Preparation method of high-fluidity TiO2 and organic surface treatment mechanism thereof

A high fluidity, surface treatment technology, applied in the direction of dyeing organosilicon compound treatment, inorganic pigment treatment, chemical instruments and methods, etc., can solve problems such as inability to prepare titanium dioxide well, low surface energy, etc., to reduce surface tension. and free energy, high fluidity, easy washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

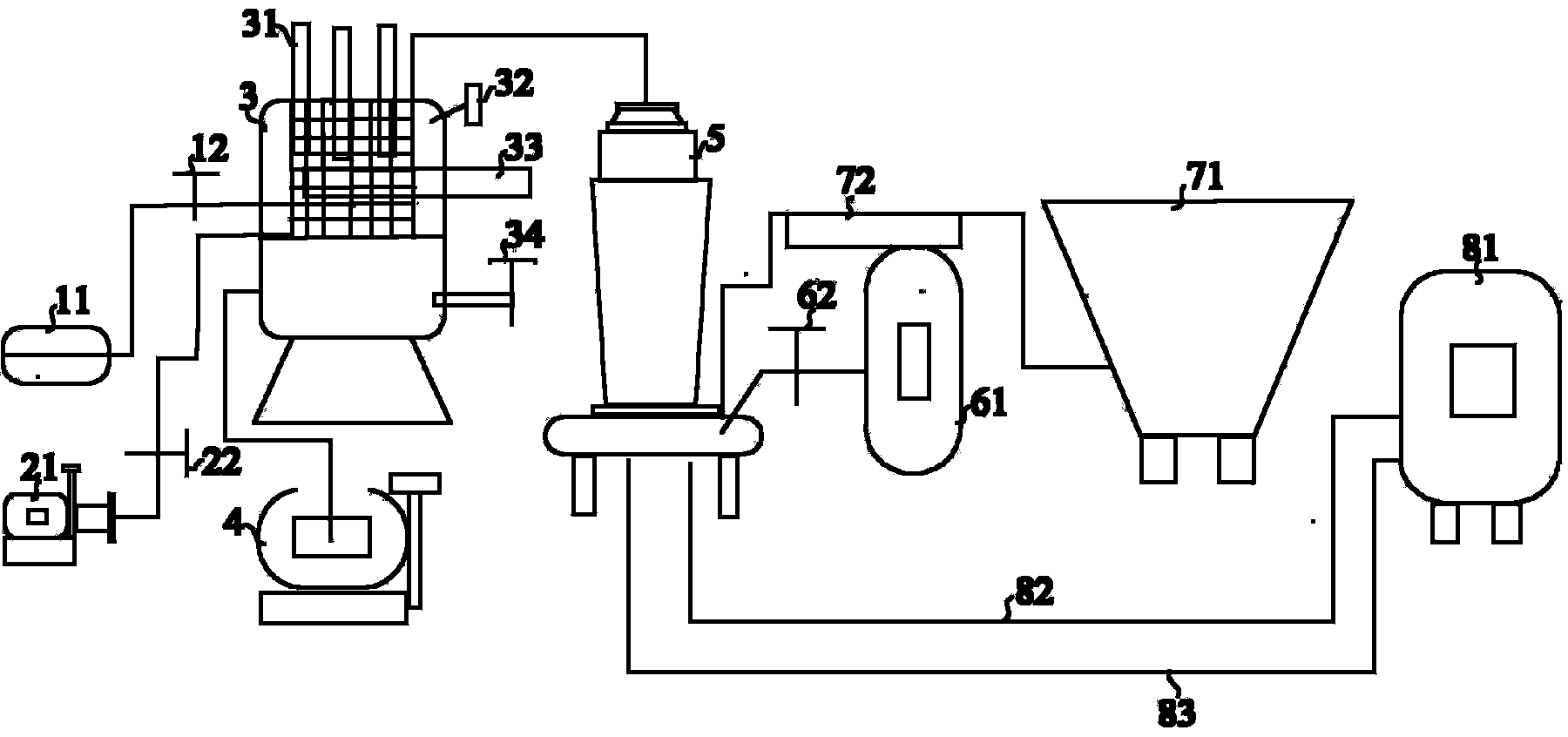

Method used

Image

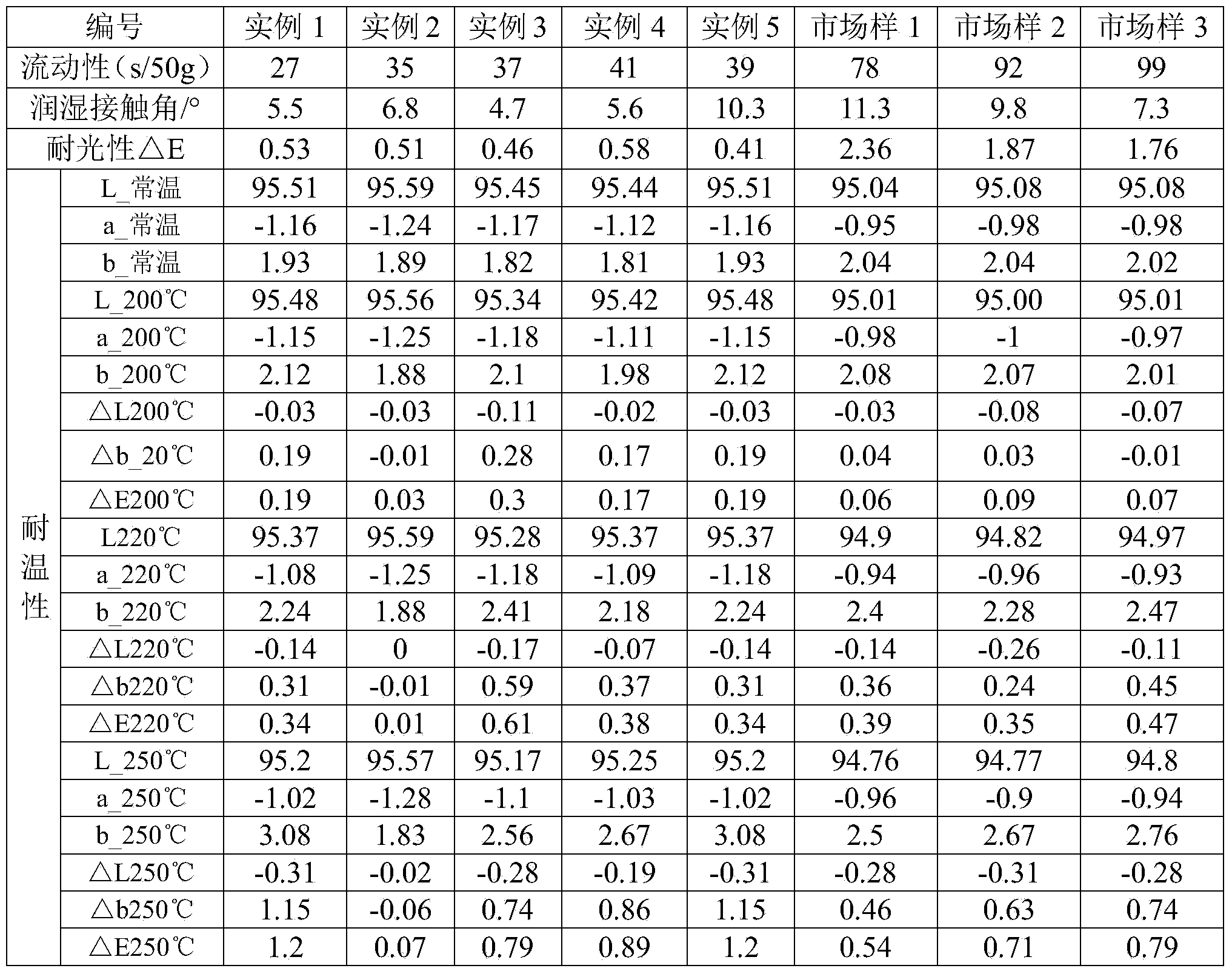

Examples

Embodiment 1

[0041] A kind of high fluidity TiO of the present embodiment 2 The preparation method, its steps are:

[0042] Step 1. Crushing and calcining the crude product of rutile titanium dioxide whose seed crystal is aluminum salt, the TiO2 in the crude product 2 The content is more than 99%, the crude product is calcined completely, the impurity content is less, the particle shape is regular, the overall particle size is larger, the surface energy is small, and the force between particles is small, so the macro fluidity is better. Use deionized water with a conductivity of 4μs cm to make a slurry with a concentration of 500g / L, and add 3‰100g / L sodium silicate as a dispersant (the concentration of sodium silicate is SiO 2 meter), the pH of the slurry is controlled to be 9.5, and the slurry is ground and dispersed.

[0043] Step 2, carry out inorganic surface coating treatment to the slurry obtained in step 1, the specific process is:

[0044] 1) Dilute the slurry obtained in step ...

Embodiment 2

[0059] A kind of high fluidity TiO of the present embodiment 2 The organic surface treatment mechanism is basically the same as in Example 1, and this example prepares high fluidity TiO 2 The process is as follows:

[0060] Step 1, after crushing the crude rutile titanium dioxide, make a slurry with a concentration of 550g / L with deionized water with a conductivity of 3.9 μs cm, and add 3.5‰120g / L of sodium hexametaphosphate as a dispersant ( Concentration is calculated as oxide), the pH of the slurry is controlled to be 9.8, and the slurry is ground and dispersed.

[0061] Step 2, carry out inorganic surface coating treatment to the slurry obtained in step 1, the specific process is:

[0062] 1) Dilute the slurry obtained in step 1 to 310g / L, heat up to 55°C, keep warm, and adjust the pH of the slurry to 4.3 with sulfuric acid with a concentration of 15% by mass at a stirring speed of 550rpm.

[0063] 2) Within 1.2h, the zirconium sulfate solution with a concentration of 1...

Embodiment 3

[0072] A kind of high fluidity TiO of the present embodiment 2 The organic surface treatment mechanism is basically the same as in Example 1, and this example prepares high fluidity TiO 2 The process is as follows:

[0073] Step 1. After crushing the crude rutile titanium dioxide, use deionized water with a conductivity of 3.5 μs cm to make a slurry with a concentration of 600 g / L, and add 3.8‰150 g / L of MIPA (isopropanolamine) as Dispersant, control slurry pH to 10, grind and disperse.

[0074] Step 2, carry out inorganic surface coating treatment to the slurry obtained in step 1, the specific process is:

[0075] 1) Dilute the slurry obtained in step 1 to 320g / L, raise the temperature to 65°C, keep it warm, and adjust the pH of the slurry to 4.5 with hydrochloric acid with a mass percentage concentration of 20% under the stirring condition of a rotation speed of 600rpm.

[0076] 2) Within 1.4h, the zirconium sulfate solution with a concentration of 140g / L (concentration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com