Rare-earth polishing powder and preparation method thereof

A rare earth polishing powder, lanthanum cerium carbonate technology, applied in chemical instruments and methods, polishing compositions containing abrasives, other chemical processes, etc., can solve the problem of low particle dispersibility, prone to agglomeration, and inability to maintain dispersion maintenance. and other problems, to achieve the effect of good suspension, high polishing accuracy and fast polishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

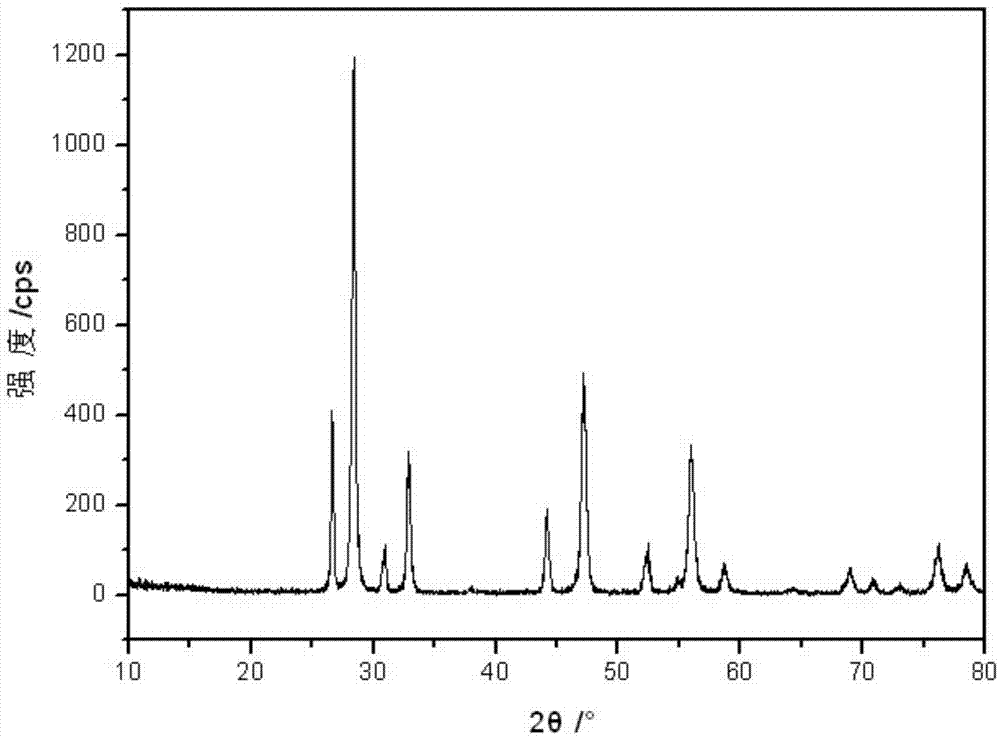

[0038] With 1000kg lanthanum cerium carbonate (REO is 45%, CeO 2 / TREO is 65%) mixed with 1000kg water, heated to 60°C, 80kg of 20% hydrofluoric acid is added dropwise, adjusted to pH 6.5 with 10% ammonium bicarbonate aqueous solution after the dropwise addition, kept for 1 hour, and dehydrated by centrifugation , Calcined at 900°C for 6h to obtain 450kg of calcined product. Mix 450kg of the roasted product with 2.28kg of citric acid and 4.56kg of magnesium oxide through a mixer, then air-jet milling, and dry-classify to D50 as D 50 =0.81μm, XRD results see figure 1 .

Embodiment 2

[0040] With 1000kg lanthanum cerium carbonate (REO is 50%, CeO 2 / TREO is 60%) mixed with 1000kg of water, heated to 80°C, 120kg of 20% hydrofluoric acid is added dropwise, after the dropwise addition, the pH is adjusted to 7 with 15% aqueous ammonium bicarbonate solution, kept for 2 hours, and dehydrated by centrifugation , Calcined at 900°C for 6h to obtain 500kg of calcined product. Mix 500kg of roasted product with 5.21kg of citric acid and 15.6kg of magnesium oxide through a mixer, then mechanically pulverize, and dry classify until D50 is D 50 =2.91 μm.

Embodiment 3

[0042] With 1000kg lanthanum cerium carbonate (REO is 50%, CeO 2 / TREO is 70%) mixed with 1000kg of water, heated to 70°C, 100kg of 20% hydrofluoric acid is added dropwise, adjusted to pH 6.8 with 12% ammonium bicarbonate aqueous solution after the dropwise addition, kept for 2 hours, and dehydrated by centrifugation , Calcined at 1000°C for 4h to obtain 500kg of calcined product. Mix 500kg of roasted product with 5.15kg of citric acid and 10.3kg of magnesium oxide through a mixer, then mechanically pulverize, and dry-classify until D50 is D 50 =1.81 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com