Yttrium-containing rare earth polishing solution and preparation method thereof

A technology of yttrium rare earth and polishing fluid, which is applied in the direction of polishing compositions containing abrasives, etc., which can solve the problems of resource backlog, low value of crude yttrium, and inability to form market sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

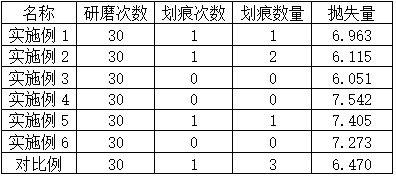

Examples

preparation example Construction

[0020] 1. The preparation of yttrium-containing rare earth polishing powder comprises the following steps:

[0021] Preparation of yttrium-containing rare earth polishing powder precursor, wherein yttrium oxide accounts for the rare earth precursor REO

[0022] 10~40%, the precursor of rare earth polishing powder is one or more mixtures of rare earth oxides, carbonates, sulfates or nitrates;

[0023] Fluorinate the above precursors, control the fluorine content to 0-20% of TREO, and the fluorinating agent is

[0024] One or more mixtures of ammonium bifluoride, silicofluoric acid, hydrofluoric acid, yttrium fluoride, sodium fluoride and ammonium fluoride; after fluorination, dry and calcined, the drying temperature is 200-900°C, and the calcination temperature is 850 ~1100℃;

[0025] The calcined product is crushed and classified, and the particle size of the crushed and classified is required to be D50: 0.5-4.0um,

[0026] D100: 3 ~ 16um.

[0027] 2. Preparation of yttriu...

Embodiment 1

[0033] The rare earth polishing liquid formula of embodiment 1 contains in every 1kg solvent water: containing yttrium rare earth polishing powder (CeO 2 : 10%, Y 2 o 3 : 60%, La 2 o 3 : 30%) 200g, dispersant sodium hexametaphosphate 0.6g, anti-caking agent silica 1.0g, synergist sodium tripolyphosphate and ammonium heptamolybdate 0.2g each, ball mill for 2 hours, ph is 8.5.

Embodiment 2

[0035] The rare earth polishing liquid formula of embodiment 2 contains in every 1kg solvent water: containing yttrium rare earth polishing powder (CeO 2 : 99.8%, Y 2 o 3 : 0.1%, La 2 o 3 : 0.1%) 200g, dispersant sodium hexametaphosphate 0.6g, anti-caking agent silica 1.0g, synergist sodium tripolyphosphate and ammonium heptamolybdate 0.2g each, ball mill for 2 hours, ph is 8.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D5 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com