Organic-inorganic compound sewage treatment agent and preparation method thereof

A sewage treatment agent and inorganic composite technology, applied in the direction of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of easy powder aggregation, long process flow, high operating cost, etc., and achieve simplified sewage treatment process , The preparation process is simple, and the effect of high-efficiency treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

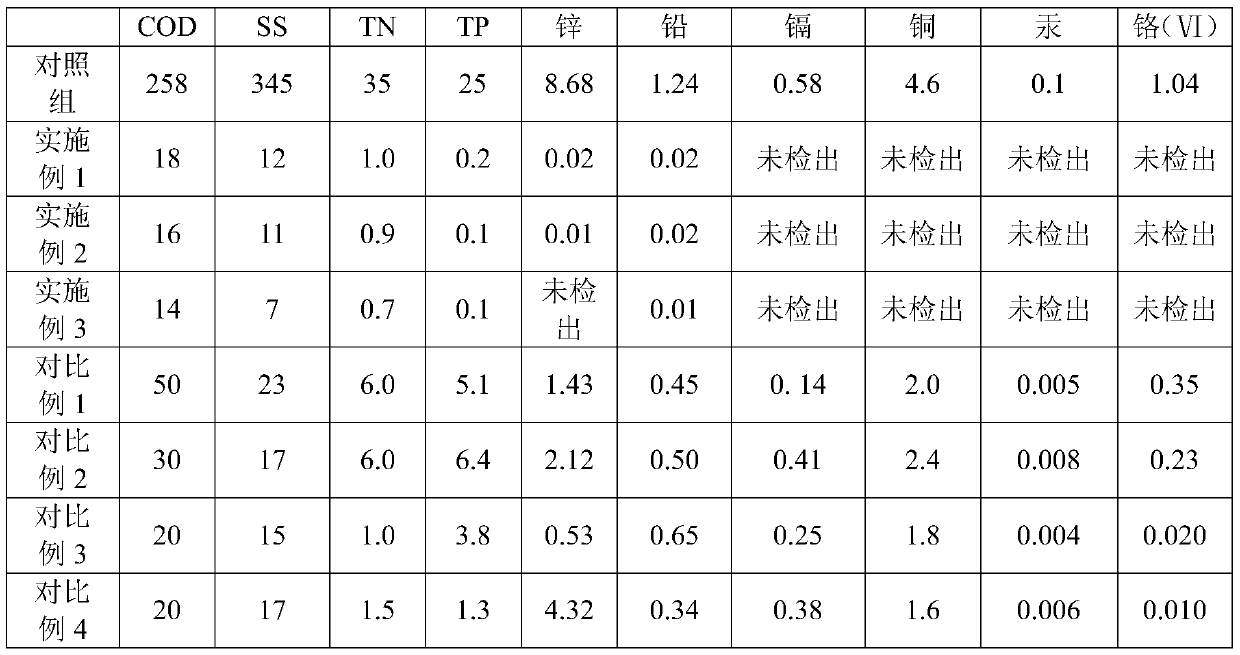

Examples

Embodiment 1

[0043] An organic-inorganic composite sewage treatment agent is prepared from the following raw materials in parts by weight: 6 parts of gelatin, 9 parts of cysteine, 9 parts of thioglycolic acid, 20 parts of sodium lignosulfonate, and 22 parts of carboxymethyl Chitosan, 12 parts of urea, 25 parts of limestone, 14 parts of sepiolite, 28 parts of bentonite, 50 parts of fly ash, 24 parts of quicklime, 13 parts of medical stone, 13 parts of aluminum sulfate, 15 parts of ferric chloride and 12 parts polyethyleneiminoxanthic acid.

[0044] Specific steps are as follows:

[0045] (1) Preparation of gelatin complex solution:

[0046] Add the gelatin in said parts by weight into a certain amount of deionized water, heat and dissolve at 55° C. to obtain a 5% gelatin solution, add a mixed solution of cysteine and thioglycolic acid dropwise to it and stir for 0.5 h, Obtain a gelatin complex solution for use, wherein the mass percent concentration of cysteine and thioglycolic acid i...

Embodiment 2

[0054] An organic-inorganic composite sewage treatment agent is prepared from the following raw materials in parts by weight: 7 parts of gelatin, 16.5 parts of cysteine, 16.5 parts of thioglycolic acid, 22 parts of sodium lignosulfonate, 24 parts of carboxymethyl Chitosan, 12.5 parts of urea, 26 parts of limestone, 15 parts of sepiolite, 29 parts of bentonite, 55 parts of fly ash, 26 parts of quicklime, 14 parts of medical stone, 14 parts of aluminum sulfate, 16 parts of ferric chloride and 13 parts parts polyethyleneiminoxanthic acid.

[0055] Specific steps are as follows:

[0056] (1) Preparation of gelatin complex solution:

[0057] Add the gelatin in said parts by weight to a certain amount of deionized water, heat and dissolve at 65°C to obtain a gelatin solution with a concentration of 12.5% by mass, and add the mixed solution of cysteine and thioglycolic acid dropwise to it and stir React for 75 minutes to obtain a gelatin complex solution, ready to use, wherein ...

Embodiment 3

[0065] An organic-inorganic composite sewage treatment agent is prepared from the following raw materials in parts by weight: 8 parts of gelatin, 24 parts of cysteine, 24 parts of thioglycolic acid, 24 parts of sodium lignosulfonate, 26 parts of carboxymethyl Chitosan, 13 parts of urea, 27 parts of limestone, 16 parts of sepiolite, 30 parts of bentonite, 60 parts of fly ash, 28 parts of quicklime, 15 parts of medical stone, 15 parts of aluminum sulfate, 17 parts of ferric chloride and 14 parts parts polyethyleneiminoxanthic acid.

[0066] Specific steps are as follows:

[0067] (1) Preparation of gelatin complex solution:

[0068] Add the gelatin in said parts by weight into a certain amount of deionized water, heat and dissolve at 75°C to obtain a 20% gelatin solution, add a mixed solution of cysteine and thioglycolic acid dropwise to it and stir for 1 hour to obtain gelatin The complex solution is ready for use, wherein the mass percent concentration of cysteine and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com