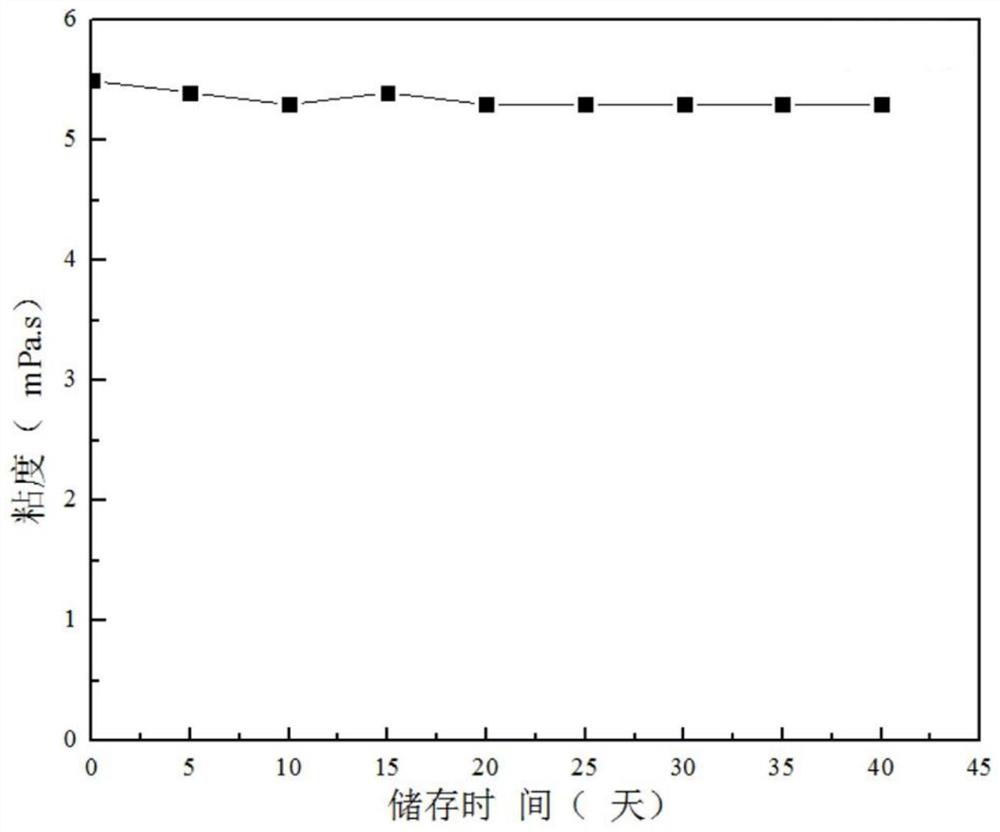

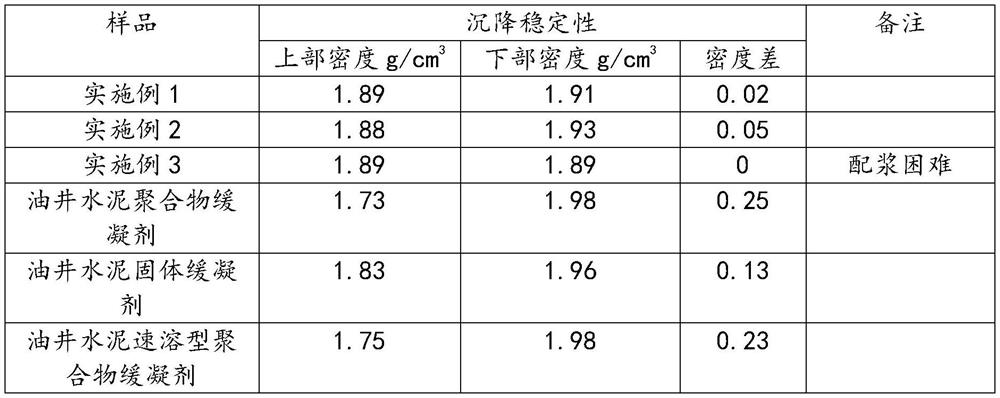

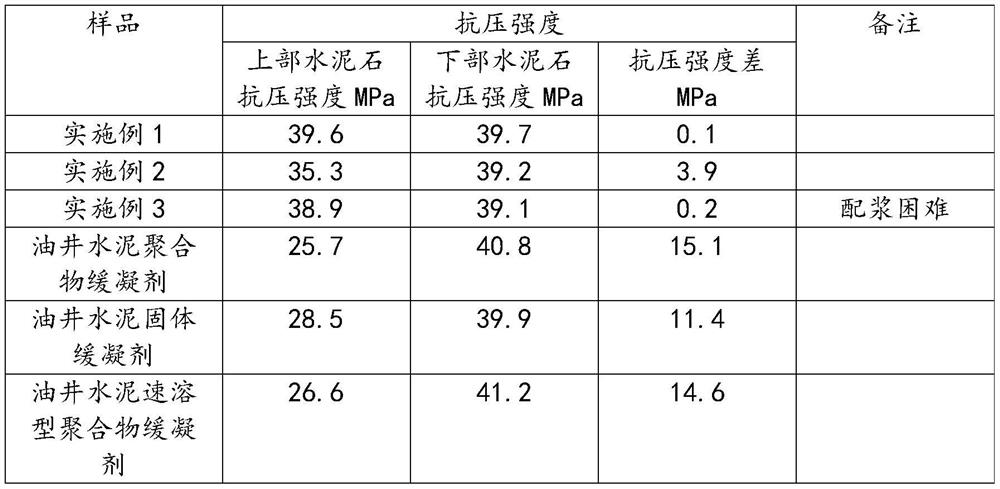

A kind of oil well cement suspension type polymer retarder and preparation method and oil well cement slurry system

The invention discloses an oil well cement suspended polymer retarder, a preparation method and an oil well cement slurry system. The oil well cement suspended polymer retarder consists of the following components: 2-acrylamide-2-methylpropanesulfonic acid, Itaconic acid, isopropanol, high-viscosity carboxymethylcellulose sodium salt (HV-CMC) for drilling fluid, 40 wt% sodium hydroxide aqueous solution, deionized water, sodium persulfate and sodium sulfite. The oil well cement slurry system is composed of basic formula cement slurry and oil well cement suspension polymer retarder. The basic formula cement slurry is composed of the following components: G grade high sulfate-resistant oil well cement 600 parts by weight + quartz sand 210 parts by weight + 42 parts by weight of G310 + 24 parts by weight of oil well cement polymer retarder + 312 parts by weight of tap water. The oil well cement suspension type polymer retarder of the present invention has the characteristics of suspension and has a wide range of applications; it can ensure the stability of the cement slurry, ensure that the cement stone has a small density difference between the upper and lower parts during the solidification process, and has good strength consistency, ensuring Cementing quality.

Owner:卫辉市化工有限公司

High-strength, high-purity, low-silicon corundum brick for petrochemical industry and preparation method thereof

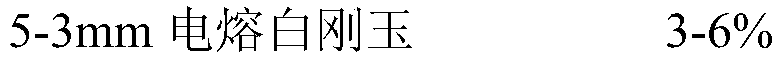

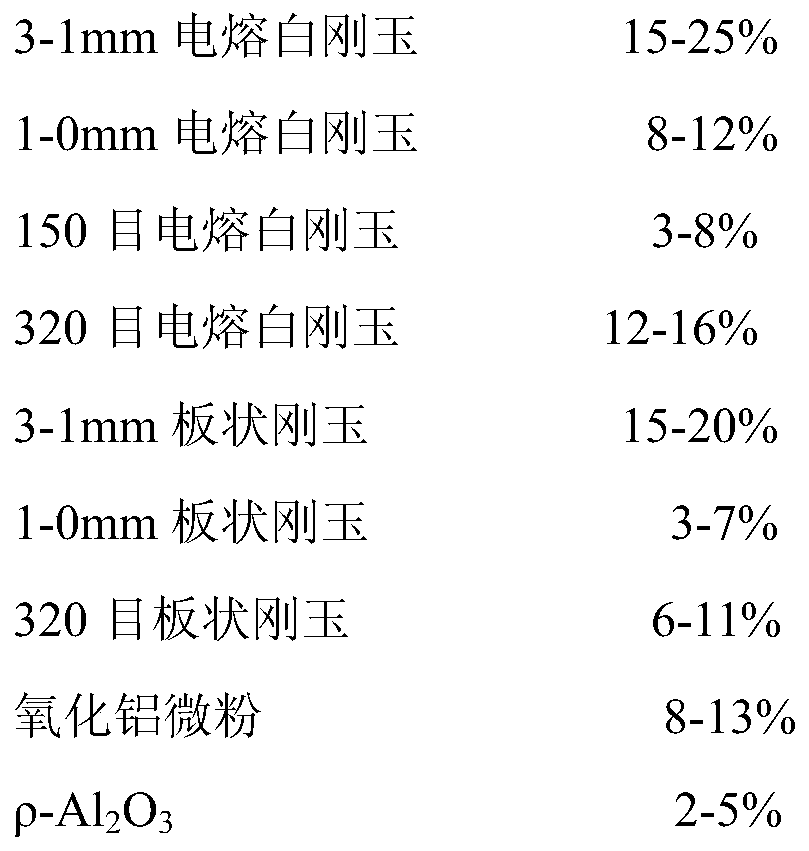

The invention discloses a high-strength, high-purity and low-silicon corundum brick for a petrochemical industry. The corundum brick comprises the following components in percentage by weight: 3-6% of 5-3 mm white fused corundum, 15-25% of 3-1 mm white fused corundum, 8-12% of 1-0 mm white fused corundum, 3-8% of 150-mesh white fused corundum, 12-16% of 320-mesh white fused corundum, 15-20% of 3-1 mm tabular corundum, 3-7% of 1-0 mm tabular corundum, 6-11% of 320-mesh tabular corundum, 8-13% of micro alumina powder and 2-5% of rho-Al2O3, wherein the total amount of the components is 100%, and the weight of aluminium collosol accounts for 6-13% of the total weight of the components. The invention further discloses a preparation method for the high-strength, high-purity and low-silicon corundum brick for the petrochemical industry. The high-strength, high-purity and low-silicon corundum brick has the characteristics of being low in firing temperature, low in impurity content, high in strength, and excellent in high-temperature property.

Owner:宜兴瑞泰耐火材料有限公司 +1

Preparation method of dope for metal type casting of magnesium alloy thin-walled component

ActiveCN102806305BImprove insulation effectHigh fire resistanceFoundry mouldsFoundry coresSodium BentoniteAlcohol

The invention discloses a preparation method of a dope for metal type casting of a magnesium alloy thin-walled component. The dope comprises the following components in percentage by weight: 1.5 to 2.5 percent of kieselguhr, 2 to 3 percent of magnesium oxide powder, 1.2 to 1.8 percent of titanium dioxide powder, 1 to 2 percent of zirconite powder, 1.5 to 2.5 percent of bentonite, 2 to 4 percent of asbestos powder, 1.2 to 1.4 percent of silica sol and the balance of alcohol. The preparation method comprises the following steps of 1) weighing the materials according to the proportion; 2) taking 30 percent of the total alcohol, adding the bentonite into the alcohol, stirring until the bentonite is suspended, sequentially adding the magnesium oxide powder, the titanium dioxide powder and the zirconite powder into the suspension, and stirring the suspension for about 15 to 25 minutes to uniformly mix the materials and obtain a mixture I; 3) mixing and stirring the kieselguhr, the asbestos powder and the silica sol for about 10 to 20 minutes, adding 20 percent of the total alcohol into the mixture, and stirring the materials for about 5 to 15 minutes to uniformly mix the materials and obtain a mixture II; and 4) mixing the mixture I, the mixture II and 50 percent of residual alcohol, and stirring the materials for about 20 to 30 minutes to obtain the dope.

Owner:临泉县卡天下电子商务有限公司

A method for preparing clay/rubber nanocomposites by slurry blending

The invention relates to a method for preparing a clay / rubber nanocomposite material by slurry blending in the technical field of rubber products. Clay is first mixed with water to prepare a clay slurry, the clay slurry is mixed with rubber by mechanical blending, and then dried to obtain a clay / rubber compound; subsequently, other rubber additives are added to the clay / rubber compound by mechanical blending Middle; Finally, clay / rubber nanocomposites were obtained by vulcanization. The preparation method of the clay / rubber nanocomposite material provided by the present invention is simple in process, does not involve clay organic modification, has less water consumption, low cost, and is green and environmentally friendly. The prepared clay / rubber nanocomposite material is dispersed in the rubber matrix Well, composites have excellent mechanical properties.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Gypsum-based self-leveling mortar composition

ActiveCN114436612AEasy constructionImprove performanceSolid waste managementCeramicwareMaterials preparationGypsum

The invention belongs to the field of material preparation, and discloses a gypsum-based self-leveling mortar composition. The mortar composition comprises aggregate, sand, desulfurized gypsum powder, cement and auxiliaries, wherein the aggregate comprises a core material, a porous layer material and a ceramic layer structure material. The aggregate used by the gypsum-based self-leveling mortar composition is of a core-porous layer-ceramic layer structure, and the product performance is stable, so that the mortar composition has good construction performance.

Owner:东方雨虹砂粉科技集团有限公司

A kind of low density oil well cement

ActiveCN106866086BImprove early strengthThickening time adjustableDrilling compositionWell cementingLow density

Belonging to the technical field of oil-gas well cementing, the invention discloses a low-density oil well cement. The oil well cement comprises the following raw materials by weight percentage: 82-90% of cement clinker, 1-8% of gypsum, 5-10% of hollow glass beads, 0-0.3% of a dispersant, and 0.5-0.8% of a retarder. The cement clinker is one of sulphate aluminium cement clinker and high belite sulphoaluminate cement clinker. The sulphate aluminium cement clinker has a specific surface area of 470-520cm<2> / g; and the content of anhydrous calcium sulfoaluminate C4A3Sbar in the sulphate aluminium cement clinker is 50-75%. The cement provided by the invention is mainly used for offshore drilling operations of shallow strata, has high early strength and long thickening time, and can meet the requirements of pressure stability before cementing, during cementing and after cementing.

Owner:JIAHUA SPECIAL CEMENT

A kind of powder fertilizer additive and its application

The invention provides a powder fertilizer additive, which is characterized in that it consists of the following parts by weight: 50-75 parts of sulfonated melamine formaldehyde condensate, 25-30 parts of naphthalene sulfonate, 15-20 parts of tannin, humic acid 5-10 parts of salt. The composition is a powder fertilizer additive obtained by weighing, mixing, miniaturization, and passing through a 50-mesh sieve. It is applied to powder fertilizers to promote the dissolution and dispersion of powder fertilizers in water, and can also be applied to powder fertilizers during storage. Long-term prevention of moisture absorption and compaction of fertilizers; during drip irrigation of fertilizers, it can promote the dissolution of fine particles of powder fertilizers to avoid agglomeration, wrapping, and agglomeration, which can effectively reduce viscosity and weaken the interaction between fertilizer particles. The powder fertilizer treated with additives can be directly dispersed in water, and is suitable for water-soluble irrigation fertilizer, drip irrigation fertilizer, and flushing fertilization.

Owner:南宁汉和生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com