Patents

Literature

40results about How to "Improve solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

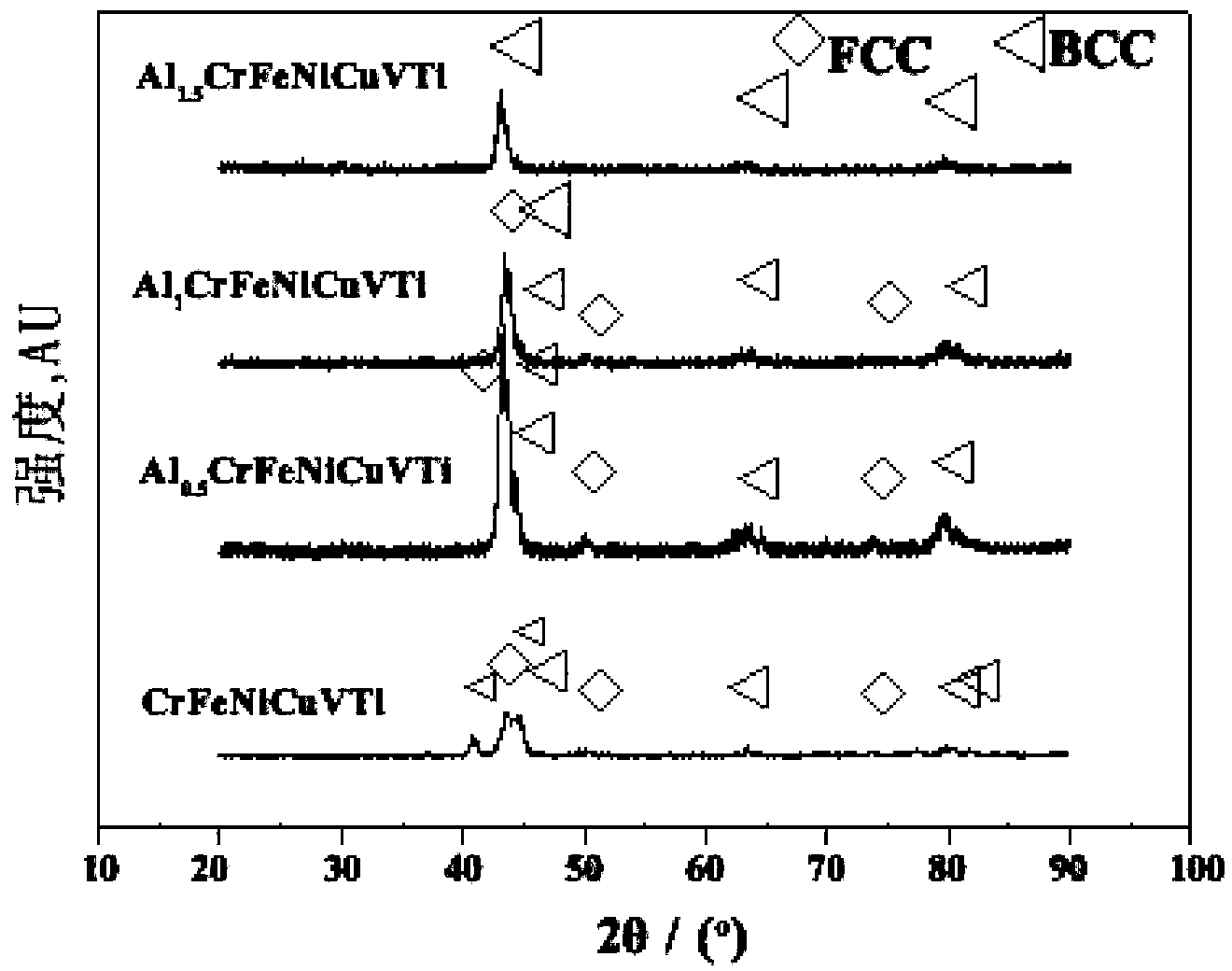

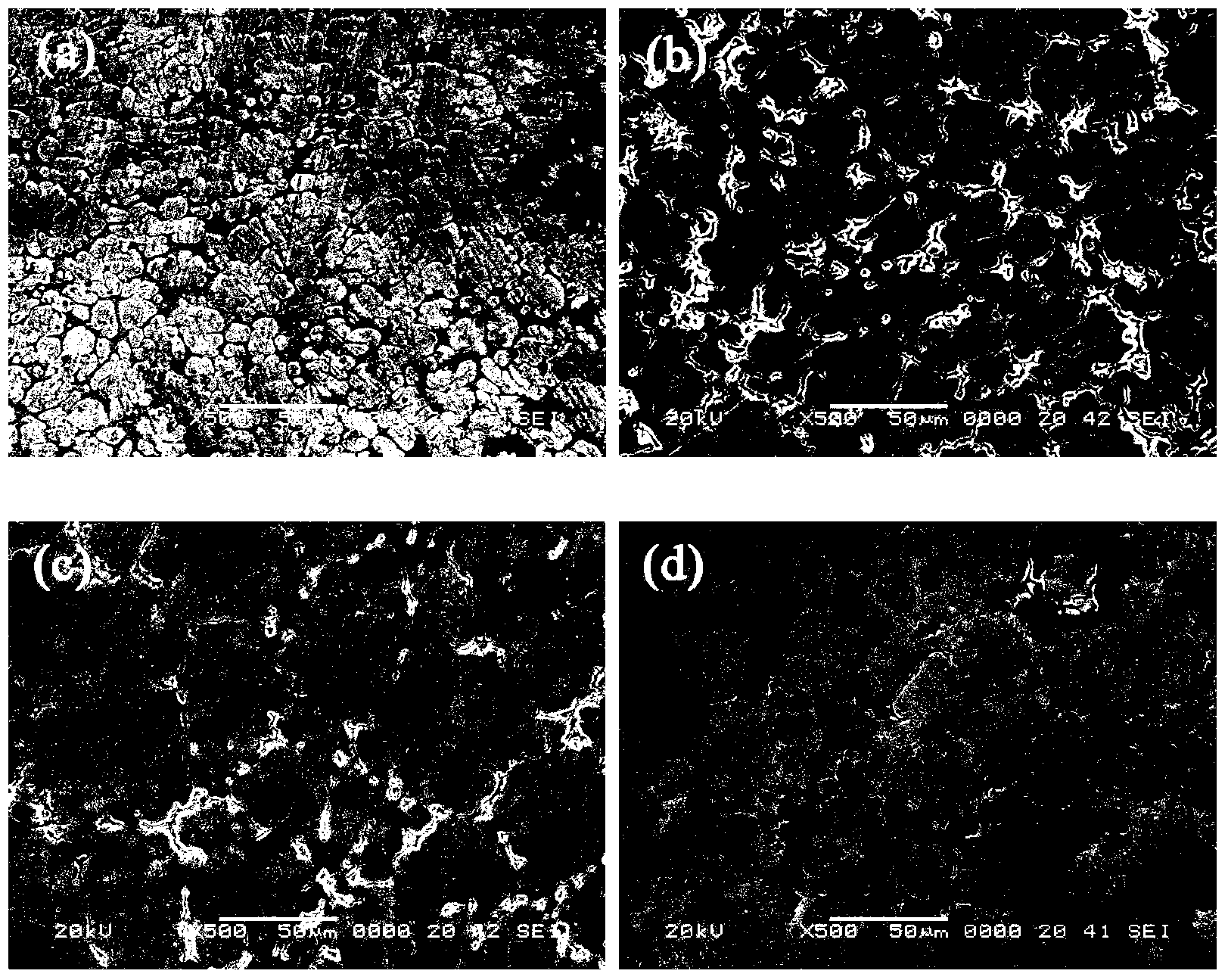

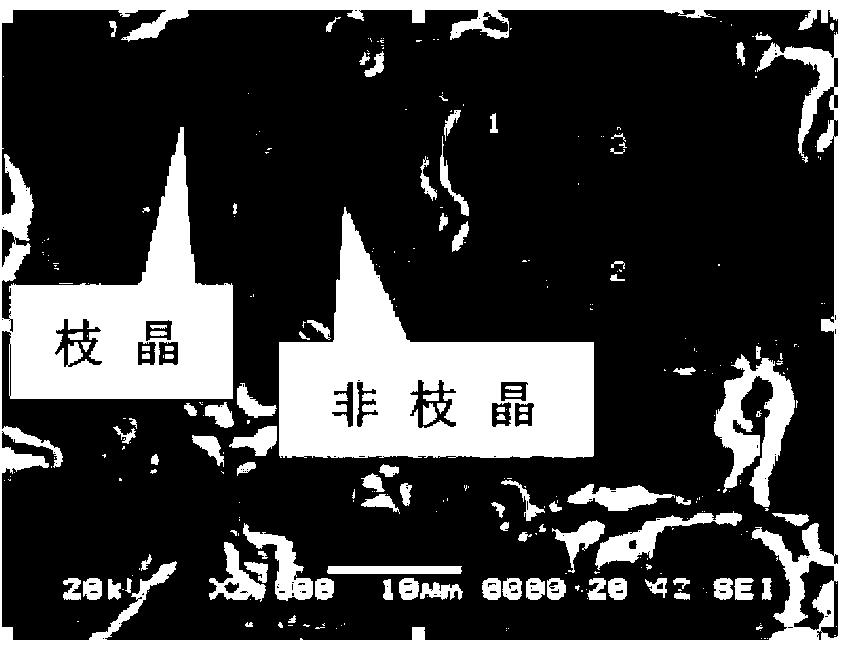

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

High-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and coating and preparing method of coating

ActiveCN105463359AImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingChromium carbideTurbine blade

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Rare earth-containing powder metallurgy natural gas engine valve seat ring

ActiveCN103589967AHigh bonding strengthImprove high temperature strengthTurbinesOther manufacturing equipments/toolsRare-earth elementValve seat

The invention provides a rare earth-containing powder metallurgy natural gas engine valve seat ring. The chemical composition of the valve seat ring comprises, by mass, 0.8-1.5% of C, 10.0-20.0% of Cr, 16.0-22.0% of Mo, 20.0-25.0% of Co, 4.0-9.0% of Ni, 20.0-24.0% of W, 0.1-0.2% of a rare earth element, 0.1-0.2% of a lubricant, 0.1-0.2% of a binder, and the balance Fe, the granularity of Fe is 60-70 meshes, and the rare earth element can be La, Ce or a Ce-rich mixed rare earth. The valve seat ring has the advantages of ideal hardness, high strength, high density, strong deoxidation and desulfurization abilities, heat resistance, corrosion resistance and the like.

Owner:ANHUI JINYI NEW MATERIALS CORP LTD

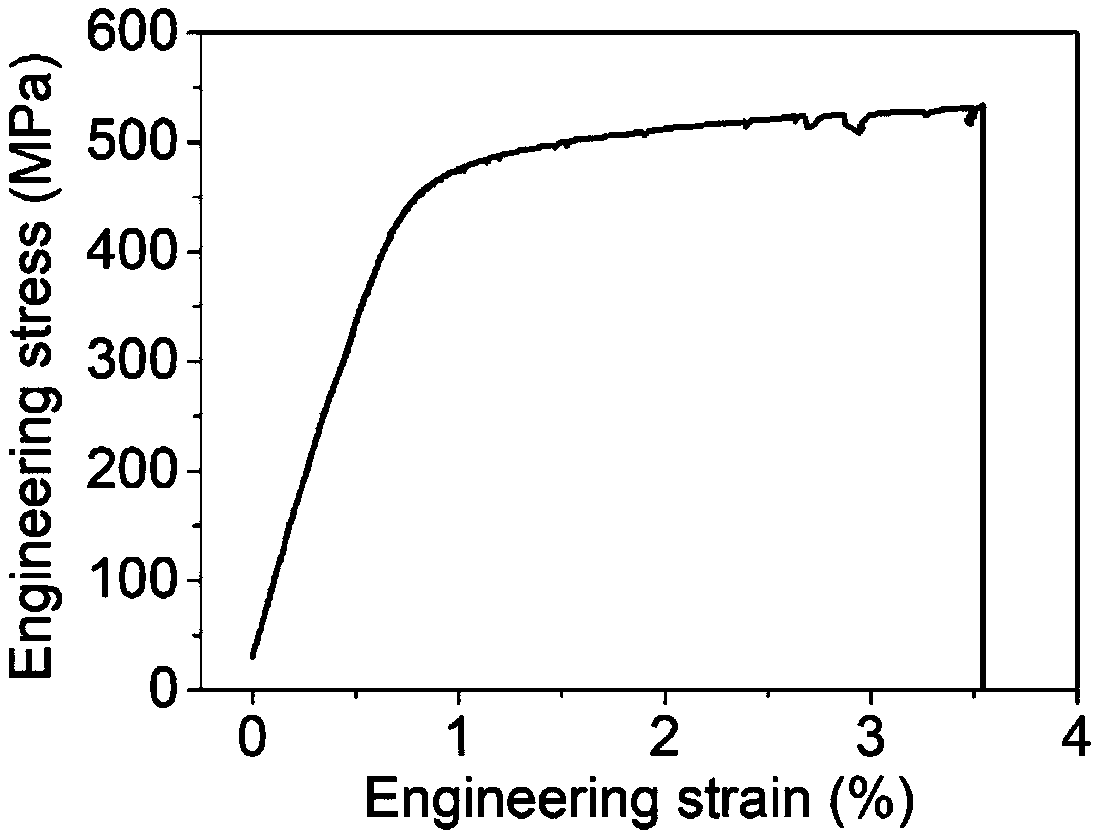

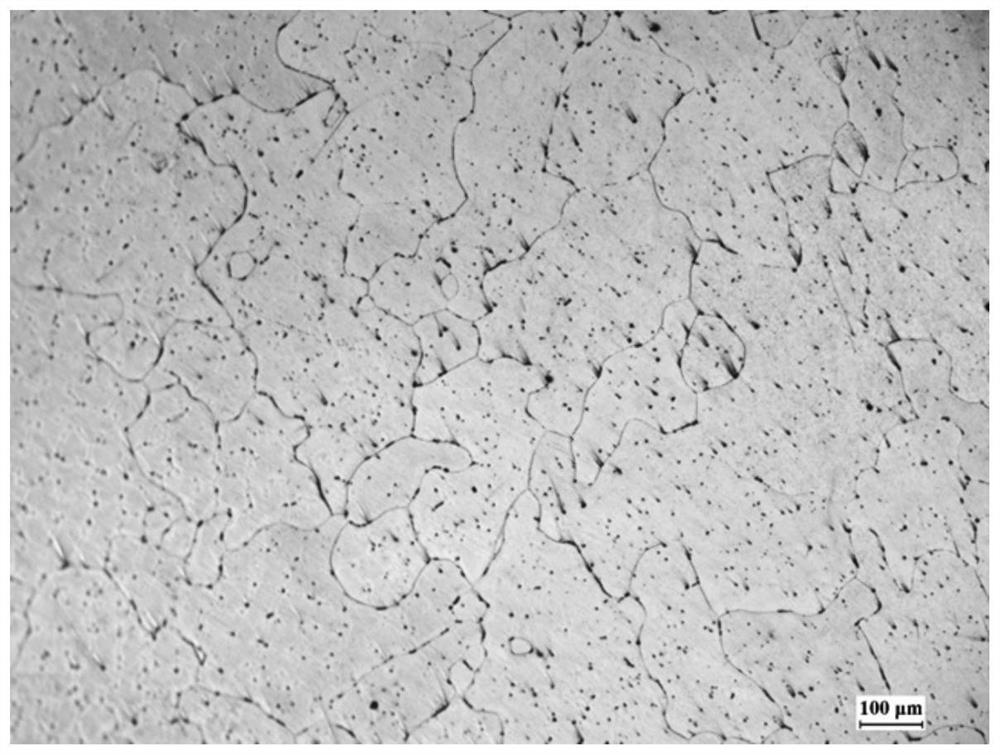

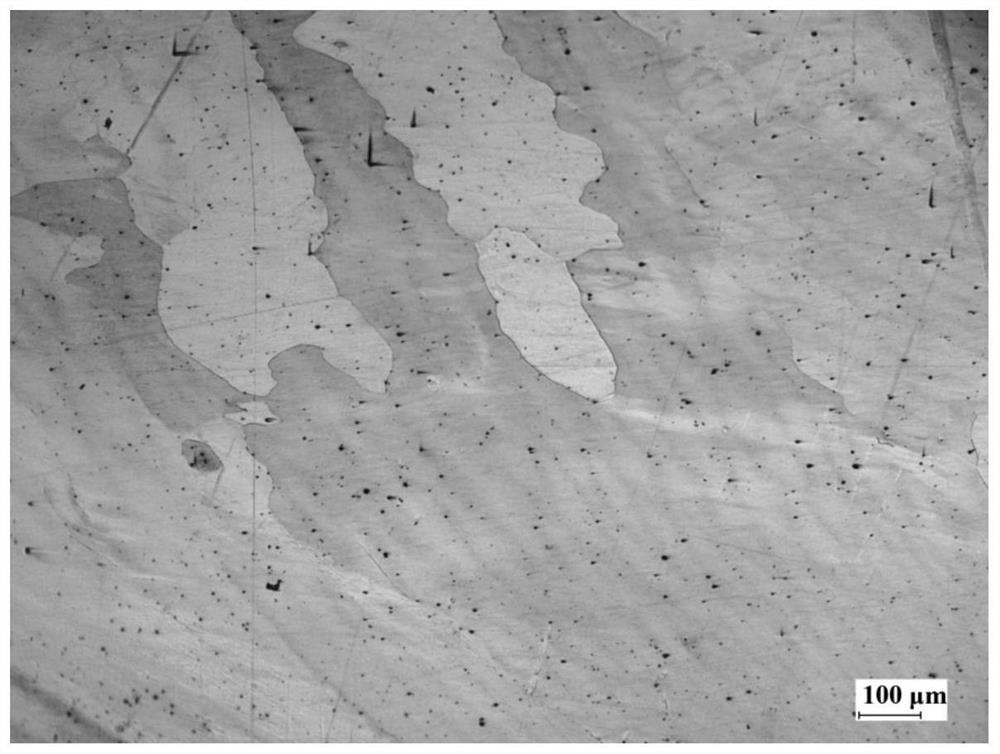

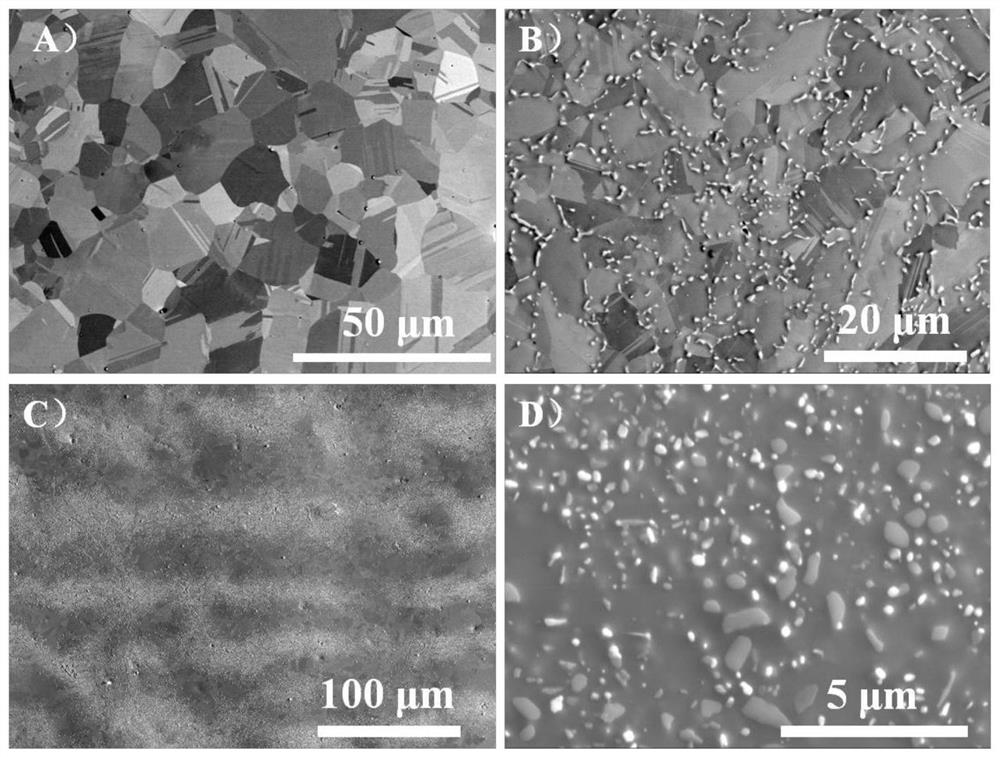

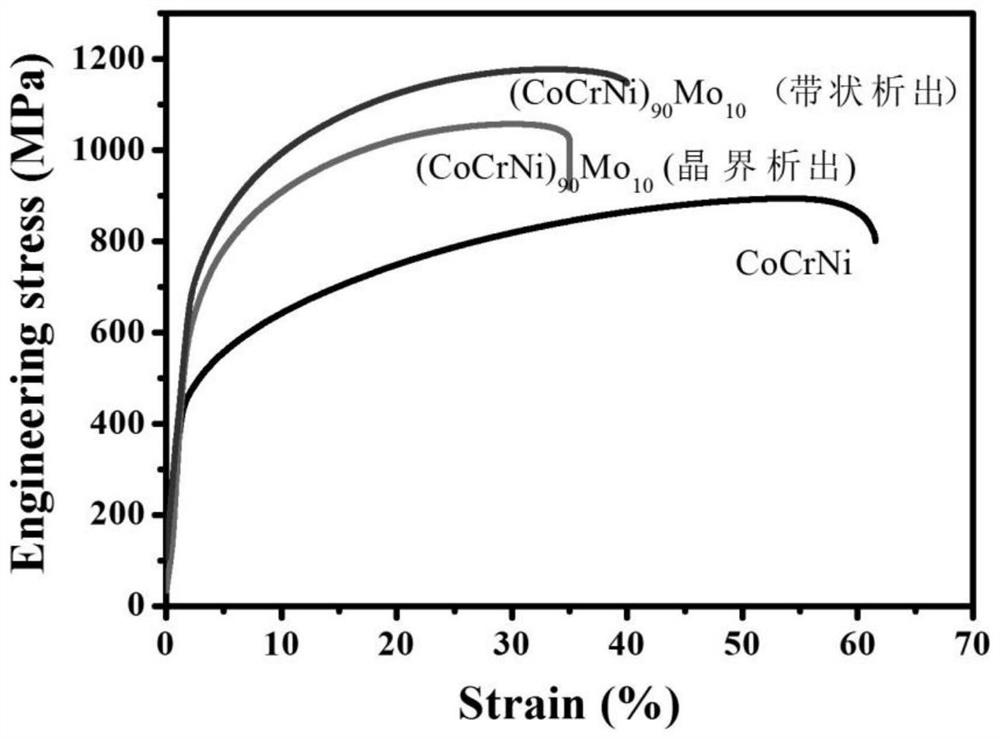

High-entropy alloy with banded precipitated phase and preparation method thereof

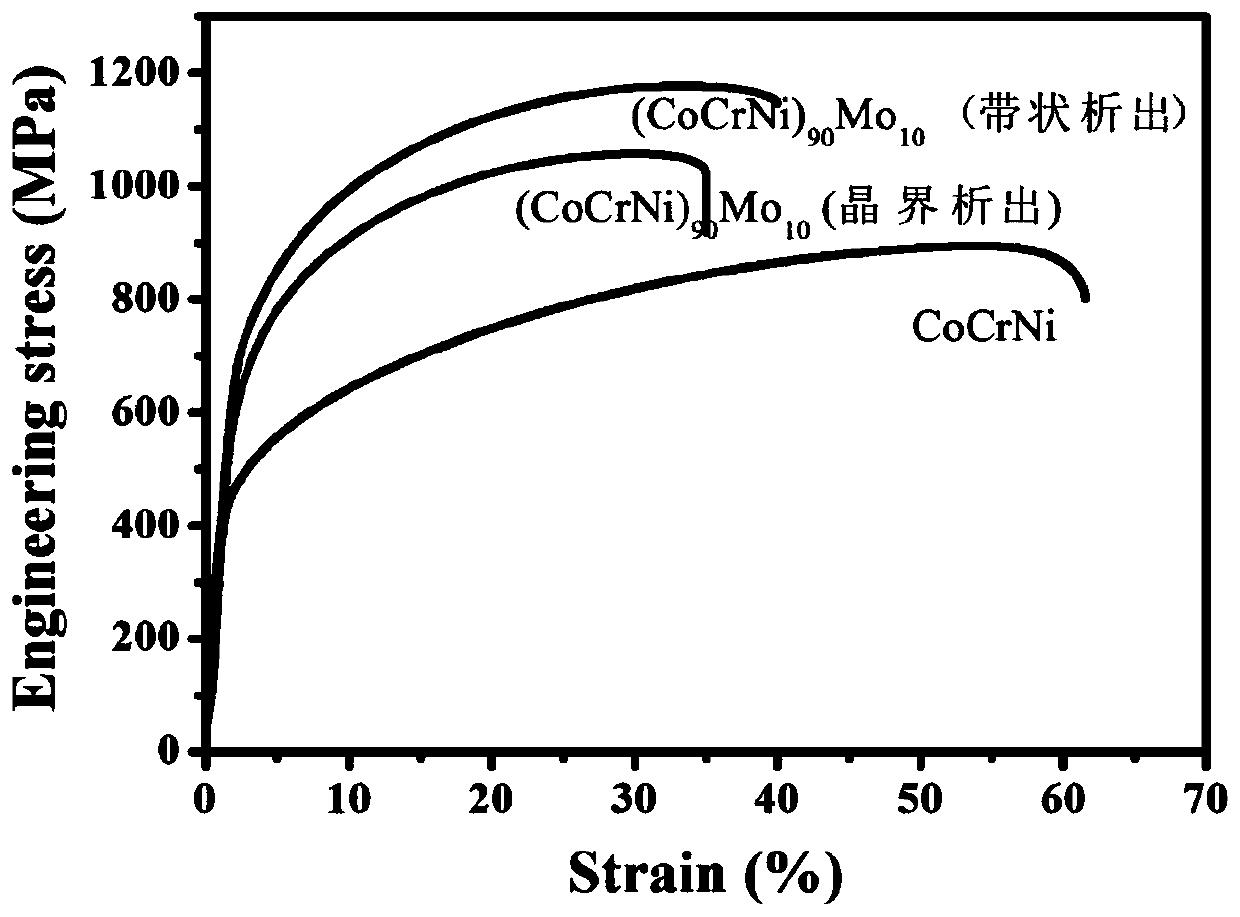

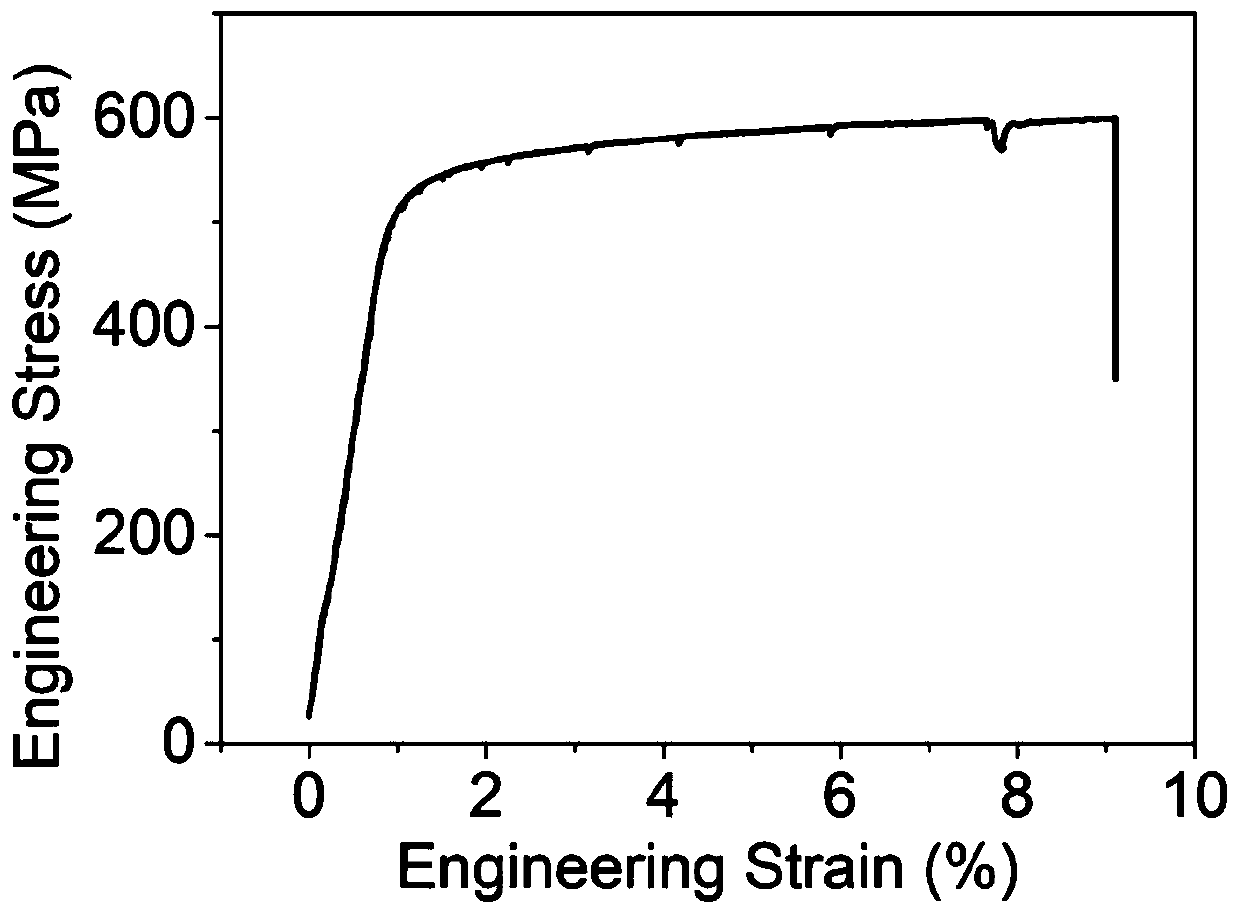

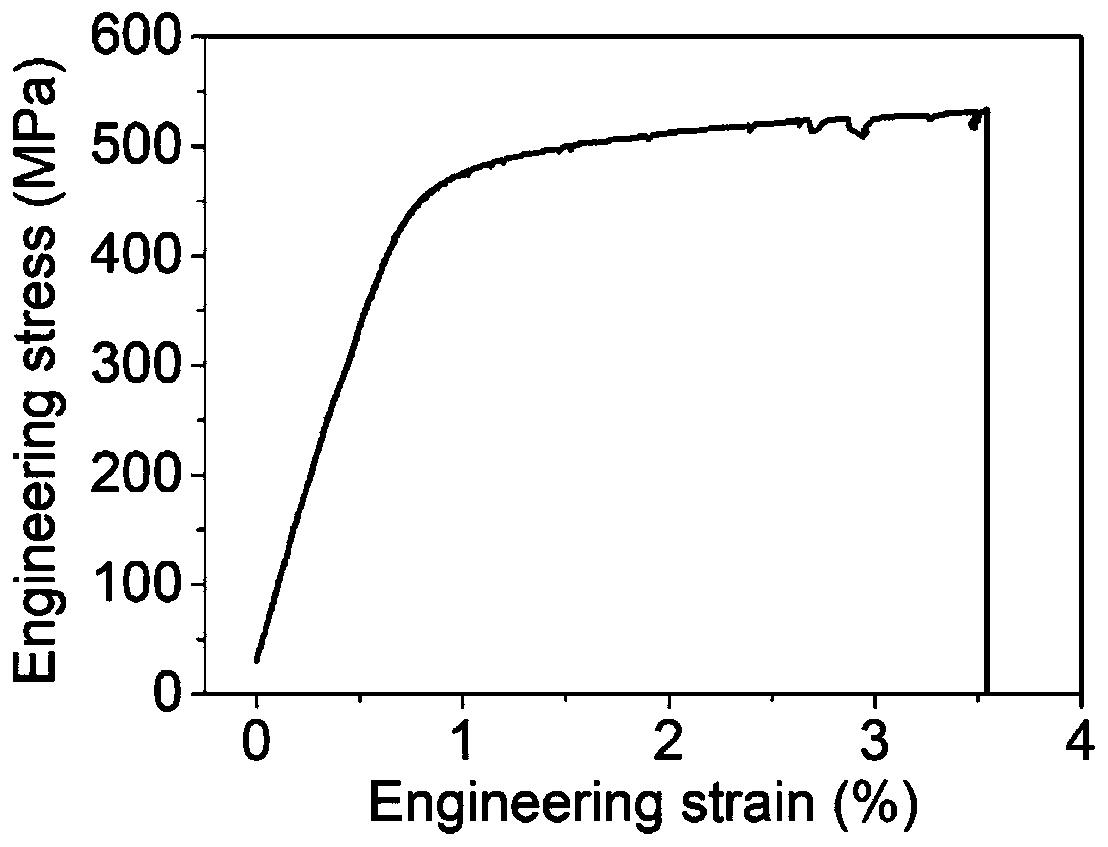

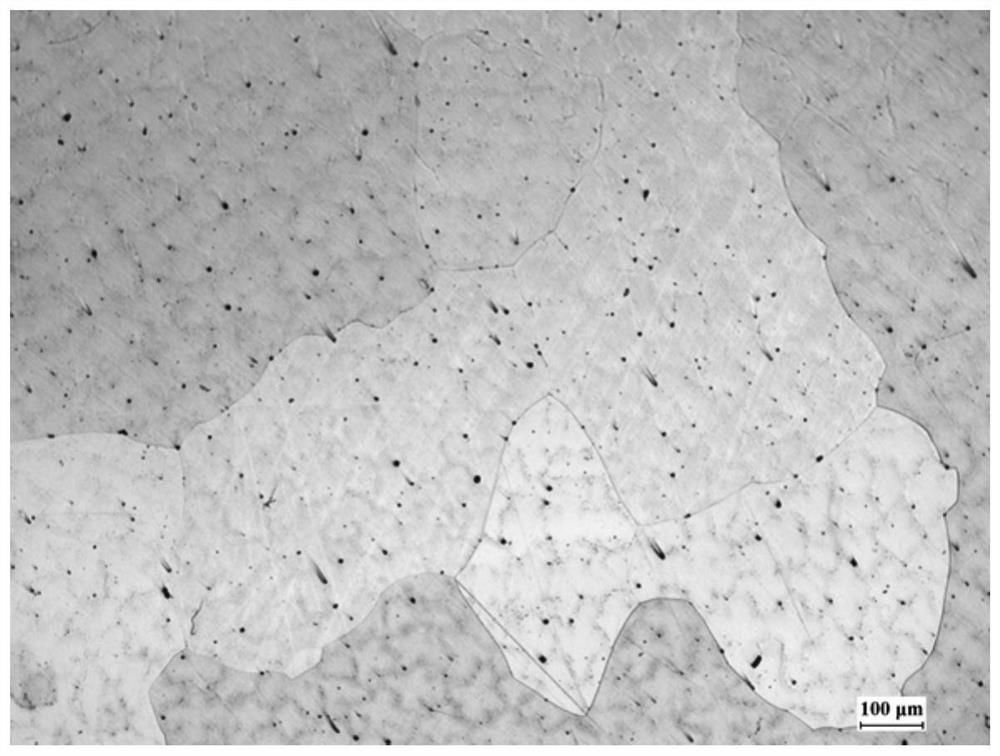

ActiveCN110106428AGood room temperature tensile propertiesImprove solid solution strengtheningHigh entropy alloysMo element

The invention discloses a high-entropy alloy with a banded precipitated phase. The high-entropy alloy consists of Co, Cr, Ni and Mo elements, wherein the atomic percent of Co is 25-35%, the atomic percent of Cr is 25-35%, the atomic percent of Ni is 25-35%, the atomic percent of Mo is 5-15%, and the sum of atomic percents of the components is 100%. The phase composition of the high-entropy alloy with the banded precipitated phase comprises a face-centered cubic phase and a sigma precipitated phase, wherein the sigma precipitated phase accounts for 40-60%. In the preparation method, the non-uniform precipitation of the Mo-rich phase is achieved through the combination of hot processing, solid solution processing, cold processing and annealing process, and the high-entropy alloy with the banded precipitated phase is obtained. The alloy can ensure excellent strength and toughness matching, and has application prospects in the fields of cutter materials, aerospace materials and the like.

Owner:HEBEI UNIV OF TECH

Small-scale finish-rolled twisted steel and production method thereof

ActiveCN104328338AImprove distributionEvenly distributedManufacturing convertersChemical compositionRebar

The invention provides small-scale finish-rolled twisted steel and a production method thereof. The small-scale finish-rolled twisted steel comprises the following chemical components in percentage by mass: 0.40-0.50% of C, 1.5-1.8% of Si, 0.8-1.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.08-0.13% of V, 0.008-0.01% of Als and the balance of Fe and inevitable impurities. The production method comprises the following steps: desulfurizing molten iron, smelting in a converter, blowing argon, performing protective casting into a square blank of 200*200mm<2>, heating the square blank, rolling, performing controlled cooling after rolling, and performing air-cooling in a cooling bed. The finish-rolled twisted steel provided by the invention is stable in property, and the production method is simple and easy to operate.

Owner:武汉钢铁有限公司

Al-Mg-In system welding wire and preparing method thereof

ActiveCN105385906AEasy to implementMeet welding technical requirementsWelding/cutting media/materialsSoldering mediaIndiumIngot casting

The invention discloses an Al-Mg-In system welding wire and a preparing method thereof. The welding wire comprises, by weight, 4.0%-6.5% of Mg, 0.15%-1.0% of In, 0.1%-0.4% of Ce, 0.4%-1.2% of Mn, 0.05%-0.15% of Ti, smaller than or equal to 0.3% of Si, smaller than or equal to 0.2% of Fe, smaller than or equal to 0.0015% of Na, and the balance Al. The preparing method comprises the following steps that an aluminum ingot, a magnesium ingot, an indium ingot, a cerium ingot and Al-10 Mn intermediate alloy are smelted in a medium-frequency induction resistance furnace according to the proportion, a refiner is made through Al-5Ti-B, and an ingot casting is formed through casting; after the ingot casting is evenly annealed, head cropping and face milling are carried out, and a rod-shaped blank is formed through thermal extrusion; and wire drawing is carried out on the rod-shaped blank through a drawing machine, and the Al-Mg-In system welding wire is obtained through surface treatment and coiling. The Al-Mg-In system welding wire has the following advantages that the technology is simple and each to achieve, the spreadability and wettability of the welding wire are good, and the heat crack sensibility is small; the structure of the welding wire is refined, and the forming technology is superior; and compared with base metal, a welding connector has high strength and tenacity matching.

Owner:广西北港新材料有限公司

Method for efficiently forming copper-nickel-silicon alloy strip through continuous casting and rolling

InactiveCN107326214AGood plasticityImprove solid solution strengtheningMetal rolling arrangementsAlloy elementCopper

The invention provides a method for continuously casting and rolling high-efficiency forming copper-nickel-silicon alloy strips, comprising the following steps: taking copper source, nickel source and silicon source as raw materials, successively melting, continuous casting, cooling and casting to obtain copper The nickel-silicon alloy slab and the copper-nickel-silicon alloy slab are sequentially rolled, aged, cooled and finished cold rolled to obtain a copper-nickel-silicon alloy strip. The examples show that the copper-nickel-silicon alloy slab with high surface quality and dense columnar grain structure obtained by the present invention has an elongation rate greater than 45% at room temperature and has excellent plasticity; Continuous casting and rapid solidification can effectively improve the solid solution strengthening and precipitation strengthening effects of alloy elements; the invention has a simple process, can effectively reduce energy consumption, reduce costs, and improve production efficiency and product yield.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Preparation method for Cu-Ni-Si-Ma alloy strip

The invention provides a preparation method for a Cu-Ni-SI-Ma alloy strip. The method comprises the following steps that a copper source, a nickel source, a silicon source and a magnesium source serve as the raw materials and are sequentially subjected to melting, continuous casting, cooling and billet drawing to obtain a Cu-Ni-SI-Ma alloy rod billet; the Cu-Ni-Si-Ma alloy rod billet is directly subjected to continuous extrusion molding to obtain a Cu-Ni-Si-Mg alloy strip billet; and then rolling and ageing treatment are sequentially conducted to obtain the Cu-Ni-Si-Mg alloy strip. Embodiments show that the elongation, under the room temperature, of the Cu-Ni-Si-Mg alloy rod billet prepared through the preparation method is greater than 45%, and excellent plasticity is achieved; and melting and continuous casting in combination of cooling enforcement measures are adopted, continuous casting and fast solidification can be achieved, the solution strengthening and precipitation strengthening effects of alloy elements are effectively improved, and the method for continuous casting, continuous extruding, rolling and efficient molding of the Cu-Ni-Si-Mg alloy strip is provided.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

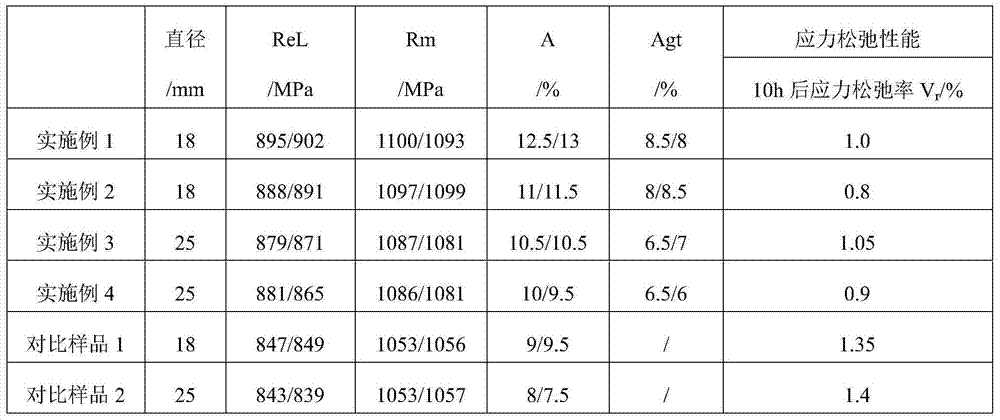

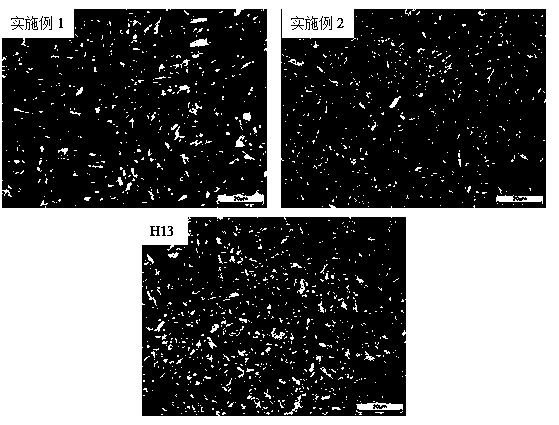

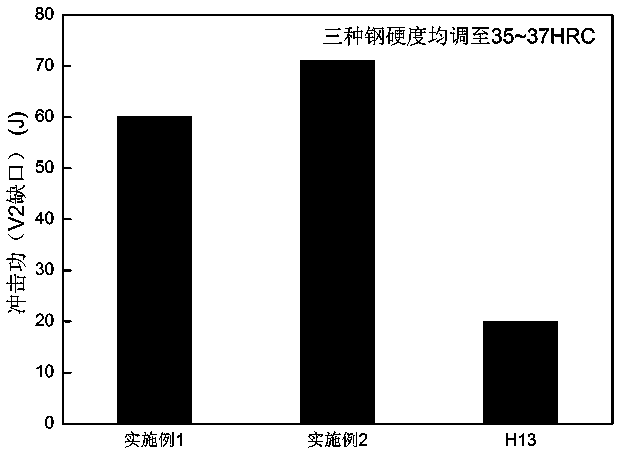

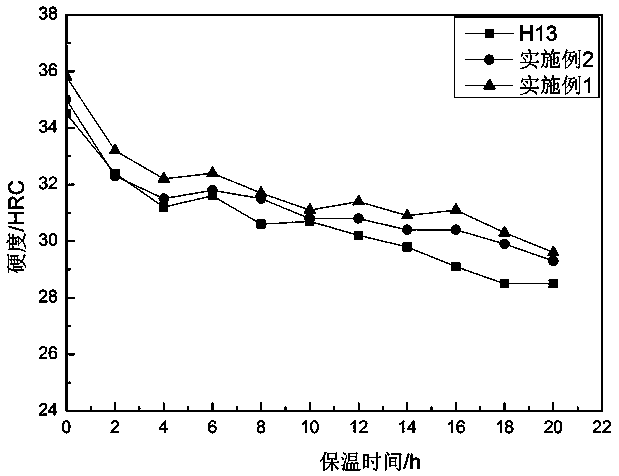

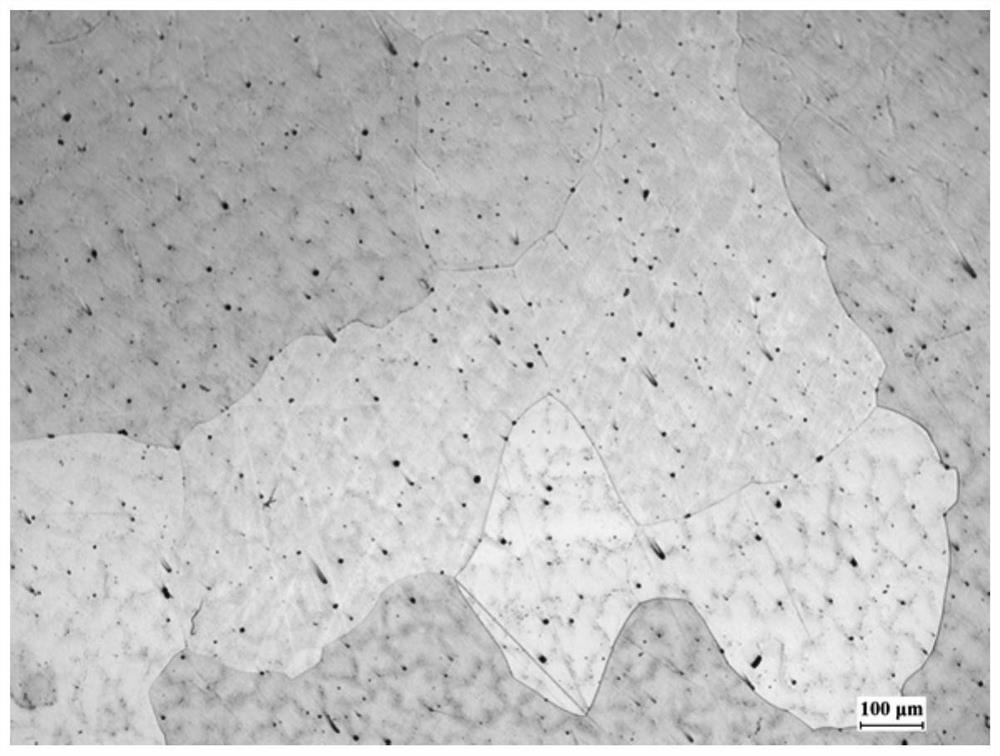

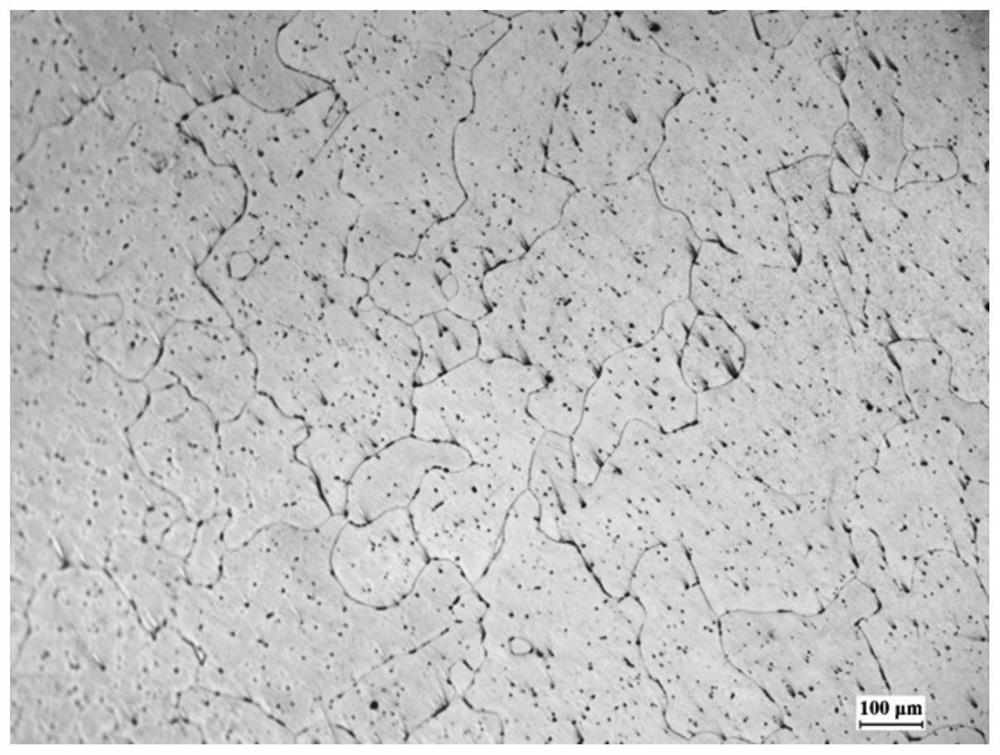

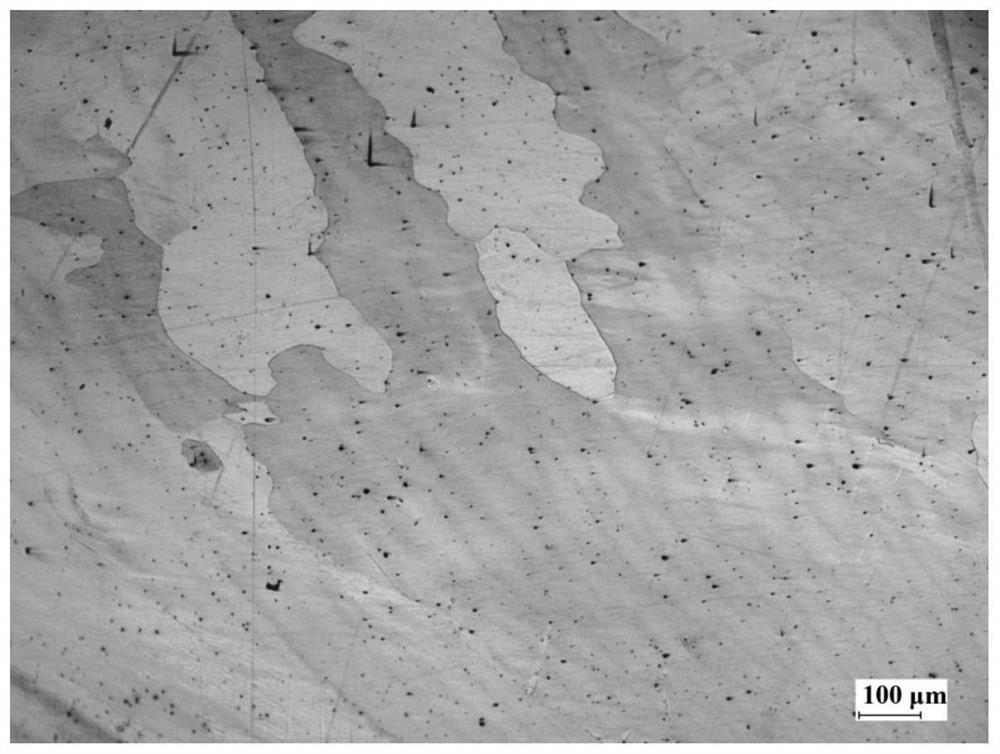

Economic type core rod alloy steel and preparation and heat treatment method thereof

The invention relates to an economic type core rod alloy steel and a preparation and heat treatment method thereof, belongs to the technical field of alloy steel manufacturing process, and is characterized in that the alloy steel comprises the following main alloy elements by mass percentage: 0.25-0.30% of C, 0.10-0.20% of Si, 1.51-1.62% of Mn, 3.60-4.10% of Cr, 0.20-0.30% of Mo, 0.20-0.40% of V, 0.03-0.05% of Nb, and the balance Fe. The alloy steel preparation process comprises the following steps: preparing materials, smelting, casting an electrode rod, and annealing; then carrying out electroslag remelting, and annealing; followed by carrying out multidirectional forging and direct water cooling; then carrying out two-section type annealing; and finally, carrying out quenching and tempering treatment. The properties of the alloy steel are equal to or exceed those of H13 steel under same conditions. The low-alloying-composition design thought of the alloy steel meets a transformation concept that current Chinese steel enterprises are in urgent need of energy saving, consumption reduction, cost reduction and benefit increase.

Owner:SHANGHAI UNIV +1

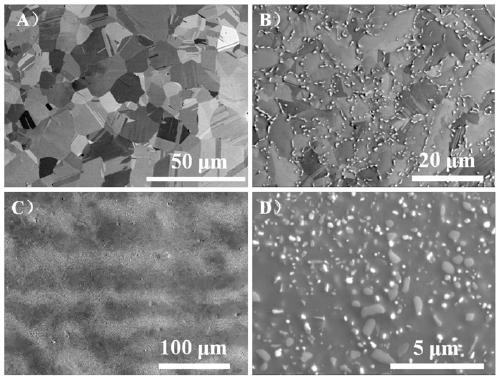

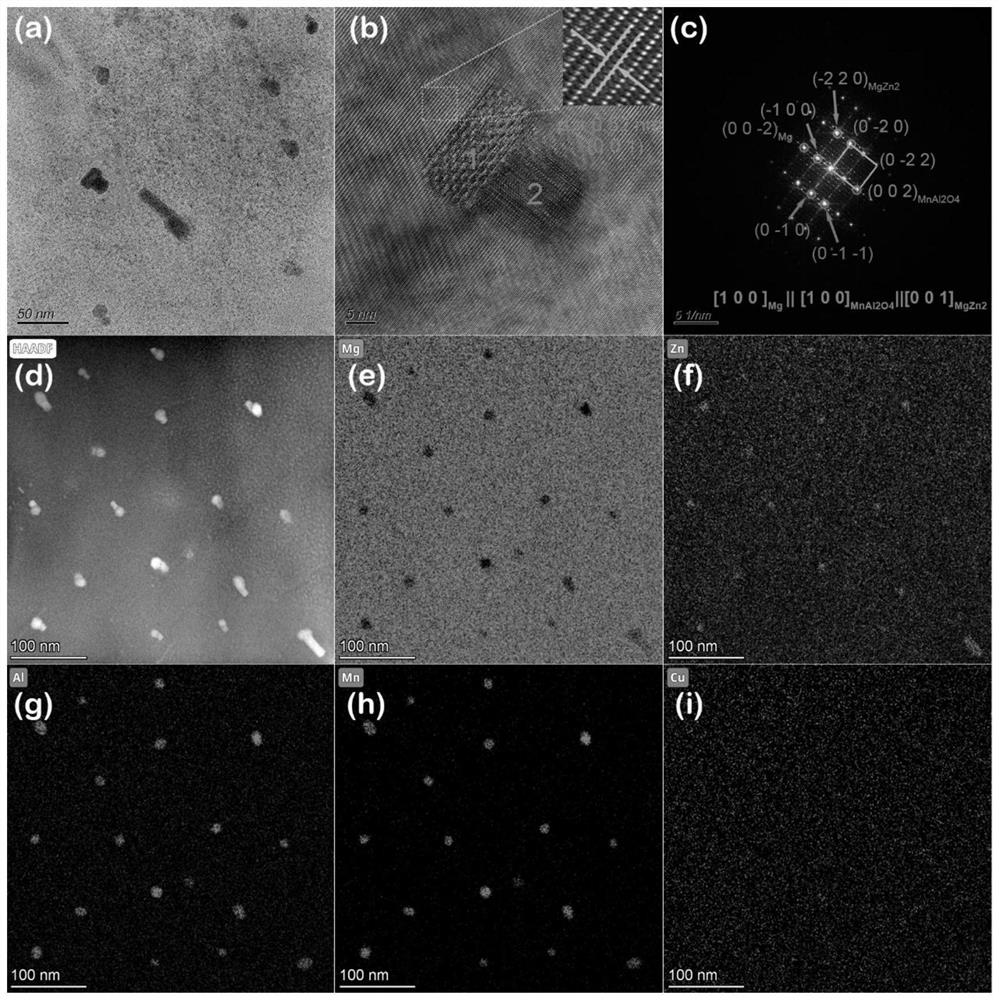

High-strength and high-plasticity high-entropy alloy and preparation method thereof

ActiveCN111961893AImprove solid solution strengtheningPromote fine grain strengtheningHigh entropy alloysMetallic materials

The invention discloses a high-strength and high-plasticity high-entropy alloy and a preparation method thereof, and belongs to the technical field of metal materials and manufacturing. The high-entropy alloy is prepared from the following raw materials of metal particles of Co, Cr, Fe and Ni and intermediate alloy particles of Al-10Er (the mass fraction of Er is 10%). The preparation method specifically comprises the following steps that the metal particles are weighed according to the set proportion, melted in a high-vacuum electric arc melting furnace and then solidified in a copper mold soas to prepare a high-entropy alloy, wherein in order to ensure the uniformity of alloy components in the smelting process, alloy blocks need to be repeatedly smelted; and the as-cast high-entropy alloy prepared in the initial stage is homogenized in a high-temperature heat treatment furnace, then water quenching is carried out, the high-entropy alloy ingot is rolled at the temperature of 500-800DEG C, and the rolled sample is cooled along with air to obtain the high-strength and high-plasticity high-entropy alloy. The high-entropy alloy prepared by using the preparation method has excellentmechanical properties, and the preparation process is simple.

Owner:SOUTHEAST UNIV

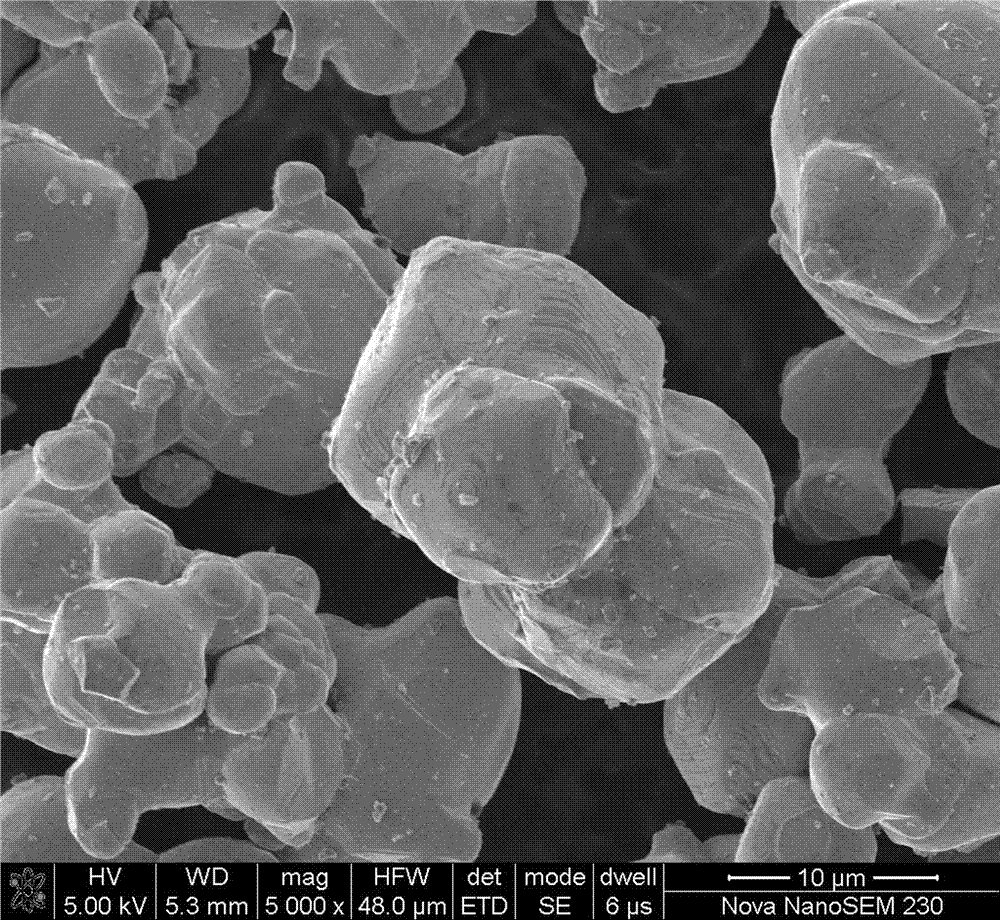

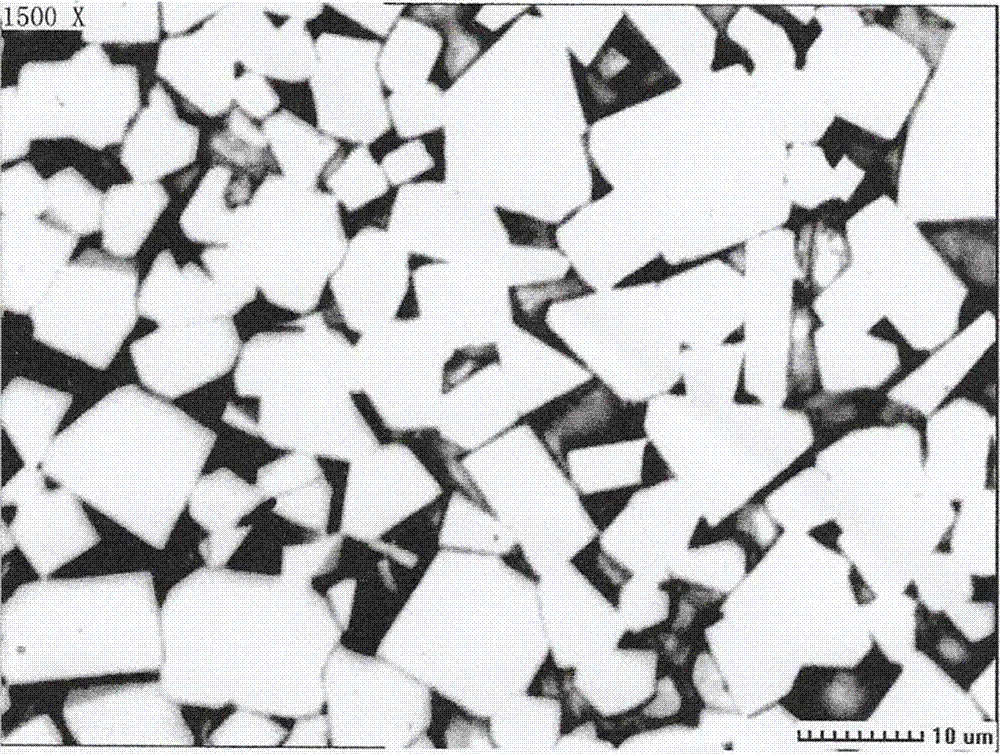

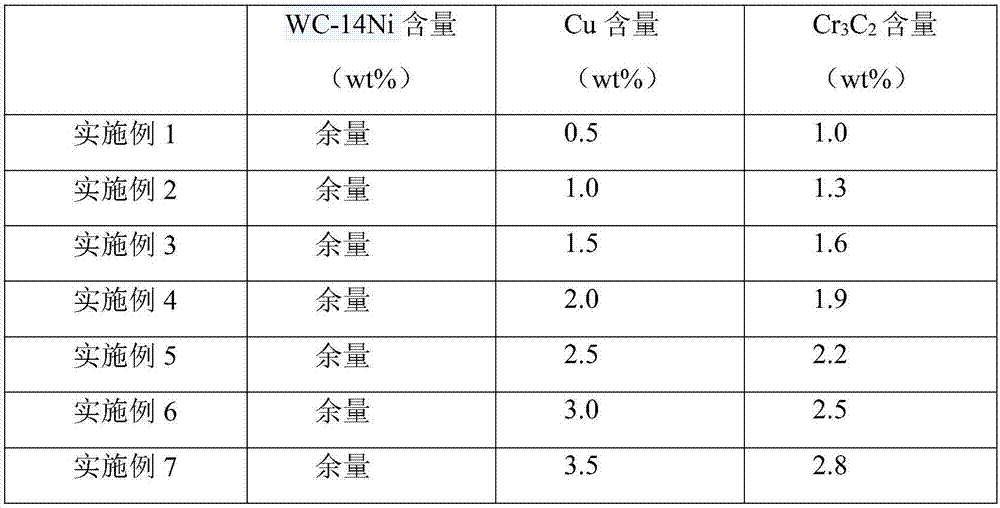

Hard alloy for soaking plate and soaking plate made of hard alloy

ActiveCN108004451AImprove thermal conductivityGood high temperature oxidation resistanceGlass reforming apparatusEconomic benefitsHardness

The invention discloses a hard alloy for a soaking plate. The hard alloy is characterized in that the hard alloy is prepared by means of the method that Cr3C2 and Cu are added into a super coarse grain WC-14Ni alloy, wherein all raw materials are weighed according to the mode that the raw materials comprise, by weight, 1.0-2.8% of Cr3C2, 0.5-3.5% of Cu and the balance super coarse grain WC-14Ni alloy. By adopting super coarse grain WC and adjusting the component ratio of Cr3C2 and Cu, a compact oxidation film protection layer is formed on the alloy surface of the soaking plate under the high-temperature work condition, thus the soaking plate has extremely good high-temperature-oxidation-resisting performance, and the heat conductivity and high-temperature hardness of the soaking plate canbe improved; and according to the hard alloy, preparation is easy, the performance of the soaking plate can be effectively improved, the gap of the field in China is filled up, and the current situation that the soaking plate of China relies on a foreign product is overcome, and huge economic benefits are achieved.

Owner:ZHUZHOU SANXIN HARD ALLOY PRODN CO LTD

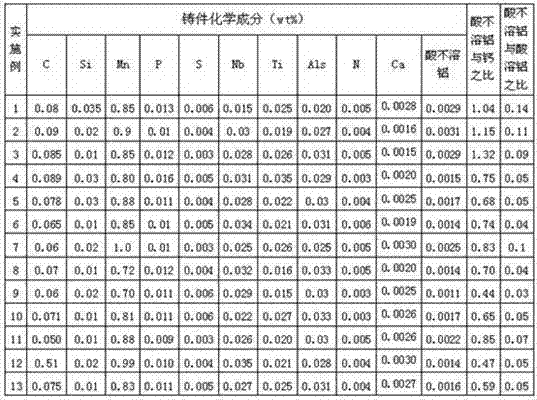

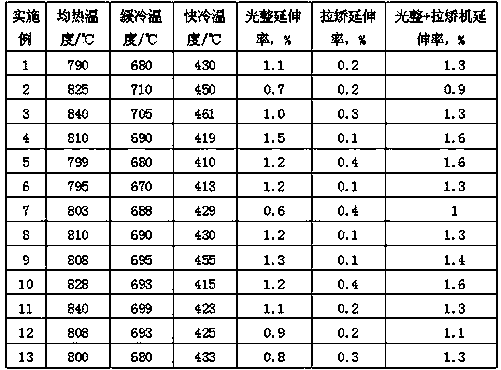

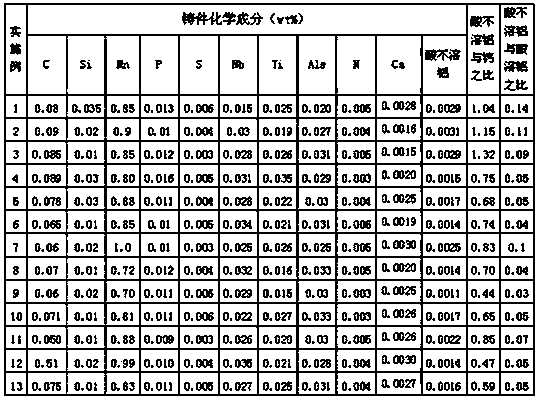

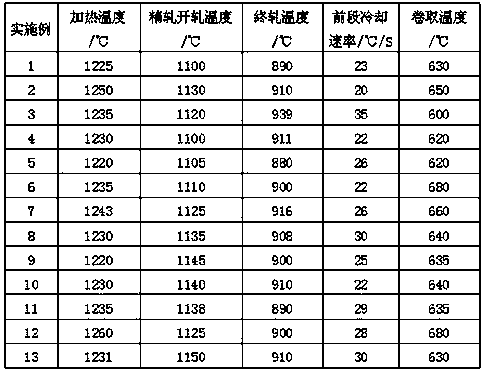

480MPa-grade galvanized strip steel and production method thereof

ActiveCN107326277AImprove solid solution strengtheningImprove welding performanceHot-dipping/immersion processesSurface levelAluminium

The invention discloses 480MPa-grade galvanized strip steel. The 480MPa-grade galvanized strip steel comprises, by mass, 0.05-0.09% of C, 0.05% or less of Si, 0.8-1.0% of Mn, 0.016% or less of P, 0.008% or less of S, 0.015-0.035% of Nb, 0.020-0.045% of Als, 0.007% or less of N, 0.015-0.035% of Ti, 0.0015-0.0030% of Ca, and the balance Fe. A production method comprises the steps that converter smelting and LF refining are conducted in a low-nitrogen mode; protective continuous casting is conducted, and nitrogen is controlled to be increased; and calcium treatment is conducted after refining is completed, wherein the mass percent of acid-insoluble aluminum in molten steel is smaller than or equal to 45 ppm, the ratio of the mass percent of the acid-insoluble aluminum to that of calcium is 0.5-1.5, and the ratio of the mass percent of the acid-insoluble aluminum to that of acid soluble aluminum is 0.05-0.20. According to the 480MPa-grade galvanized strip steel, the production cost is low, the overall mechanical performance of the product is superior, and the surface quality meets the requirements of FB surface levels in GB2518 and EN10346.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

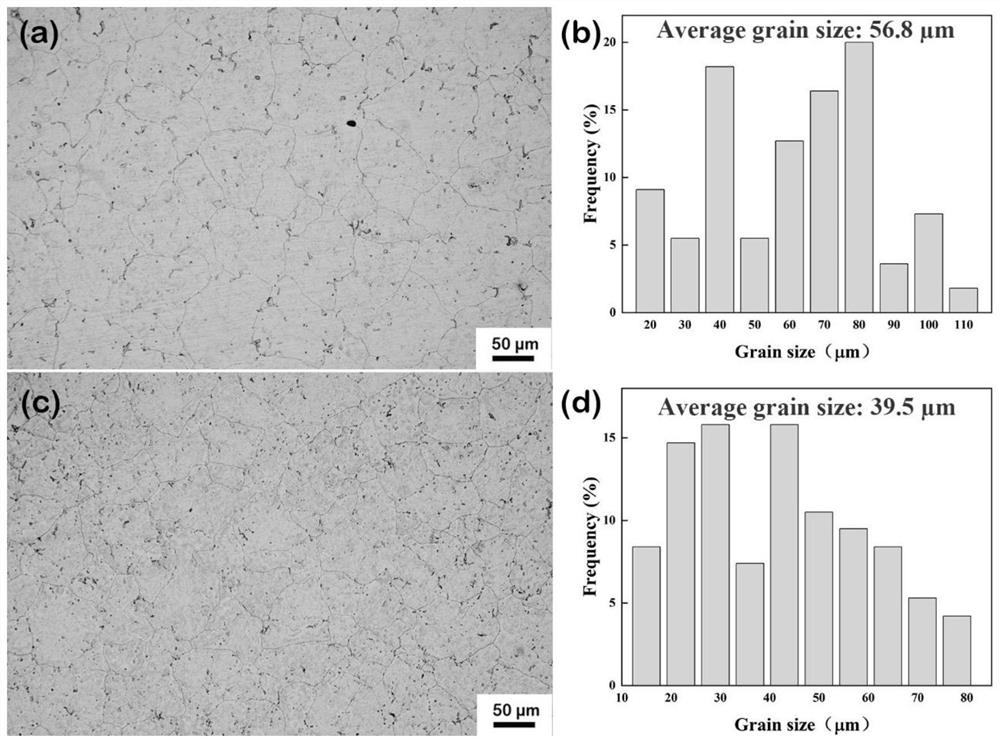

Low-cost high-strength high-ductility rare earth magnesium alloy and preparation method thereof

The invention discloses a low-cost high-strength high-ductility rare earth magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following specific components including, by weight, 0.1 to 6.0 percent of Y, 0.1 to 6.0 percent of Gd, 0.1 to 6.0 percent of Sm, 0.01 to 2.0 percent of Zn, 0.01 to 2.0 percent of Sn, 0.01 to 2.0 percent of Bi, 0.01 to 1.0 percent of Sb, 0.1 to 1.0 percent of Zr and the balance Mg and inevitable impurities, wherein the impurity content is less than or equal to 0.1 percent by weight. According to the low-cost high-strength high-ductility rare earth magnesium alloy and the preparation method, by reasonably controlling the contents of cheap rare earth elements including Sm, Y and Gd and non-rare earth elements including Zn, Sn, Bi and Sb in the alloy, precipitation of a magnesium rare earth strengthening phase is promoted, a brand new non-basal precipitated phase and a non-rare earth precipitated phase are formed, and the rare earth content is reduced; and a new process combining high-temperature low-speed extrusion cogging and variable-temperature variable-speed rolling is adopted, grains and a second phase are further refined, and the high-strength and high-ductility rare earth magnesium alloy with the flat and smooth alloy surface is prepared. At the normal temperature, the alloy tensile strength of an alloy plate prepared through the method is larger than or equal to 515 MPa, the yield strength is larger than or equal to 450 MPa, and the ductility is larger than or equal to 10%; and the tensile strength of the alloy at the high temperature of 200 DEG C is larger than or equal to 501 MPa, the yield strength is larger than or equal to 430 MPa, and the ductility is larger than or equal to 12%.

Owner:赣州虔博新材料科技有限公司

High-strength Ti-Cr-Zr-Mo-Al series titanium alloy and preparation method

The invention discloses a high-strength Ti-Cr-Zr-Mo-Al series titanium alloy and a preparation method . The titanium alloy is prepared from the following components in percentage by mass: 2.5% to 6.0% of Al, 1.5% to 5.0% of Cr, 1.4% to 5.0% of Zr, 2.0% to 8.0% of Mo, less than or equal to 0.35% of O and the balance of Ti and other inevitable impurities. After the alloy is subjected to smelting, forging, solid solution and aging treatment, high strength and good plasticity can be obtained, composition segregation is not likely to be caused, meanwhile, the cost of alloy raw materials is low, and the production and manufacturing cost of the alloy is reduced to a certain degree. According to the high-strength Ti-Cr-Zr-Mo-Al series titanium alloy and the preparation method, the alloy meets the requirements of various industrial fields for high performance of titanium alloy structural parts, and can be widely applied to the industrial fields of aviation, aerospace, automobiles and the like.

Owner:XI AN JIAOTONG UNIV

Method for improving high-strength and high-conductivity performances of copper-based high-strength and high-conductivity material

The invention discloses a method for improving high-strength and high-conductivity performances of copper-based high-strength and high-conductivity material. The high-strength and high-conductivity performances are improved by carrying out melt overheating insulation treatment on the copper-based high-strength and high-conductivity alloy material under certain temperature. The method comprises the steps of alloy melting, overheating treatment, cooling and pouring. According to the invention, the melt overheating treatment is introduced into a smelting process of high-strength and high-conductivity copper alloy, and the method of melt overheating insulation treatment under high temperature is adopted to improve the structure of the alloy melt, thereby further influencing and enhancing alloy solidification structure and property. By adopting the method provided by the invention, under the premise of avoiding introducing heterogeneous elements which can lower the conductivity of the alloy, the high-strength and high-conductivity property of the copper alloy can be further improved, and other mechanical properties such as alloy plasticity can also be enhanced to certain degree.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

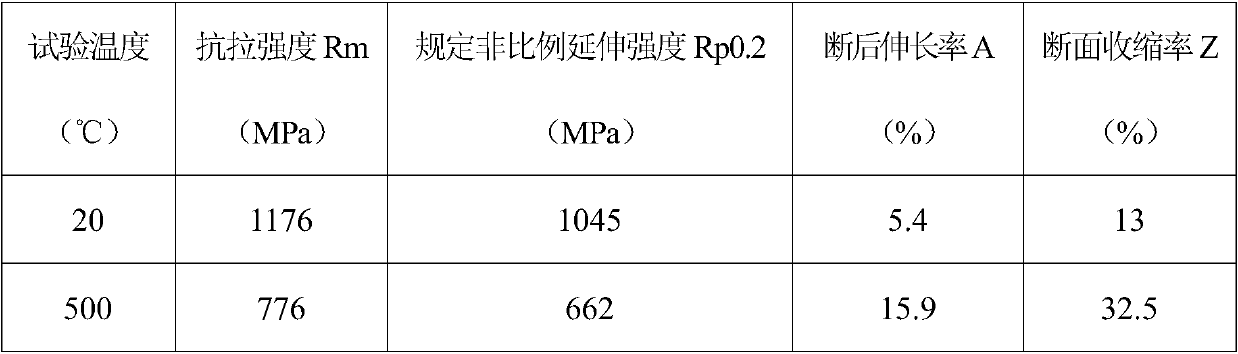

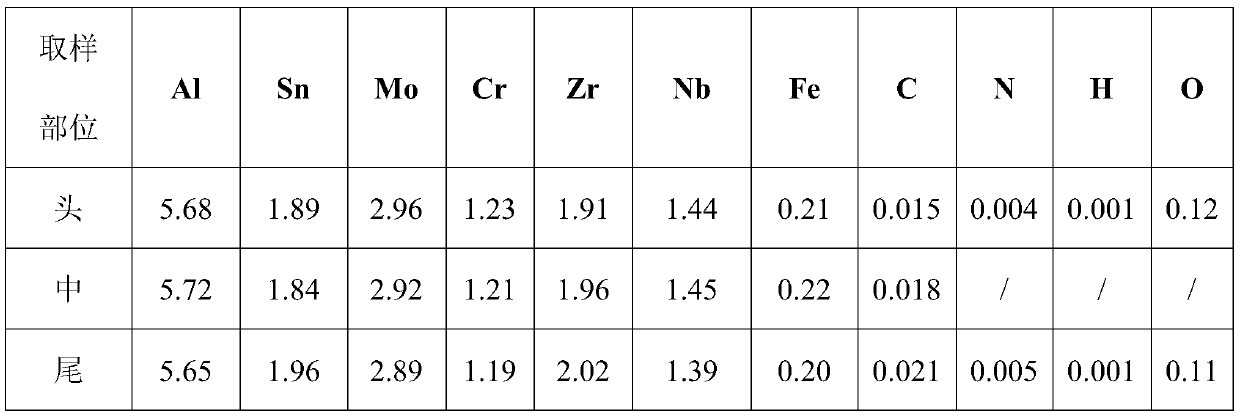

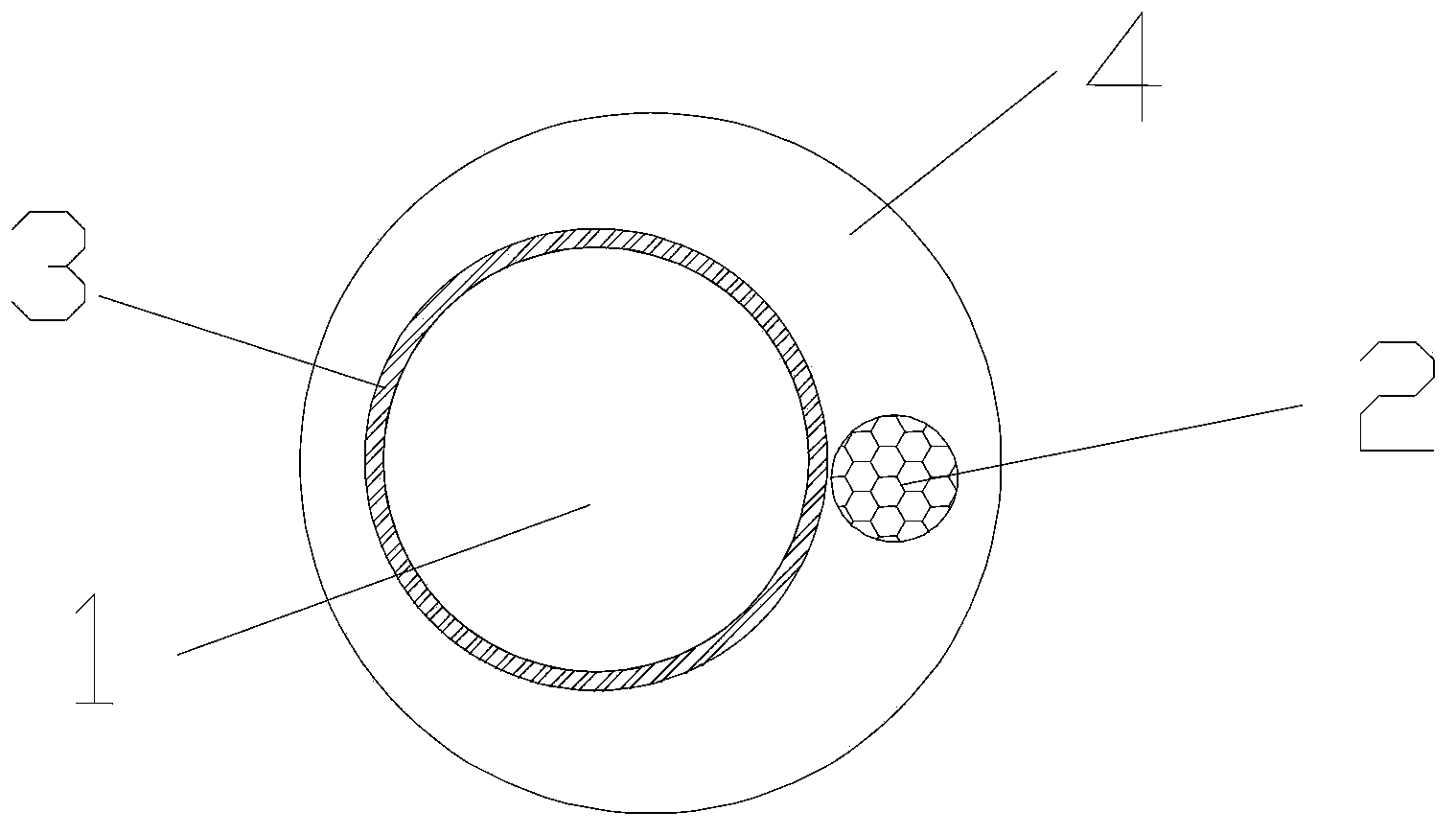

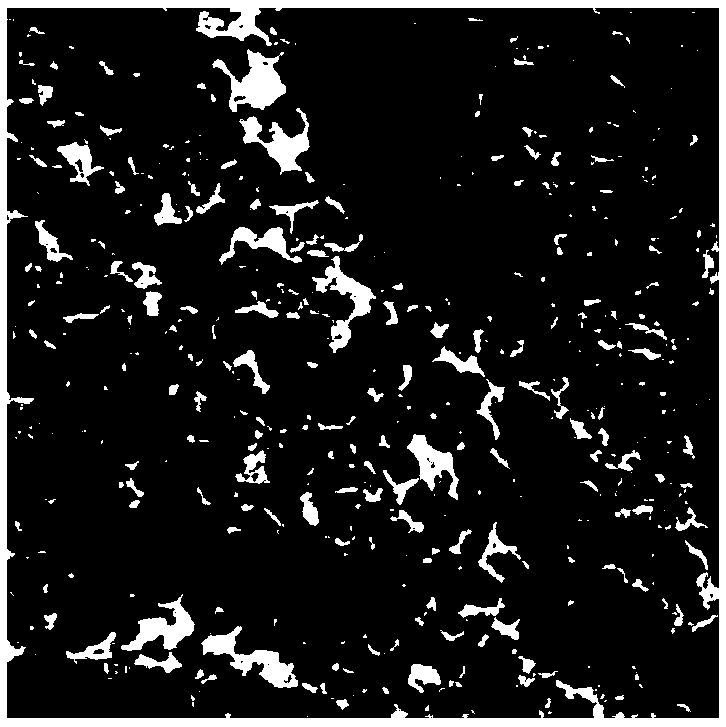

High-strength casting titanium alloy and preparation method thereof

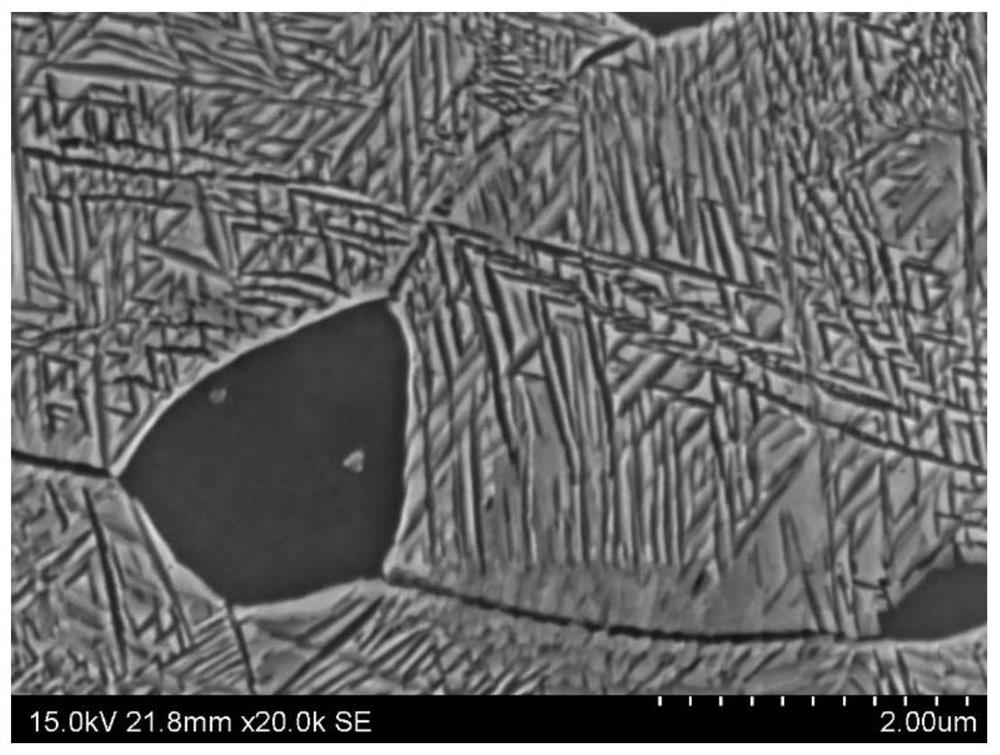

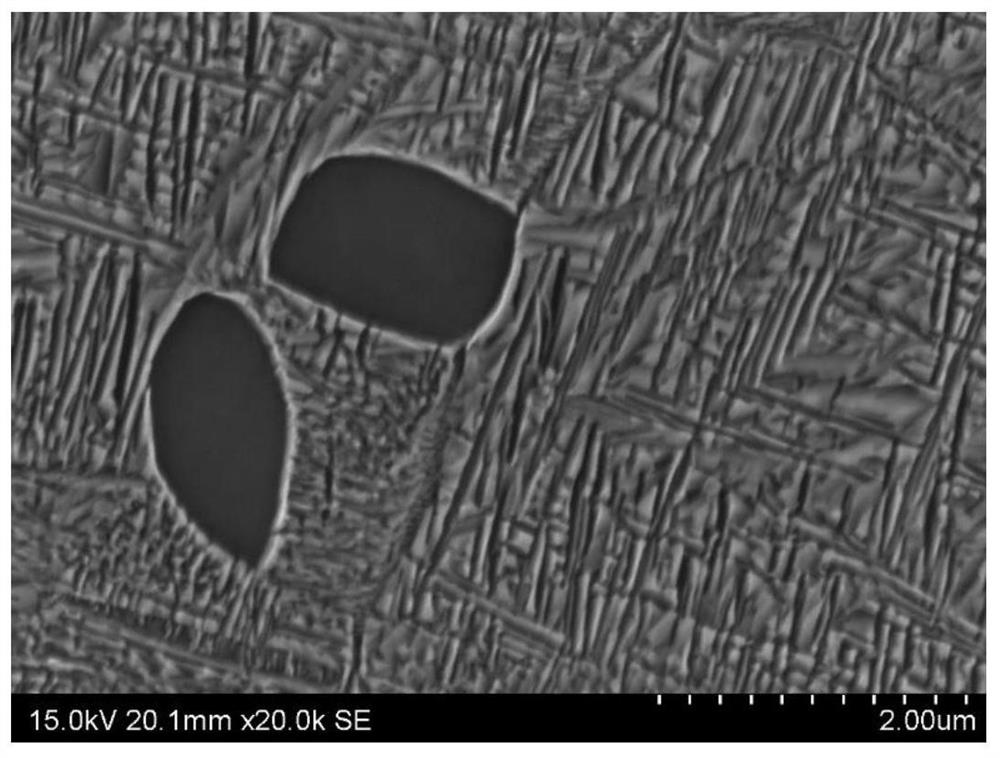

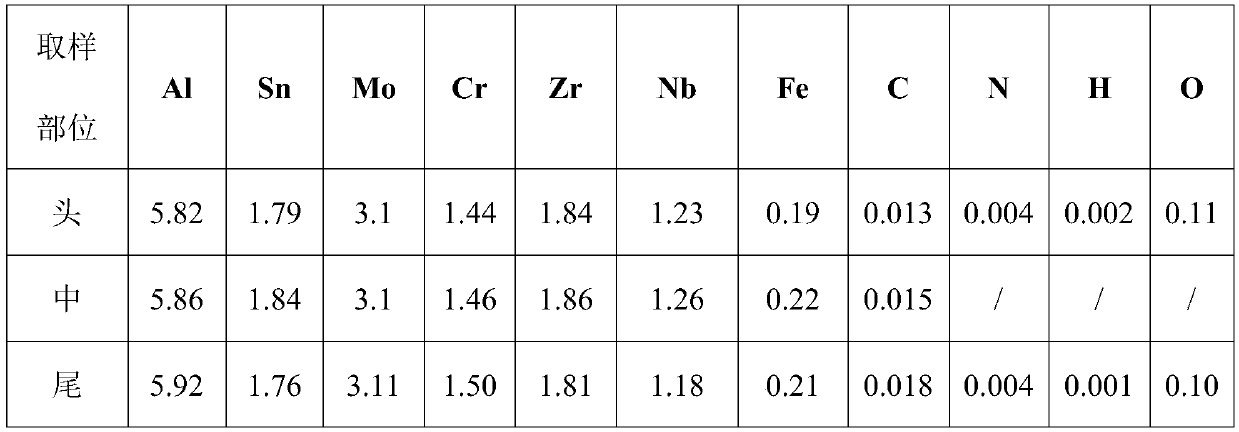

InactiveCN109763026AImprove solid solution strengtheningInhibition of deterioration of alloy high temperature performanceTitanium alloyMetal

The invention discloses high-strength casting titanium alloy and preparation method thereof. The preparation method comprises the following steps that titanium sponge, aluminum shots, aluminum-molybdenum alloy, niobium-titanium alloy, sponge zirconium, titanium-tin alloy and metal chromium are mixed according to the mass percentage of 5.2%-6.8% of Al, 1.6%-2.5% of Sn, 1.6%-2.5% Zr, 2.2%-4.0% of Mo, 0.8%-2.3% of Nb, 0.8%-2.2% of Cr, 0.1%-0.4% of Fe, less than or equal to 0.20% of O, less than or equal to 0.08% C, less than or equal to 0.05% N, less than or equal to 0.015% of H and the balance titanium, and are pressed to be made into strip-shaped electrode blocks; the pressed electrode blocks are assembled and welded into a strip-shaped electrode; the strip-shaped electrode is forged into acasting mother alloy electrode after smelting; and casting is performed, heat treatment is performed on the casting, and the high-strength casting titanium alloy is obtained. The high-strength casting titanium alloy is excellent in mechanical property, and can meet the high strength requirements of industrial complex structural parts for aviation equipment, aerospace equipment, weapon equipment and other equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +2

High-strength aerial cable

ActiveCN103354128AImprove solid solution strengtheningHigh tensile strengthInsulated cablesPower cablesFiberAerial cable

The invention provides a high-strength aerial cable, comprising a conductor, and an insulating layer. The conductor is made of high-strength aluminium alloy. The aluminium alloy conductor is in a cylindrical shape. A complex fiber core comprises carbon fiber filaments and fiber glass filaments. An insulating film wraps outside the conductor, and then the complex fiber core is winded on the periphery of the conductor, and finally, a protective coating is extruded on the periphery of the complex fiber core and the conductor. The protective coating is made of duplex-polyvinyl chloride. First, proper amount of Cr, Cu, and Mg is added in the aluminium alloy, solution strength of the aluminium alloy is increased, so strength of the aluminium alloy, especially tensile strength of the aluminium alloy are substantially improved. In addition, on the periphery of the conductor is the complex fiber core, so tensile strength of the cable is greatly increased. Moreover, the outermost layer uses the duplex-polyvinyl chloride, so tensile strength of the cable is enhanced to a certain extent.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Heat treatment method of promoting precipitation of nano-scale carbide in W-containing alloy steel

Owner:WUHAN UNIV OF SCI & TECH

Ultralow-temperature rolling preparation method for deformed Al-Mg alloy with ultrahigh Mg content

The invention relates to an ultralow-temperature rolling preparation method for a deformed Al-Mg alloy with ultrahigh Mg content. The ultralow-temperature rolling preparation method comprises the following steps: performing component homogenizing treatment, compacting treatment and treatment for enabling solid solution to form a single-phase solid solution on a cast ingot of the Al-Mg alloy at a temperature lower than an alloy solid-phase line temperature of 0-80 DEG C; performing ultralow-temperature rolling; and annealing at a temperature of 50-200 DEG C to obtain the final deformed Al-Mg alloy with ultrahigh Mg content. The technology in the invention remarkably improve dislocations strengthening and grain boundary strengthening in the Al-Mg alloy with ultrahigh Mg content, improves strength, can be used for producing with high efficiency and low cost on a large scale, and has a wide industrial prospect.

Owner:WUHAN UNIV OF TECH

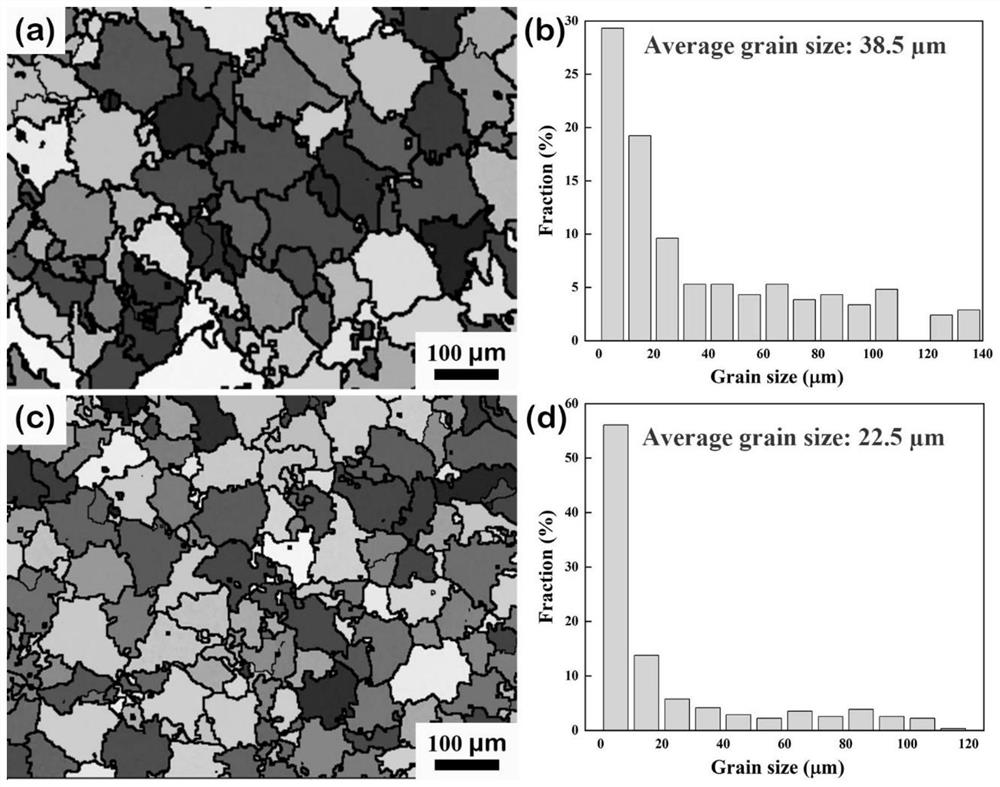

Method for refining Mn-containing Mg-Zn-Al series cast magnesium alloy grains

PendingCN114703388AGrain refinementHigh yield strengthProcess efficiency improvementShielding gasIngot

The invention relates to a method for refining Mn-containing Mg-Zn-Al series cast magnesium alloy grains, and belongs to the field of Mg-Zn-Al series cast magnesium alloy preparation. The preparation method comprises the following steps: preheating raw materials, putting metal Mg, metal Al, metal Zn, metal Cu and Mg-5wt.% Mn intermediate alloy into a smelting furnace, introducing protective gas, smelting at the temperature of 720-760 DEG C until the metal is completely molten, and keeping the temperature for 10-15 minutes to obtain an alloy melt A; adding dry magnesium carbonate powder into the alloy melt A, uniformly stirring, slagging, and standing for 10-20 minutes to obtain a grain refined alloy melt B; an RJ-6 refining agent is adopted for conducting purification and refining treatment on the alloy melt B obtained after grain refinement for 5-10 min, the temperature of the melt is adjusted to 720-740 DEG C after slagging-off treatment, standing is conducted for 20-40 min, and a refined alloy melt C is obtained; pouring the refined alloy melt C into a preheating mold, demolding, and cooling to room temperature in air to obtain an alloy ingot; and the alloy ingot is subjected to solid solution-two-stage aging treatment to obtain the magnesium alloy ingot. Cast magnesium alloy grains are refined through magnesium carbonate, and the magnesium alloy is high in yield strength and good in plasticity after heat treatment.

Owner:CHONGQING UNIV

Al-Mg-Er welding wire and preparation process thereof

ActiveCN101716704BThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaAluminum substrateMixing ratio

The invention discloses an Al-Mg-Er welding wire and a preparation process thereof. The Al-Mg-Er welding wire mainly comprises the following chemical components in percentage by mass: 4.3 to 6.5 percent of Mg, 0.4 to1.2 percent of Mn, 0.05 to 1.3 percent of Zr, 0.1 to 0.6 percent of Er and the balance of Al and other inevitable impurities. The preparation method comprises: preparing pure aluminumingots, pure magnesium ingots, Al-Mn(10.0) preliminary alloy, Al-Er (0.6) preliminary alloy and Al-Zr (4.5) preliminary alloy; melting the alloys in a mixing ratio in a medium frequency induction electric resistance furnace and performing casting to make a cast ingot; subjecting the homogenized cast ingot to end cutting and face milling and hot extrusion; and after intermediate annealing, performing wire drawing in a wire drawing machine while performing pass annealing, subjecting the wire drawn to surface treatment, and coiling the wire to obtain the Al-Mg-Er welding wire of the invention. The welding wire of the invention has the advantages that: the smelting process is stable and easy to implement and the drawing performance of the welding wire is high; the obvious refining molding performance of the structure of the welding wire is high, the strength of weld joint metal is guaranteed and that the plasticity of weld joint metal is equal to that of a parent metal is guaranteed; and the impurity content of the Al-Mg-Er welding wire is low, the toughness is improved, the solution strengthening of an aluminum substrate is promoted, and the strength of the weld joint metal is improved effectively.

Owner:BEIJING UNIV OF TECH

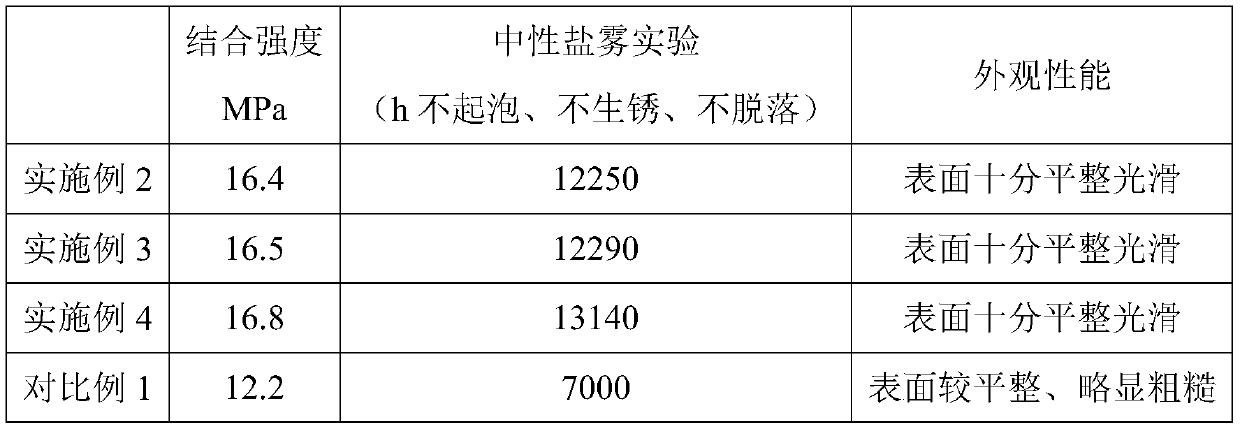

Rare earth alloy hot-dip coating steel plate and production method thereof

ActiveCN110777316AHigh tensile bond strengthImprove corrosion resistanceHot-dipping/immersion processesAlloyDip-coating

The invention discloses a rare earth alloy hot-dip coating steel plate and a production method thereof. The rare earth alloy hot-dip coating steel plate comprises a base steel plate and a rare earth alloy hot-dip coating; the rare earth alloy hot-dip coating covers the surface of the base steel plate; the rare earth alloy hot-dip coating comprises, by mass, 0.1-0.8% of magnesium, 0.05- 0.15% of aluminum, 0.002-0.090% of lanthanum and vanadium, 0.03-0.09% of nickel, 0.01-0.25% of bismuth, 0.05-0.13% of lead and the balance zinc and inevitable impurities; and the ratio of the mass of the lanthanum and the vanadium is 1: (0.42-0.48). According to the rare earth alloy hot-dip coating steel plate, the tensile bonding strength of the rare earth alloy hot-dip coating and the base steel plate is high; in the case of the same thickness of the coating, compared with a traditional pure zinc coating, the corrosion resistance of the rare earth alloy hot-dip coating steel plate is greatly improved to 175% or above; and the obtained coating surface is quite smooth.

Owner:JINJIANG ANNENG BUILDING MATERIALS MFG

Nickel-chromium-chromium carbide composite powder, coating and preparation method thereof with high temperature resistance, wear resistance, corrosion resistance and cavitation resistance

ActiveCN105463359BImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingCavitationWear resistant

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Preparation method of wrought al-mg alloy with ultra-high mg content

ActiveCN108330420BImprove solid solution strengtheningEnhanced dislocation strengtheningMg alloysManufacturing technology

Owner:WUHAN UNIV OF TECH

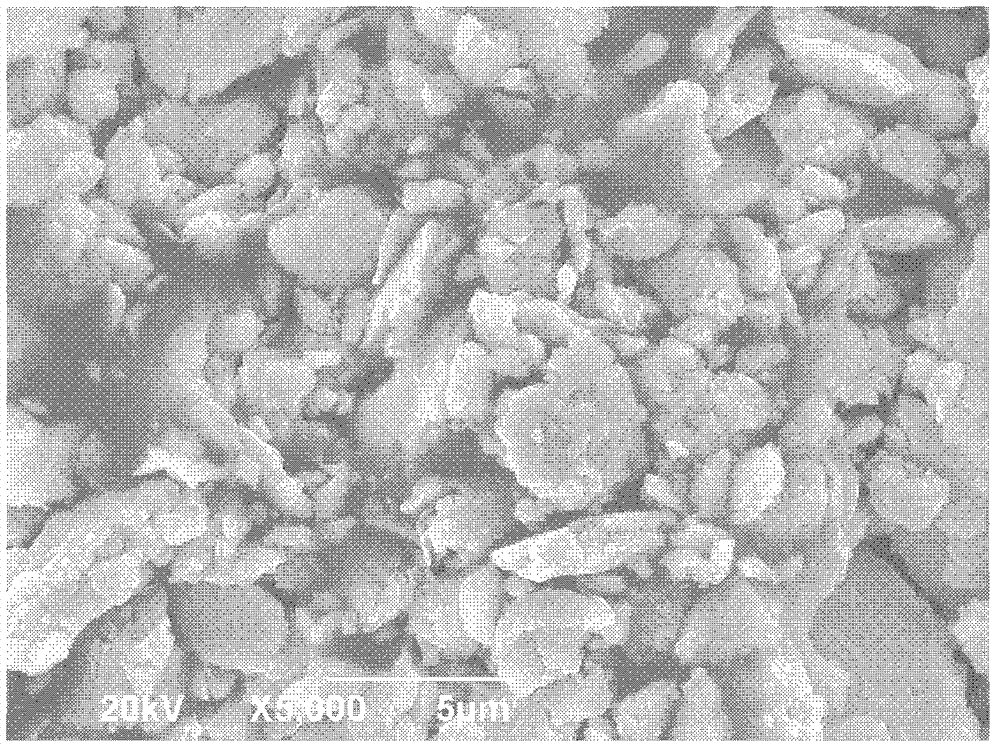

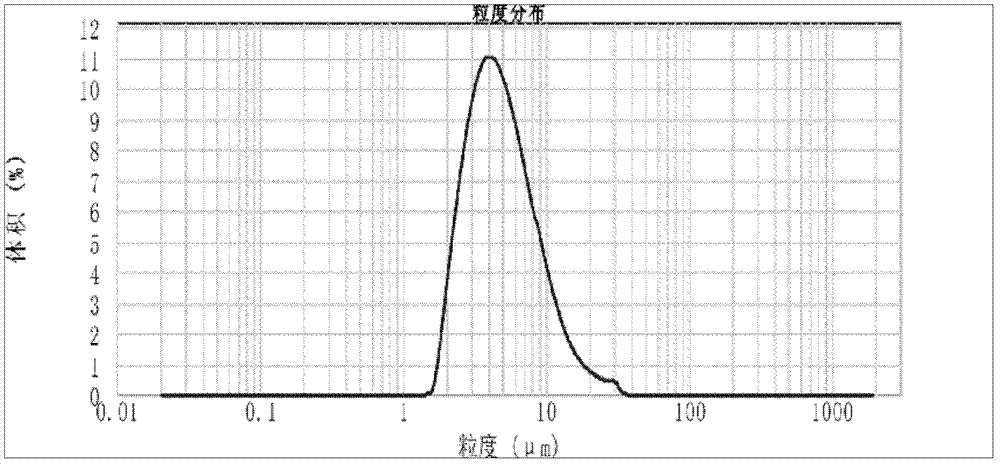

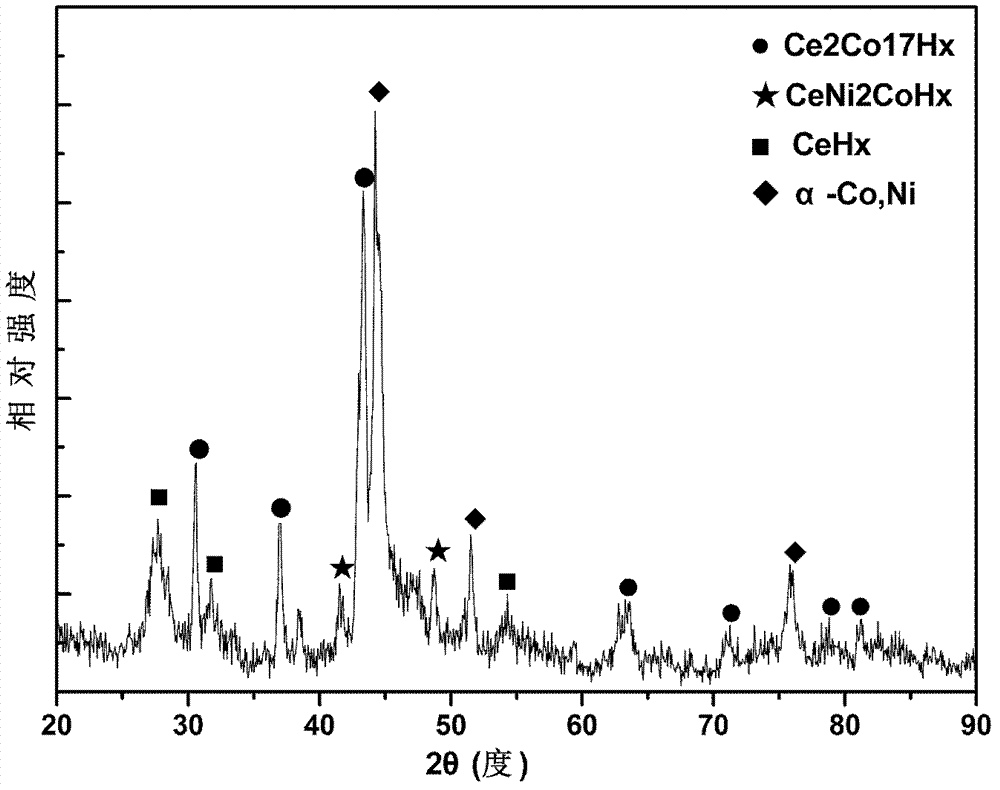

Rare earth additive for hard alloy and preparation method thereof

ActiveCN102528017BImprove solid solution strengtheningImprove mechanical propertiesHydrogenGranularity

The invention discloses a rare earth additive for hard alloy. The rare earth additive for hard alloy is rare earth-binder phase alloy powder with a granularity smaller than 10mum, and the weight percentage of components of the raw materials are as follows: 60-99 percent of binder phase raw material and 1-40 percent of rare earth, wherein the binder phase raw material is formed by Co, Mn and M, and M is at least one out of Ni, Fe, Cr, V, Cu and Al. Two preparation methods are available for the rare earth additive. The first preparation method comprises the steps of casting the binder phase raw material and the rare earth into ingot, smashing the ingot into blocks with size smaller than 20mm, performing homogenizing annealing to the blocks under vacuum condition, or performing rapid quenching to the blocks in an electric-arc remelting rapid quenching furnace to form a rare earth-binder phase alloy thin strip and performing hydrogen absorption, and carrying out ball-milling smashing to the product treated by hydrogen absorption under the protection of argon. The second preparation method comprises the steps of casting the binder phase raw material and the rare earth into ingot, smashing the ingot into blocks with size smaller than 20mm, and performing atomization to the alloy blocks after the alloy blocks are smelted into alloy melts, so as to form atomized powder.

Owner:SICHUAN UNIV

480mpa grade galvanized steel strip and its production method

ActiveCN107326277BImprove purityEnhance fine-grain strengtheningHot-dipping/immersion processesNitrogenSurface level

The invention discloses 480MPa-grade galvanized strip steel. The 480MPa-grade galvanized strip steel comprises, by mass, 0.05-0.09% of C, 0.05% or less of Si, 0.8-1.0% of Mn, 0.016% or less of P, 0.008% or less of S, 0.015-0.035% of Nb, 0.020-0.045% of Als, 0.007% or less of N, 0.015-0.035% of Ti, 0.0015-0.0030% of Ca, and the balance Fe. A production method comprises the steps that converter smelting and LF refining are conducted in a low-nitrogen mode; protective continuous casting is conducted, and nitrogen is controlled to be increased; and calcium treatment is conducted after refining is completed, wherein the mass percent of acid-insoluble aluminum in molten steel is smaller than or equal to 45 ppm, the ratio of the mass percent of the acid-insoluble aluminum to that of calcium is 0.5-1.5, and the ratio of the mass percent of the acid-insoluble aluminum to that of acid soluble aluminum is 0.05-0.20. According to the 480MPa-grade galvanized strip steel, the production cost is low, the overall mechanical performance of the product is superior, and the surface quality meets the requirements of FB surface levels in GB2518 and EN10346.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

A kind of cupronickel tube used in marine engineering and its preparation method

The invention relates to the field of cupronickel pipes, and in particular relates to a cupronickel pipe for the ocean engineering and a manufacturing method thereof. The cupronickel pipe comprises the following chemical components by weight percent: 22.0 to 24.0 percent of nickel (Ni), 2.0 to 4.0 percent of zinc (Zn), 2.0 to 4.0 percent of cobalt (Co), 1.0 to 3.0 percent of manganese (Mn), 1.0 to 2.0 percent of iron (Fe), 1.0 to 2.0 percent of aluminum (Al), 0.3 to 0.5 percent of tin (Sn), 0.1 to 0.3 percent of titanium (Ti), 0.005 to 0.01 percent of boron (B), 0.05 to 0.15 percent of rare earth (RE) and the balance of copper (Cu). After a cupronickel pipe blank is obtained by adopting an induction smelting way, the cupronickel pipe blank is subjected to coil drawing, namely horizontal continuous casting, pipe blank surface milling, planetary rolling through three rollers, straight drawing through three continuous drawing machines, inverted coil drawing, refining rewinding, annealing and finished product inspection. The cupronickel pipe for the ocean engineering is strong in seawater corrosion resistance. Meanwhile, the problems that the traditional copper-nickel alloy material is short in service life and cannot adapt to the coil drawing production way due to the low plasticity can be solved, and the coil drawing of the cupronickel pipe can be realized.

Owner:江西九星铜业有限公司

Ultra-low temperature rolling preparation method of wrought al-mg alloy with ultra-high mg content

The invention relates to an ultralow-temperature rolling preparation method for a deformed Al-Mg alloy with ultrahigh Mg content. The ultralow-temperature rolling preparation method comprises the following steps: performing component homogenizing treatment, compacting treatment and treatment for enabling solid solution to form a single-phase solid solution on a cast ingot of the Al-Mg alloy at a temperature lower than an alloy solid-phase line temperature of 0-80 DEG C; performing ultralow-temperature rolling; and annealing at a temperature of 50-200 DEG C to obtain the final deformed Al-Mg alloy with ultrahigh Mg content. The technology in the invention remarkably improve dislocations strengthening and grain boundary strengthening in the Al-Mg alloy with ultrahigh Mg content, improves strength, can be used for producing with high efficiency and low cost on a large scale, and has a wide industrial prospect.

Owner:WUHAN UNIV OF TECH

A kind of high-strength high-plasticity high-entropy alloy and preparation method thereof

ActiveCN111961893BImprove solid solution strengtheningPromote fine grain strengtheningHigh entropy alloysMetallic materials

The invention discloses a high-strength and high-plastic high-entropy alloy and a preparation method thereof, belonging to the technical field of metal materials and manufacture. The raw materials for the preparation of the high-entropy alloy of the present invention are Co, Cr, Fe, Ni metal particles and Al-10Er (Er mass fraction is 10%) intermediate alloy particles, and the preparation method is as follows: the above-mentioned metal particles are weighed according to the set ratio , melted in a high-vacuum arc melting furnace and then solidified in a copper mold to prepare a high-entropy alloy. In the melting process, in order to ensure the uniformity of the alloy composition, the alloy block needs to be smelted repeatedly. Homogenize the as-cast high-entropy alloy prepared initially in a high-temperature heat treatment furnace, then water quench, and roll the high-entropy alloy ingot at a temperature of 500-800°C, and cool the rolled sample with air , a high-entropy alloy with high strength and high plasticity can be obtained. The high-entropy alloy prepared by the invention has excellent mechanical properties and simple preparation process.

Owner:SOUTHEAST UNIV

A kind of high-entropy alloy with band-shaped precipitated phase and preparation method thereof

ActiveCN110106428BGood room temperature tensile propertiesImprove solid solution strengtheningHigh entropy alloysMo element

The invention discloses a high-entropy alloy with a banded precipitated phase. The high-entropy alloy consists of Co, Cr, Ni and Mo elements, wherein the atomic percent of Co is 25-35%, the atomic percent of Cr is 25-35%, the atomic percent of Ni is 25-35%, the atomic percent of Mo is 5-15%, and the sum of atomic percents of the components is 100%. The phase composition of the high-entropy alloy with the banded precipitated phase comprises a face-centered cubic phase and a sigma precipitated phase, wherein the sigma precipitated phase accounts for 40-60%. In the preparation method, the non-uniform precipitation of the Mo-rich phase is achieved through the combination of hot processing, solid solution processing, cold processing and annealing process, and the high-entropy alloy with the banded precipitated phase is obtained. The alloy can ensure excellent strength and toughness matching, and has application prospects in the fields of cutter materials, aerospace materials and the like.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com