Ultra-low temperature rolling preparation method of wrought al-mg alloy with ultra-high mg content

An ultra-low temperature and alloy technology, applied in the field of materials, can solve the problems that the porosity and porosity of the as-cast structure cannot be eliminated, damage the plasticity of the Al-Mg alloy, and the grains of the as-cast state cannot be refined, so as to achieve the accumulation and strengthening of dislocations. Grain boundary strengthening effect, effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

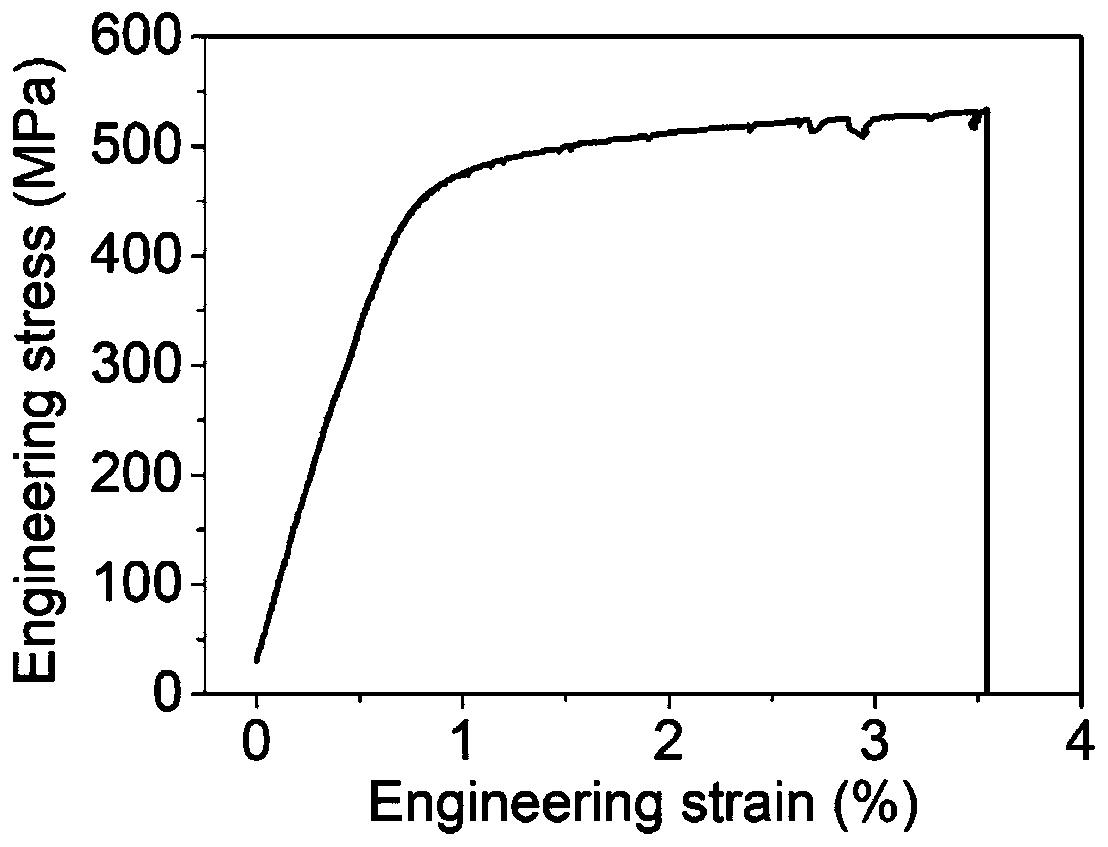

Embodiment 1

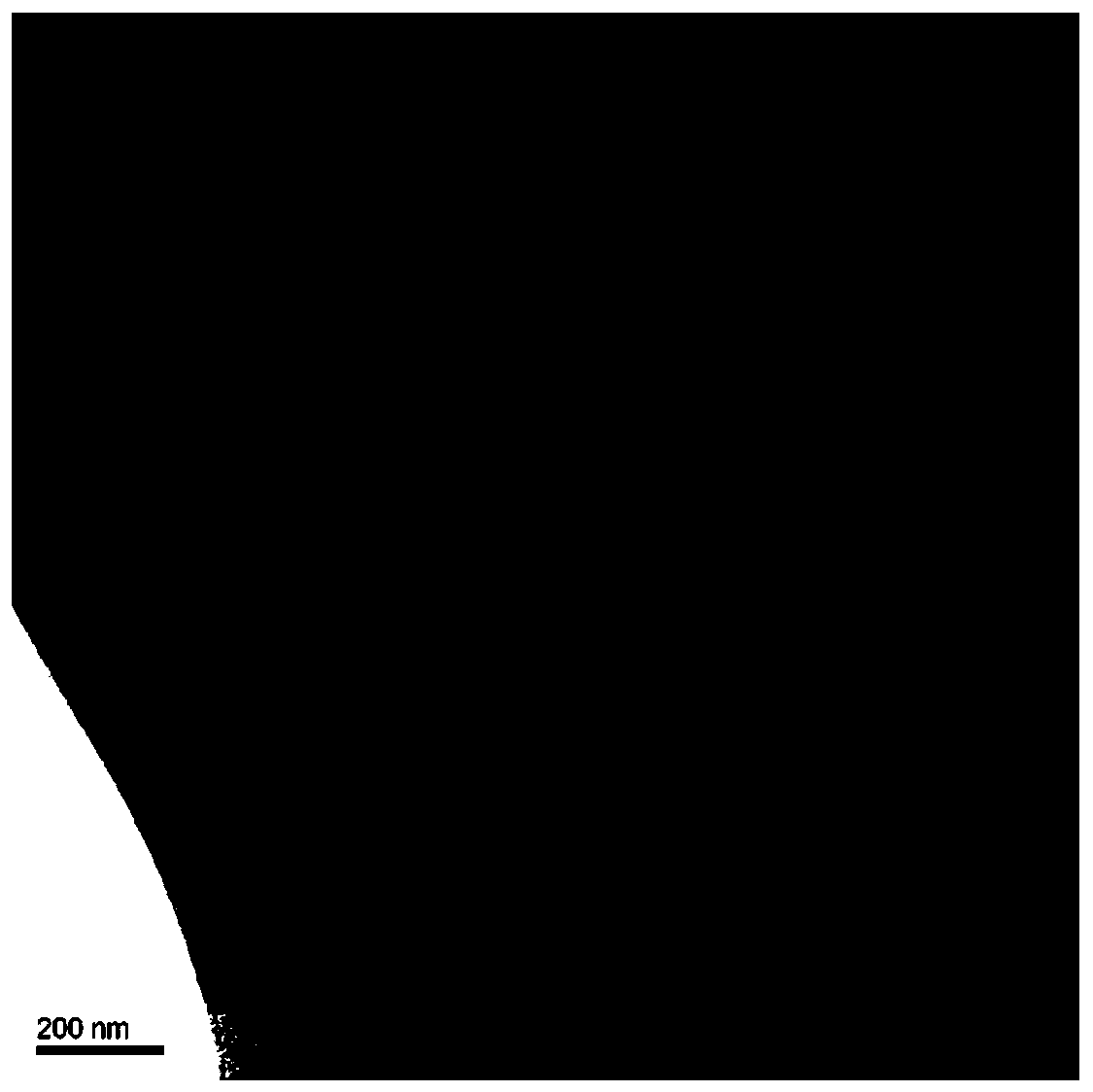

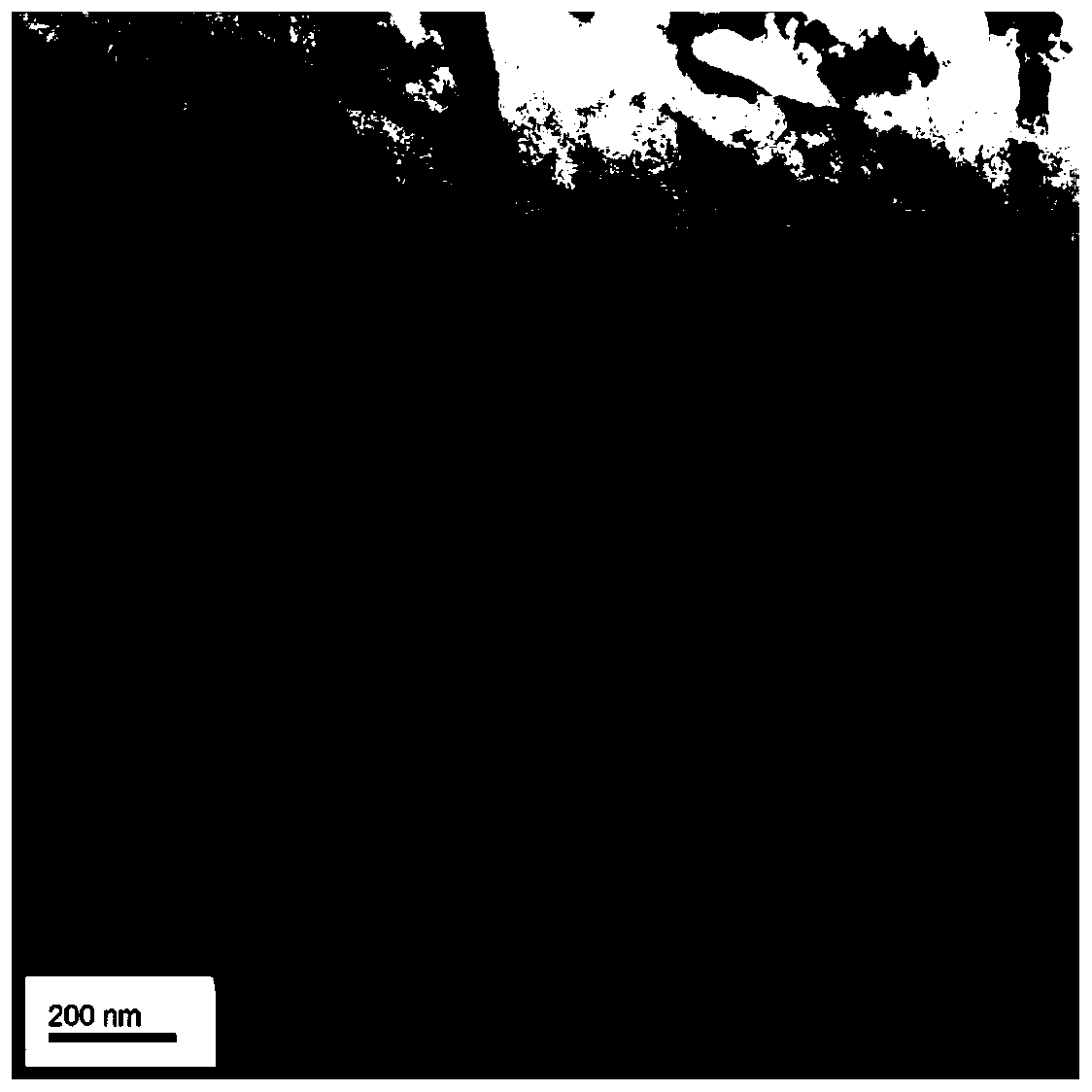

[0034] Add pure Mg and pure Al to a vacuum resistance melting furnace for smelting according to the mass percentage of Mg of 11%, and electromagnetically stir to make the composition of the liquid Al-11wt.% Mg alloy (wt.% represents mass percentage) uniform, and pour it into a cast iron mold An Al-11 wt.% Mg alloy ingot was obtained. First, in the nitrogen protection atmosphere heating furnace, the ingot is heated to a temperature of 425°C, which is 80°C lower than the Al-11wt.%Mg alloy solidus temperature of 505°C. At this time, the Al-11wt.%Mg alloy is in a single-phase solid solution State, keep at this temperature for 8 hours, and carry out the homogenization treatment of the composition of the ingot. Next, the Al-11wt.% Mg alloy ingot that has been homogenized is put into a hot-press furnace protected by nitrogen, and kept at 425°C and a pressure of 75MPa for 2.5 hours, and is densified by hot pressing. Eliminates porosity in cast alloys. Then, reheat the Al-11wt.% Mg a...

Embodiment 2

[0037] According to the mass percentage of Mg, pure Mg and pure Al are added into a vacuum induction melting furnace for melting, and the electromagnetic stirring effect of the induction melting furnace itself makes the composition of the liquid Al-14wt.% Mg alloy uniform, and then pours it into a cast iron mold to obtain Al-14wt.% Mg alloy ingot. First, in a heating furnace with a nitrogen protective atmosphere, the ingot is heated to a temperature of 430°C, which is 45°C lower than the solidus temperature of the Al-14wt.%Mg alloy at 475°C. At this time, the Al-14wt.%Mg alloy is in a single-phase solid solution State, keep at this temperature for 12 hours, and carry out the homogenization treatment of the composition of the ingot. Next, the homogenized Al-14wt.%Mg alloy ingot is hot-extruded at 430° C. with an area shrinkage ratio of 6 to completely eliminate the pores in the cast alloy. Then, reheat the Al-14wt.% Mg alloy that has been homogenized and densified in a nitroge...

Embodiment 3

[0040] According to the mass percentage of Mg, pure Mg and pure Al are added to the vacuum induction melting furnace for melting, and the electromagnetic stirring effect of the induction melting furnace itself makes the composition of the liquid Al-11wt.% Mg alloy uniform, and then it is poured into a cast iron mold to obtain Al-11wt.% Mg alloy ingot. First, in the nitrogen protection atmosphere heating furnace, the ingot is heated to a temperature of 425°C, which is 80°C lower than the Al-11wt.%Mg alloy solidus temperature of 505°C. At this time, the Al-11wt.%Mg alloy is in a single-phase solid solution State, keep at this temperature for 8 hours, and carry out the homogenization treatment of the composition of the ingot. Next, hot rolling the Al-11wt.% Mg alloy ingot treated with homogenization at 425° C. until the total reduction of the thickness is 50%, completely eliminates the pores in the cast alloy. Then, reheat the Al-11wt.% Mg alloy that has been homogenized and den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com