AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

A high-entropy alloy and alloy technology, which is applied in the field of AlxCrFeNiCuVTi high-entropy alloy materials and their preparation, can solve the problems of confining the degree of freedom of alloy composition, theoretical analysis or practical application obstacles, and limiting the development of alloy microstructure and properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below through specific examples.

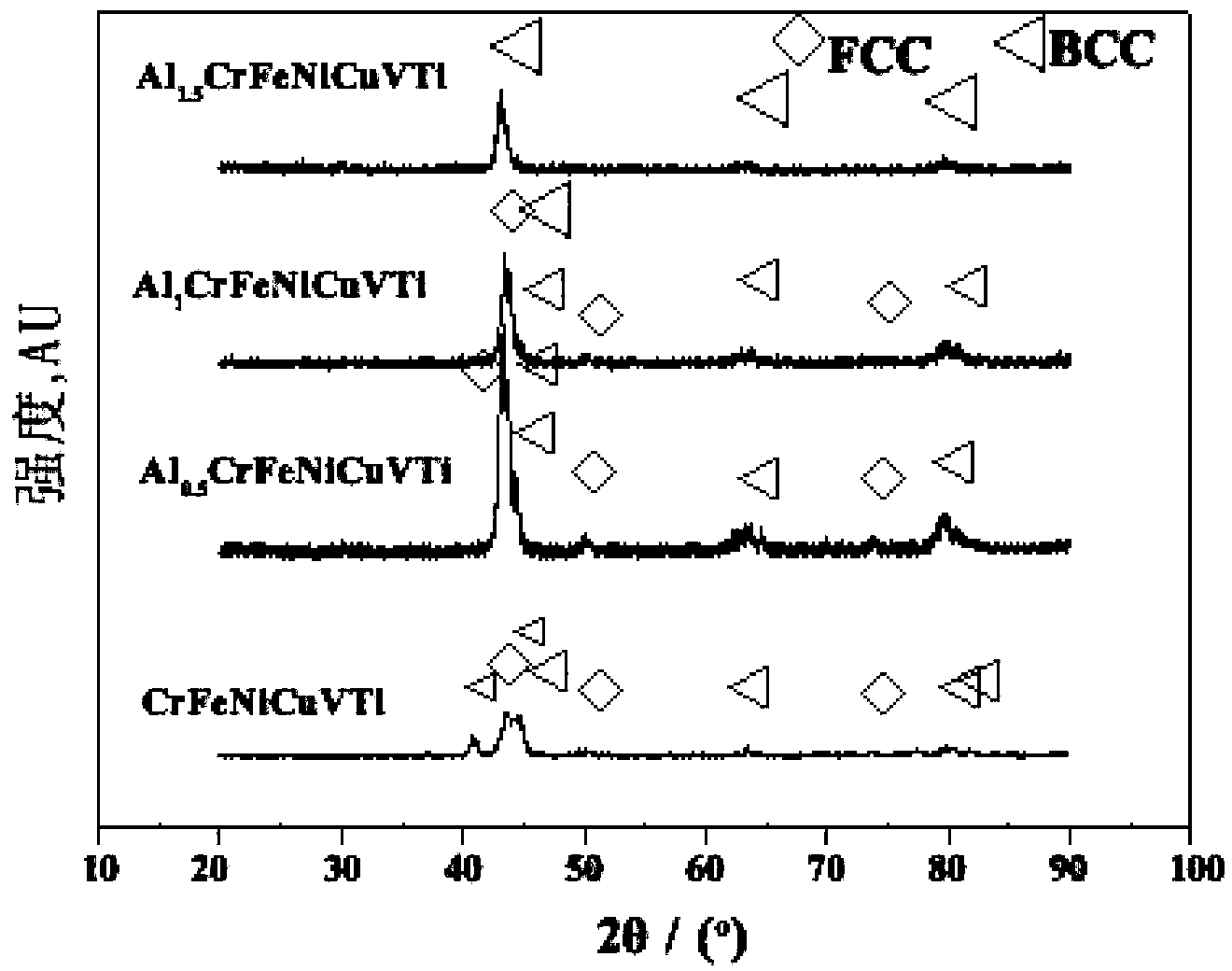

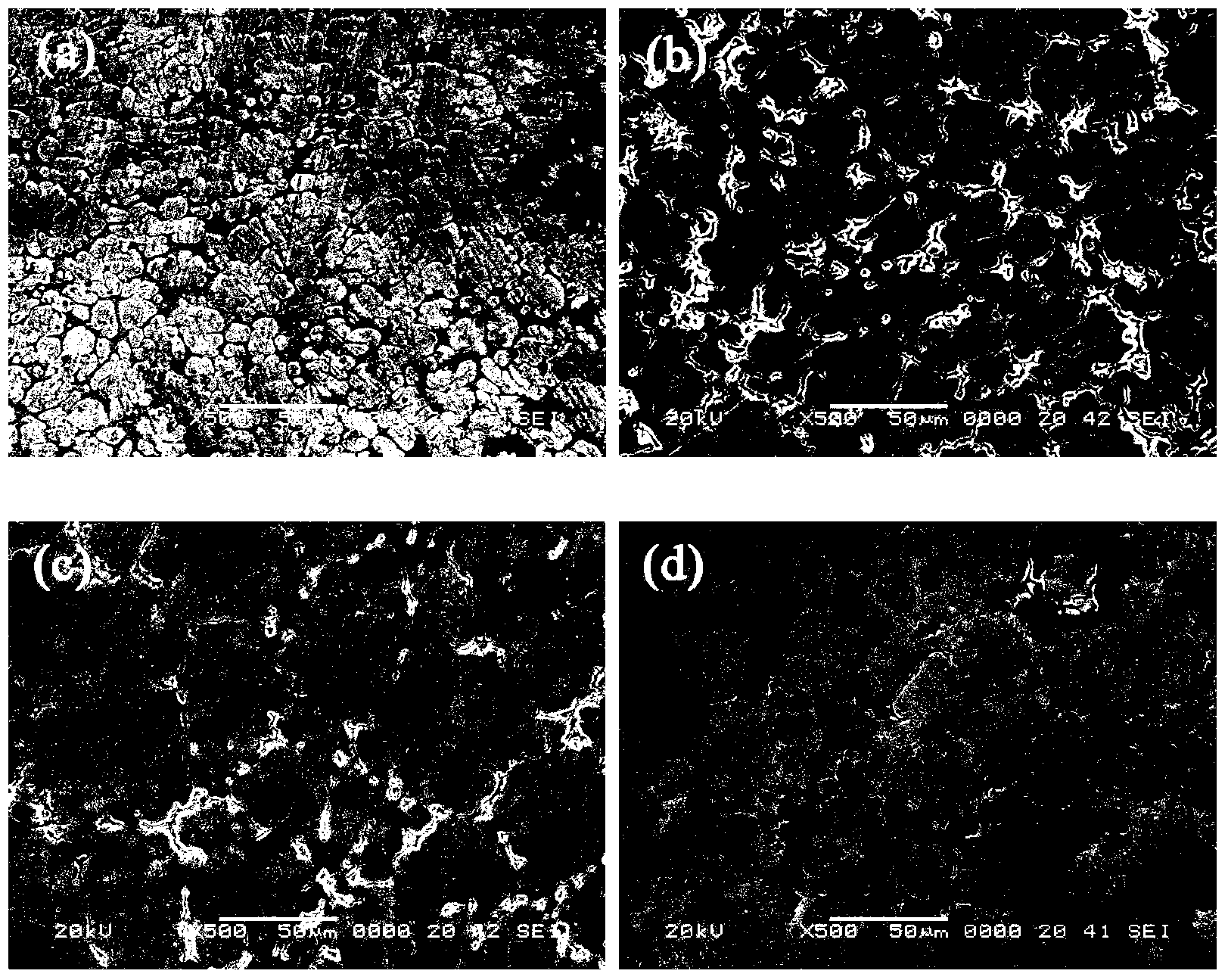

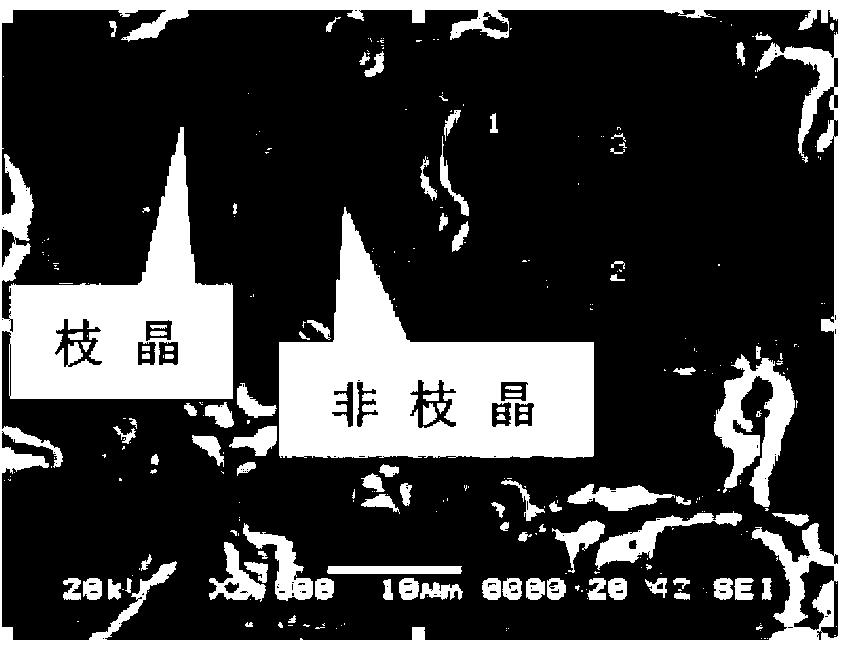

[0023] Al with different Al content x The preparation method of CrFeNiCuVTi system (x=0, 0.5, 1, 1.5) high-entropy alloy material comprises the following steps:

[0024] 1. Pre-treatment of raw materials, purchase pure Al, Cr, Fe, Ni, Cu, V, Ti raw materials, and the purity of the raw materials is not less than 99.99%. Put various alloy raw materials in a beaker, pour acetone solution, and then place it in an ultrasonic oscillator for cleaning for about 20 to 30 minutes to remove oil and impurities attached to the surface, then pour ethanol into it and repeat the same steps Once, after completion, place it in an oven at 50°C for 6 hours to evaporate the moisture of the raw material for use in smelting;

[0025] 2. Ingredients, each alloy is prepared according to the ratio in Table 1, and the raw materials are weighed on a photoelectric analytical balance with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com