Method for refining Mn-containing Mg-Zn-Al series cast magnesium alloy grains

A technology for casting magnesium alloys and grain refinement, which is applied in the direction of improving process efficiency, can solve problems such as unfavorable magnesium alloy application scope, increase production costs, etc., to ensure mechanical properties and corrosion resistance, improve quality, and simple methods. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

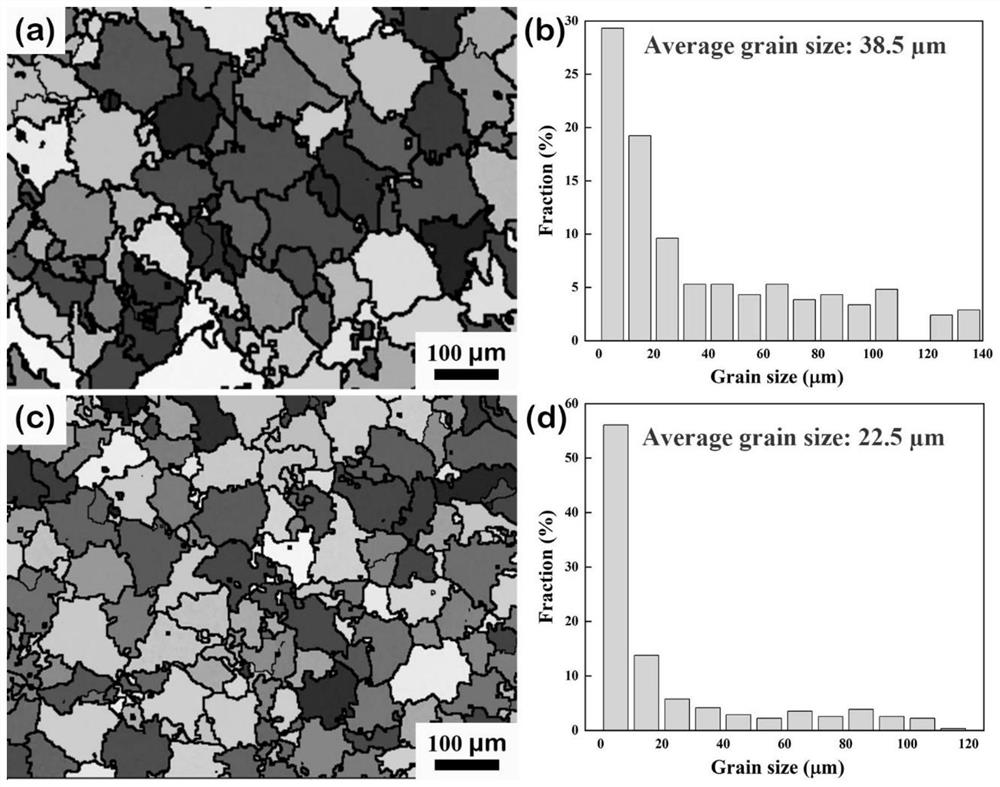

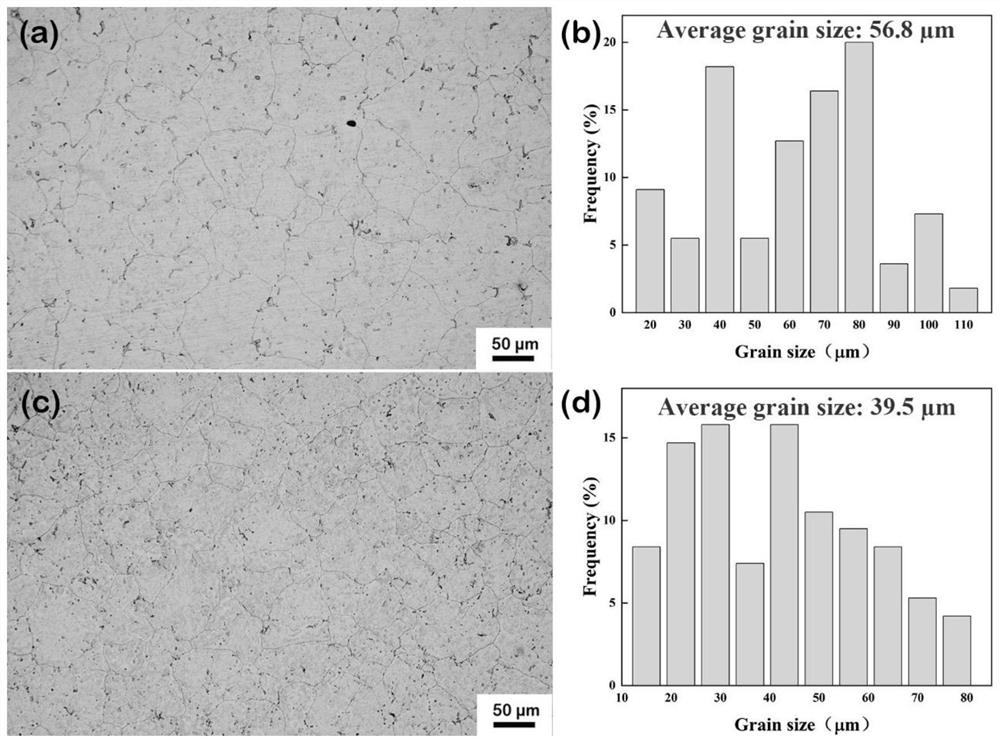

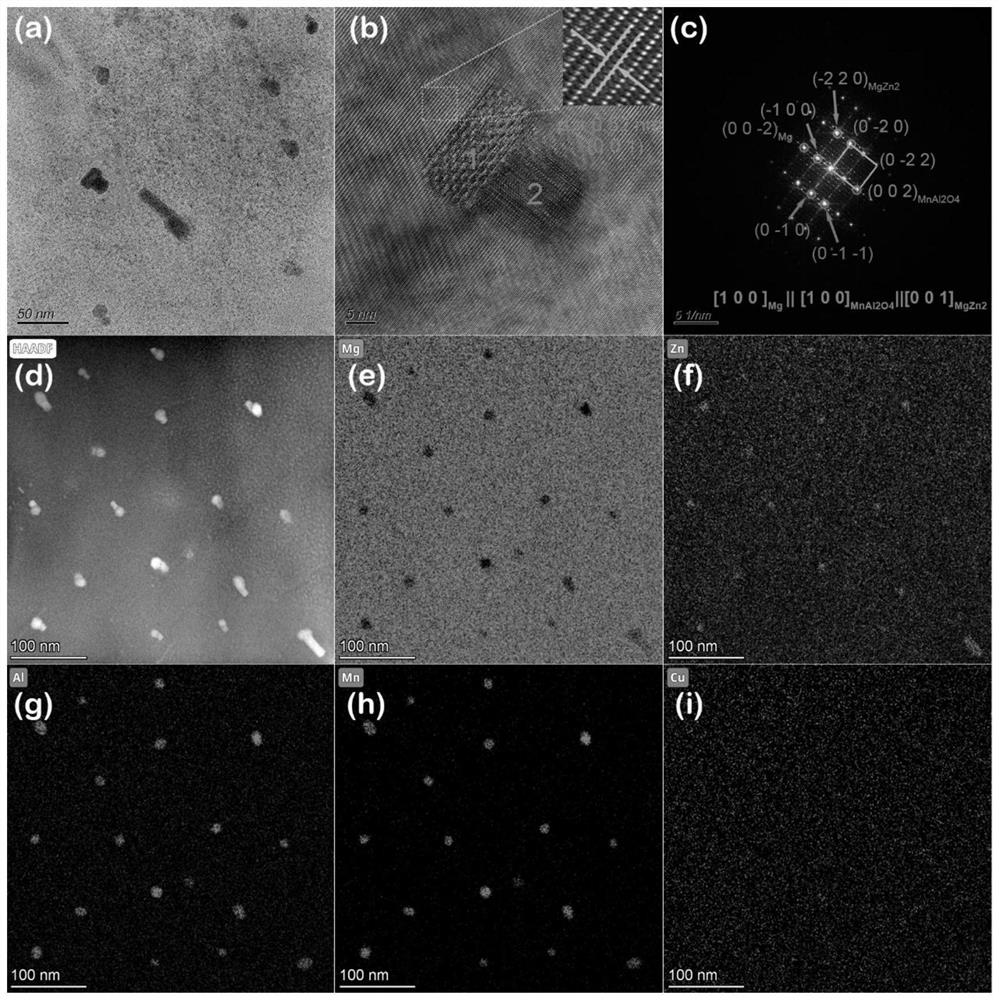

[0043] Example 1: Low-cost and high-strength Mg-Zn-Al-Mn-Cu cast magnesium alloy, 0.2% mass fraction of magnesium carbonate was added as a grain refiner during the smelting process, and the constituent elements and weight percentages were: Zn 10.0% , Al 1.0%, Mn 0.3%, Cu 0.5%, the rest are Mg and unavoidable impurities in the smelting process, and the total content of impurities is less than 0.1%; element addition method: Mg, Zn, Al, Cu to pure Mg (99.97% ) block, pure Zn (99.9%) block, pure Al (99.7% block), pure Cu (99.9%) block are added, and Mn element is added in the form of Mg-5wt.%Mn master alloy;

[0044] (1) Batching: The raw materials are pure metal Mg, pure metal Zn, pure metal Al, pure metal Cu and Mg-5wt.%Mn master alloy, and are batched according to the weight percentage; before smelting, the oxide film on the surface of the raw material is polished and cleaned , and consider the element burning loss in the smelting process, and calculate the element burning loss...

Embodiment 2

[0053] Example 2: Low-cost and high-strength Mg-Zn-Al-Mn-Cu cast magnesium alloy, 0.5% mass fraction of magnesium carbonate was added as a grain refiner during the smelting process, and the constituent elements and weight percentages were: Zn 10.0% , Al 1.0%, Mn 0.3%, Cu 0.5%, the rest are Mg and unavoidable impurities in the smelting process, and the total content of impurities is less than 0.1%; element addition method: Mg, Zn, Al, Cu to pure Mg (99.97% ) block, pure Zn (99.9%) block, pure Al (99.7% block), pure Cu (99.9%) block are added, and Mn element is added in the form of Mg-5wt.%Mn master alloy;

[0054] (1) Batching: The raw materials are pure metal Mg, pure metal Zn, pure metal Al, pure metal Cu and Mg-5wt.%Mn master alloy, and are batched according to the weight percentage; before smelting, the oxide film on the surface of the raw material is polished and cleaned , and consider the element burning loss in the smelting process, and calculate the element burning loss...

Embodiment 3

[0063] Example 3: High-strength Mg-Zn-Al-Mn-Cu cast magnesium alloy, the constituent elements and weight percentages are: Zn 10.0%, Al 1.0%, Mn 0.3%, Cu 0.5%, the rest are Mg and the smelting process Inevitable impurities, the total content of impurities is less than 0.1%; element addition method: Mg, Zn, Al, Cu, pure Mg (99.97%) block, pure Zn (99.9%) block, pure Al (99.7% block), pure Cu (99.9%) is added in bulk, and Mn is added in the form of Mg-5wt.%Mn master alloy;

[0064] (1) Batching: The raw materials are pure metal Mg, pure metal Zn, pure metal Al, pure metal Cu and Mg-5wt.%Mn master alloy, and are batched according to the weight percentage; before smelting, the oxide film on the surface of the raw material is polished and cleaned , and consider the element burning loss in the smelting process, and calculate the element burning loss rate according to the actual situation;

[0065](2) Smelting: after preheating the raw materials in step (1) at a temperature of 180-20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com