480mpa grade galvanized steel strip and its production method

A production method, 480mpa technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of lack of applicability, extremely high requirements for rapid cooling capacity, high cost of precious alloys, and reduce inclusions The probability of defects, the effect of improving the solid solution strengthening effect, and reducing the difficulty of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

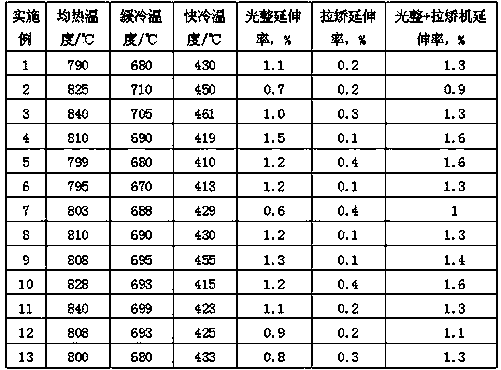

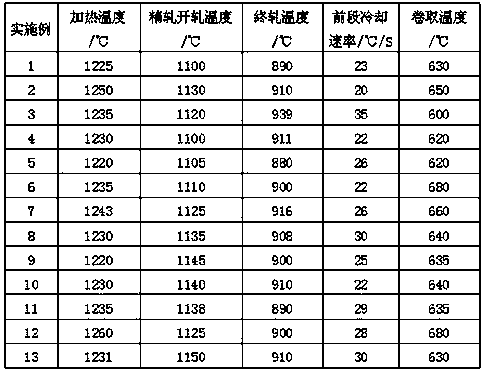

[0016] Examples 1-13: The final chemical composition and process conditions of the production method of the 480MPa grade galvanized steel strip are as follows.

[0017] (1) The galvanized steel strip is prepared by converter smelting, LF refining, continuous casting, hot rolling, cold rolling, continuous annealing, and galvanizing. The chemical composition of the casting after the continuous casting process is shown in Table 1:

[0018] Table 1: Casting Chemical Composition

[0019]

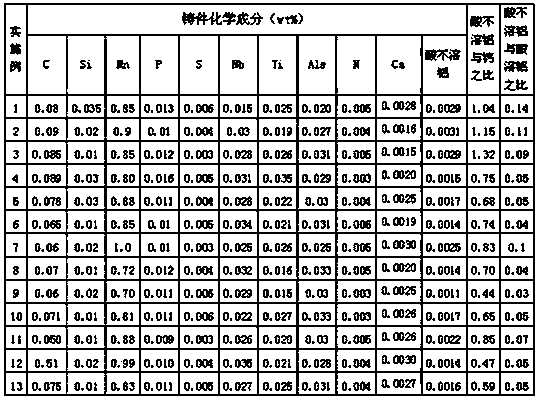

[0020] (2) Hot rolling process:

[0021] During the hot rolling process, the solid solution and precipitation of the second phase particles, the deformation and recrystallization of austenite, and the transformation of ferrite will occur, so hot rolling is an important part of quality control; The joint setting of temperature and the control of the cooling in the front section after finishing rolling can lead to the precipitation of dispersed fine two-phase particles and realize grain refinem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com