A method for preparing an esterified starch film former for glass fiber wetting

A technology of esterified starch and glass fiber, which is applied in the field of preparation of esterified starch film-forming agent for glass fiber infiltration, can solve the problems of difficult to meet the production technology, no self-emulsifying film-forming agent, etc., to overcome the difficulty of hot cleaning, Viscosity reduction and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

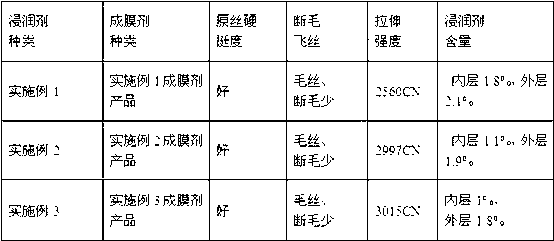

Embodiment 1

[0027] Put 40 parts by mass of cornstarch into the reactor, add 400 parts by mass of distilled water, stir, heat up to 75°C, gelatinize for 2 hours, cool down to 45°C, and adjust the pH value to 5 with acidic and alkaline regulators. Add 4 parts by mass of isoamylase, react for 1.5h, and pass the solution through an 80-mesh sieve. Then raise the temperature to 85°C, react for 15 minutes, cool down to 35°C, slowly add sodium carbonate and 2 parts by mass of octenyl succinic anhydride alternately, and keep the reaction pH of the system at 8.0. After the dropwise addition was completed, the reaction was sealed for 4 hours. After the reaction was completed, the pH of the system was adjusted to 6.8 with 2% hydrochloric acid solution. Cool down to room temperature, suction filter, and freeze-dry the solid to obtain off-white powdery modified starch product.

Embodiment 2

[0029] Put 40 parts by mass of cornstarch into the reaction kettle, add 320 parts by mass of distilled water, stir, heat up to 80°C, gelatinize for 1 hour, cool down to 50°C, and adjust the pH value to 6 with sodium dihydrogen phosphate acid regulator. Add 3 parts by mass of isoamylase, react for 2 hours, and pass the solution through an 80-mesh sieve. Then raise the temperature to 90°C, react for 10 minutes, cool down to 40°C, add an appropriate amount of sodium hydroxide to make the pH value 10, slowly add 1.6 parts by mass of octenyl succinic anhydride to keep the reaction pH of the system at 7.5, and then dropwise add hydroxide Sodium, keep the pH of the reaction at 7.5, and the dropwise addition time is 2 hours. After the dropwise addition, the reaction was carried out for 5h. After the reaction was completed, it was neutralized to pH 7.0 with 3% hydrochloric acid solution. The system was lowered to room temperature, suction filtered, and freeze-dried to obtain off-whit...

Embodiment 3

[0031] Put 40 parts of corn starch into the reaction kettle, add 360 parts by mass of distilled water, stir, heat up to 85°C, gelatinize for 1 hour, cool down to 48°C, and adjust the pH value to 5.5 with dilute hydrochloric acid solution. Add 4 parts by mass of isoamylase, fully react for 1 hour, and pass the solution through an 80-mesh sieve. The filtrate was heated up to 90°C, reacted for 10min, cooled to 35°C, added dropwise 0.25mol / L potassium hydroxide solution to raise the pH value to 8.5, stopped the dropwise addition, and then slowly added 1.2 parts by mass of octenyl succinic anhydride dropwise, keeping The reaction pH of the system is 8.0, and potassium hydroxide and acid anhydride are slowly added dropwise in sequence to maintain the pH of the reaction system at 8-8.5. Dropping time was controlled at 1.5 hours. After the dropwise addition, the reaction was carried out for 3.5h. Then neutralize the solution with 2.5% hydrochloric acid solution to pH 6.8. The syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com