Rare earth additive for hard alloy and preparation method thereof

A technology of rare earth additives and cemented carbide, which is applied in the field of rare earth additives for cemented carbide and its preparation, can solve the problems of single composition of rare earth additives, uneven distribution of rare earth elements, coarse particle size, etc., and achieve the elimination of uneven distribution, mechanical mechanical The effect of performance improvement and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

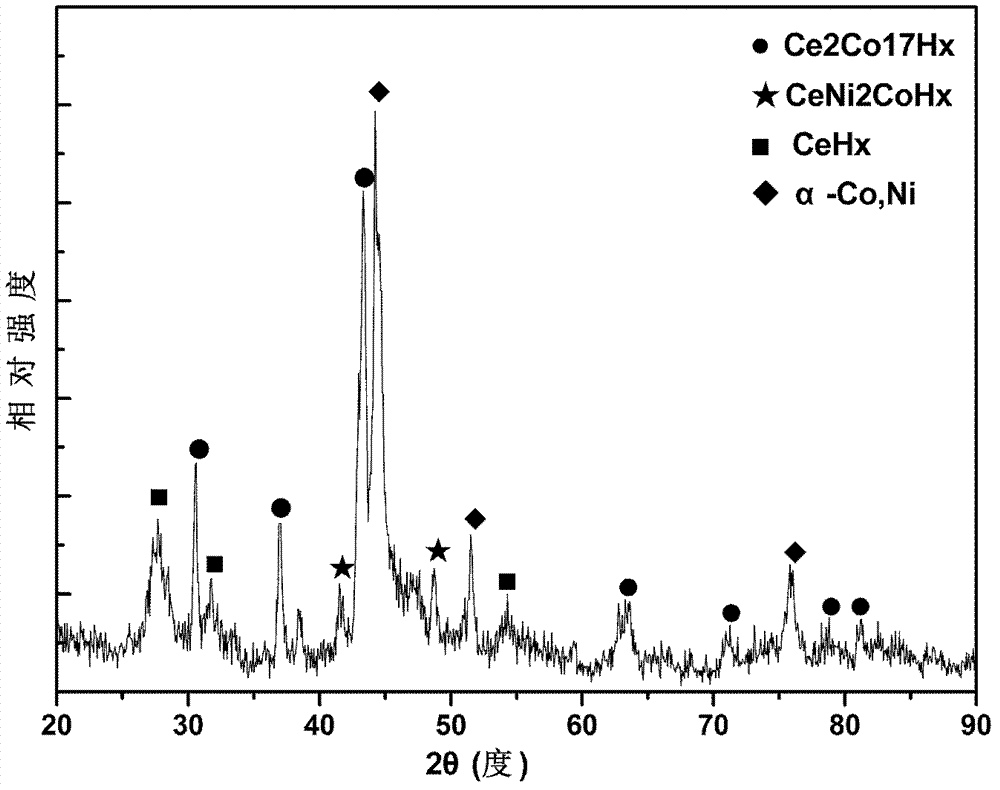

[0042] Raw materials used in this embodiment: Ce 27.87wt%, binder phase raw material (Co, Mn, Ni) 72.13wt%; said binder phase raw material (Co, Mn, Ni), Co 56.28wt%, Mn 0.1wt% , Ni 15.75wt%.

[0043] The processing steps of the present embodiment:

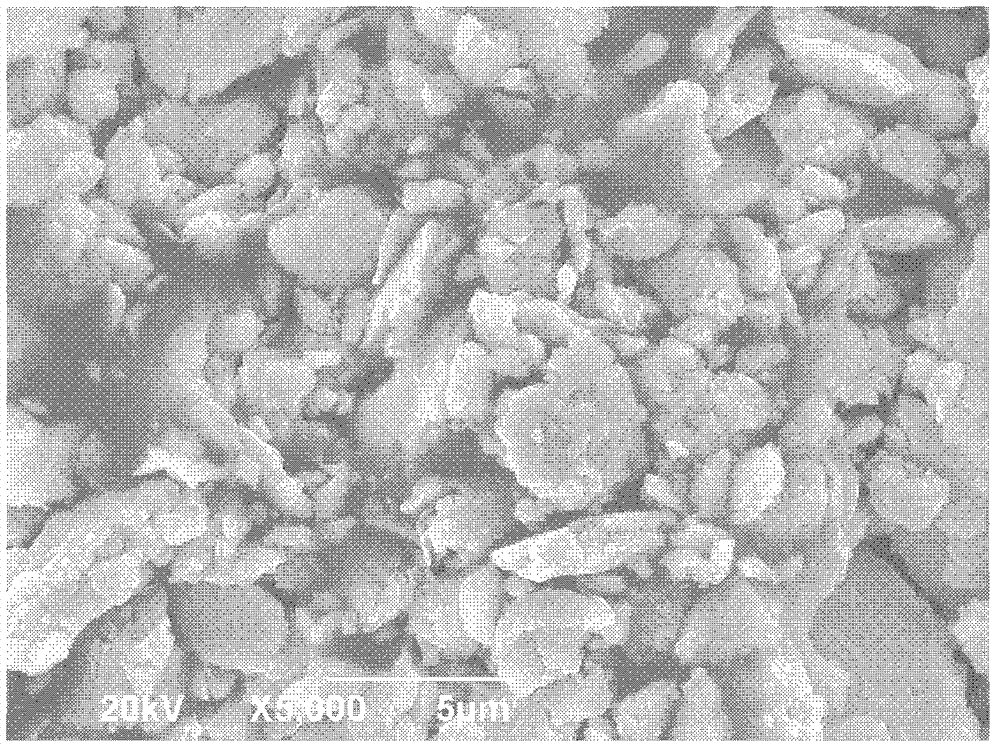

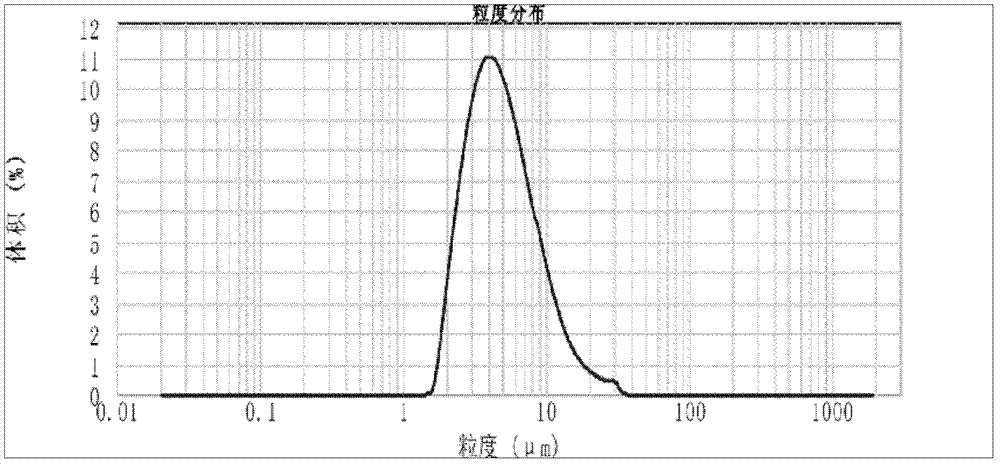

[0044]After the above-mentioned raw materials are measured according to their weight percentages, they are melted in a vacuum induction melting furnace and cast into rare earth-bonding phase alloy ingots. The pouring temperature is 1380 ° C, and the heat preservation is 5 minutes. The ingots are coarsely broken into alloy blocks smaller than 20mm by a jaw crusher; the alloy blocks formed after the alloy ingots are roughly crushed are placed in a vacuum heating furnace for homogenization and annealing, and the vacuum degree is controlled at 1×10 -1 Pa, the annealing temperature is 1100°C, and the annealing time is 10 hours; the above-mentioned homogenized annealed alloy block is placed in a tubular heat treatment furnace, and the v...

Embodiment 2

[0047] Raw materials used in this embodiment: Sm 16.08wt%, Dy 1.0wt%, binder phase raw materials (Co, Mn, Fe, Cu, Al) 82.92wt%; said binder phase raw materials (Co, Mn, Fe, Cu, In Al), Co 31.21wt%, Mn 11.8wt%, Fe 32.68wt%, Cu 6.09wt%, Al 1.14wt%.

[0048] The processing steps of the present embodiment:

[0049] After the above-mentioned raw materials are measured according to their weight percentages, they are melted in a vacuum induction melting furnace and cast into rare earth-bonding phase alloy ingots. The pouring temperature is 1420 ° C and the heat preservation is 8 minutes. The ingots are coarsely broken into alloy blocks smaller than 20mm by a jaw crusher; the alloy blocks formed after the alloy ingots are roughly crushed are put into an arc remelting quick quenching furnace and vacuumed to 1×10 -2 a, then pass in argon gas with a purity ≥99.99%, control its partial pressure at 0.2MPa, inductively heat and melt under the protection of argon gas, and spray the molten m...

Embodiment 3

[0051] Raw materials used in this embodiment: Pr12.95wt%, La 11wt%, Yb 0.05wt%, binder phase raw material (Co, Mn, Ni, Fe) 76wt%; said binder phase raw material (Co, Mn, Ni, Fe ), Co 50.68wt%, Mn 5.0wt%, Ni 15.24wt%, Fe 5.08wt%.

[0052] The processing steps of the present embodiment:

[0053] After the above-mentioned raw materials are measured according to their weight percentages, they are melted in a vacuum induction melting furnace and cast into rare earth-bonding phase alloy ingots. The pouring temperature is 1370 ° C and the heat preservation is 4 minutes. The ingots are coarsely broken into alloy blocks smaller than 20mm by a jaw crusher; the alloy blocks formed after the alloy ingots are roughly crushed are placed in a vacuum heating furnace for homogenization and annealing, and the vacuum degree is controlled at 6.5×10 -2 Pa, the annealing temperature is 1120°C, and the annealing time is 16h; the alloy block after homogenization annealing is placed in a tubular heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com