Patents

Literature

44results about How to "Avoid wall flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stable gas membrane and method used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater

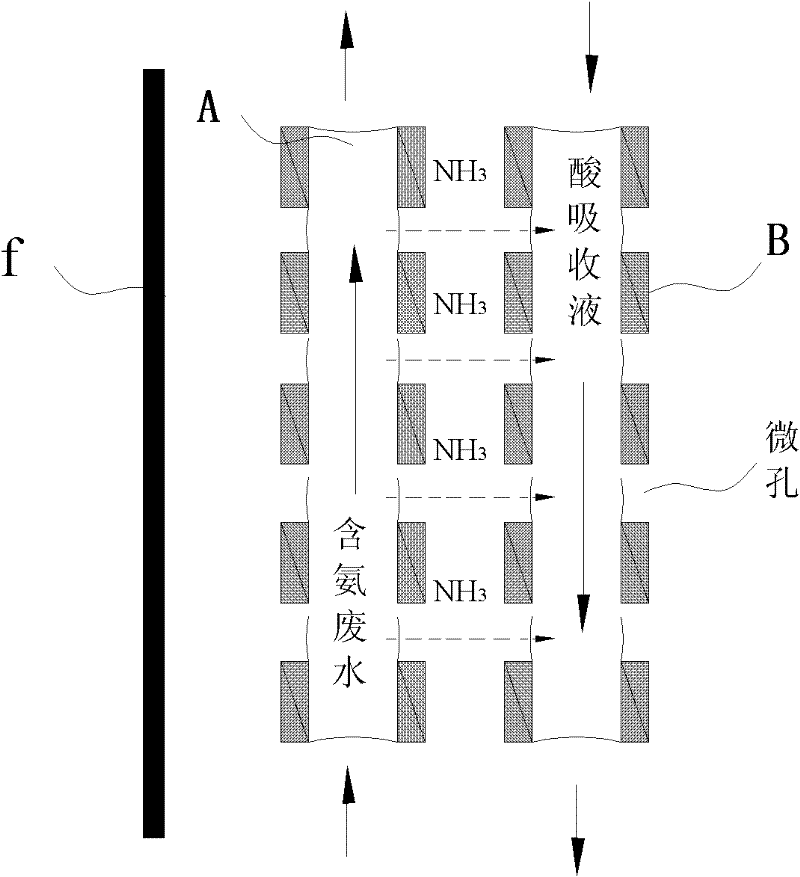

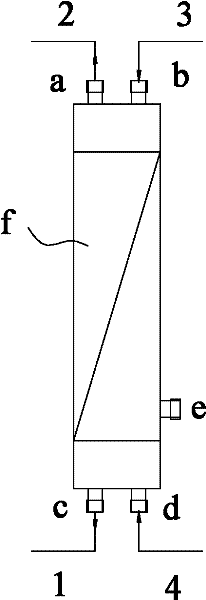

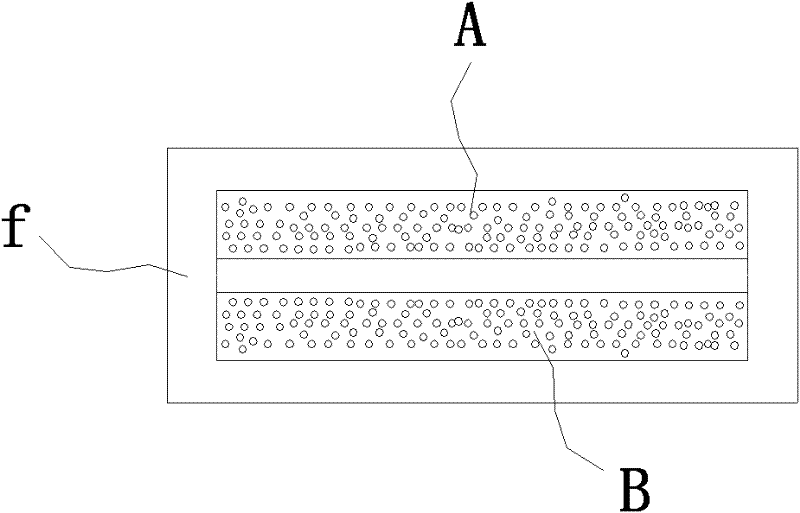

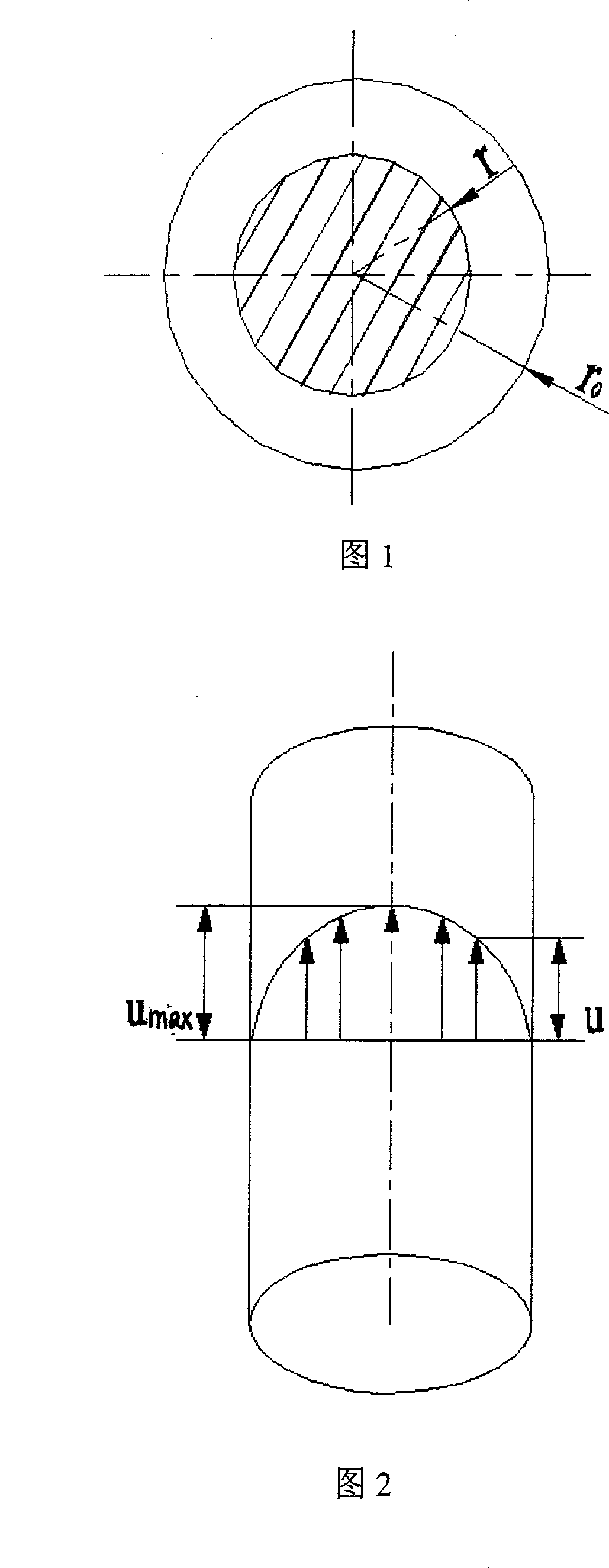

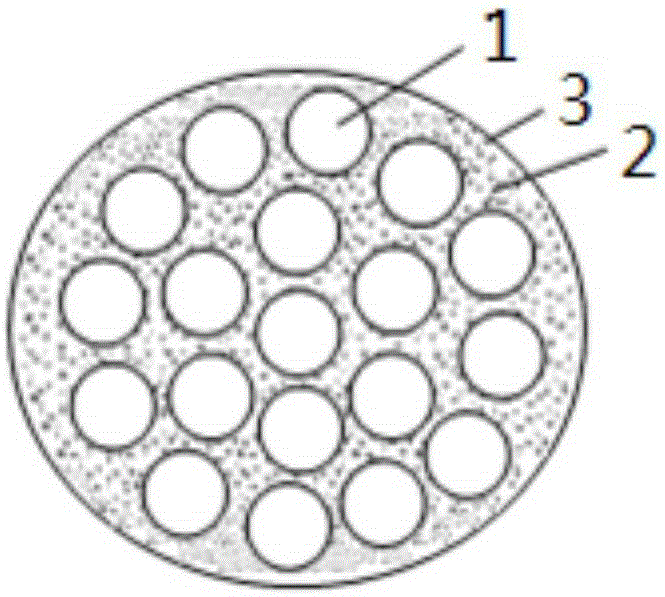

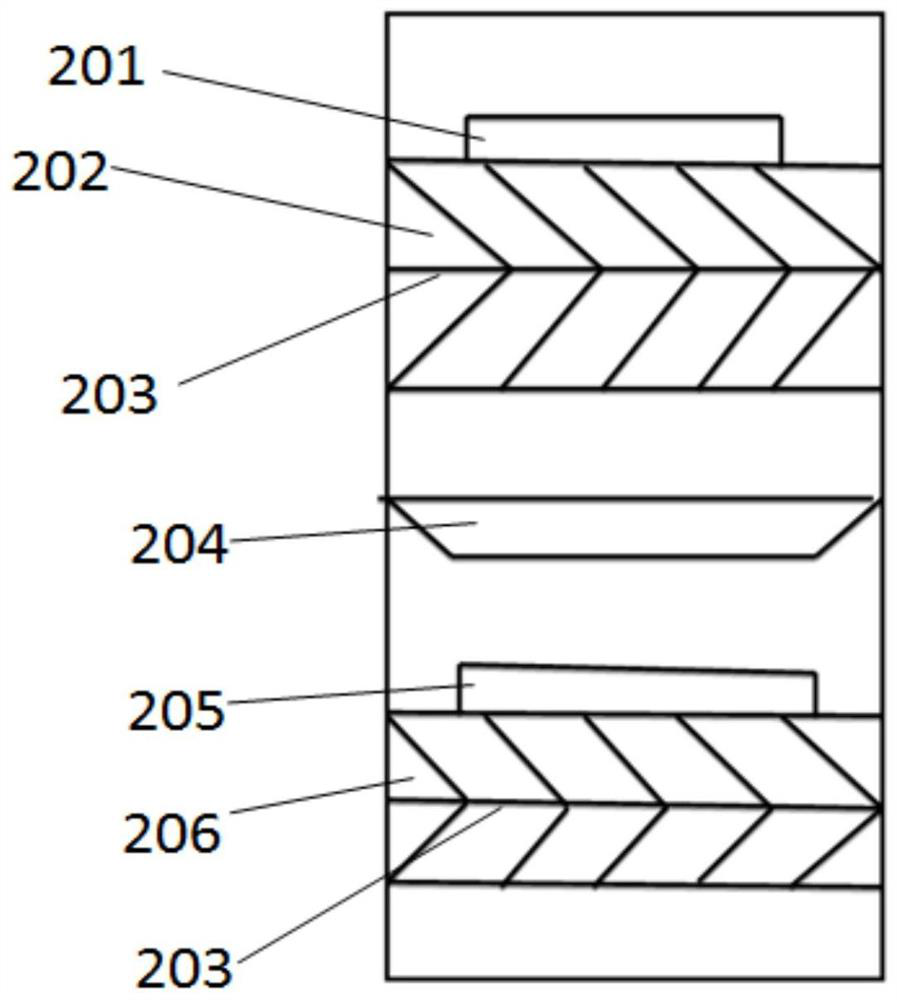

The invention relates to a stable gas membrane used for removing, recovering, and gathering ammonia or organic amine from dosage liquor or wastewater. The gas membrane comprises a membrane shell, hollow fibrous membranes (A) and hollow fibrous membranes (B). A cavity is provided in the middle of the membrane shell. An inlet and an outlet are respectively arranged on each of the two ends of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are positioned in the cavity of the membrane shell. A shell pass outlet communicating with the atmosphere is arranged on a lower end of the membrane shell. The hollow fibrous membranes (A) and the hollow fibrous membranes (B) are uniformly arranged in the membrane shell with regular spaces. Dosage liquor or wastewater containing ammonia or organic amine is delivered through the tube pass of the hollow fibrous membranes (A), and absorption liquid is delivered through the tube pass of the hollow fibrous membranes(B). With the gas membrane provided by the invention, problems of traditional gas membranes of leakage and low service life are overcome; dilution of a byproduct ammonium salt solution caused by a concomitant osmotic distillation phenomenon can be effectively inhibited; ammonium salt concentration of the byproduct ammonium salt solution can be increased from 10-20% to 20-40%; mass transfer coefficient at the acid absorption liquid side can be substantially improved; the ammonia removing efficiency is high; the ammonia removing effect is stable for a long-term; and the service life of membranesets can be improved by 3-10 times than common gas membranes.

Owner:天津凯铂能膜工程技术有限公司

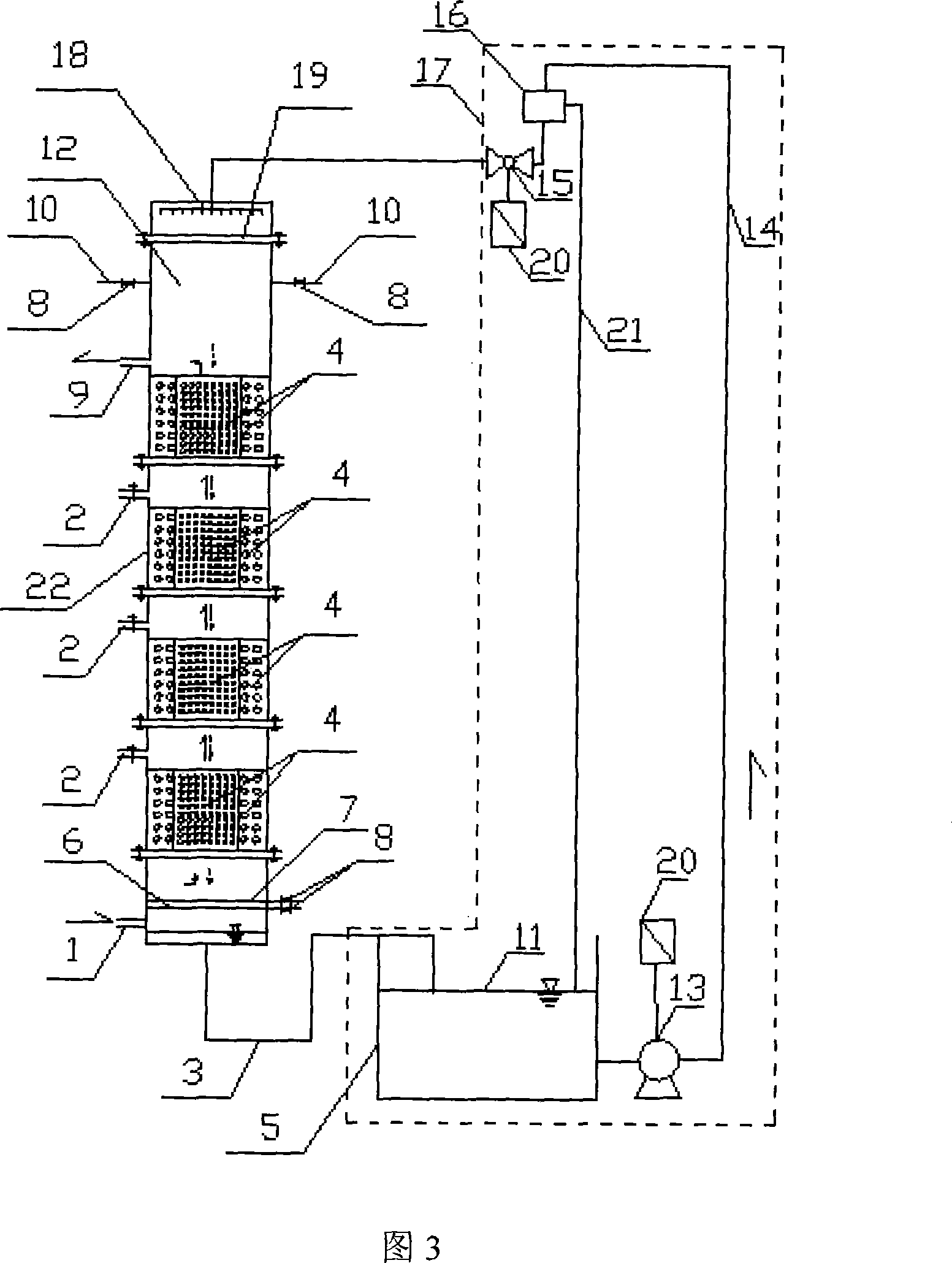

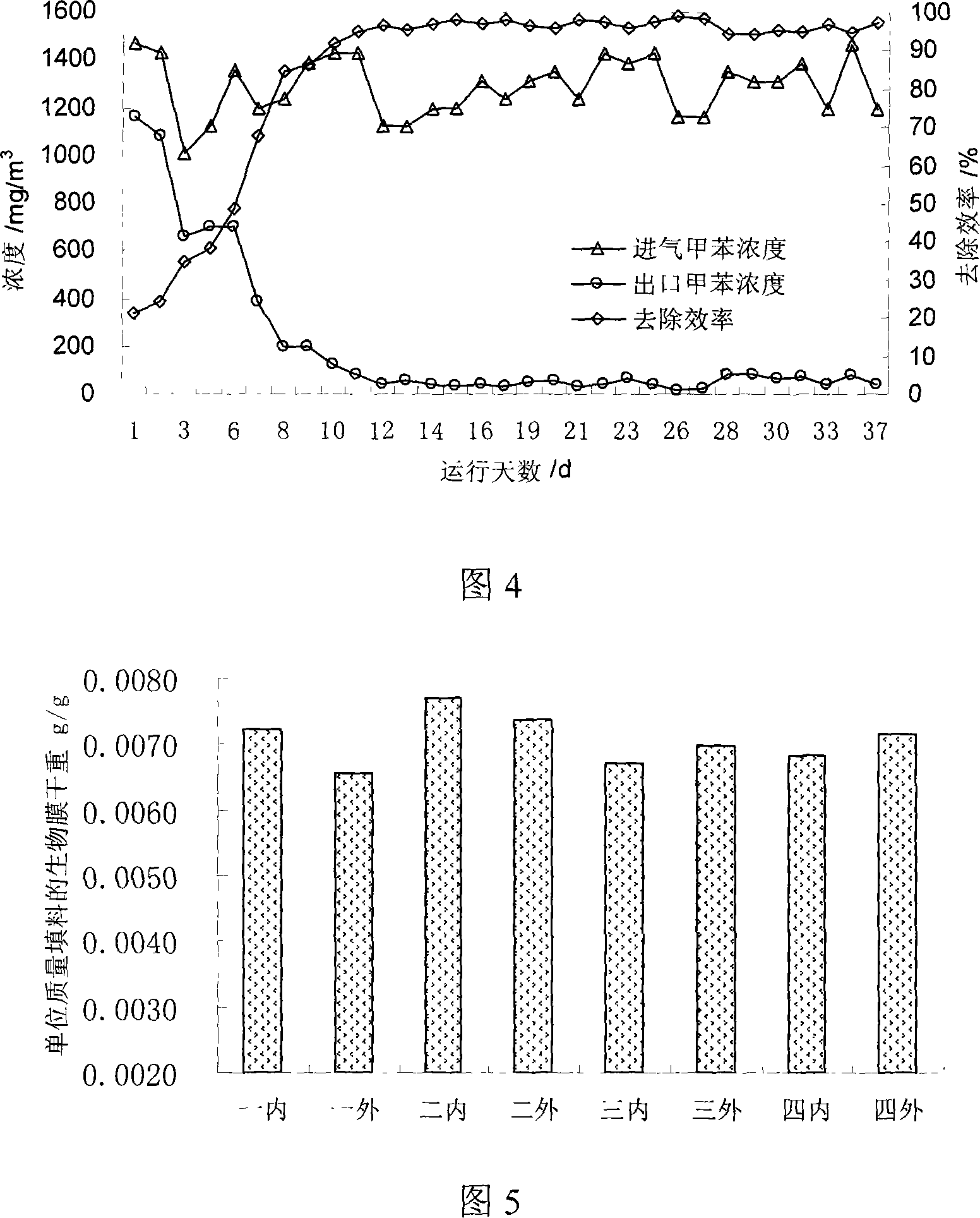

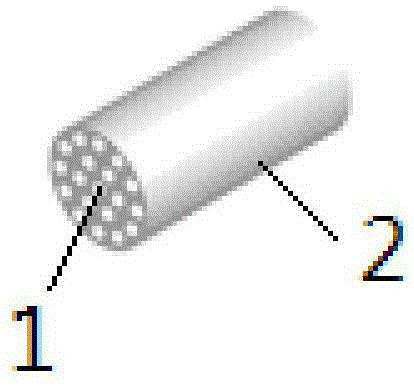

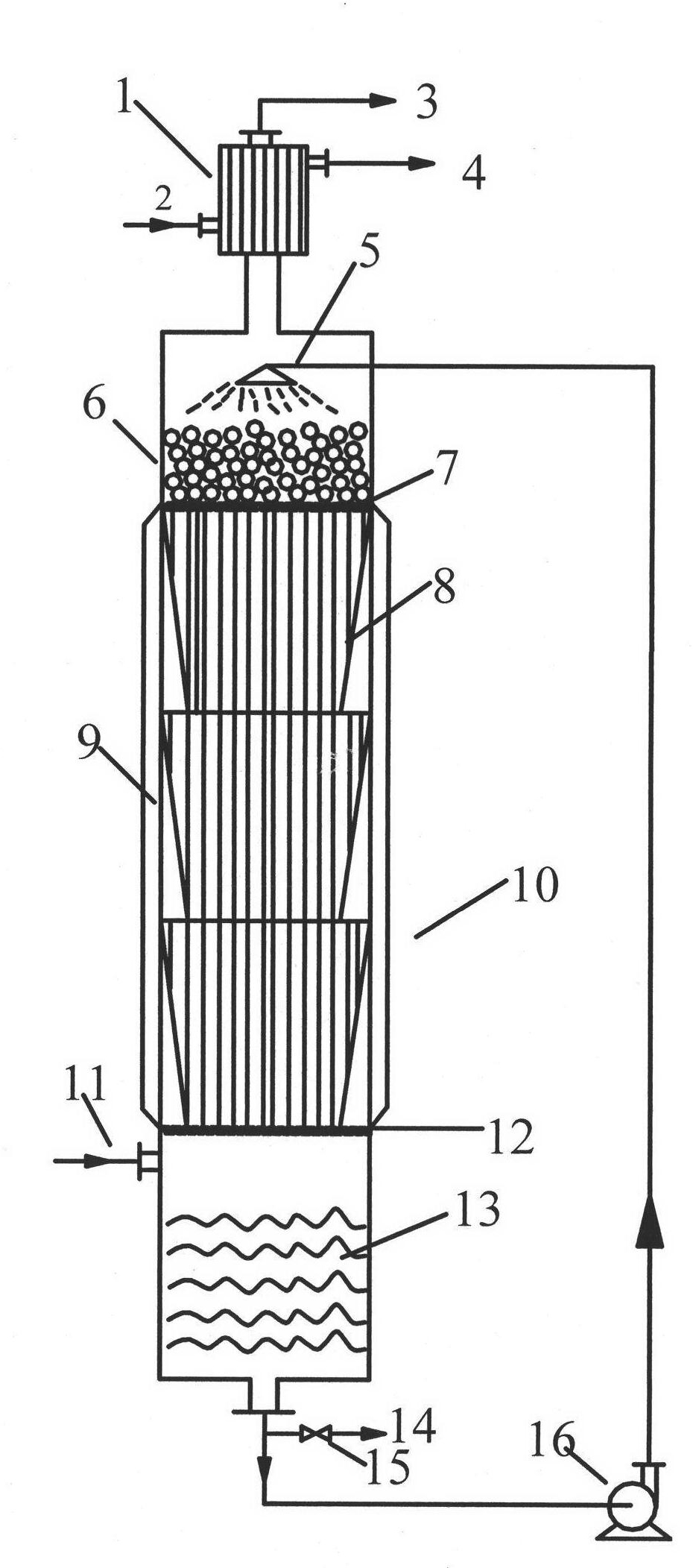

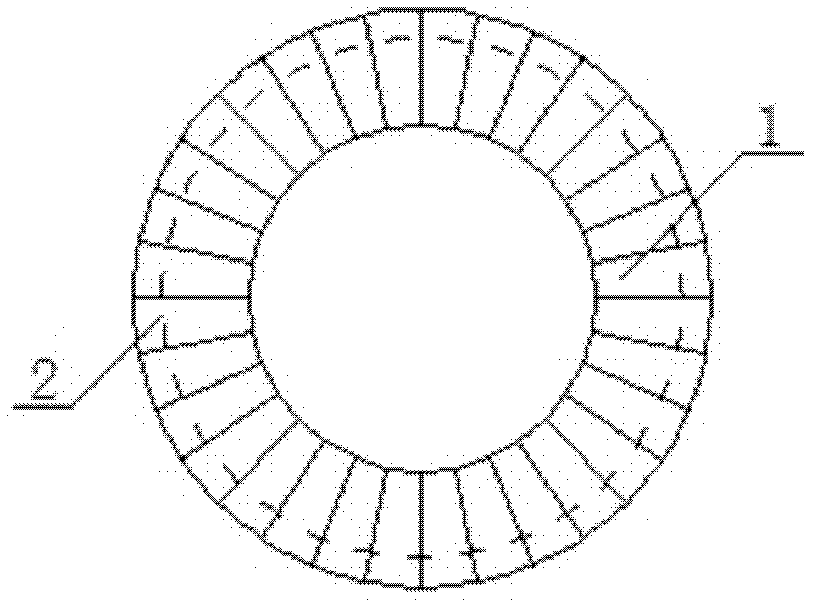

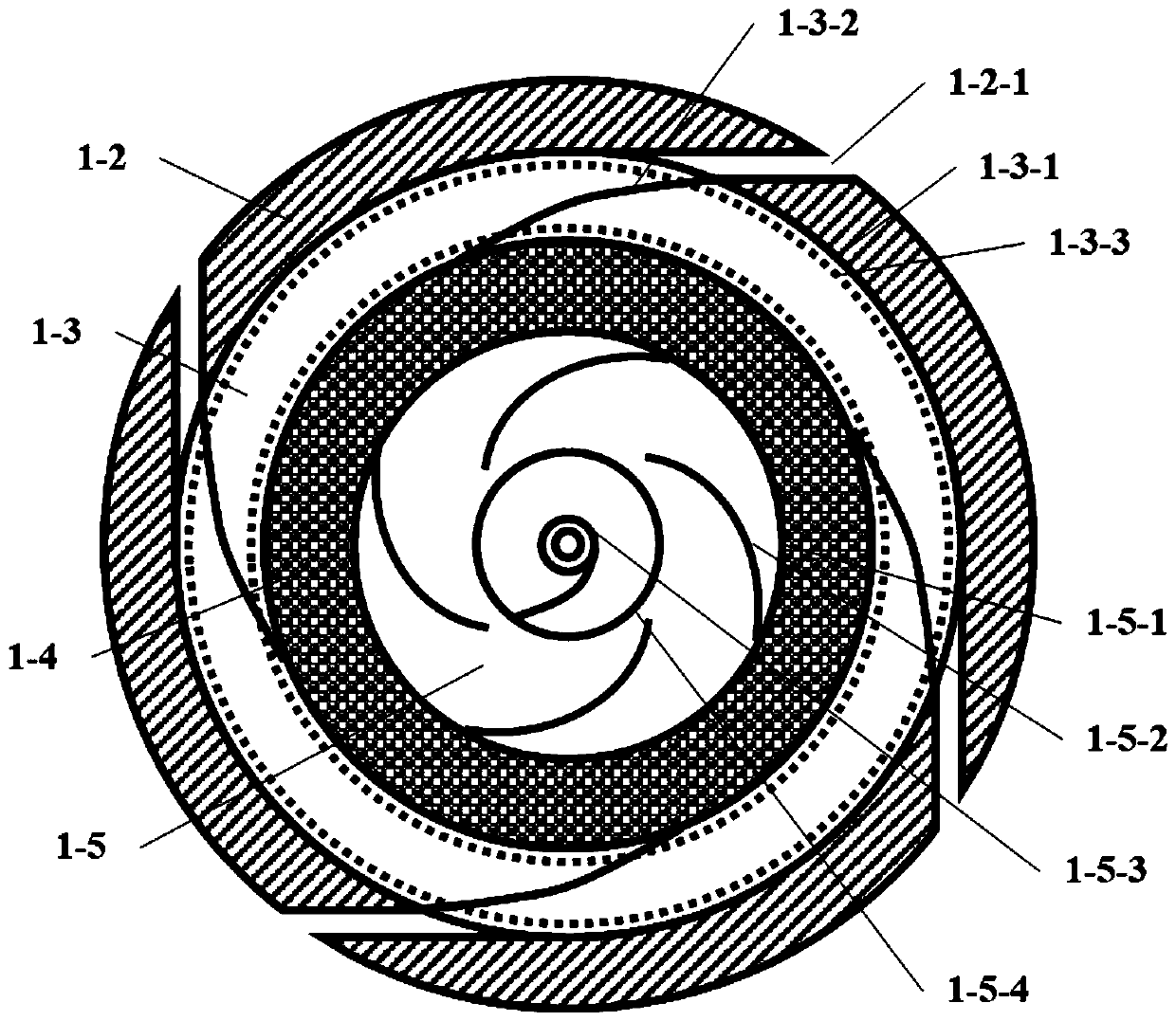

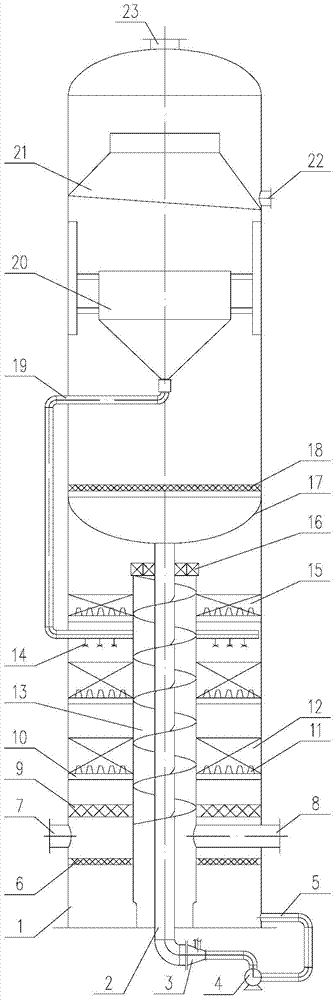

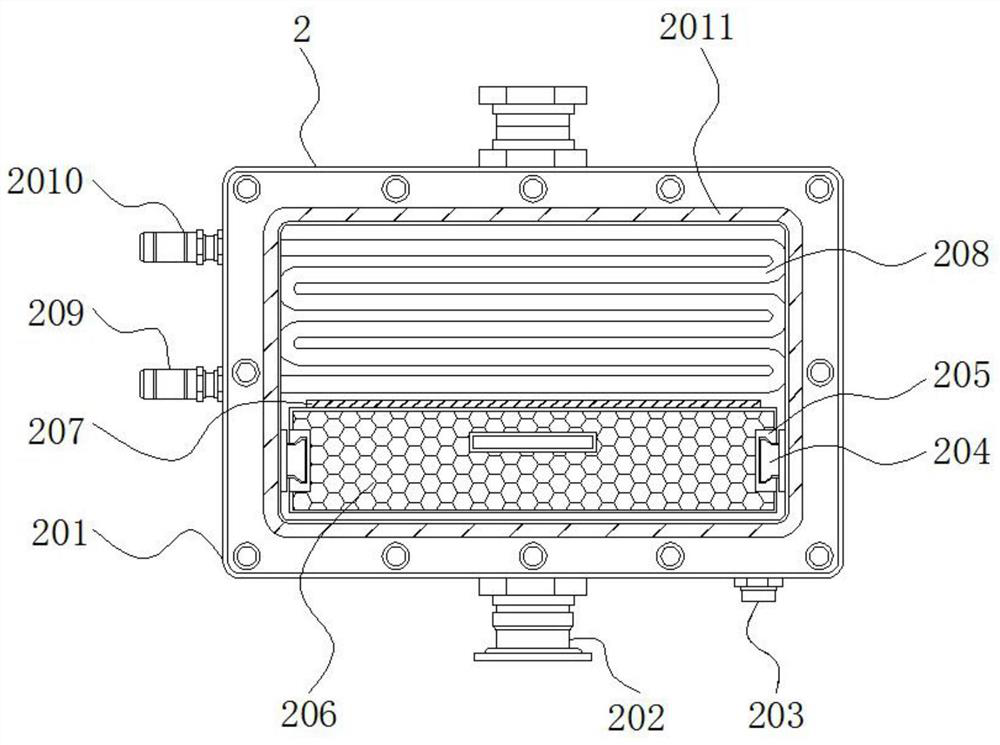

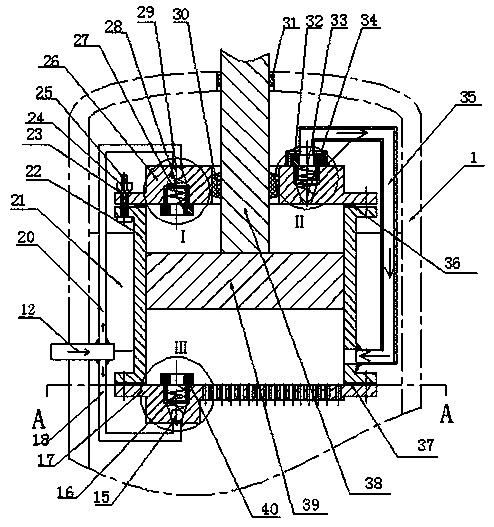

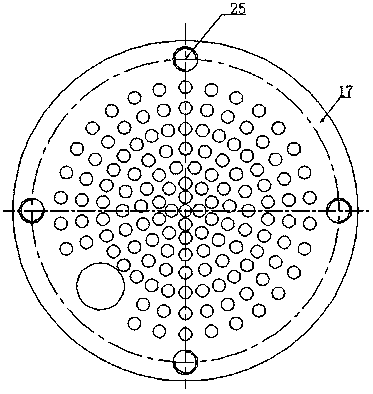

Biotrickling filter for treating volatile organic waste gas

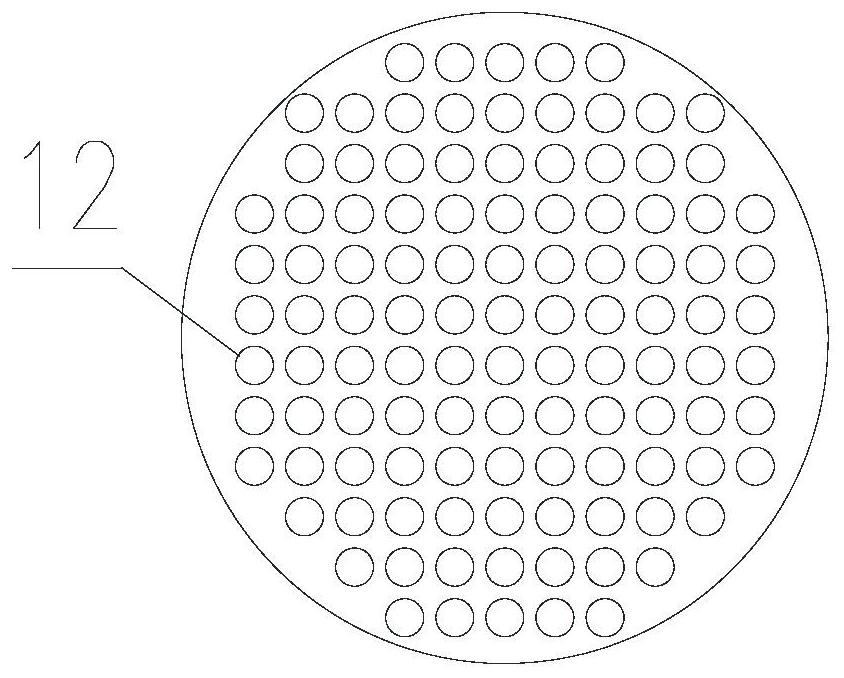

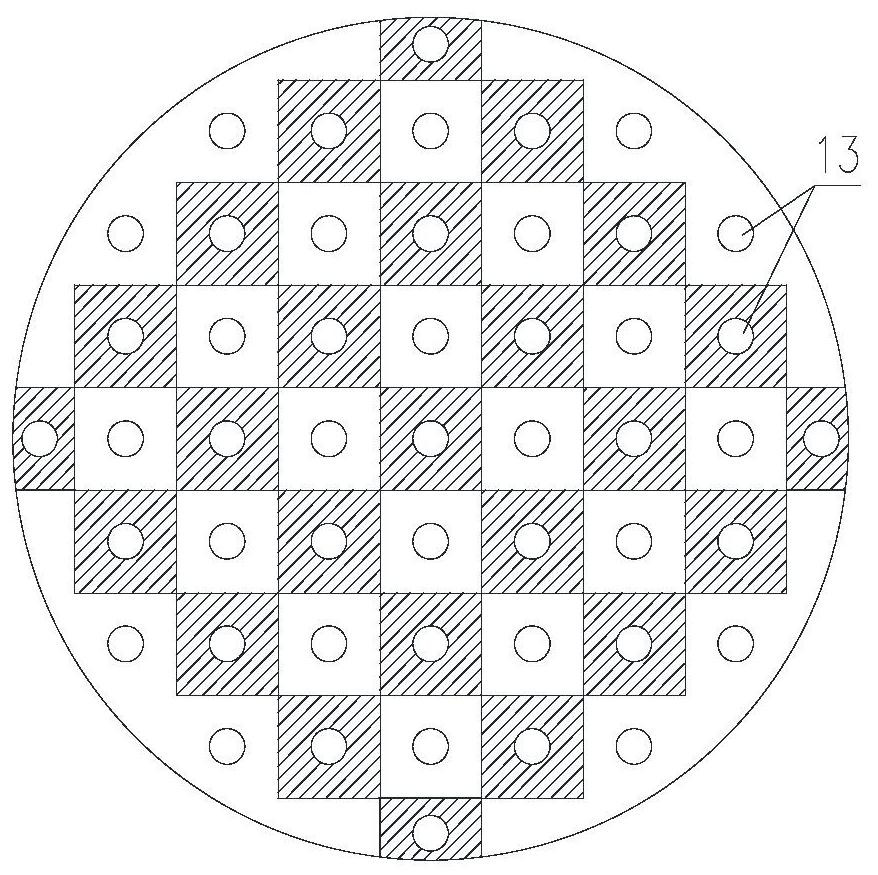

InactiveCN101125280AEvenly distributedAvoid wall flowDispersed particle separationAir quality improvementVoltage dropEngineering

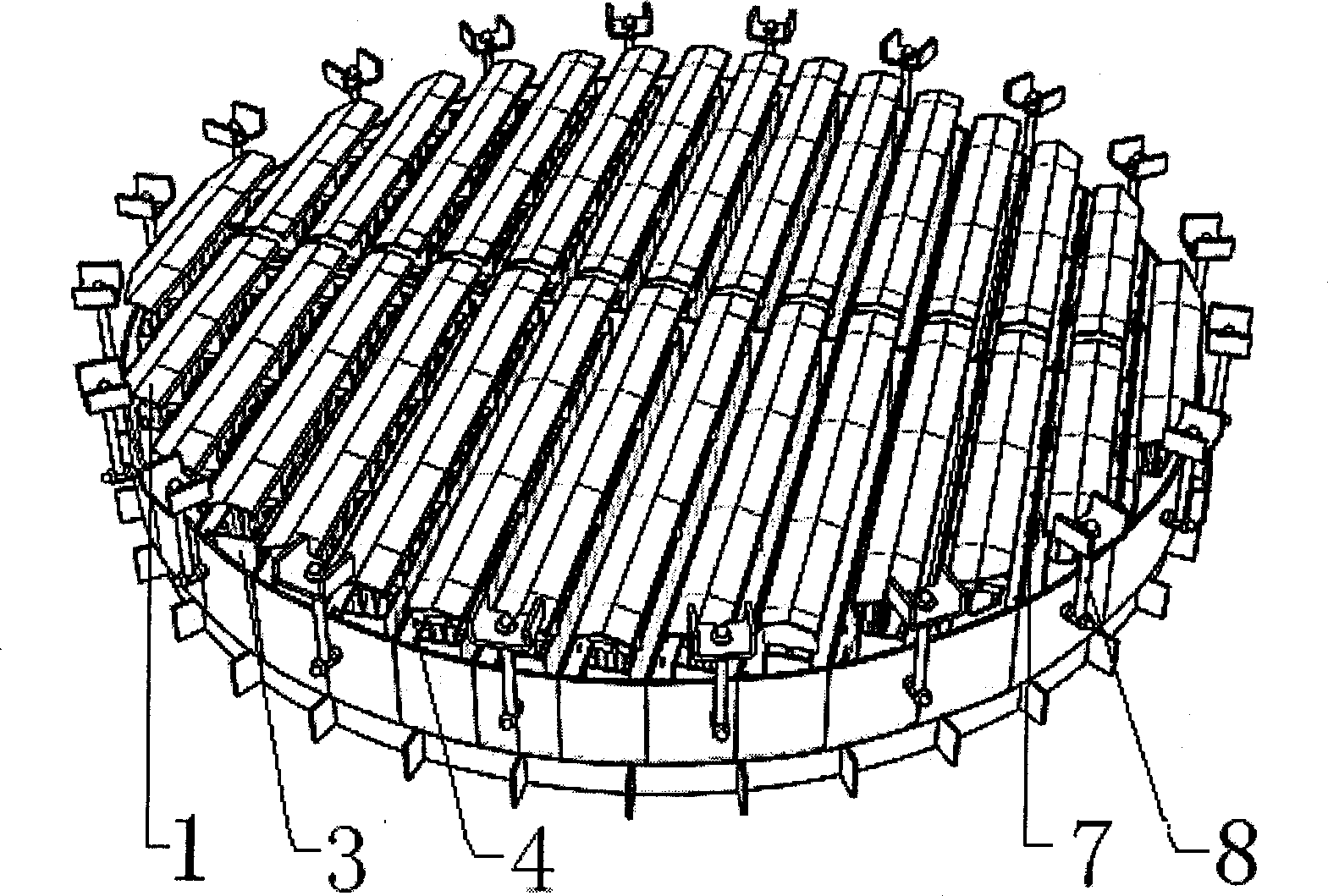

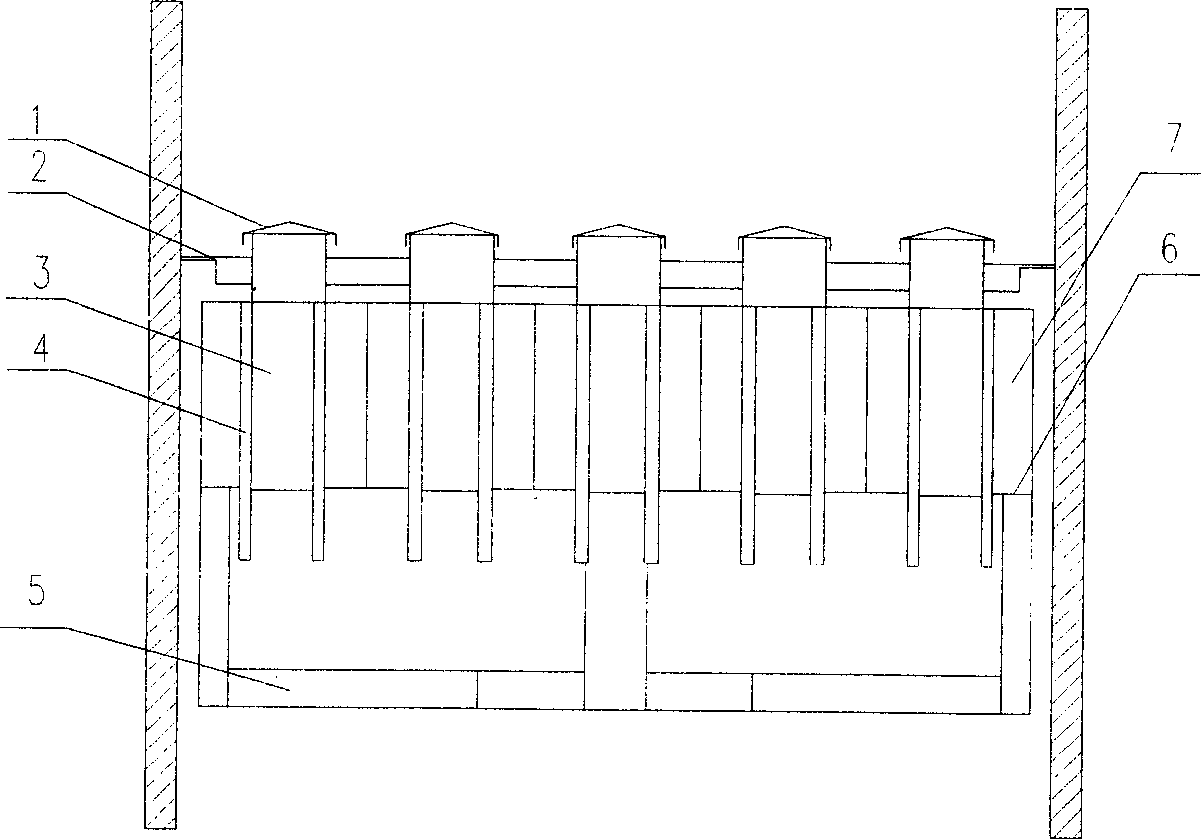

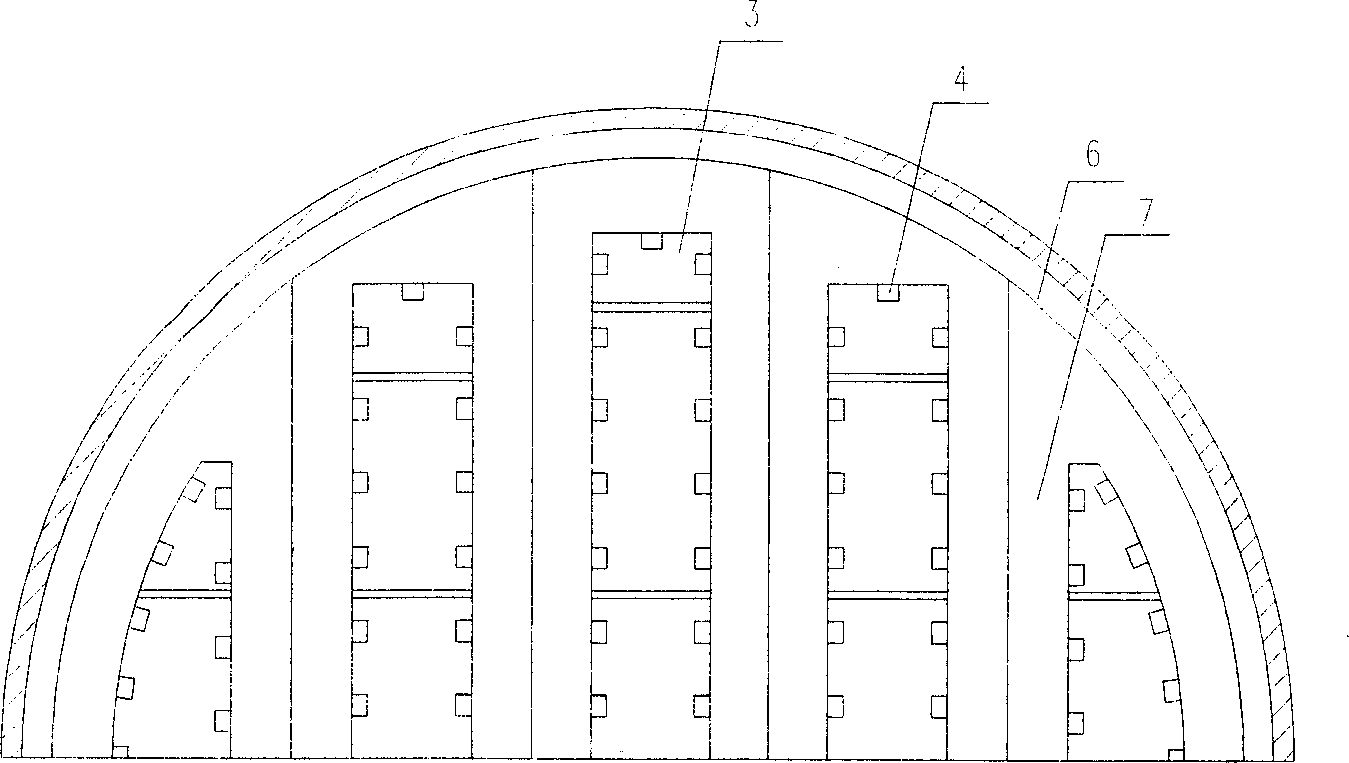

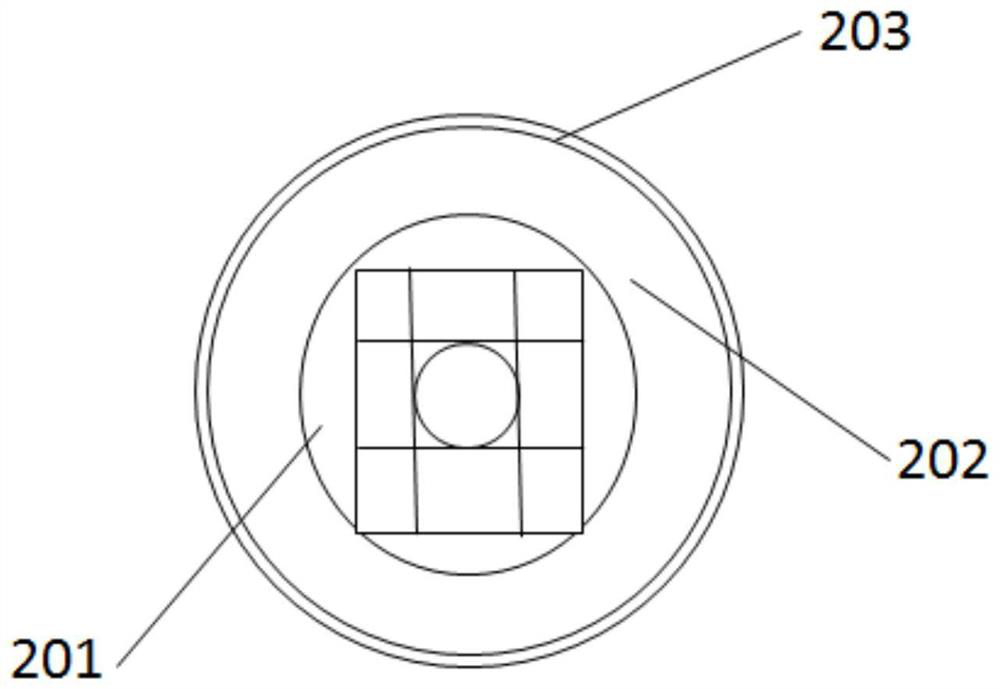

The present invention relates to a BTF used for dealing with the volatile waste gas, belonging to the field of treatment of the volatile waste gas, which aims at solving the problems that the prior BTF has uneven air flow distribution and biomass distribution, high center gas speed and voltage drop, and the prior BTF is easy to be blocked. The technic proposal is that: the volatile waste gas passes through an intake pipe (1) and then comes into a biofilter (22), and then being drained away by an exhaust pipe (9) after having the processes of degradation and purification; a nutrient solution (11) comes into the biofilter (22) through a nutrient solution shower (18) and a dropwise adding distributor device (19) having fixed quantities at fixed time; the present invention is characterized in that adopting a light and cheap packing (4) with different grain diameters, the biofilter (22) takes a homocentric column shape sleeve structure , the grain diameters of the filled packing (4) from the center to the edge are distributed from small to big, the centre area is filled with the packing (4) with small grain diameters, the ring area of the around close walls is filled with the packing (4) of big grain diameters. The present invention makes the distribution of the biomass in the biofilter even, thereby fully utilizing the useful space of the biofilter.

Owner:BEIJING UNIV OF TECH

Preparing method for cyclohexane-1,2-dibasic diformate

ActiveCN106554278AGuaranteed complete hydrogenationReduce hot spot temperatureOrganic compound preparationCarboxylic acid esters preparationHydrogenation reactionDibasic ester

The invention relates to the field of hydrogenation for preparing cyclohexane-1,2-dibasic diformate, and discloses a preparing method for cyclohexane-1,2-dioctyl phthalate dibasic ester. The method comprises the steps that firstly, hydrogenation raw materials containing phthalic acid dibasic ester and H2 are subjected to first contact in a main hydrogenation reactor in the presence of a first catalyst, and first gas-liquid mixing fluid is obtained; secondly, the first gas-liquid mixing fluid is subjected to gas-liquid separation; thirdly, hydrogen is injected into main hydrogenation reaction liquid through holes with the average hole diameter being the nanometer size, the main hydrogenation reaction liquid is separated out in the second step, and second gas-liquid mixed fluid is obtained; fourthly, the second gas-liquid mixed fluid is subjected to second contact in a rear hydrogenation reactor in the presence of a second catalyst, and third gas-liquid mixed fluid is obtained; and fifthly, the third gas-liquid mixed fluid is subjected to gas-liquid separation. The method has the beneficial effects that the raw material conversion rate, the product selectivity and the cis-structure product content are high.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

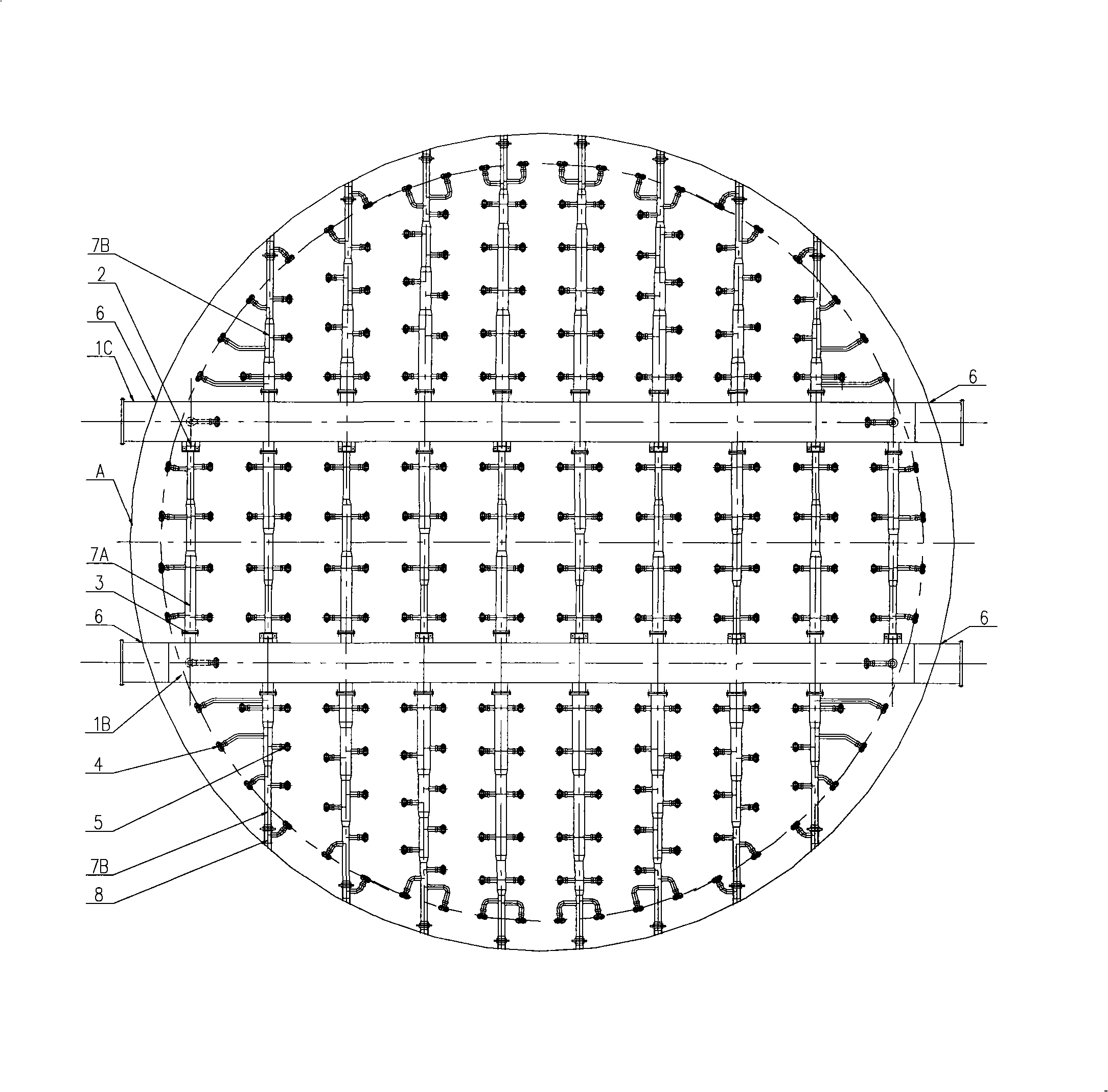

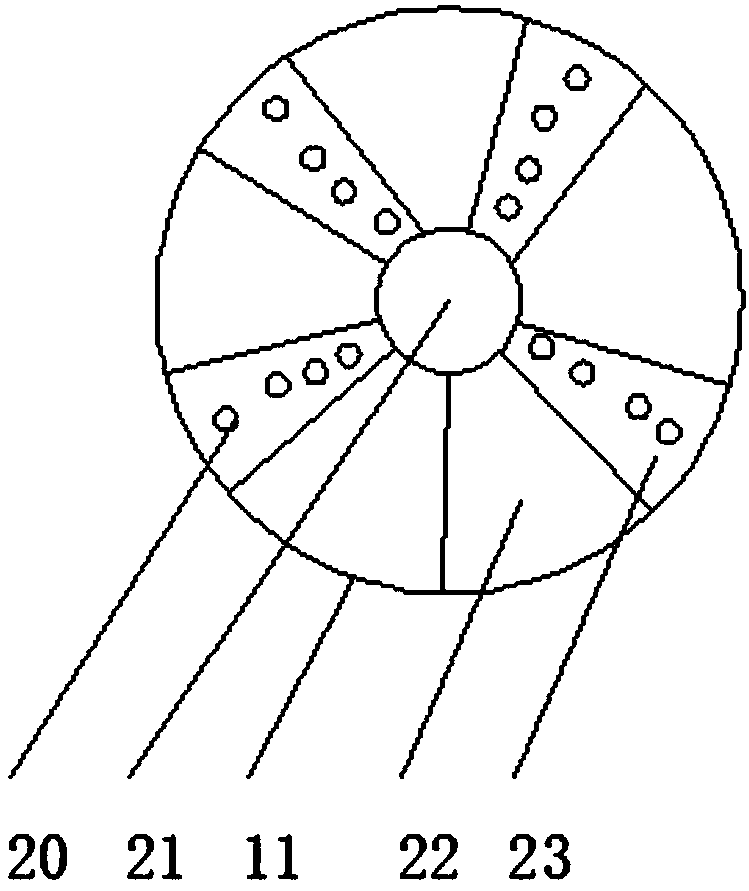

Modularized liquid distributor

InactiveCN1864785ARealize surface distributionAvoid entrainmentDispersed particle separationFractional distillationEngineeringTower

The invention relates to a modularized liquid distributor. It comprises: air-raising tank, drainage tank, collecting tank and liquid collecting awl. The air-raising tank connected to each other up-and-down is allocated evenly on chassis, four walls of air-raising tank is equipped with drainage tank, the upper in relative to drainage tank is provided with a spray hole, drainage tank is connected to lower side of liquid collecting awl, the upper side of liquid collecting awl is connected to tower wall to guide liquid flowing down tower wall, space near air raising tank forms collecting tank to collect and redistribute liquid. The invention can realize effect of collecting liquid, linery distribution of liquid and even distribution of gas. The invention is characterized by compact construction, convenient detachment, small leakage amount and avoidness of entrainment. When it is used for reflux liquid distribution, the cap liquid baffle board can be demounted for liquid collection and gas surface distribution.

Owner:TIANJIN UNIV

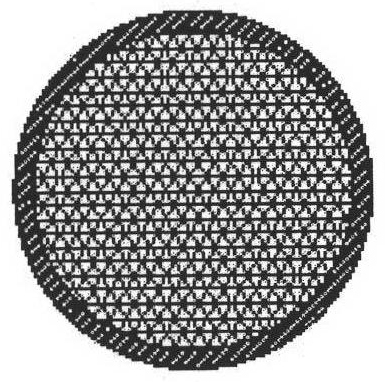

Device and method for preparing acetoxime

InactiveCN102500284AImprove conversion rateHigh selectivityOximes preparationChemical recyclingChemical industryMolecular sieve

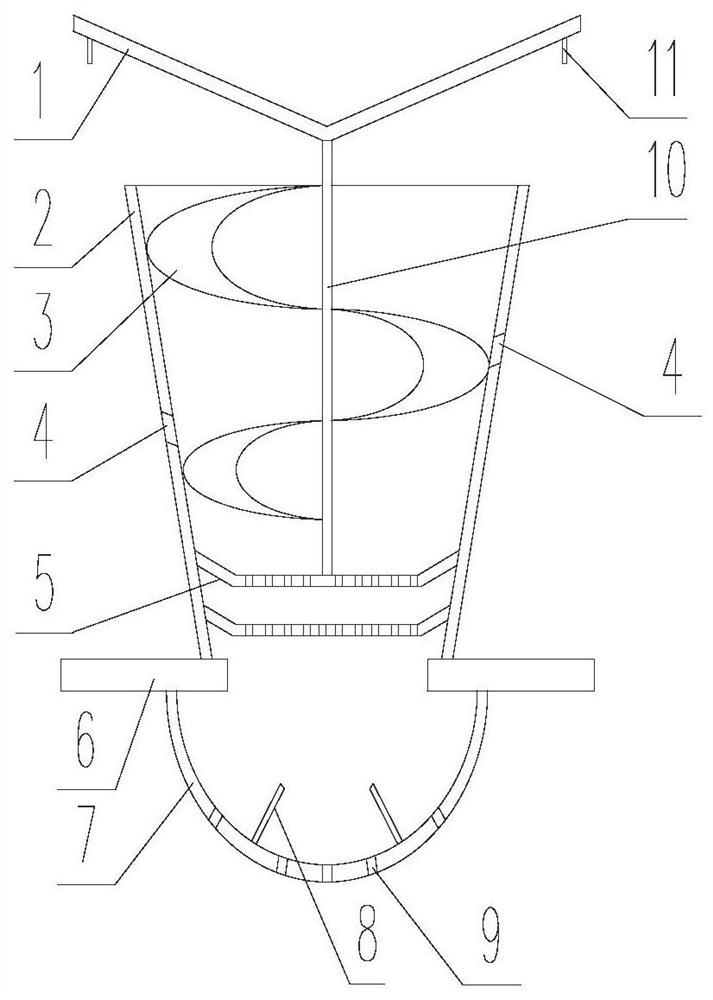

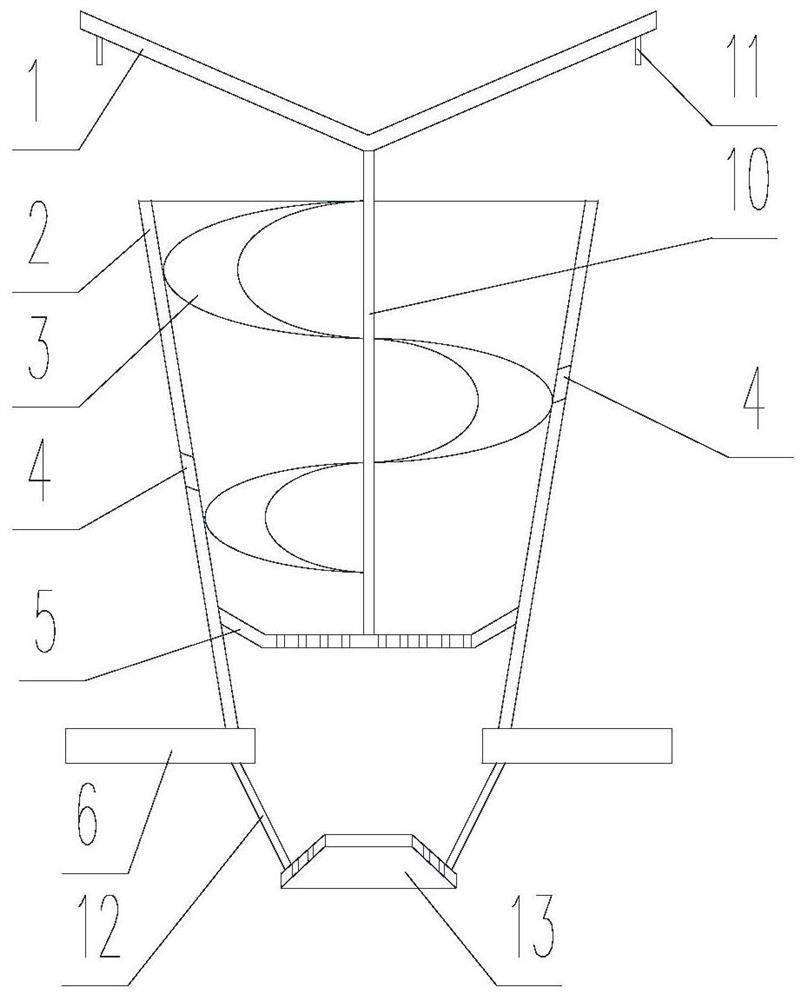

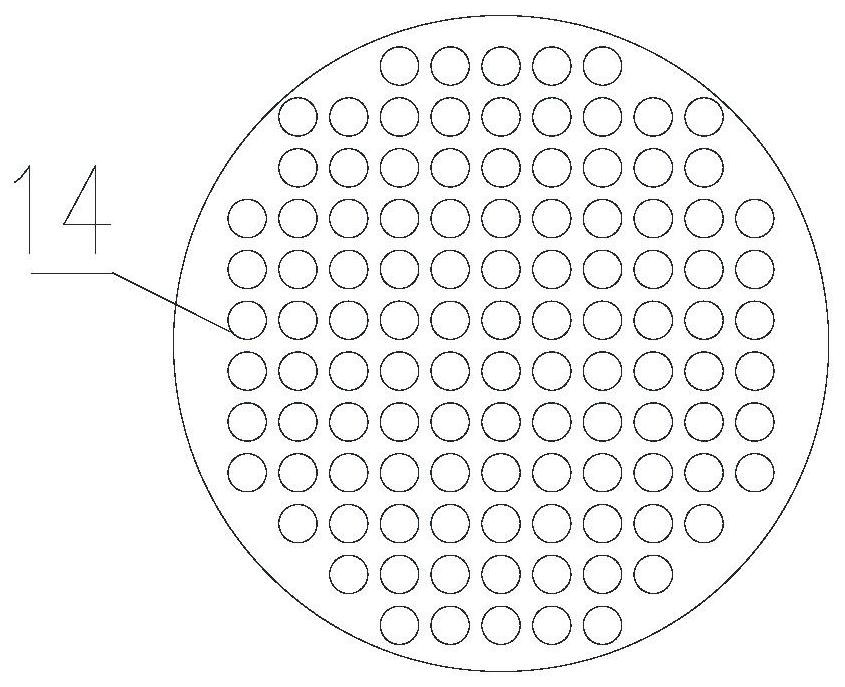

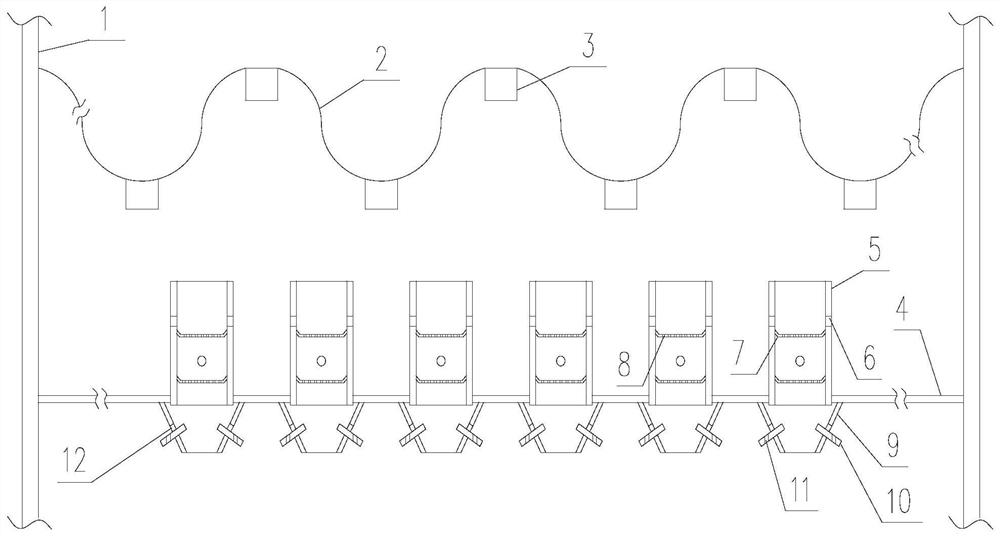

The invention belongs to the technical field of chemical industry and relates to a device and a method for preparing acetoxime. The acetoxime is prepared from acetone, tertiary butanol, water, ammonia water and hydrogen peroxide by using an integrated TS-1 molecular sieve as a catalyst (an integrated titanium silicalite molecular sieve serves as a catalyst) and through liquid solid phase acetone ammoxidation. The device comprises a condenser, an integrated reactor and an external circulation pump. The integrated TS-1 catalyst (the integrated titanium silicalite molecular sieve serves as the catalyst) synthesized by using frustum-shaped cordierite as a carrier is loaded in the integrated reactor and is applied to preparation of the acetoxime. By adoption of the frustum-shaped cordierite carrier in the device, the wall flow phenomenon can be effectively avoided, so that activity of the catalyst and catalytic efficiency of the reactor are greatly improved. By the device and the method, the problem that the traditional powdered catalyst is difficult to recycle is solved. The device and the method have a wide market application prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Oil-bearing car-washing wastewater treatment method and equipment

InactiveCN106946377AFast precipitationGood clarificationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationWater quality

The invention provides a car-washing wastewater treatment method and equipment which are applied to small-sized car-washing stations. The car-washing wastewater treatment method comprises the following steps of: clarifying in a coagulating sedimentation tank with sloping plates by using a coagulant; carrying out turbidity removal and oil absorption by using fiber bundle media; carrying out air-water backwashing after the fiber bundle media become invalid; carrying out oil removal treatment on oil stain accumulated in the fiber bundle media by adding a cleaning agent at a certain water temperature; for residual organic matters of the fiber bundle media, firstly soaking the fiber bundle media by using an agent, and then cleaning; and adsorbing the organic matters and a surface active agent by using diatomite and activated carbon. The equipment adopting the method comprises the coagulating sedimentation tank designed by modular combination, a fiber filtration tank and an adsorption tank; and matched wastewater collection tanks and clear water tanks can be buried in the ground. The equipment is small in volume, low in manufacturing cost and operation cost, simple to operate and convenient to maintain and has a good effluent effect. The quality of water treated by the method and equipment can reach Water Quality Standard for Domestic Miscellaneous Water (CJ / T48-1999). The method and equipment have wide application prospect.

Owner:BEIHUA UNIV

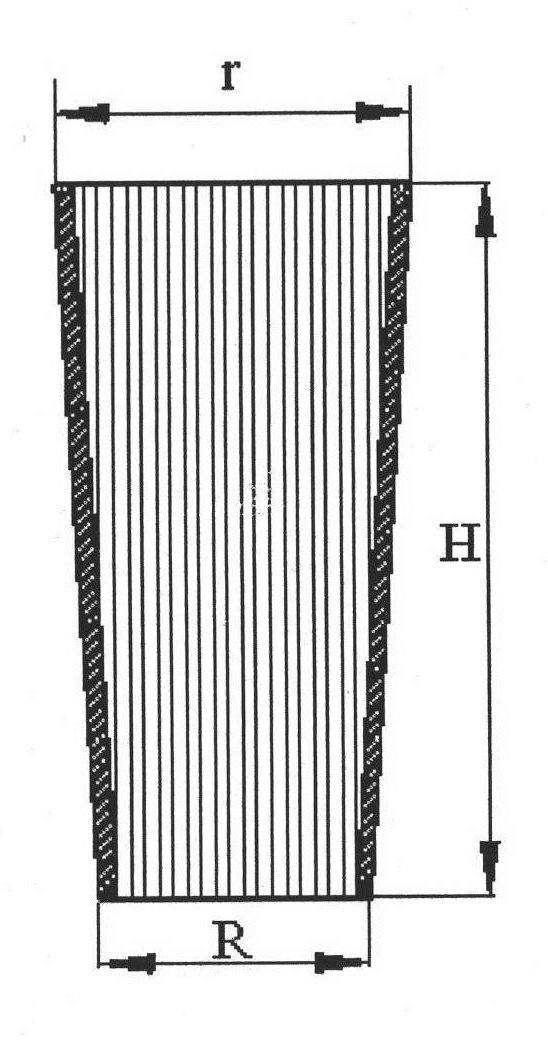

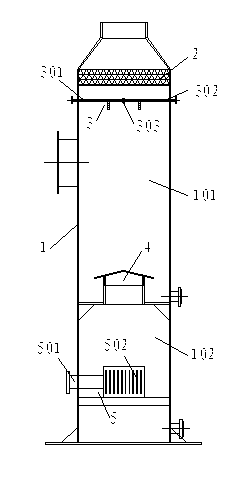

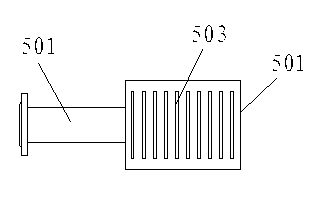

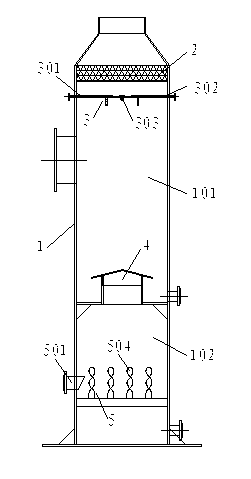

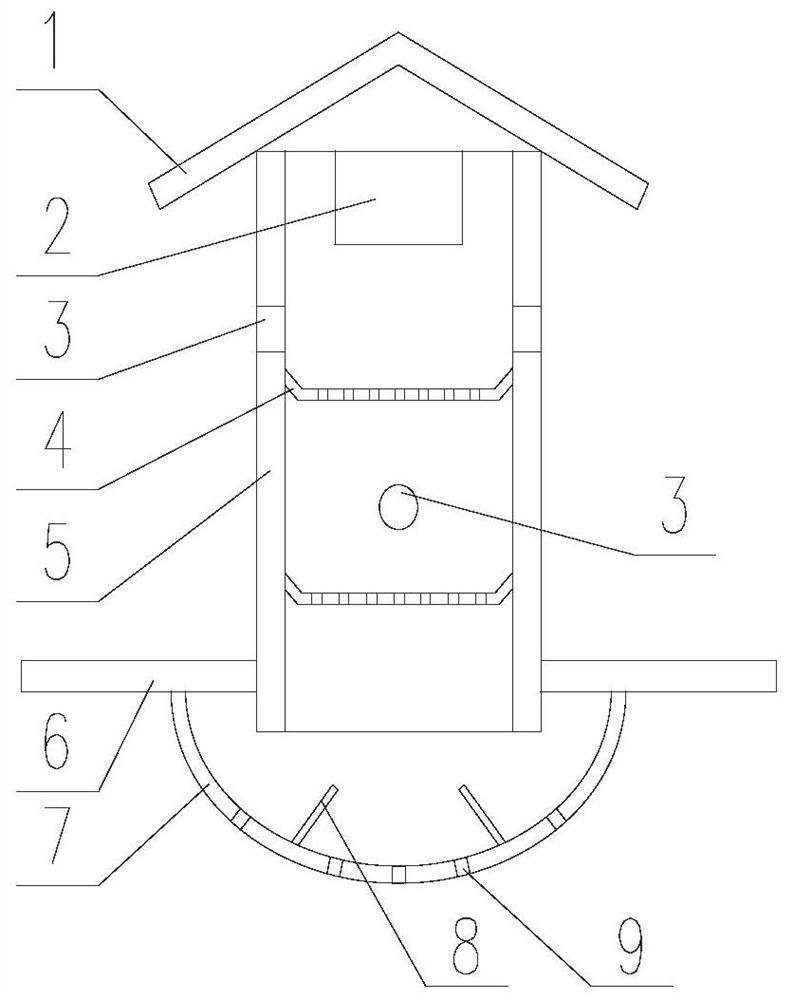

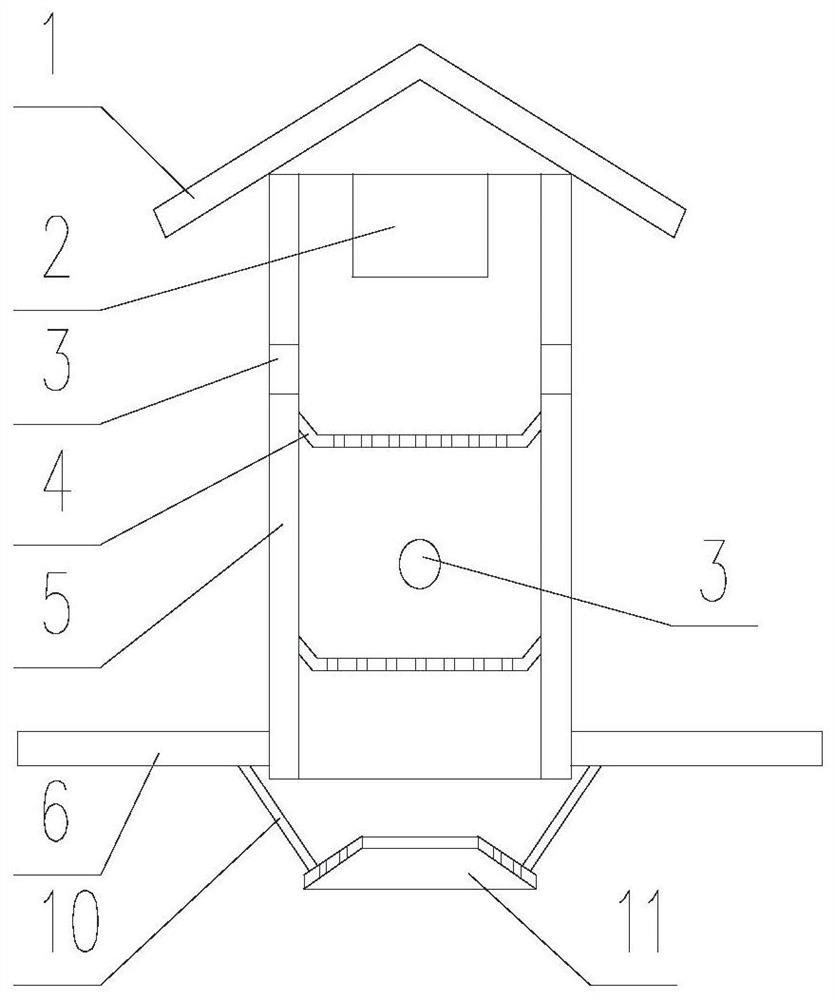

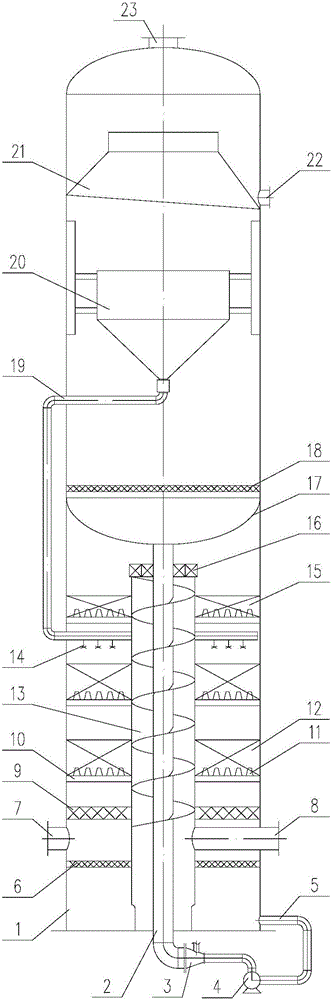

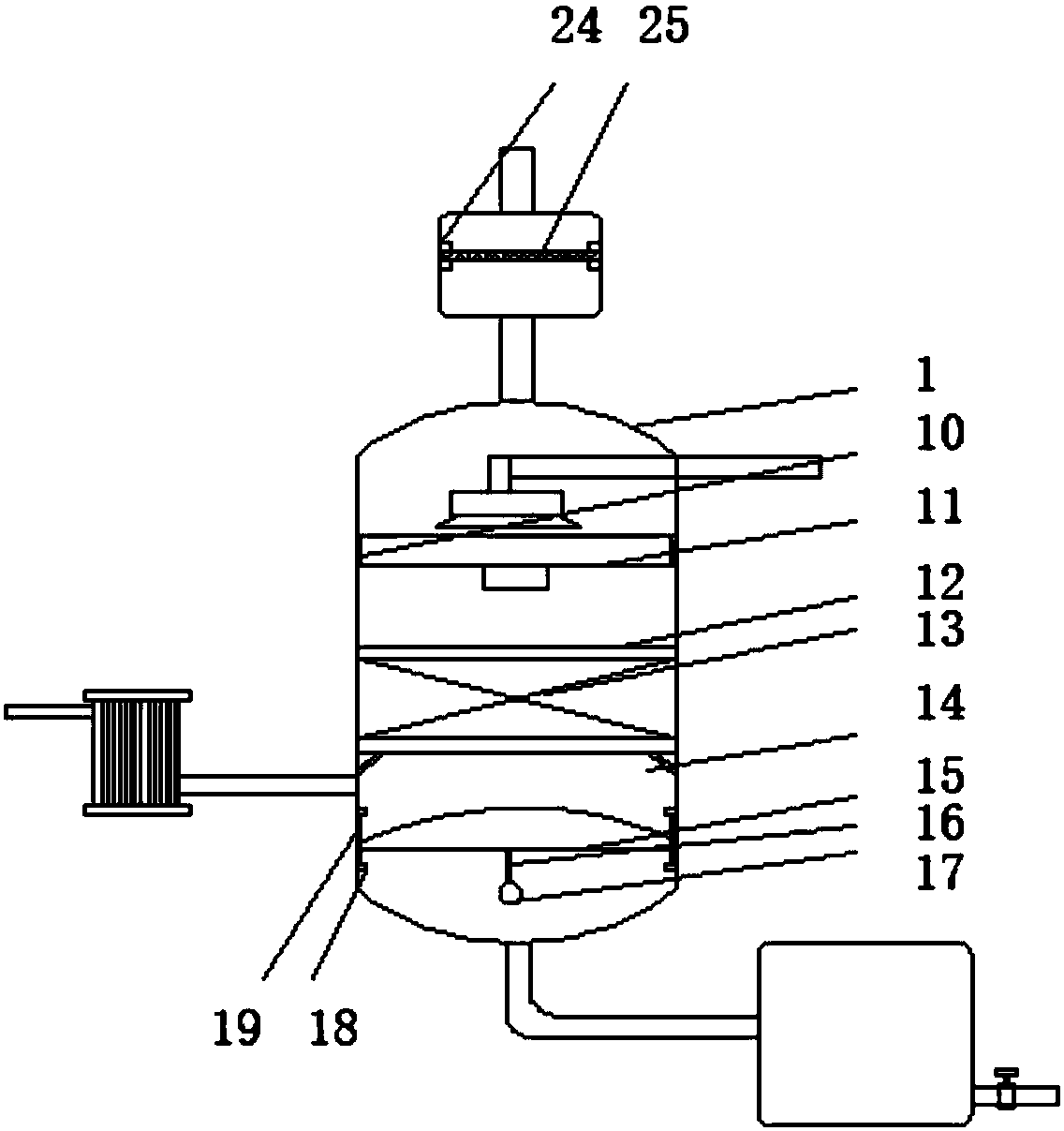

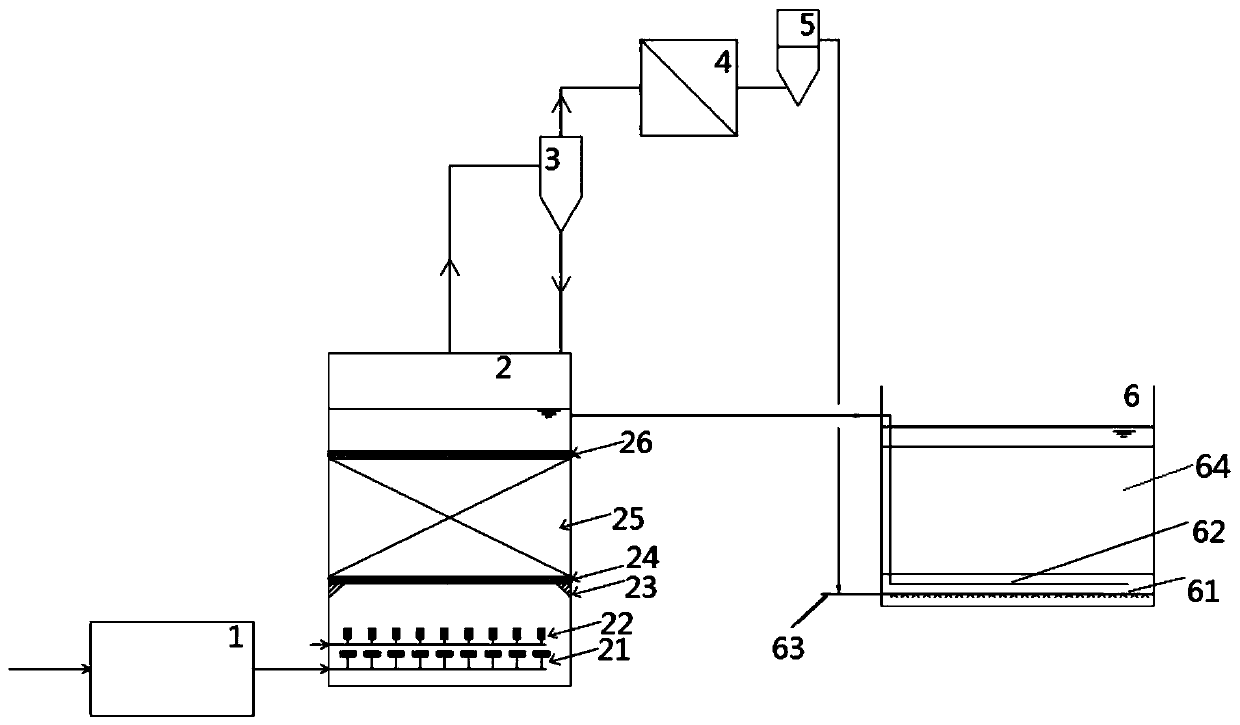

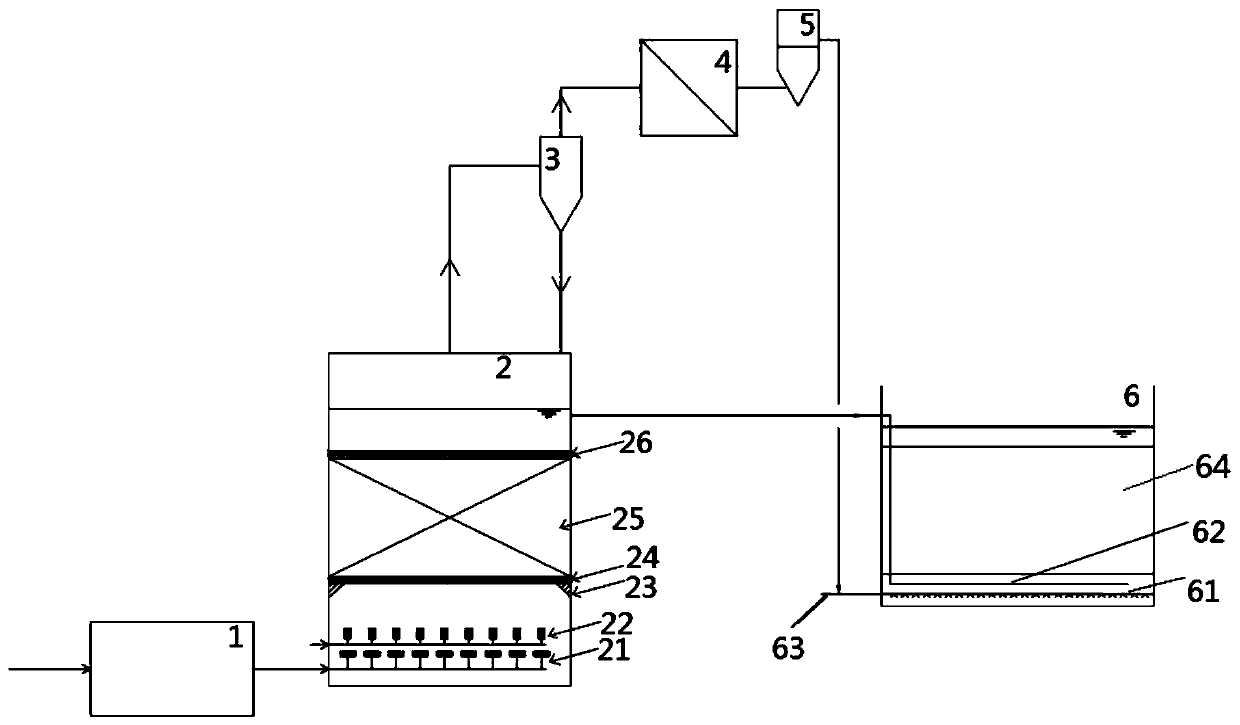

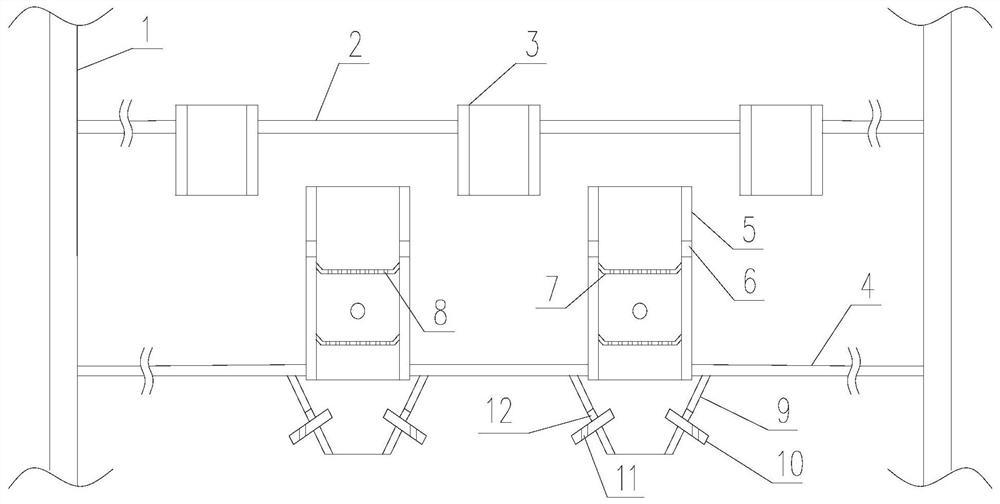

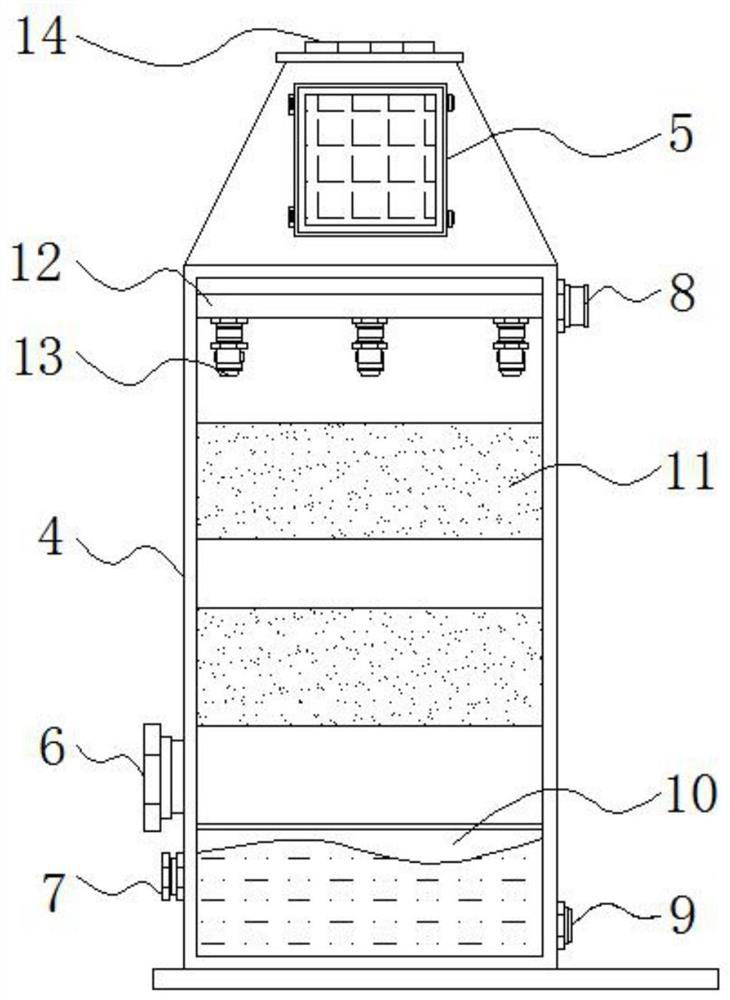

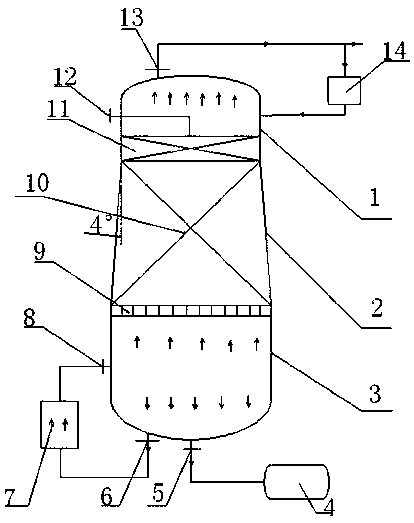

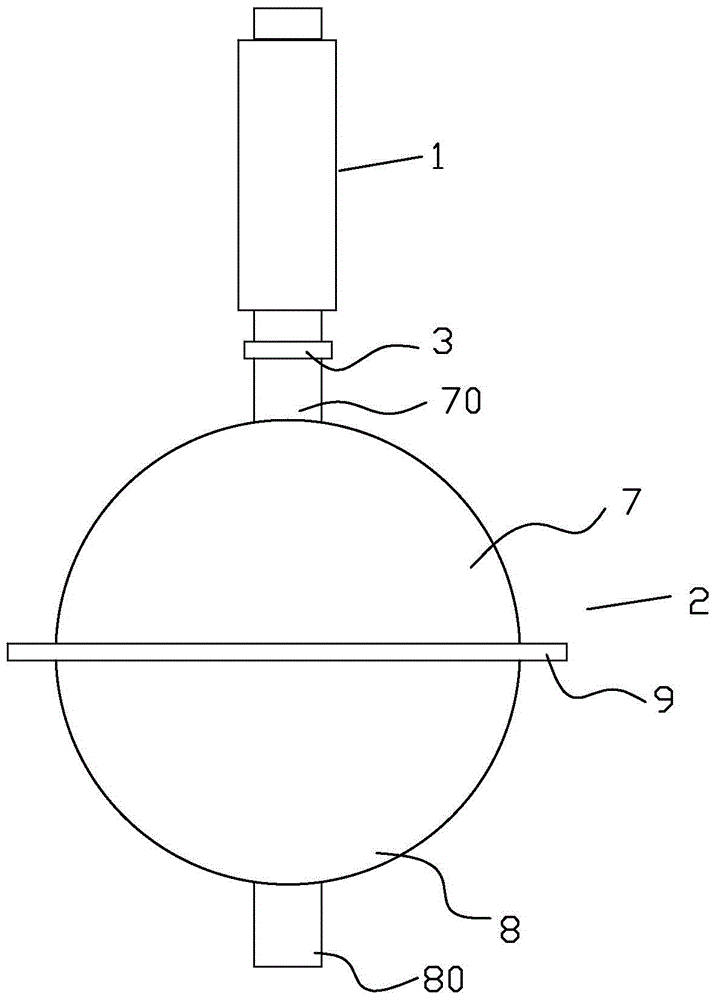

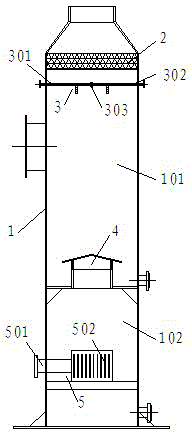

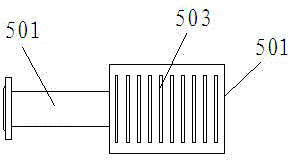

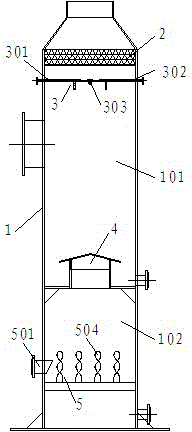

Wastewater ammonia nitrogen blow-off treatment reaction device

ActiveCN102701307AAvoid wastingAvoid wall flowWater/sewage treatment by degassingLiquid wasteDraining tube

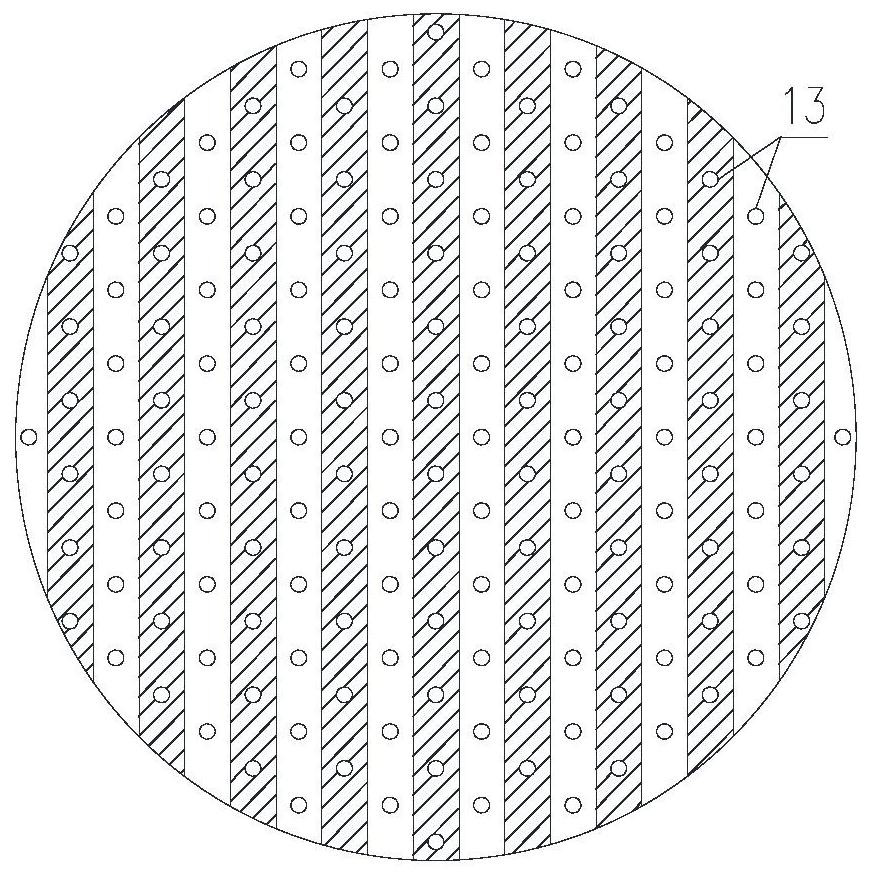

The invention discloses a wastewater ammonia nitrogen blow-off treatment reaction device which comprises a shell, wherein a gas water separation layer, a water distribution device, an umbrella-shaped water shield and a gas distribution device are distributed in the shell at intervals from top to bottom in sequence; the shell is divided into an upper chamber and a lower chamber by the umbrella-shaped water shield; a drain pipe is arranged on the shell at the bottom of the upper chamber; the water distribution device consists of a water inlet pipe, a gas inlet pipe and a double-fluid spray nozzle, wherein the water inlet pipe and the gas inlet pipe are communicated; and the communication part of the water inlet pipe and the gas inlet pipe is provided with the downward double-fluid spray nozzle to form a three-way structure, so that gas-liquid waste caused by mixing gas and liquid by utilizing a packing layer can be effectively avoided, channeling and wall flow phenomena can be effectively prevented, and the stability of ammonia nitrogen blow-off treatment is improved.

Owner:JIANGSU YIHUAN GROUP

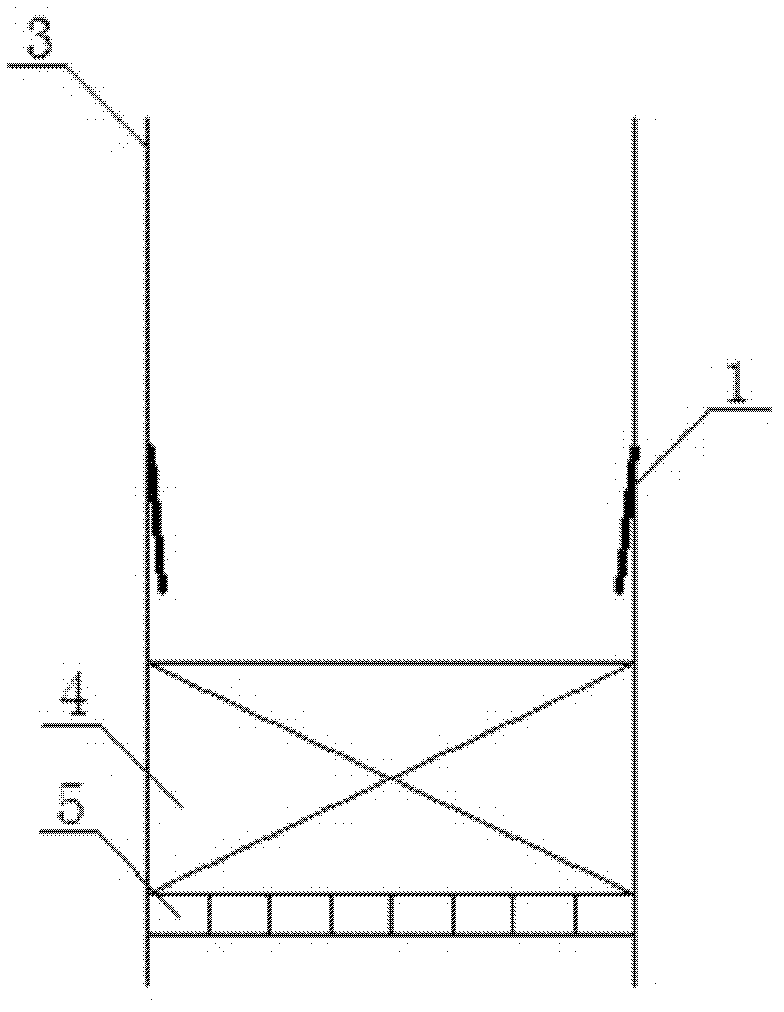

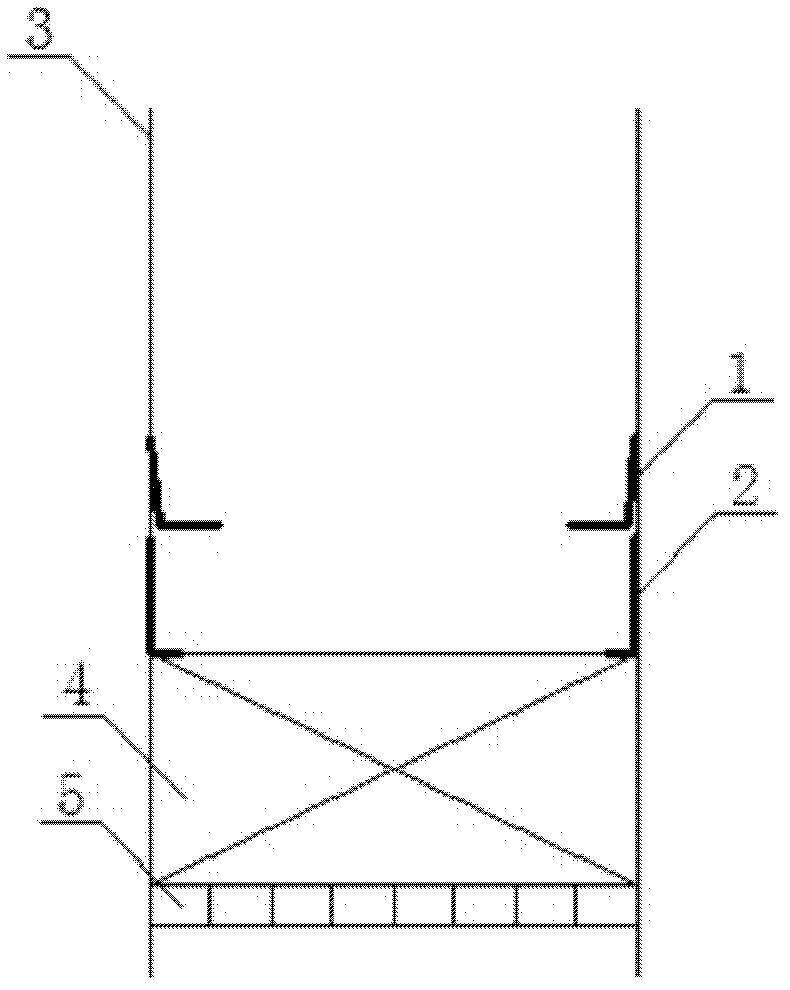

Device capable of completely eliminating wall flow effect and integrated with tower body and method for mounting device

InactiveCN102600789AImprove separation efficiencyEliminate wall flow effectsChemical/physical/physico-chemical processesEngineeringTower

The invention relates to a device capable of completely eliminating a wall flow effect and integrated with a tower body and a method for mounting the device. The device is composed of a liquid collecting circle 1 and a liquid redistribution circle 2, wherein the upper end of the liquid collecting circle is welded to the inner wall of the tower below a packing layer, while the lower end thereof is cut out; the liquid redistribution circle is a barrel with a circular ring at the bottom; the liquid redistribution circle is inserted between the tower wall 3 and the liquid collecting circle; the upper end of the liquid redistribution circle is higher than the lower end of the cut-out position of the liquid collecting circle; and the bottom circular ring of the liquid redistribution circle is arranged on the packing layer. No gap is reserved between the upper part of the liquid collecting circle of the device and the tower body, so that the phenomenon that liquid flowing along the wall is collected incompletely can be avoided; therefore, secondary wall flow is prevented.

Owner:TIANJIN UNIV

Gas-liquid distribution device

ActiveCN111992145AAvoid uneven distributionImprove solubilityChemical/physical processesCircular discFluid phase

The invention discloses a gas-liquid distribution device, which comprises an umbrella cap, an overflow pipe and a distribution disc which are arranged from top to bottom; the umbrella cap is conical and umbrella-shaped and is arranged at the upper end of the overflow pipe; the overflow pipe is a circular pipe with two open ends; the lower end is fixed on a mounting hole of the distribution plate;a gas-phase channel is arranged at the joint of the overflow pipe and the umbrella cap, one or two or more layers of overflow holes are evenly formed in the pipe wall in the circumferential directionto serve as liquid-phase channels, a liquid collecting disc is arranged below each layer of overflow holes in the overflow pipe, the liquid collecting discs are concave flat-bottom discs and fixedly connected with the pipe wall of the overflow pipe through convex concave edges, and distribution holes are evenly distributed in the bottoms of the liquid collecting discs for gas-liquid two-phase passing. According to the invention, gas-liquid two-phase contact can be enhanced, the gas-liquid two-phase atomization effect is promoted, and the wall flow phenomenon in the overflow pipe is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

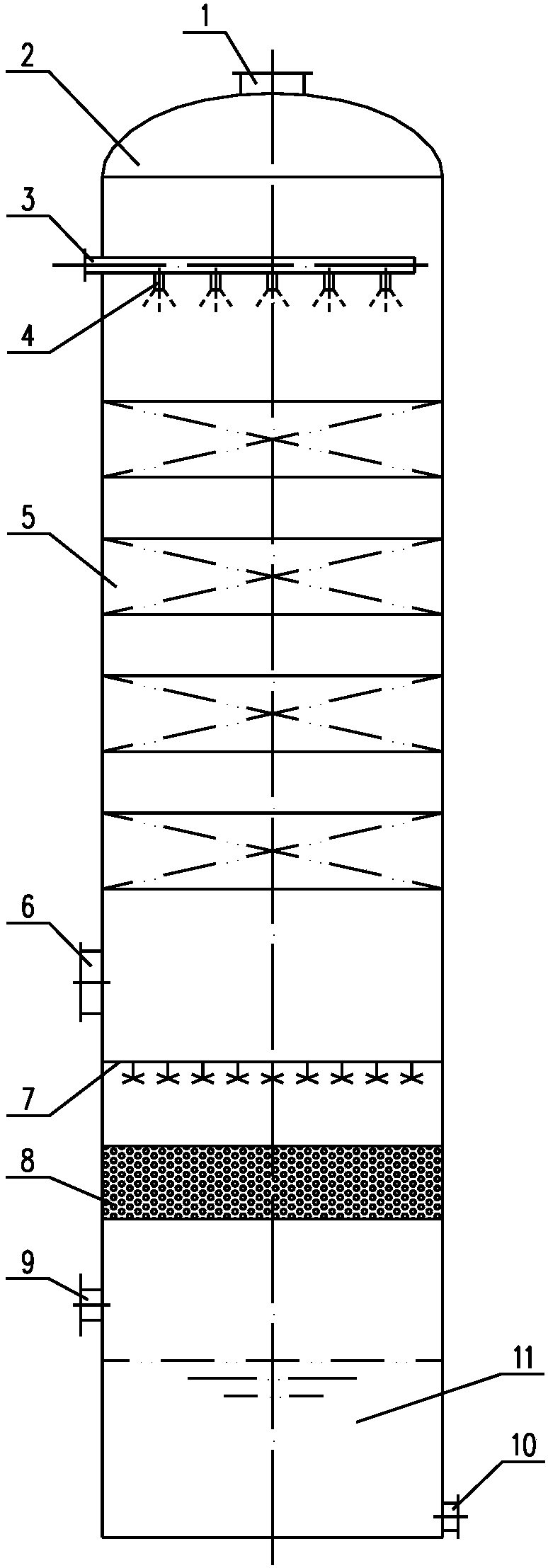

Desulfuration regeneration tower

ActiveCN104987895AEffective absorptionReduce pollutionGas purification by liquid washingGas contaminants removalLiquid temperatureContact time

The invention relates to a desulfuration regeneration tower. Coal gas and a desulfurizing liquid are subjected to mass transfer in a filling material to remove hydrogen sulfide in coal gas, the desulfurizing liquid reaches an upper regeneration section through a desulfurizing liquid conveying pipe, and the coal gas is regenerated by utilization of air under the action of a catalyst, and returns to a lower desulfuration section to be subjected to desulfuration. The desulfuration regeneration tower is divided into the lower desulfuration section and the upper regeneration section, wherein the lower desulfuration section comprises a coal gas inlet, a coal gas outlet, a coal gas distributor, a filling material, a mist collecting filling material, a filter, a cyclone separator and a desulfurizing liquid outlet; the upper regeneration section comprises a bubble separator, an inclined conical section, a foam outlet, a regenerated air outlet and a gas distributor. According to the desulfuration regeneration tower, an HPF wet oxidation process desulfuration technology is adopted, so that the desulfurizing liquid and air can be better mixed, the contact time is prolonged, the influence on desulfurizing liquid temperature by environmental temperature is reduced, meanwhile space is saved, lots of materials are saved, the desulfuration efficiency is improved by utilization of self structural advantages, and the environmental pollution of a coking plant is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Spraying system

The utility model discloses a spraying system which is arranged in a wet-method flue-gas desulfurization and absorption tower. The spraying system comprises a plurality of layers of spraying layers, wherein, main spraying pipes, branch spraying pipes and a nozzle are arranged in the spraying layers, at least two parallel main spraying pipes are arranged on each spraying layer and two ends of the main spraying pipe are supported on the tower wall of the absorption tower. For the absorption tower with large cross section, after at least two main spraying pipes are adopted, support beams of the branch spraying pipes can be saved so as to reduce the erosion to the support beam; by adopting the solid and tapered nozzle that is arranged near the periphery of the tower wall of the absorption tower, the wall-flow phenomenon and the spraying amount of the slurry can be reduced and the spraying effect of the slurry can be ensured to be more effective.

Owner:上海融新能源环境科技有限公司 +5

Packing tower for industrial waste gas treatment

InactiveCN107913581AGood removal effectEasy to collectGas treatmentDispersed particle separationThermal energyPlate heat exchanger

The invention discloses a packing tower for industrial waste gas treatment. The packing tower comprises a packing tower body, wherein a heat exchanger is mounted on a gas inlet pipe, a liquid discharge pipe is arranged at the lower side of the packing tower body, a collecting box is mounted at one end of the liquid discharge pipe, an exhaust pipe is welded to the upper side of the packing tower body, a dehumidifying box is mounted on the exhaust pipe, an active carbon filtering layer is mounted in the dehumidifying box, a liquid inlet pipe penetrates through one side of the packing tower body,one end, positioned at the packing tower, of the liquid inlet pipe is provided with a nozzle, a baffle plate is welded to the internal bottom side of the packing tower body, the baffle plate is welded with a guide rod, a swash plate penetrates through the guide rod, two support grid plates are mounted on the inner wall of the packing tower body, packing is arranged between the support grid plates, and an anti-wall-flow ring is mounted at the internal upper side of the packing tower body and comprises a chassis, a gas vent, a diversion trench and a through hole. The heat exchanger is a plate type heat exchanger, so that heat energy in waste gas can be well utilized, and energy saving and environmental protection are realized.

Owner:朱智慧

Acid gas absorption oxidization tower and method for operating same

PendingCN108434948AEffective absorptionReduce pollutionDispersed particle separationAmmonium sulfatesLiquid wasteTower

The invention relates to an acid gas absorption oxidization tower and a method for operating the same. The acid gas absorption oxidization tower comprises a tower, a surplus ammonia water spray device, a plurality of layers of fillers, a re-distributor and a catalyst layer. The surplus ammonia water spray device, the multiple layers of fillers, the re-distributor and the catalyst layer are sequentially arranged in the tower from top to bottom; a purified gas outlet is formed in the top of the tower, an acid gas inlet is formed in a side of the tower and is particularly formed in a position between the lowermost layer of fillers and the re-distributor, an ammonium sulfate solution storage tank is arranged at the bottom of the tower, an air inlet is formed in a side of the tower and is particularly formed in a position below the catalyst layer and above the ammonium sulfate solution storage tank, and an ammonium sulfate solution outlet is formed in a side of the bottom of the ammonium sulfate solution storage tank. The acid gas absorption oxidization tower and the method have the advantages that the acid gas absorption oxidization tower is simple in structure and convenient to operate and is used for absorbing and then oxidizing acid gas generated when desulfurization waste liquid is incinerated, and then preparing ammonium sulfate solution, accordingly, the traditional desulfurization waste liquid treatment technological processes can be simplified on the basis that the desulfurization waste liquid is treated, and the equipment investment can be saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

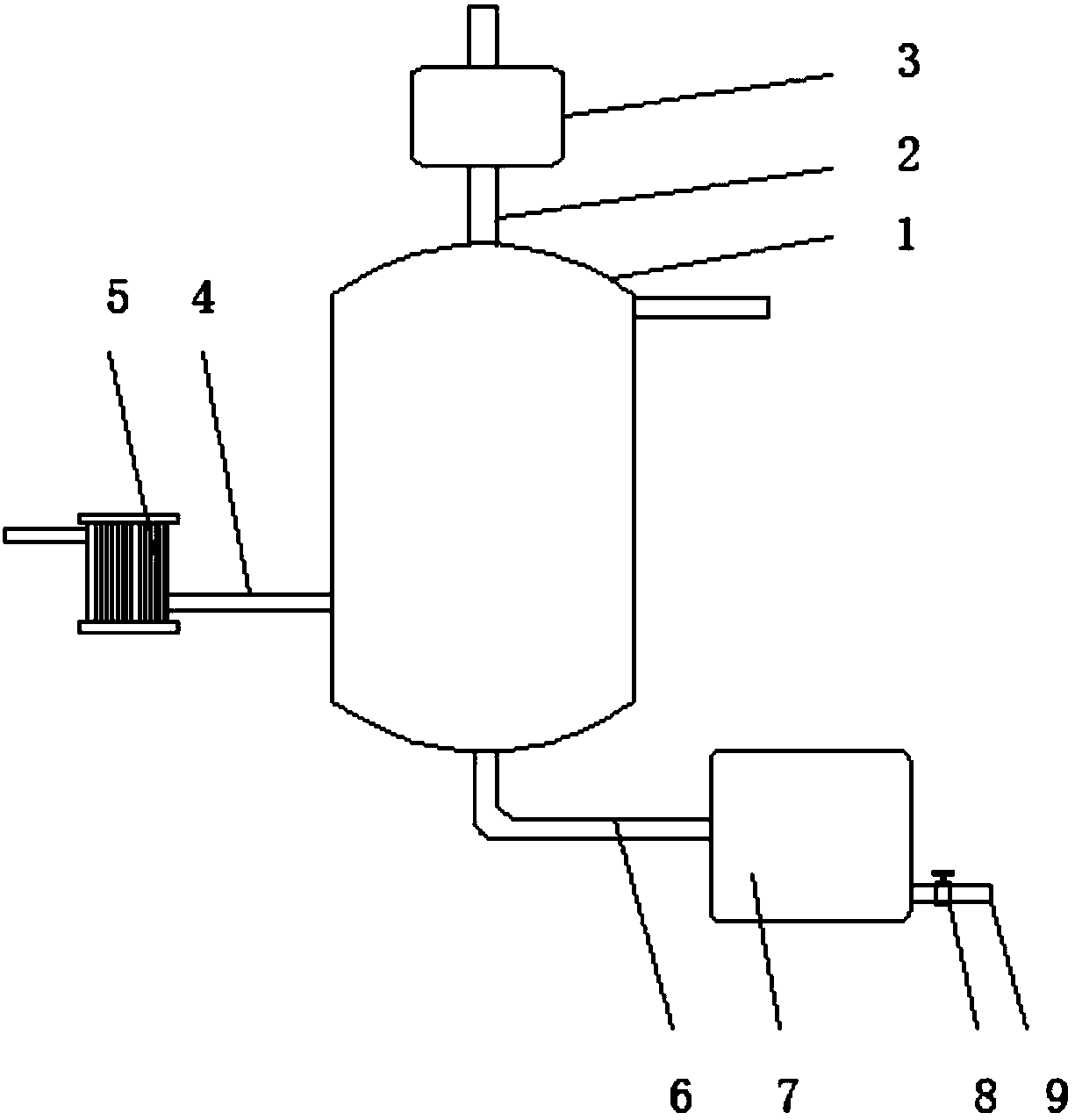

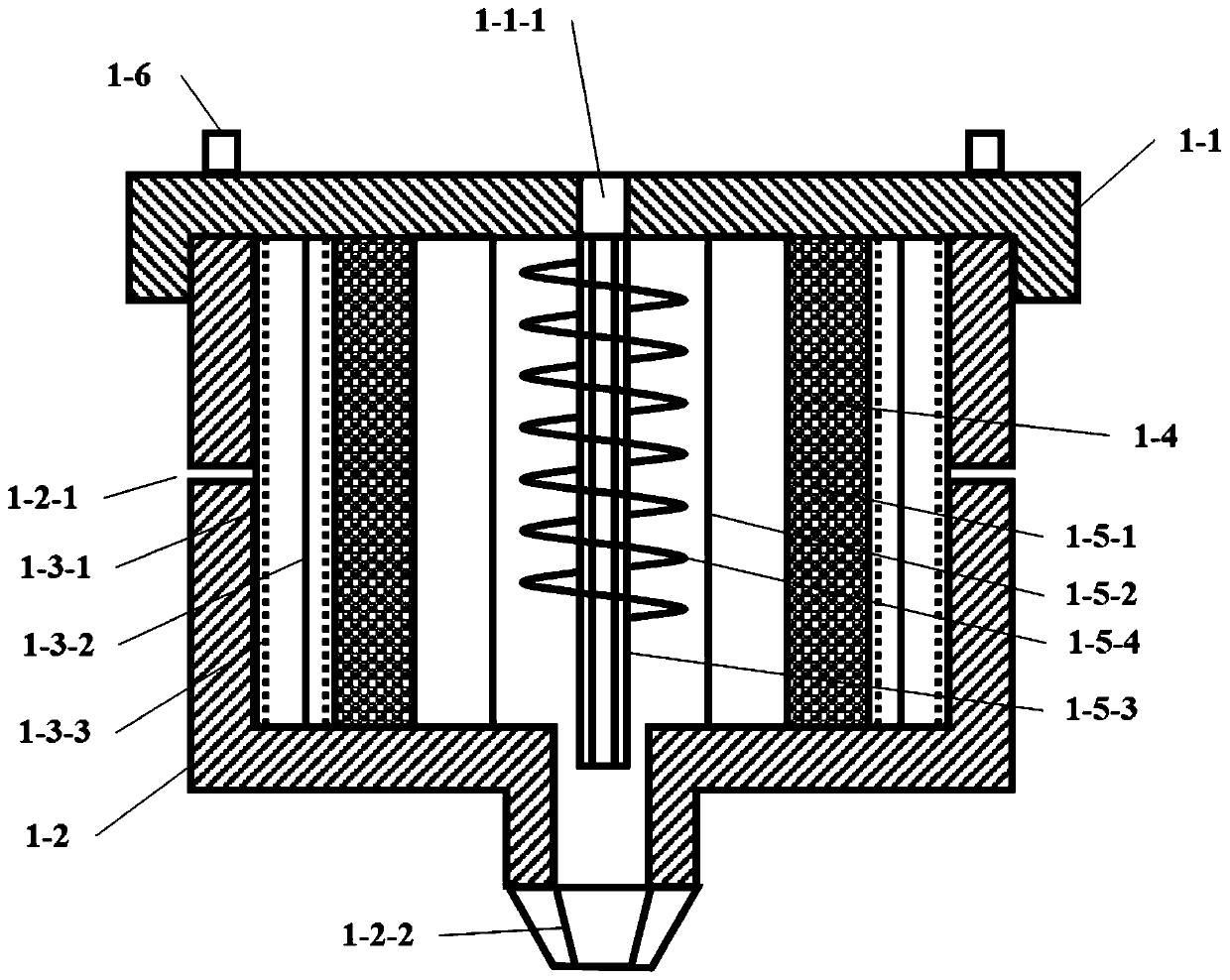

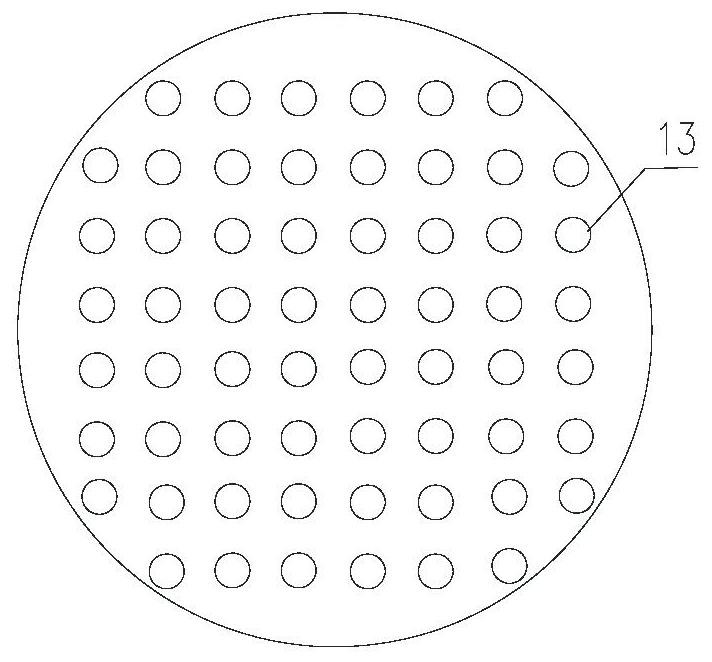

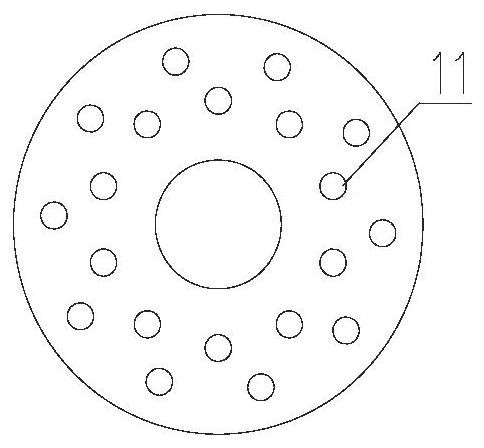

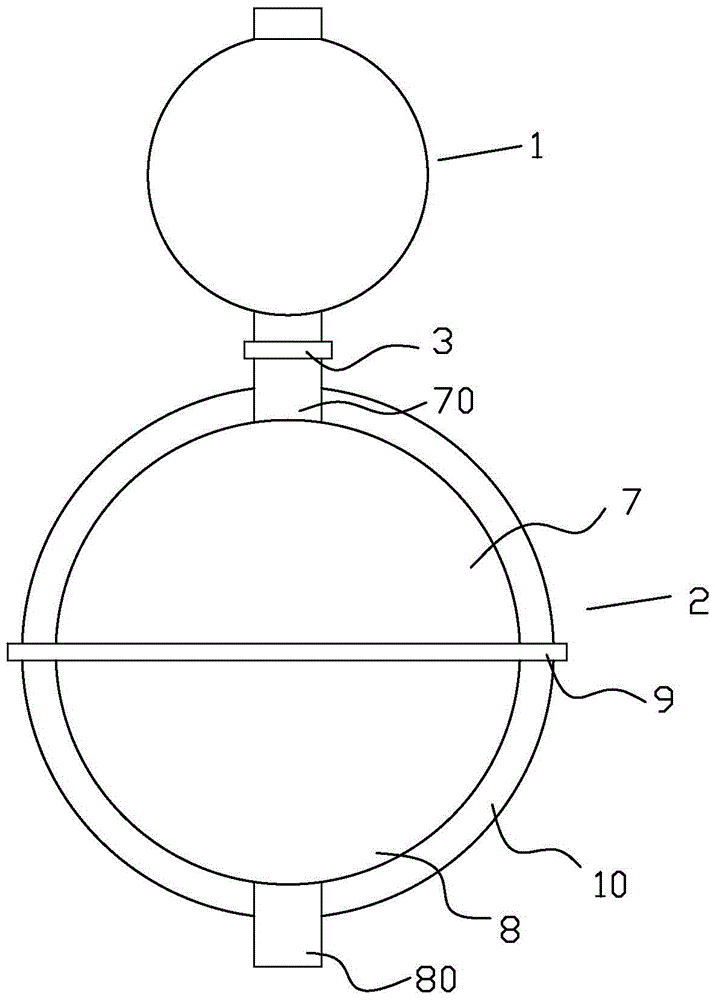

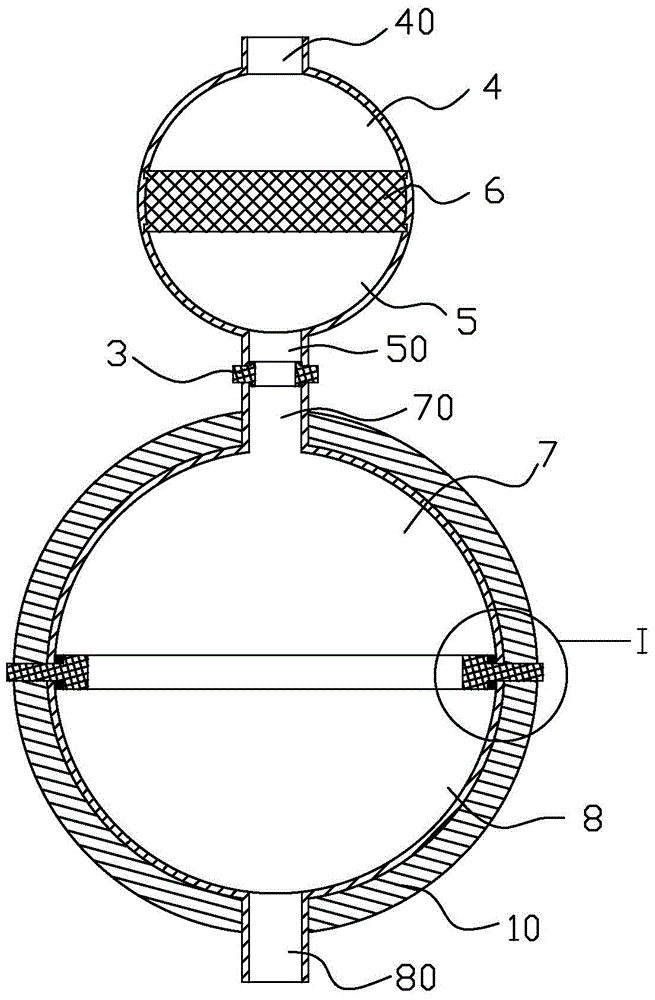

Supercritical extraction separation kettle, extraction system and extraction method

PendingCN111558234AIncrease contact areaImprove extraction yieldCo-current extractionSolid solvent extractionPorous mediumPhysical chemistry

The invention discloses a supercritical extraction separation kettle, an extraction system and an extraction method. The supercritical extraction separation kettle comprises a kettle body and a top cover, and further comprises an annular extraction layer, an annular porous medium layer and a cyclone separator which are sequentially arranged in the kettle body in a sleeved mode from outside to inside. On one hand, such an annular layered structure enables an extraction agent to complete extraction in an internal rotation flowing mode, so a contact area between the extraction agent and an objectto be extracted in the flowing process of the extraction agent is increased, and extraction yield is greatly increased; on the other hand, the space utilization rate in the extraction kettle is increased, and the common wall flow problem in the supercritical extraction process is avoided; meanwhile, a flow field in the extraction separation kettle is more uniform and stable by designing the orientation of air inlet holes and arranging an arc-shaped flow guiding plate. The supercritical extraction separation kettle of the invention has three functions including extraction, pressure reduction,and separation and purification, and can realize high-quality and high-efficiency bioactive component extraction and cyclic reutilization of the extraction agent.

Owner:北京斯坦励能源科技有限公司

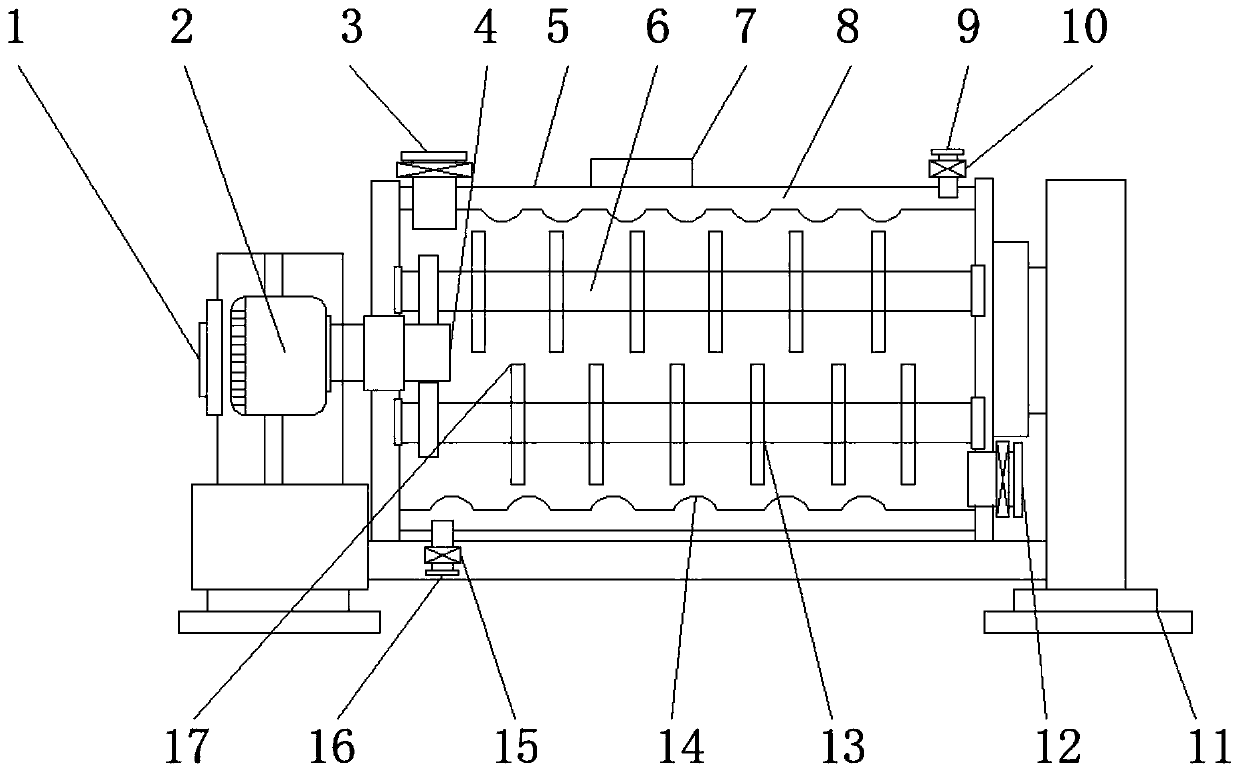

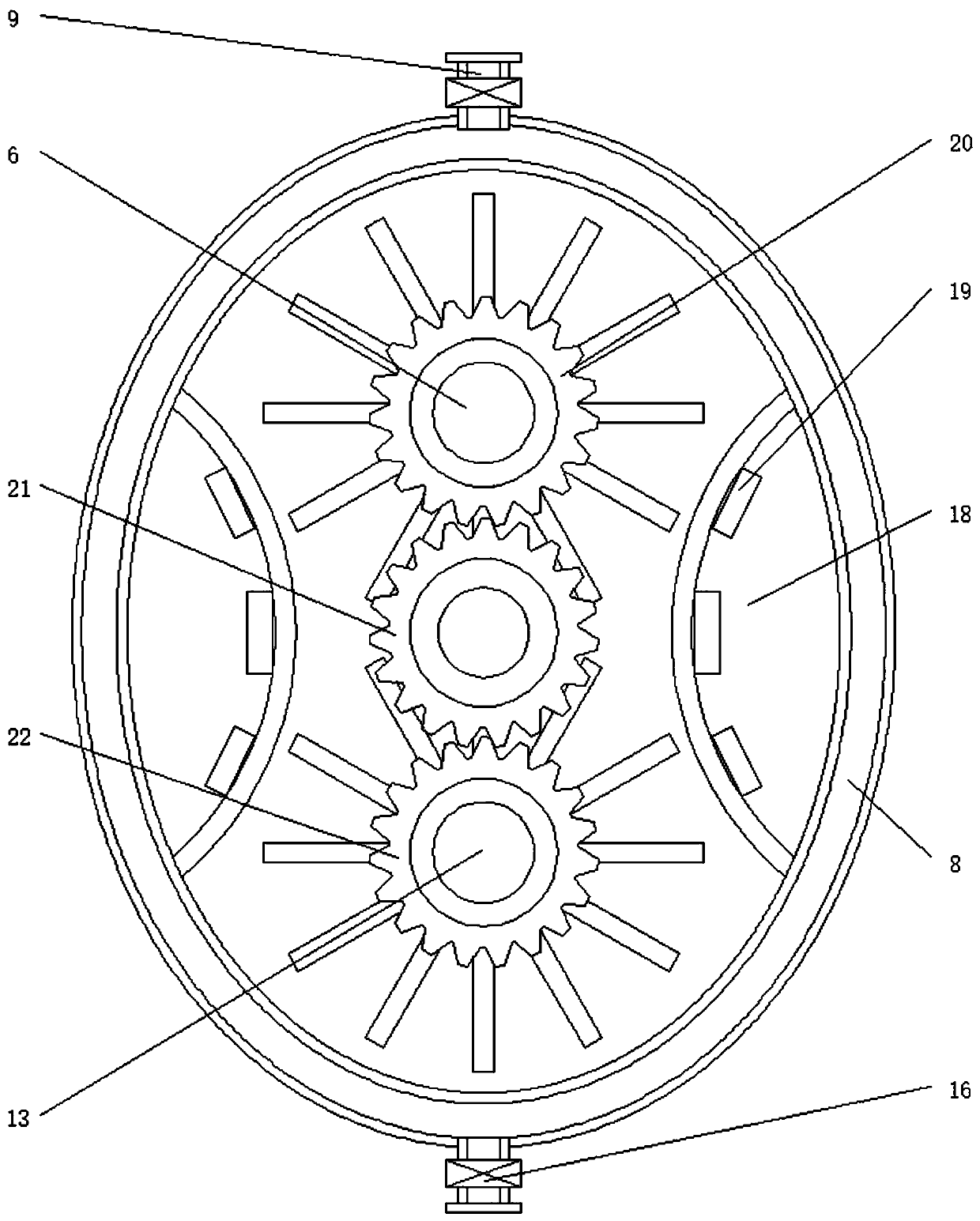

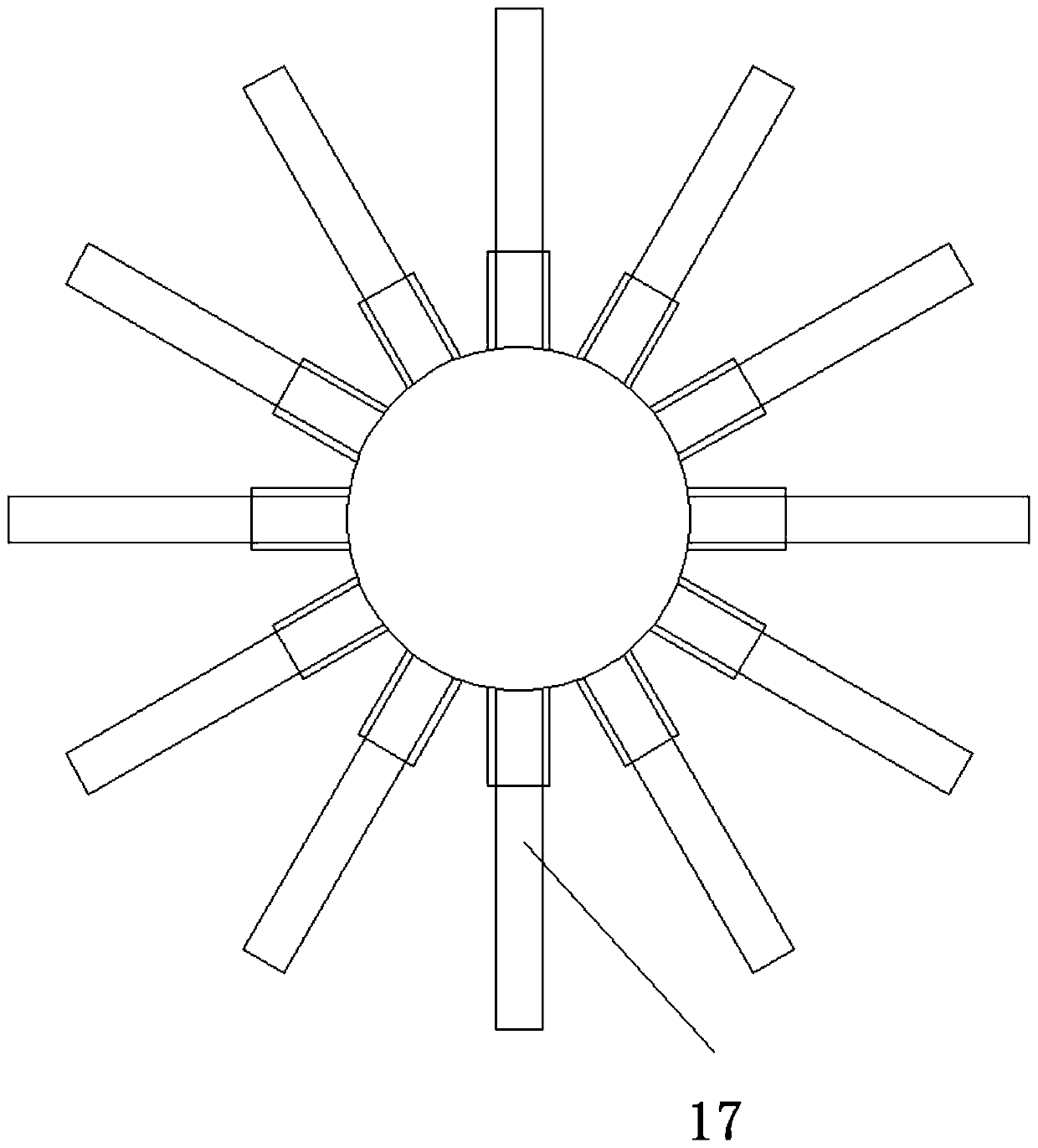

Plastic bag raw material mixer

The invention discloses a plastic bag raw material mixer. The plastic bag raw material mixer comprises a heat dissipation fan, a motor device, a barrel body and a thermometer, wherein the left side ofthe motor device is equipped with the heat dissipation fan; the right side of the motor device is fixedly connected with a drive shaft; the right side of the drive shaft is arranged inside the barrelbody; the upper side of the drive shaft is equipped with a first transmission shaft; a discharge hole is formed in the middle of the right side of the barrel body; the barrel body is fixedly arrangedon the bracket; the left lower side of the barrel body is equipped with a steam outlet; and an outlet regulating valve is arranged on the steam outlet. The plastic bag raw material mixer disclosed bythe invention adopts dual transmission shafts, and dispersing discs are uniformly arranged on the transmission shafts in a spaced mode, so that raw materials do not form fixed rotating vortex duringrotation, raw material mixing is more uniform, mixing time is shortened, working efficiency is improved, mixing work of plastic bag raw materials can be performed better, and development of the plastic bag processing industry is promoted.

Owner:颍上县浩楠塑料包装有限公司

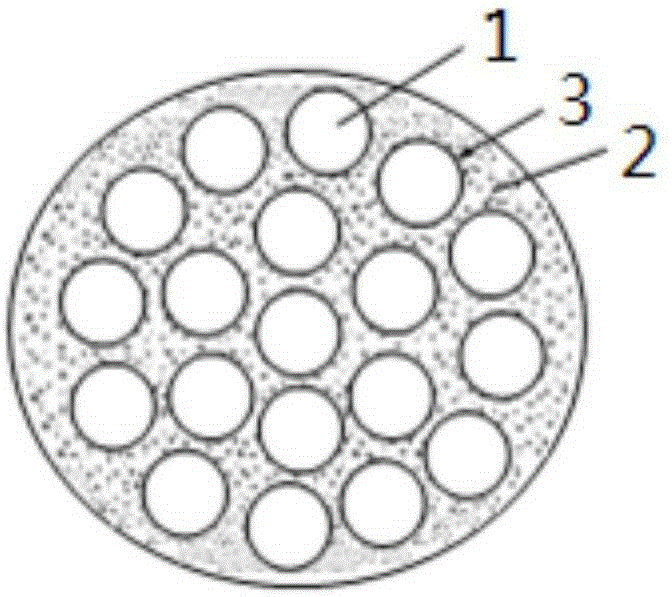

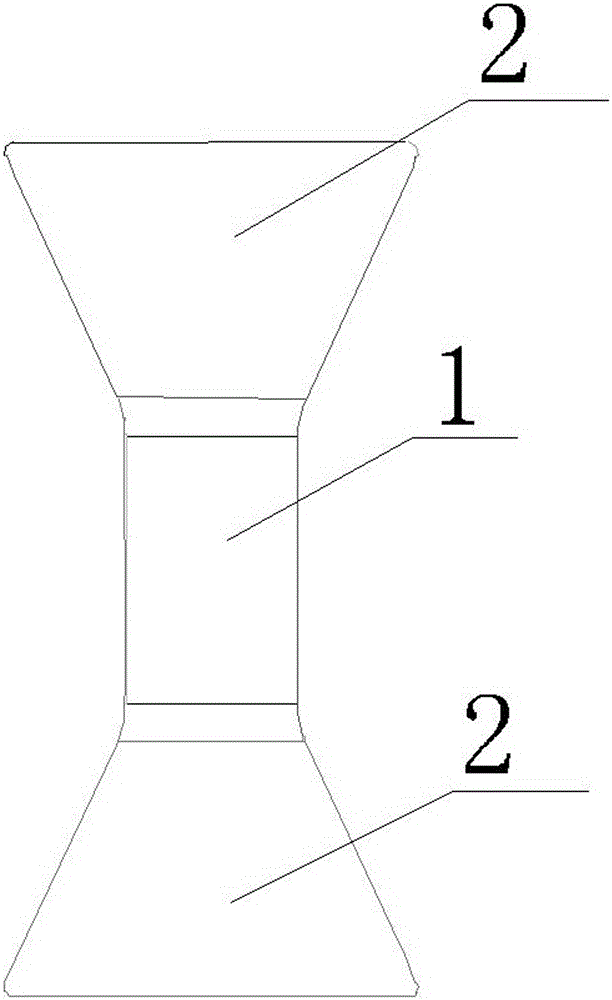

Raschig ring filling material

InactiveCN105013427AEvenly distributedExtended service lifeChemical/physical/physico-chemical processesPorosityEpoxy

The invention relates to a raschig ring filling material, which belongs to the technical field of petroleum chemical mass transfer separating equipment. The raschig ring filling material comprises a tubular body, the symmetrical trumpet-shaped flarings are arranged at two ends of the tubular body; a corrosion resisting coating is sprayed on the surface of the raschig ring filling material, the corrosion resisting coating comprises the following components by weight percentage: 10-20% of terephthalate epoxy resin, 10-15% of polyvinyl formal, 11-15% of cross-linking agent, 6-8% of anhydrous auxiliary agent, 2-3% of catalyst, and the balance of water. The symmetrical trumpet-shaped flaring are arranged at two ends of the tubular body, each filling material enables point contact while stacking, distribution is more uniform, porosity is increased, channeling and wall flow phenomena can be effectively prevented, wetting on the surface in the filling material is convenient due to trumpet-shaped flaring, and production efficiency is increased.

Owner:SUZHOU KD PETROCHEM ENG

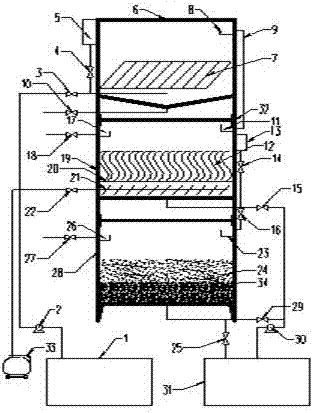

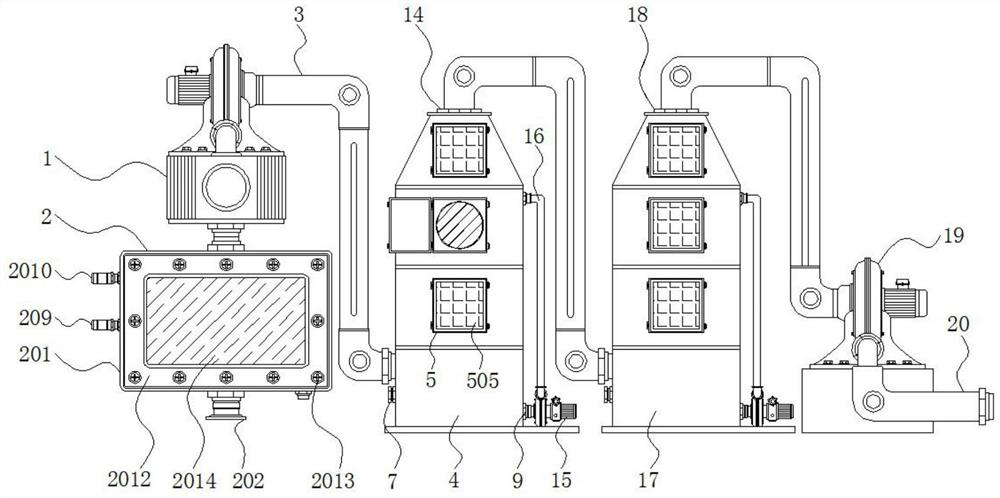

Biological membrane biochemical reaction system based on ozone and wastewater purifying process

InactiveCN109824215AImprove reaction efficiencyReduce energy consumptionTreatment using aerobic processesWater contaminantsOzone generatorDecomposition

The invention belongs to the field of wastewater processing, and particularly relates to a biological membrane biochemical reaction system based on ozone and a wastewater purifying process. The biological membrane biochemical reaction system comprises an ozone reactor for purifying wastewater through the ozone, an oxygen-rich aeration biological membrane biochemical reactor communicated with an ozone generator and used for deeply purifying and discharging the purified waste, and an ozone decomposition reactor communicated with the ozone generator, the oxygen-rich aeration biological membrane biochemical reactor and used for decomposing the ozone passing through the ozone reactor but not completely reacting into oxygen. The low-energy-consumption, high-efficiency and economical wastewater deep purifying process is provided, and the ozone catalytic oxidization is fixedly connected with the biological membrane biochemical reactor in series. The wastewater can be purified for up-to-standard discharging under the low energy consumption.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

Ozone-based biofilm biochemical reaction system and wastewater purification process

PendingCN110526527AReduce energy consumptionImprove efficiencyTreatment using aerobic processesWater contaminantsBiofilmOzone generator

The invention belongs to the field of wastewater treatment, and particularly relates to an ozone-based biofilm biochemical reaction system and a wastewater purification process. The system comprises an ozone reactor, an oxygen-enriched aeration biofilm biochemical reactor, and an ozone decomposition reactor, wherein the ozone reactor is used for purifying wastewater by using ozone, the oxygen-enriched aeration biofilm biochemical reactor communicates with an ozone generator, and is used for carrying out deep purification treatment of the purified wastewater and performing discharge, and the ozone decomposition reactor respectively communicates with the ozone generator and the oxygen-enriched aeration biofilm biochemical reactor, and is used for decomposing the unreacted ozone after passingthrough the ozone reactor into oxygen. The invention provides a low-energy-consumption, high-efficiency, and economical wastewater deep purification process: an ozone catalytic oxidation in series with fixed biofilm biochemical reactor. With relatively low energy consumption, wastewater can be purified and discharged up to standard.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

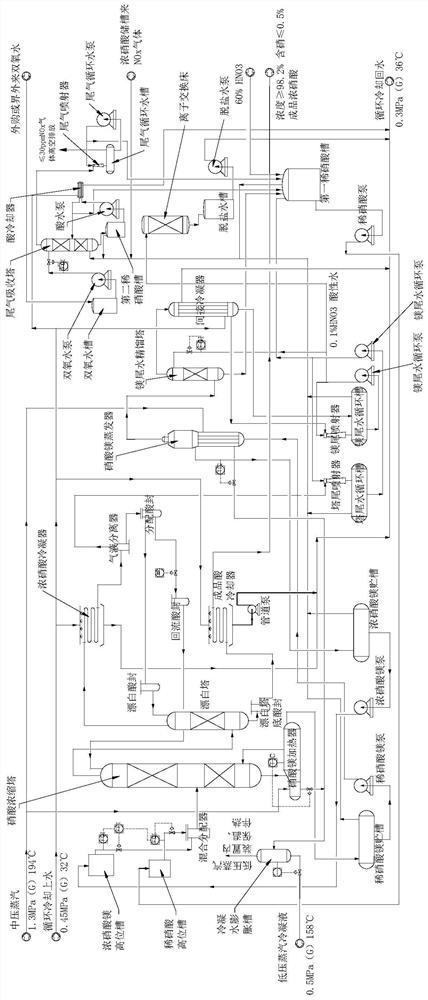

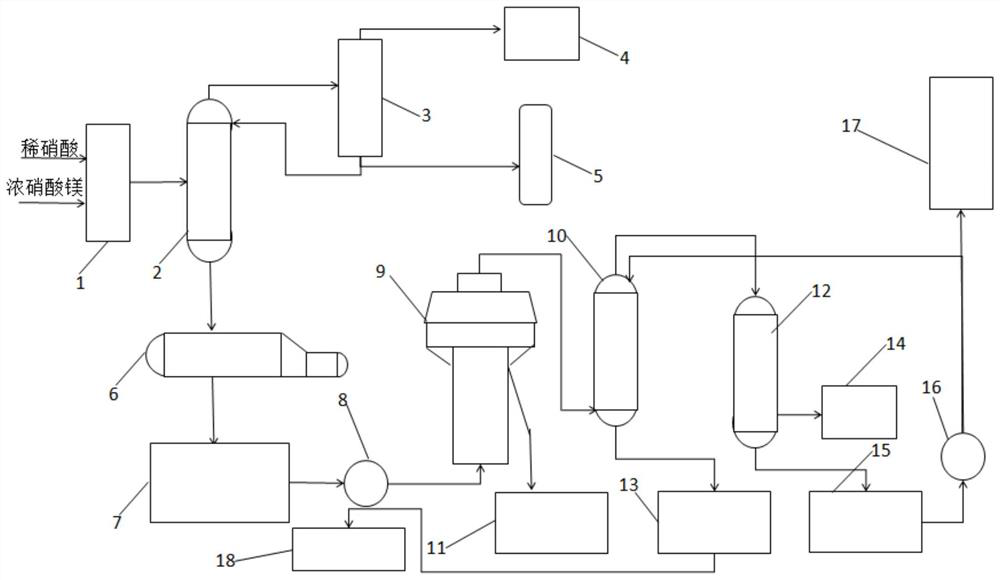

Novel magnesium nitrate method based concentrated nitric acid production system

PendingCN111807338AIncrease the shower densityIncrease contact areaNitric acidPhysical chemistryChemical engineering

The invention belongs to the technical field of chemical engineering, and particularly relates to a novel magnesium nitrate method based concentrated nitric acid production system which comprises a nitric acid concentration tower and a bleaching tower. Dispersers positioned at the top of the nitric acid concentration tower and the top of the bleaching tower are groove-type dispersers, the sprinkling aperture of the disperser at the top of the nitric acid concentration tower is 6mm, and the sprinkling aperture of the disperser at the top of the bleaching tower is 4mm. The height specification of two tower sections of the nitric acid concentration tower is 15300mm. Compared with a traditional disperser of a disc type structure, the novel magnesium nitrate method based concentrated nitric acid production system has the advantages that the spraying density can be increased, column flow is prevented from being generated during spraying, the gas-liquid contact area is increased, mass transfer and heat transfer between gas and liquid are improved, and the nitrate content of dilute magnesium nitrate is reduced; and compared with the traditional tower section specification and the nitric acid concentration tower with the height of 14900mm, the system has the advantages that the rectification height of the concentrated nitric acid is increased to stabilize the concentration of the finished product acid to be more than 98.2% (w / w), meanwhile, the denitration height is increased, and the nitrate content in the dilute magnesium nitrate is reduced.

Owner:济南双硝技术开发有限公司

A desulfurization regeneration tower

ActiveCN104987895BEffective absorptionReduce pollutionDispersed particle separationGas purification by liquid washingLiquid temperatureCoking plant

The invention relates to a desulfuration regeneration tower. Coal gas and a desulfurizing liquid are subjected to mass transfer in a filling material to remove hydrogen sulfide in coal gas, the desulfurizing liquid reaches an upper regeneration section through a desulfurizing liquid conveying pipe, and the coal gas is regenerated by utilization of air under the action of a catalyst, and returns to a lower desulfuration section to be subjected to desulfuration. The desulfuration regeneration tower is divided into the lower desulfuration section and the upper regeneration section, wherein the lower desulfuration section comprises a coal gas inlet, a coal gas outlet, a coal gas distributor, a filling material, a mist collecting filling material, a filter, a cyclone separator and a desulfurizing liquid outlet; the upper regeneration section comprises a bubble separator, an inclined conical section, a foam outlet, a regenerated air outlet and a gas distributor. According to the desulfuration regeneration tower, an HPF wet oxidation process desulfuration technology is adopted, so that the desulfurizing liquid and air can be better mixed, the contact time is prolonged, the influence on desulfurizing liquid temperature by environmental temperature is reduced, meanwhile space is saved, lots of materials are saved, the desulfuration efficiency is improved by utilization of self structural advantages, and the environmental pollution of a coking plant is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

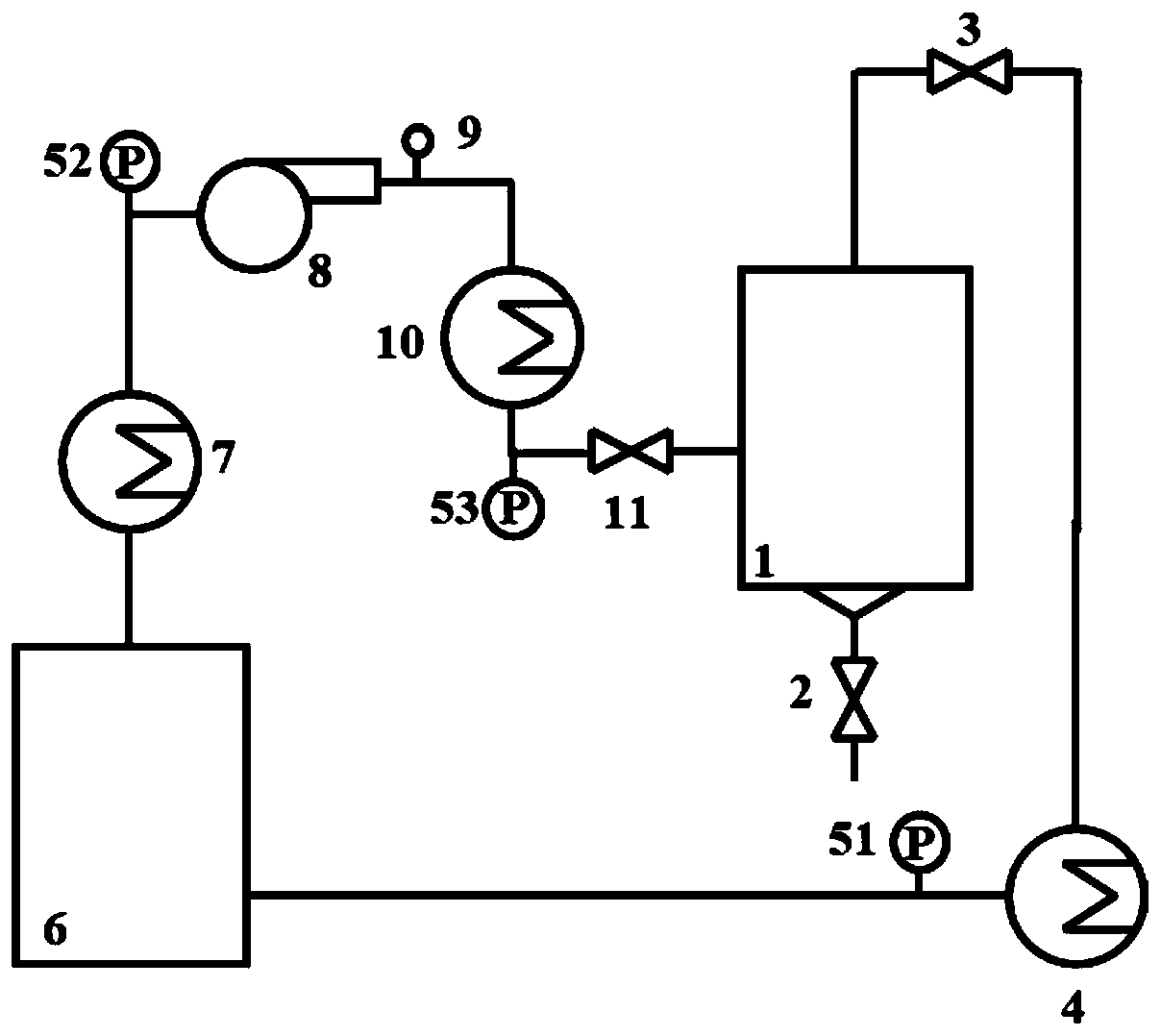

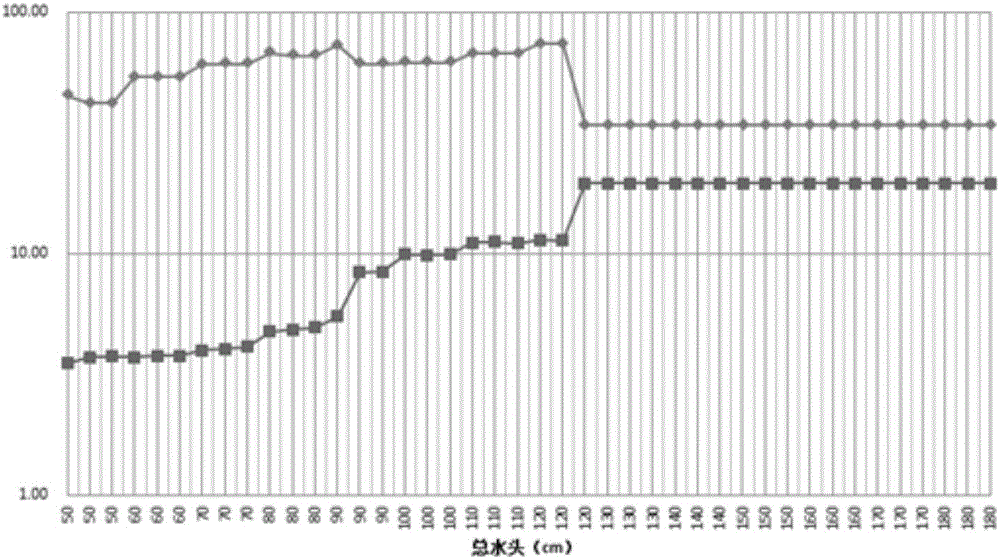

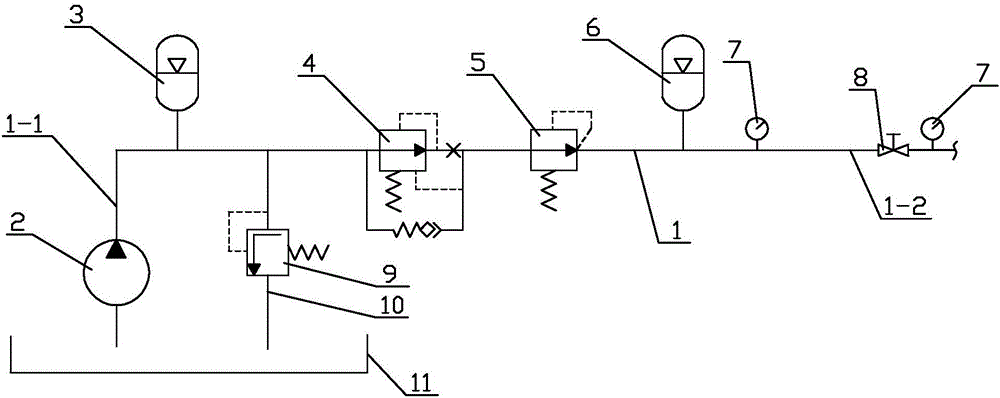

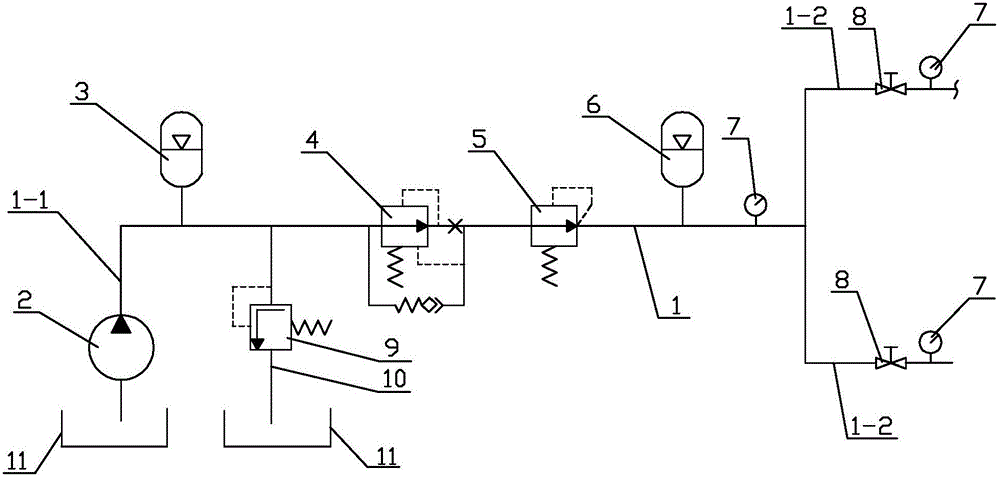

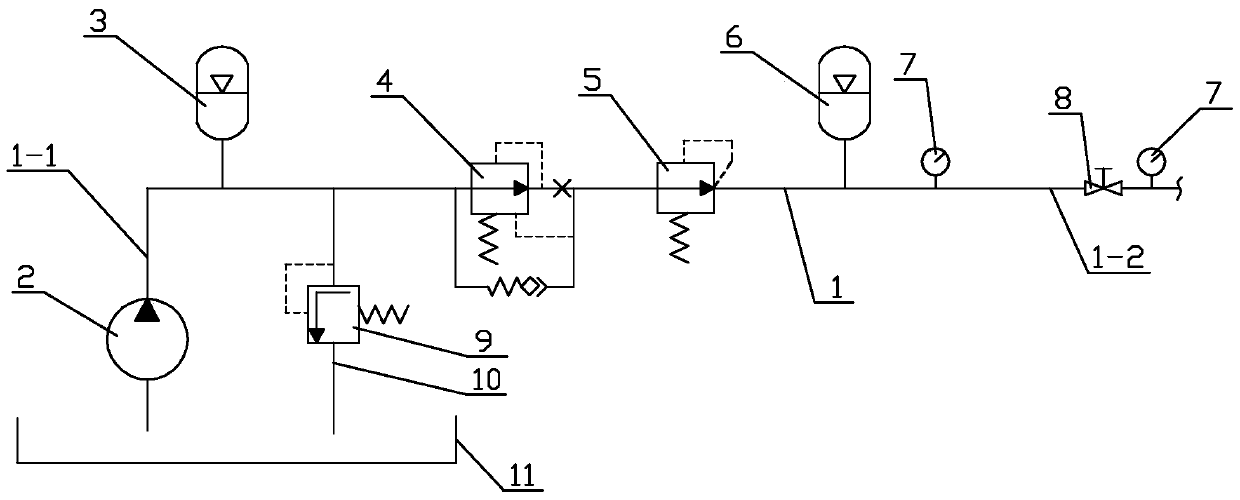

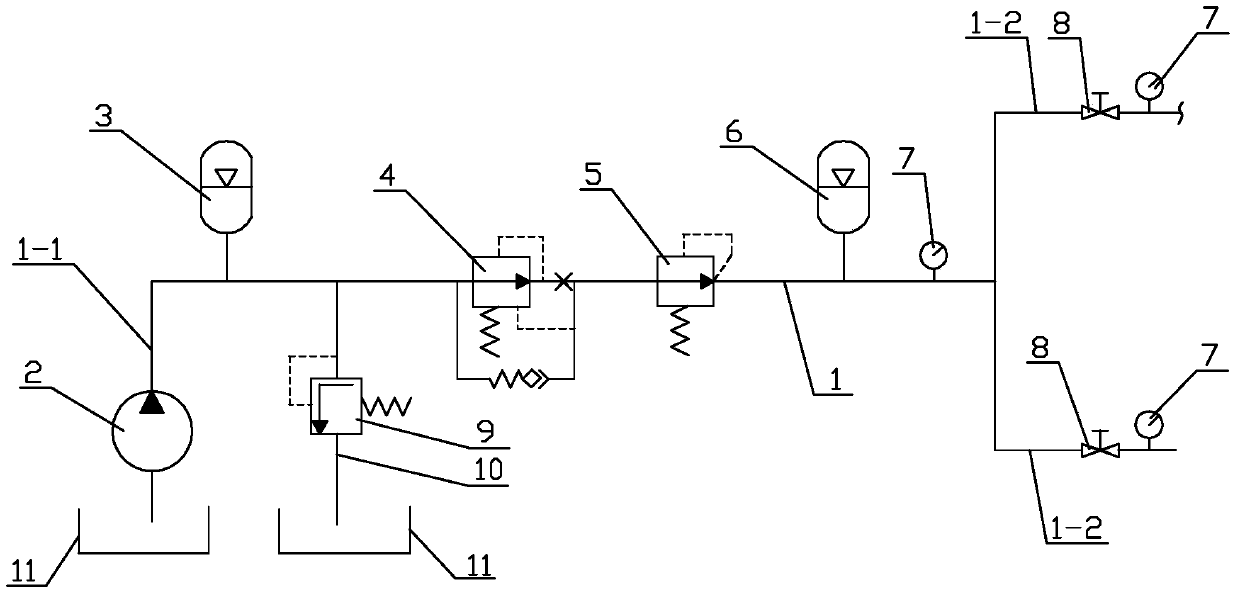

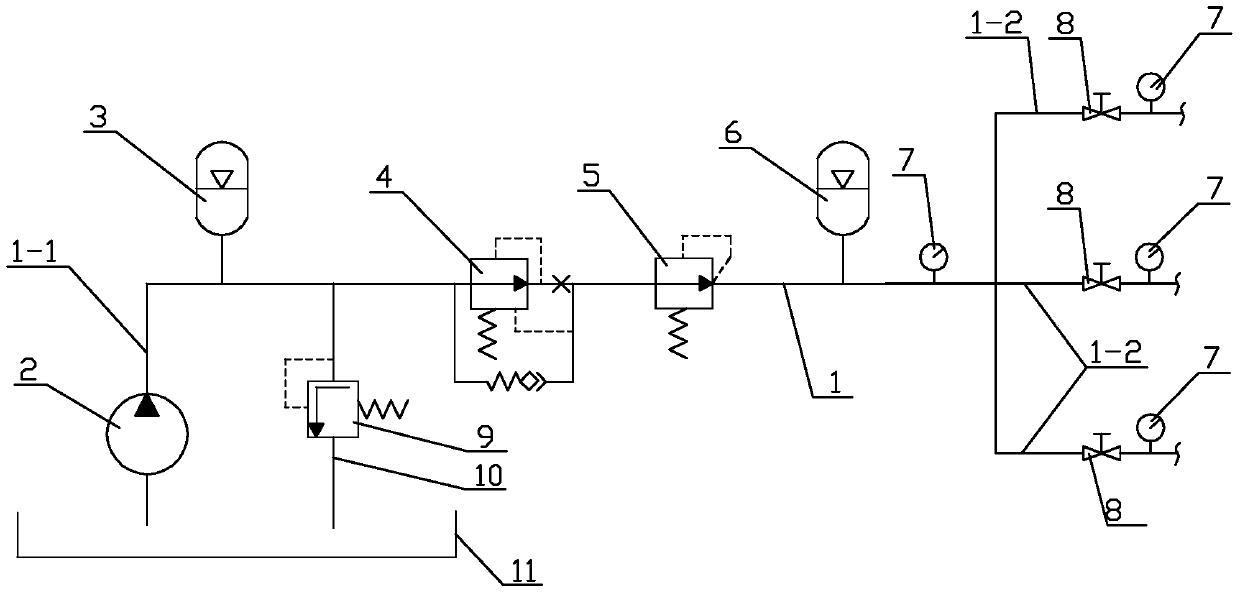

Water head pressure control system and apparatus for pinhole seepage deformation test

ActiveCN105021504AImprove accuracy and reliabilityLarge adjustable rangePermeability/surface area analysisPipingEngineering

The present invention discloses a water head pressure control system and an apparatus for a pinhole seepage deformation test. The water head pressure control system comprises a water storage device and water supply pipes for supplying water for a seepage deformation device, wherein the water supply pipes comprise a water supply main pipe and at least a water supply branch pipe communicated with the water supply main pipe, one end of the water supply main pipe is communicated with the water storage device, the other end is communicated with each water supply branch pipe, the water supply main pipe is further provided with a water drain pipe, each water supply branch pipe end being not connected with the water supply main pipe is respectively communicated with the water inlet pipes in each seepage deformation device, the water supply main pipe is sequentially provided with a metering pump, a first accumulator, a speed regulating valve, a pressure reducing valve, a second accumulator and a pressure gauge, the water drain pipe is arranged between the first accumulator and the speed regulating valve and is provided with an overflow valve, and each water supply branch pipe is provided with a shut-off valve and a pressure gauge. According to the present invention, the structure of the apparatus is simple, the seepage deformation water pressure during the experiment process can be continuously, stably and accurately controlled, and the reliability of the experimental data can be improved.

Owner:INST OF KARST GEOLOGY CAGS

Gas-liquid distribution device

ActiveCN113070001AEliminate uneven distributionReduce the amount of processingChemical/physical processesFluid phaseEngineering

The invention discloses a gas-liquid distribution device. The gas-liquid distribution device comprises a reactor wall, and a distribution plate, an overflow pipe and a distribution disc which are arranged along the reactor wall from top to bottom, wherein the distribution plate is a flat plate, is consistent with the section of a reactor in shape, is supported on the wall of the reactor and is provided with flow guide holes; the overflow pipe is a circular pipe with two open ends, the lower end of the overflow pipe is fixed on a mounting hole in the distribution disc, and overflow holes are uniformly formed in the pipe wall along the circumferential direction to serve as liquid phase channels; and the upper end of the overflow pipe is a free end, is positioned below the distribution plate, is over against the center of a non-perforated area between the flow guide holes in the distribution plate and is completely shielded by the non-perforated area. Compared with a common scheme of blocking overflow pipes one by one in the prior art, the distribution plate used in the invention has the advantages of small processing amount, short manufacturing period and low cost while the purpose of preventing an upper liquid phase from directly entering the overflow pipes can also be achieved. According to the invention, the contact time of a gas phase and a liquid phase is prolonged, dissolution of the gas phase in the liquid phase is promoted, and meanwhile, the phenomenon of inner wall flow of the overflow pipe is effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP +2

Gas-liquid distribution equipment

ActiveCN111992143AAvoid uneven distributionIncrease contact timeBio-feedstockChemical/physical processesCircular discFluid phase

The invention discloses gas-liquid distribution equipment. The gas-liquid distribution equipment comprises a blocking cap, a mixing pipe and a distribution disc which are arranged from top to bottom;the blocking cap is in a circular flat plate or conical umbrella shape and is arranged at the upper end of the mixing pipe, and a gap between the blocking cap and the upper end of the mixing pipe serves as a gas-phase channel; the mixing pipe is an inverted conical pipe with two open ends, wherein the upper end is a large end serving as a mixing pipe inlet, and the lower end is a small end servingas a mixing pipe outlet; the lower end of the mixing pipe is fixed on a mounting hole of the distribution disc; overflow holes are formed in the pipe wall of the mixing pipe as liquid phase channels;the inner wall of the mixing pipe is provided with a rotary guide vane; the tail end of the rotary guide vane and the inner wall of the mixing pipe in front of an outlet of the mixing pipe are provided with one or two or more layers of liquid collecting discs; the liquid collecting discs are concave flat-bottom discs and are fixedly connected with the wall of the mixing pipe through convex concave edges; and distribution holes are uniformly distributed in the bottoms of the liquid collecting discs to allow a gas phase and a liquid phase to pass through. According to the invention, gas-liquidtwo-phase contact can be enhanced, the gas-liquid two-phase atomization effect is promoted, and the wall flow phenomenon in the overflow pipe is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Industrial acidic waste gas treatment device for preventing white smoke from emitting from two fluids

InactiveCN112691452AEasy to clean and replaceImprove placement efficiencyDispersed particle filtrationTransportation and packagingExhaust fumesProcess engineering

The invention discloses an industrial acidic waste gas treatment device for preventing white smoke from emitting from two fluids, and relates to the technical field of industrial acidic waste gas treatment. The industrial acidic waste gas treatment device comprises a gas collection device, a first washing tower, a second washing tower and a fan. The lower end of the gas collection device is connected with a condensed gas-liquid separator, and the right side of the upper end of the gas collection device is connected with a gas guide pipe. The first washing tower is connected to the other end of the gas guide pipe, an observation window is formed in the outer side of the front end of the first washing tower, and a first washing tower gas inlet and a first washing tower water inlet are sequentially formed in the left side of the first washing tower from top to bottom. Through the arrangement of two ball packing layers, the removal rate of waste gas can be effectively increased, meanwhile, the wall flow phenomenon can be effectively avoided, the gas-liquid collision probability is increased, the reaction time is prolonged, and therefore the actual filtering effect of the first washing tower is greatly improved. Meanwhile, the shape and structure of the second washing tower are consistent with those of the first washing tower, and the treatment quality is ensured while the acid waste gas treatment efficiency is ensured.

Owner:茂裕环保科技南通有限公司

A head pressure control system and device for pinhole penetration deformation test

ActiveCN105021504BHigh precisionImprove reliabilityPermeability/surface area analysisWater storageControl system

The present invention discloses a water head pressure control system and an apparatus for a pinhole seepage deformation test. The water head pressure control system comprises a water storage device and water supply pipes for supplying water for a seepage deformation device, wherein the water supply pipes comprise a water supply main pipe and at least a water supply branch pipe communicated with the water supply main pipe, one end of the water supply main pipe is communicated with the water storage device, the other end is communicated with each water supply branch pipe, the water supply main pipe is further provided with a water drain pipe, each water supply branch pipe end being not connected with the water supply main pipe is respectively communicated with the water inlet pipes in each seepage deformation device, the water supply main pipe is sequentially provided with a metering pump, a first accumulator, a speed regulating valve, a pressure reducing valve, a second accumulator and a pressure gauge, the water drain pipe is arranged between the first accumulator and the speed regulating valve and is provided with an overflow valve, and each water supply branch pipe is provided with a shut-off valve and a pressure gauge. According to the present invention, the structure of the apparatus is simple, the seepage deformation water pressure during the experiment process can be continuously, stably and accurately controlled, and the reliability of the experimental data can be improved.

Owner:INST OF KARST GEOLOGY CAGS

A packed tower with anti-clogging and anti-wall flow

ActiveCN107158730BEasy to separateIncrease contact surfaceDispersed particle separationDistillation separationTowerMechanical engineering

The present invention discloses an anti-clogging and anti-wall-flow filler tower, which comprises a cylinder, a filler positioned in the cylinder, and a filler support grate positioned in the cylinder, wherein a liquid outlet is arranged below the cylinder and is connected to a finished product tank, a material inlet is arranged above the cylinder, the cylinder is provided with a gas outlet, a filler is arranged in the cylinder, the lower portion is the filler support grate, the cylinder is formed by sequentially connecting a first part, a second part and a third part from top to bottom, the second part has a cone table shape, the diameter of the lower end of the second part is larger than the diameter of the upper end, and the filler is positioned in the second part, and is stacked to form a cone table shape. According to the present invention, the anti-clogging and anti-wall-flow filler tower has characteristics of simple structure and convenient use; and when the high temperature gas passes through the cone-table-shaped cylinder, the speed is accelerated, such that the separation of the liquid at the wall surface is rapid, and the contact surface between the gas and the quid is large so as to completely contact.

Owner:JIANGSU KESHENG CHEM MACHINERY

high performance liquid chromatography sphere

Owner:CAPITAL NORMAL UNIVERSITY

A kind of production equipment of magnesium nitrate method to produce concentrated nitric acid

ActiveCN108557786BReduce nitrateEasy to separateDistillation regulation/controlFractional distillationWastewaterEnvironmental chemistry

The embodiment of the present application shows a kind of production equipment for producing concentrated nitric acid by magnesium nitrate method. Through the transformation of the concentration tower, the occurrence of wall flow and vertical downflow of magnesium nitrate solution can be effectively avoided, and the concentration of dilute nitric acid can also be greatly reduced. The content of magnesium is such that the concentration of magnesium tail water formed by the condensation of the acid vapor evaporated from the magnesium nitrate evaporator is below 0.1%. By adding an acid separator, the magnesium tail water and acid vapor can be fully exchanged in gas-liquid in the acid separator, effectively reducing the concentration of the tower tail water. Magnesium tail water is used as production water and sent to the circulating pool as supplementary water for production. Through the above modification, the comprehensive utilization of tower tail water and magnesium tail water acidic wastewater can be realized, and zero discharge of acidic wastewater can be realized.

Owner:宁夏润夏能源化工有限公司

Gas-liquid distribution equipment

ActiveCN113070002AEliminate uneven distributionReduce the amount of processingChemical/physical processesFluid phaseMechanical engineering

The invention discloses gas-liquid distribution equipment. The gas-liquid distribution equipment comprises a reactor wall as well as a distribution plate, an overflow pipe and a distribution disc which are arranged along the reactor wall from top to bottom, wherein the distribution plate is a corrugated plate, the shape of the distribution plate is consistent with the shape of a cross section of a reactor, the distribution plate is supported on the wall of the reactor, and flow guide holes are formed in the corrugated plate and are formed in crests or troughs of the corrugated plate; the overflow pipe is a circular pipe with two open ends, the lower end of the overflow pipe is fixed on a mounting hole of the distribution disc, and one or two or more layers of overflow holes are uniformly formed in the pipe wall along the circumferential direction to serve as liquid phase channels; and the upper end of the overflow pipe is a free end, is positioned below the distribution plate, faces non-perforated areas among the flow guide holes in the distribution plate and is completely shielded by the non-perforated areas. Compared with a common scheme of blocking overflow pipes one by one in the prior art, the distribution plate used in the invention has the advantages of small processing amount, short manufacturing period, low cost and excellent scaling resistance while the purpose of preventing an upper liquid phase from directly entering the overflow pipes can also be achieved; and meanwhile, the phenomenon of inner wall flow of the overflow pipe is effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP +2

Wastewater ammonia nitrogen blow-off treatment reaction device

ActiveCN102701307BAvoid wastingAvoid wall flowWater/sewage treatment by degassingLiquid wasteDraining tube

The invention discloses a wastewater ammonia nitrogen blow-off treatment reaction device which comprises a shell, wherein a gas water separation layer, a water distribution device, an umbrella-shaped water shield and a gas distribution device are distributed in the shell at intervals from top to bottom in sequence; the shell is divided into an upper chamber and a lower chamber by the umbrella-shaped water shield; a drain pipe is arranged on the shell at the bottom of the upper chamber; the water distribution device consists of a water inlet pipe, a gas inlet pipe and a double-fluid spray nozzle, wherein the water inlet pipe and the gas inlet pipe are communicated; and the communication part of the water inlet pipe and the gas inlet pipe is provided with the downward double-fluid spray nozzle to form a three-way structure, so that gas-liquid waste caused by mixing gas and liquid by utilizing a packing layer can be effectively avoided, channeling and wall flow phenomena can be effectively prevented, and the stability of ammonia nitrogen blow-off treatment is improved.

Owner:JIANGSU YIHUAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com