Gas-liquid distribution equipment

A technology of equipment and distribution plate, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of poor gas-phase atomization and liquid-phase ability, large manufacturing workload, and short contact time between gas-phase and liquid-phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

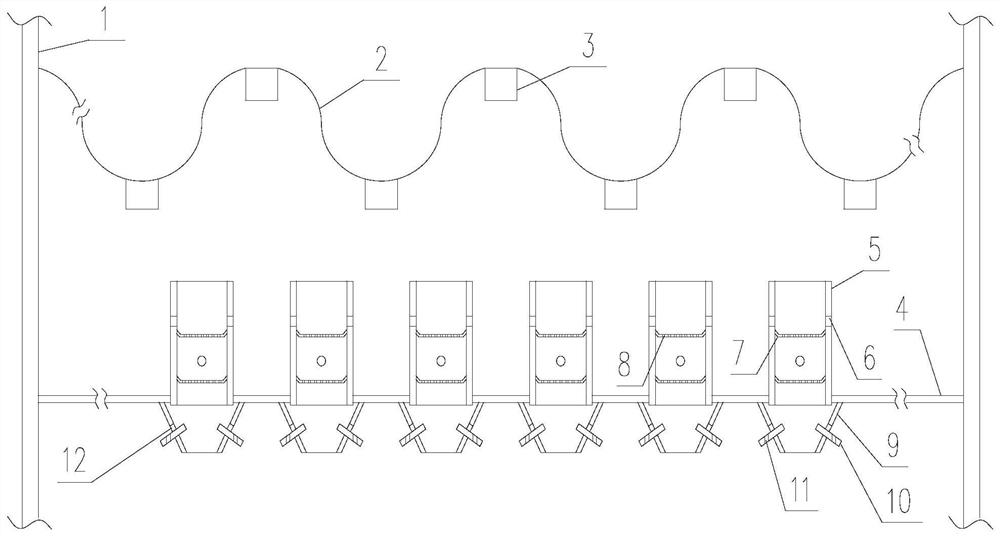

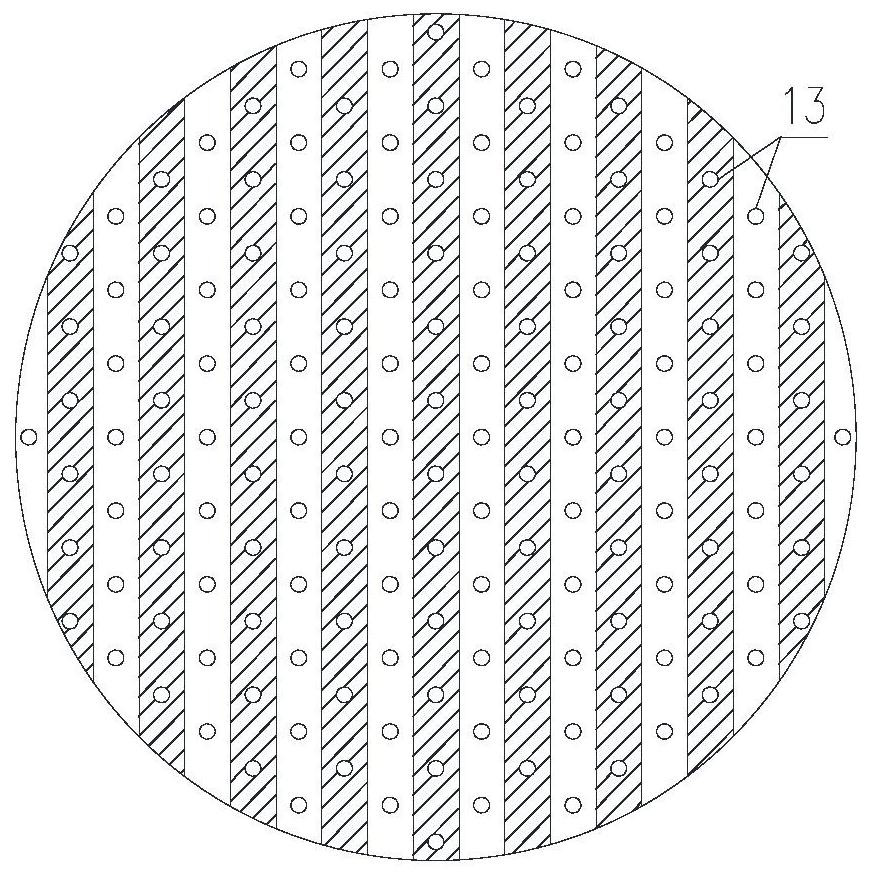

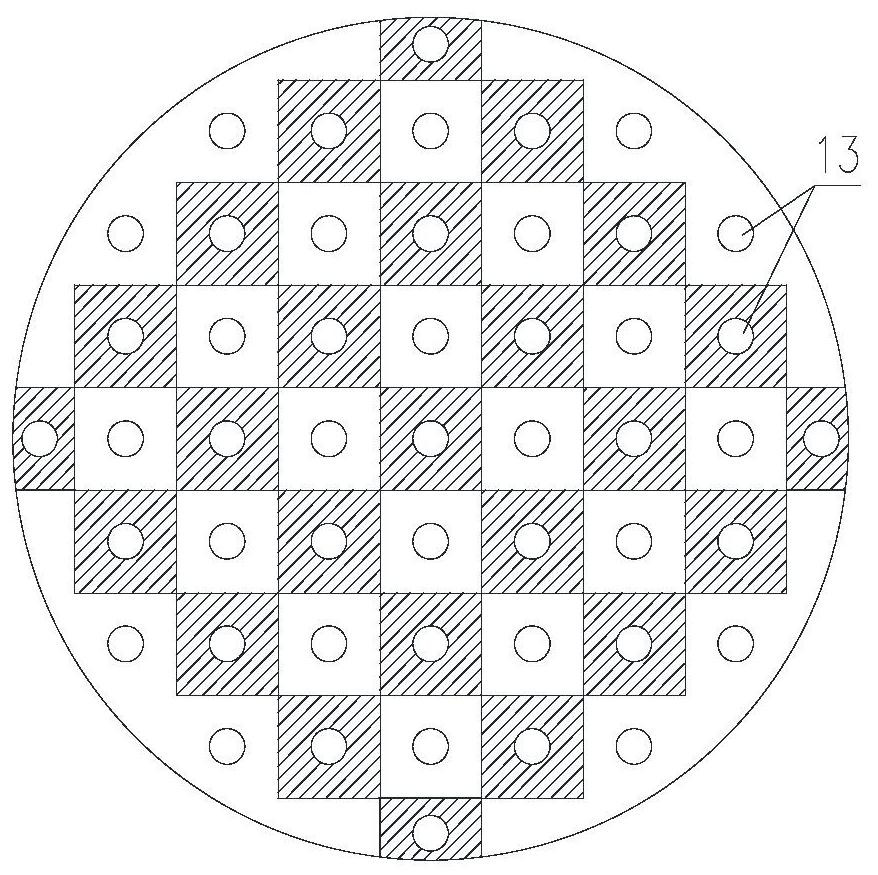

[0049] like Figure 1~4 As shown, the gas-liquid distribution equipment provided by the present invention includes a reactor wall 1 and a distribution plate 2 arranged from top to bottom along the reactor wall, a guide pipe 3, an overflow pipe 5, a distribution plate 4, fixed on the distribution plate Disperser arranged under the plate 4 and coaxial with the overflow pipe 5; the distribution plate 2 is a corrugated plate, the shape is consistent with the cross-sectional shape of the reactor, supported on the reactor wall 1, and a circular guide hole 13 is set on the corrugated plate (See Figure 2 ~ Figure 3 ), the guide hole 13 is located at the crest or trough of the corrugated plate; figure 2 The adjacent crests and troughs on the corrugated board shown are alternately arranged in strips, and the longitudinal spacing of the diversion holes on the crests and troughs should be 20-300mm. figure 2 For the corrugated board shown, it can be set as two adjacent layers up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com