High-strength aerial cable

An overhead cable, high-strength technology, used in insulated cables, power cables, cables, etc., can solve the problems of large overhead scale, increased cost, and low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described below through specific embodiments.

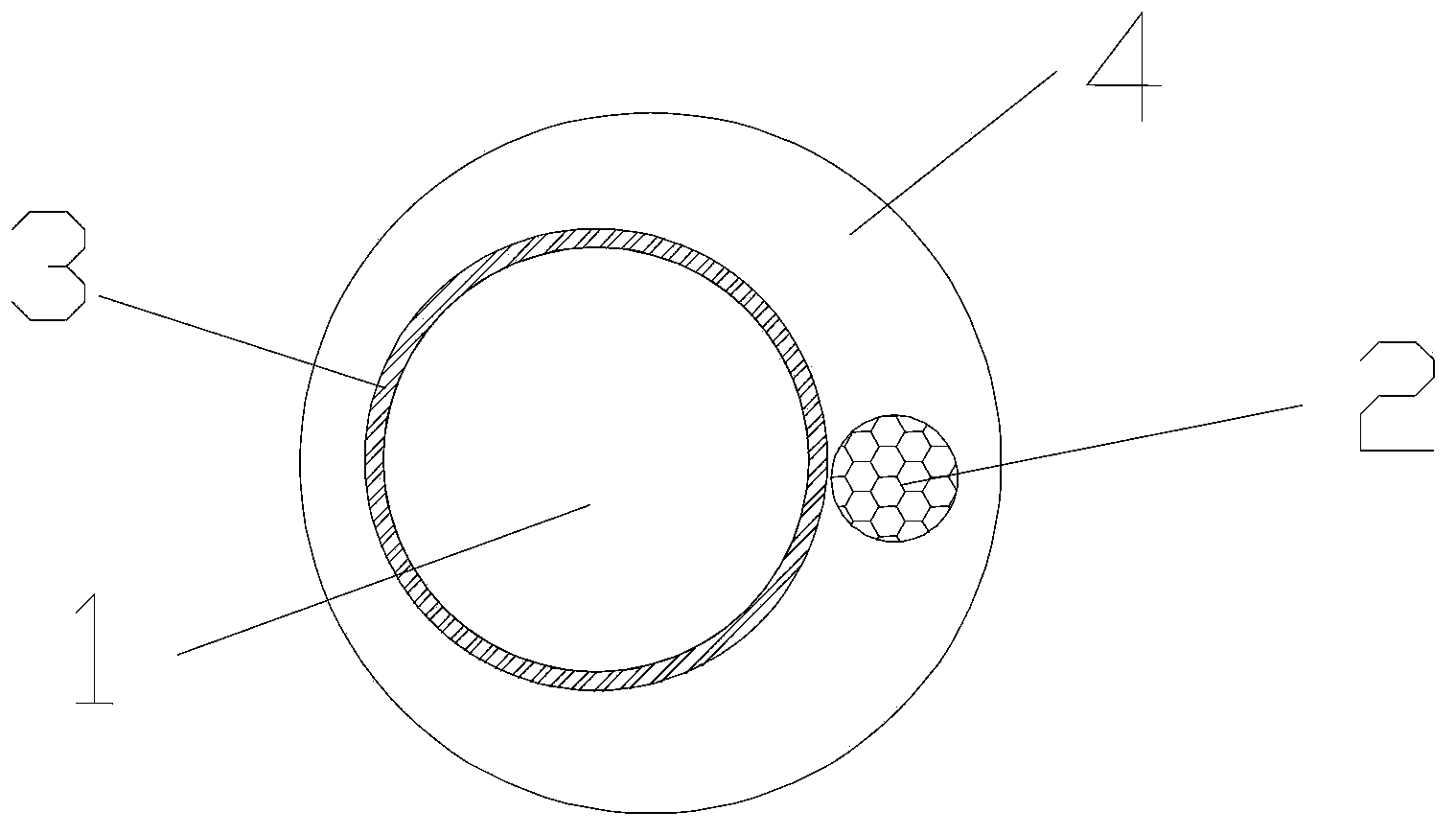

[0012] like figure 1 As shown, the present invention provides a high-strength overhead cable, including a conductor and an insulating layer. The conductor 1 is made of high-strength aluminum alloy, and the aluminum alloy conductor 1 is cylindrical with a diameter of 4mm. The alloy element of the aluminum alloy is According to the mass fraction percentage, Cr0.2%, Cu0.1%, Mg0.15%, and the rest are Al; it also includes a composite fiber core 2, and the composite fiber core 2 includes carbon fiber filaments and glass fiber filaments, and the carbon fiber filaments The metal Cu is sprayed on the glass fiber, and Cu is dip-plated on the glass fiber, and then the two are mixed, and cured by phenolic resin to form a cable; the conductor is wrapped with an insulating film 3, and then the composite fiber core is wound On the outer periphery of the conductor; finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com