Patents

Literature

723 results about "Metal metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

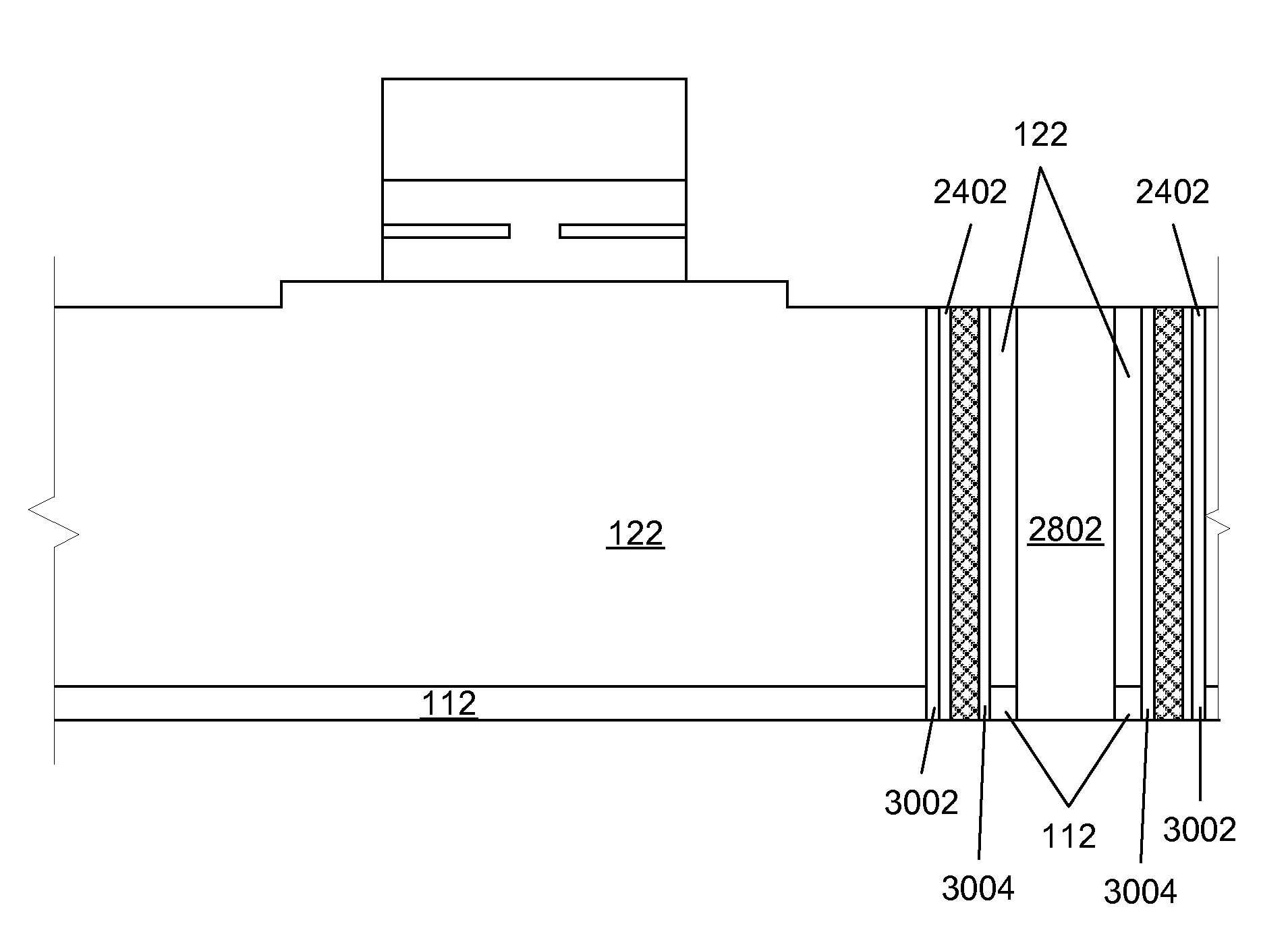

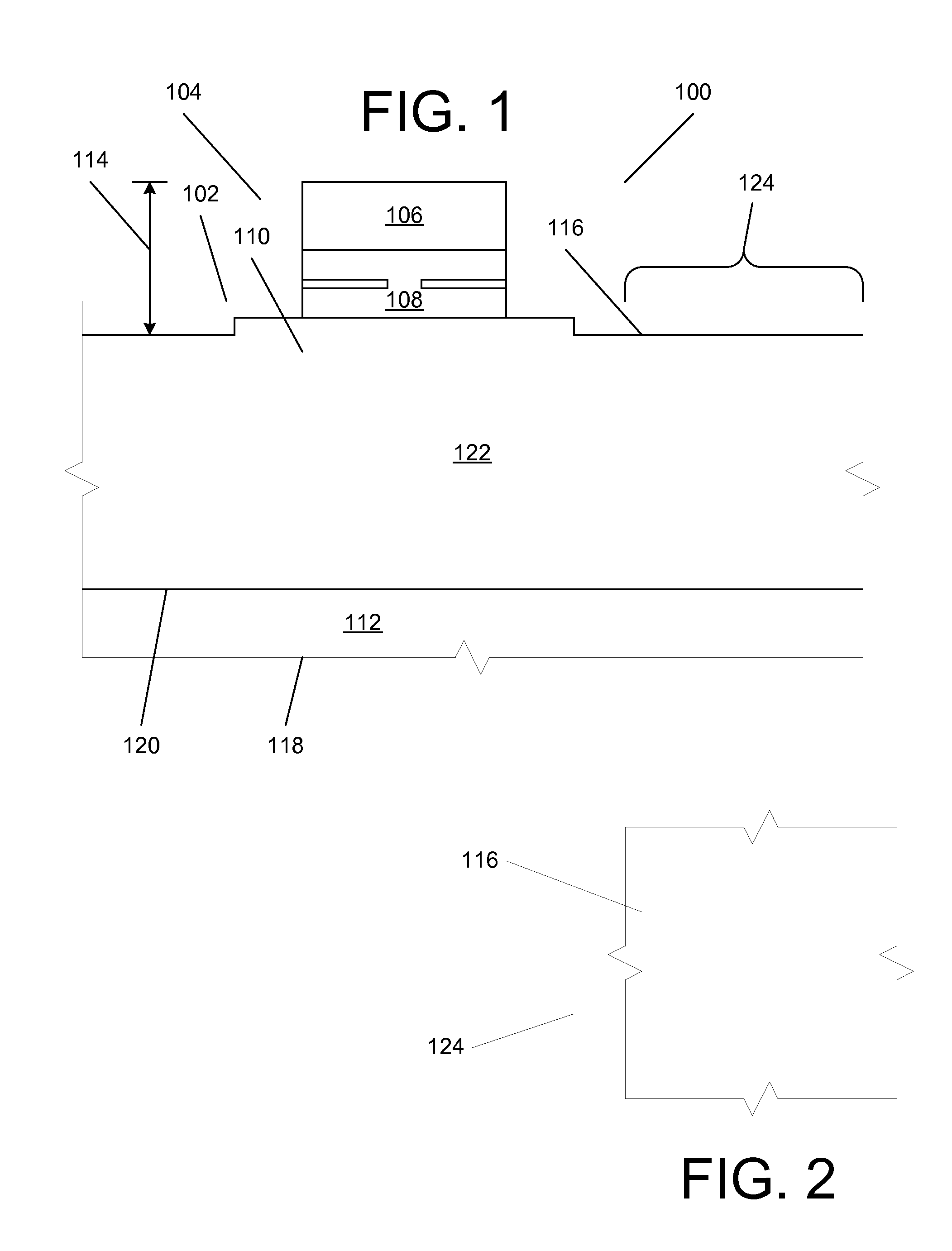

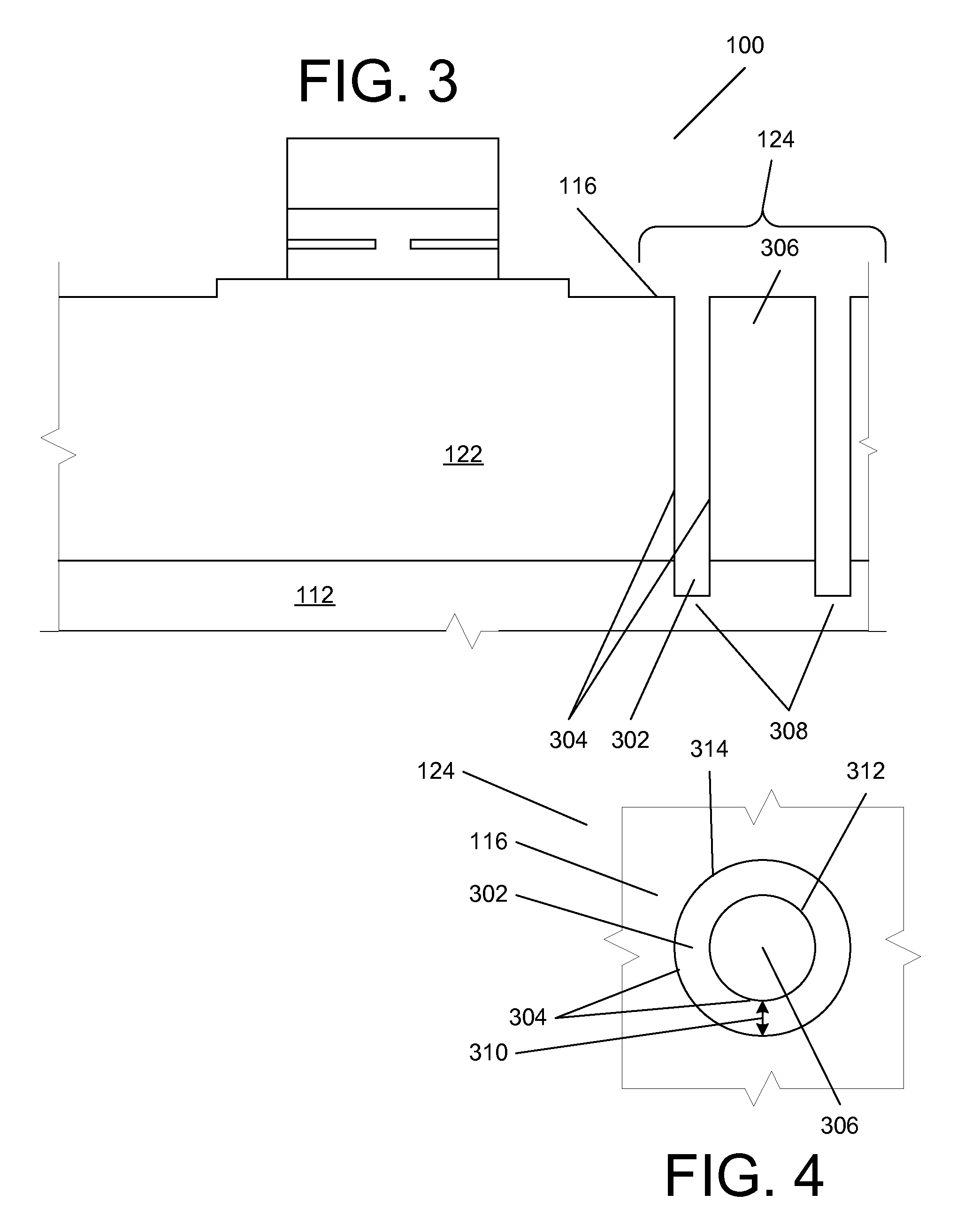

Coaxial through chip connection

ActiveUS7157372B1Laser detailsSemiconductor/solid-state device detailsConductive materialsSemiconductor

A method performed on a wafer having multiple chips, each including a doped semiconductor and substrate, involves etching an annulus trench partially into the substrate, metalizing the annulus trench with a metal, etching a via trench within the periphery of the annulus trench, making a length of the via trench electrically conductive, and thinning the substrate to expose the metal and the electrically conductive material.

Owner:CUFER ASSET LTD LLC

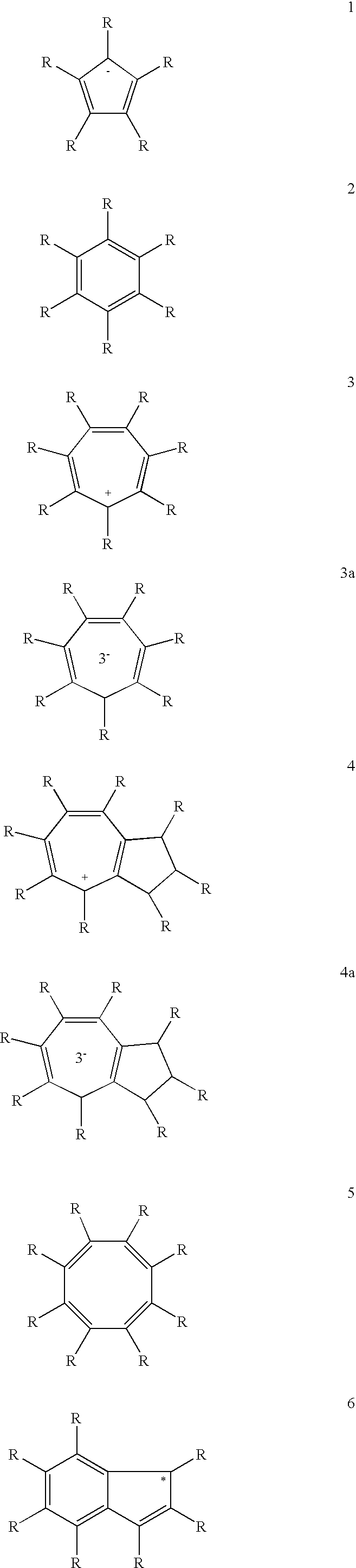

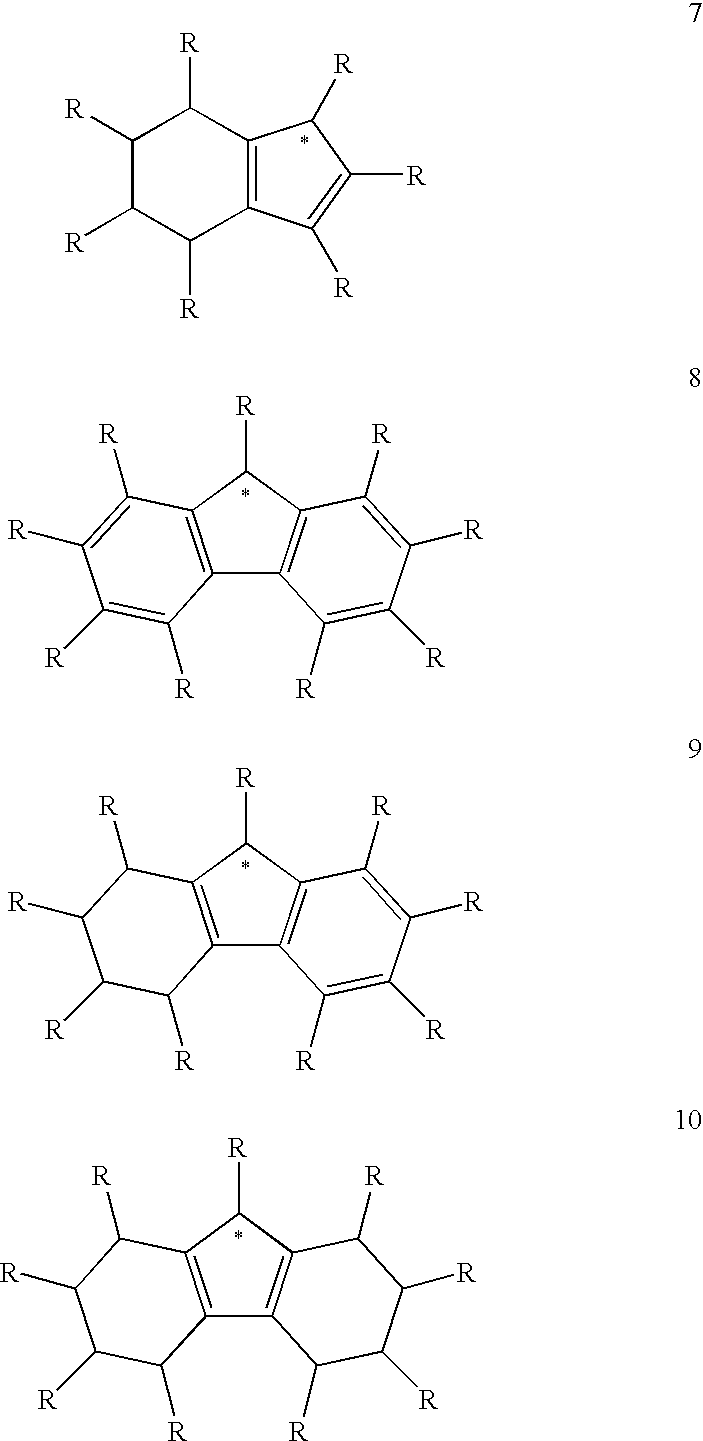

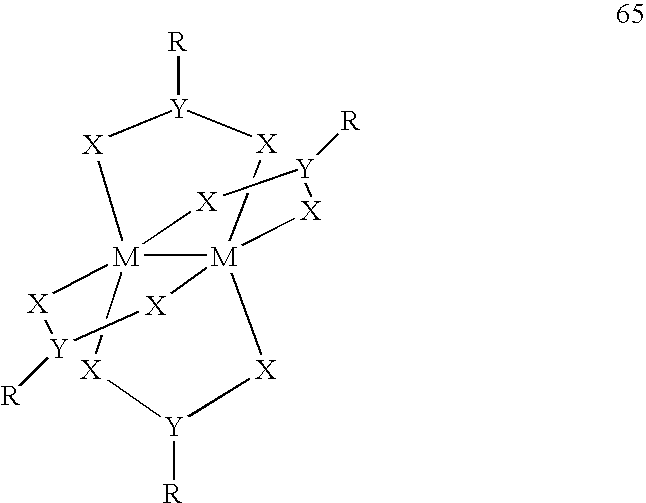

Use of a Metal Complex as an N-Dopant for an Organic Semiconducting Matrix Material, Organic of Semiconducting Material and Electronic Component, and also a Dopant and Ligand and Process for Producing same

ActiveUS20090212280A1Low oxidation potentialEasy to chargeGroup 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsCarbanionValence electron

A method of using a metal complex as an n-dopant for doping an organic semiconducting matrix material in order to alter the latter's electrical characteristics is provided. In order to provide n-doped organic semiconductors with matrix materials having a low reduction potential, while achieving high conductivities, the n-dopant is a neutral electron-rich metal complex with a neutral or charged transition metal atom as a central atom and having at least 16 valence electrons. The complex can be polynuclear and can possess at least one metal-metal bond. At least one ligand can form a π complex with the central atom, which can be a bridge ligand, or it can contain at least one carbanion-carbon atom or a divalent atom. Methods for providing the novel n-dopants are provided.

Owner:NOVALED GMBH

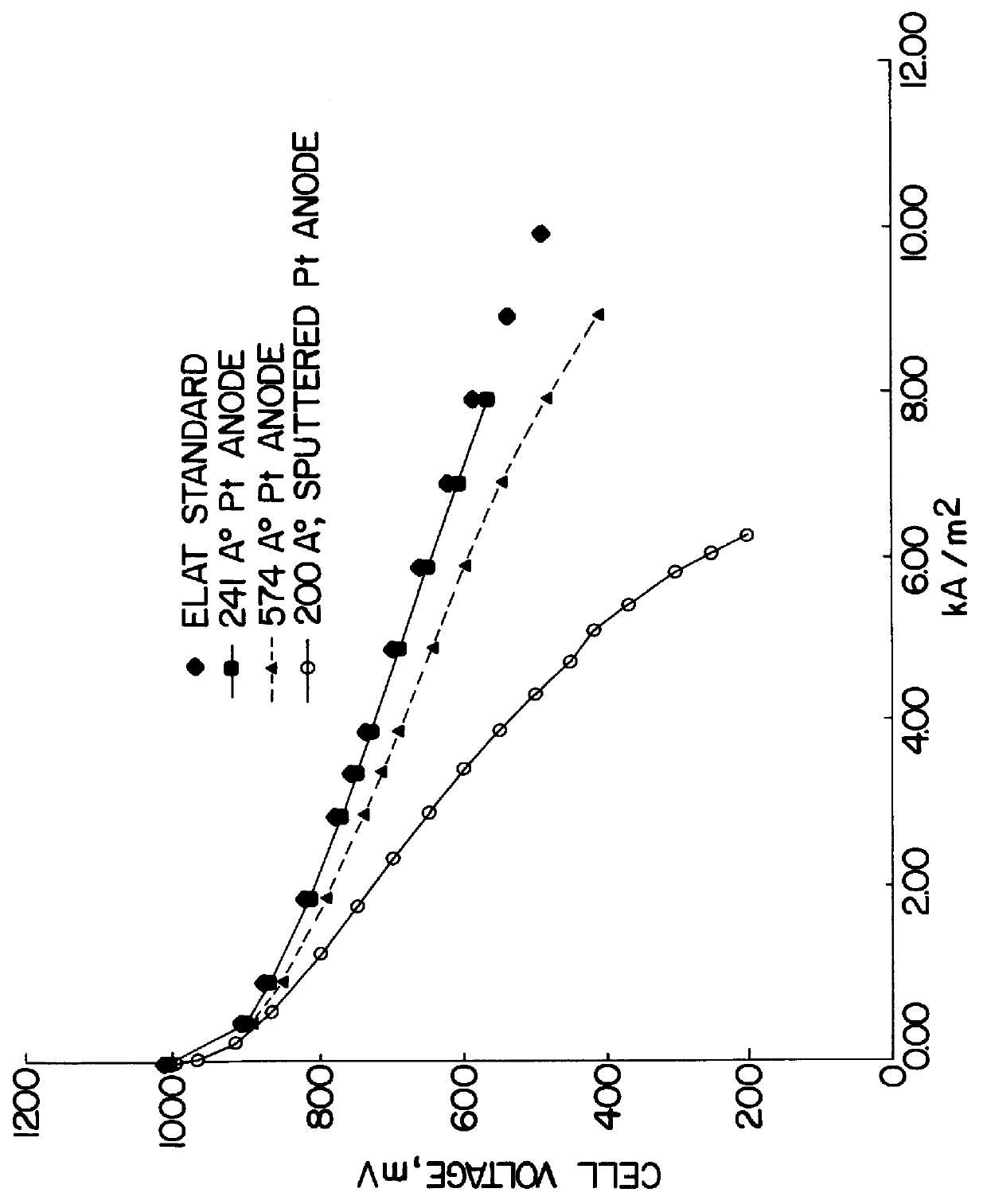

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

Reactive compositions for fluid treatment

InactiveUS20030196966A1Perfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersFiltrationPhosphate

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

Method for treating wood with a metal-containing treating agent and wood treated thereby

InactiveUS6541038B1Reduce leachingEasy to fixBiocideHeavy metal active ingredientsLignosulfonatesMetal

A method for treating wood, characterized by impregnating wood with a metal-containing treating agent containing lignin and / or lignin derivatives and a metal, a metal compound, and / or a metal ion and oxidizing and / or macromolecularizing of the lignin and / or lignin derivatives in the wood to fix the metal component in the wood, and wood and woody materials obtained by the treating method. According to the method of the present invention, while effectively utilizing lignins, lignosulfonic acids, or lignosulfonic acid salts, leaching of the metal component can be suppressed to a low level to thereby retain the effects due to the incorporation of the metal components for a prolonged period.

Owner:SDS BIOTECH CO LTD

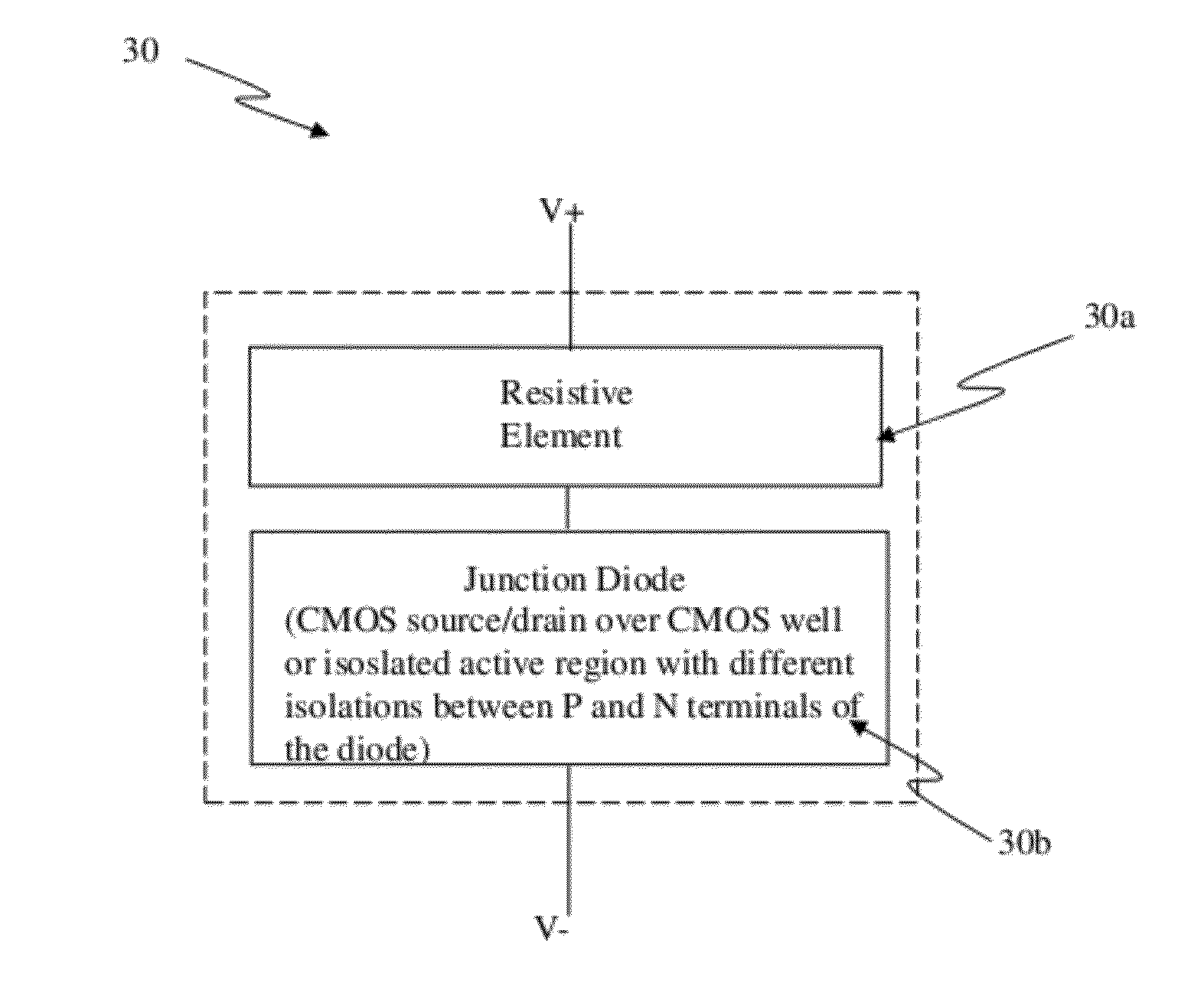

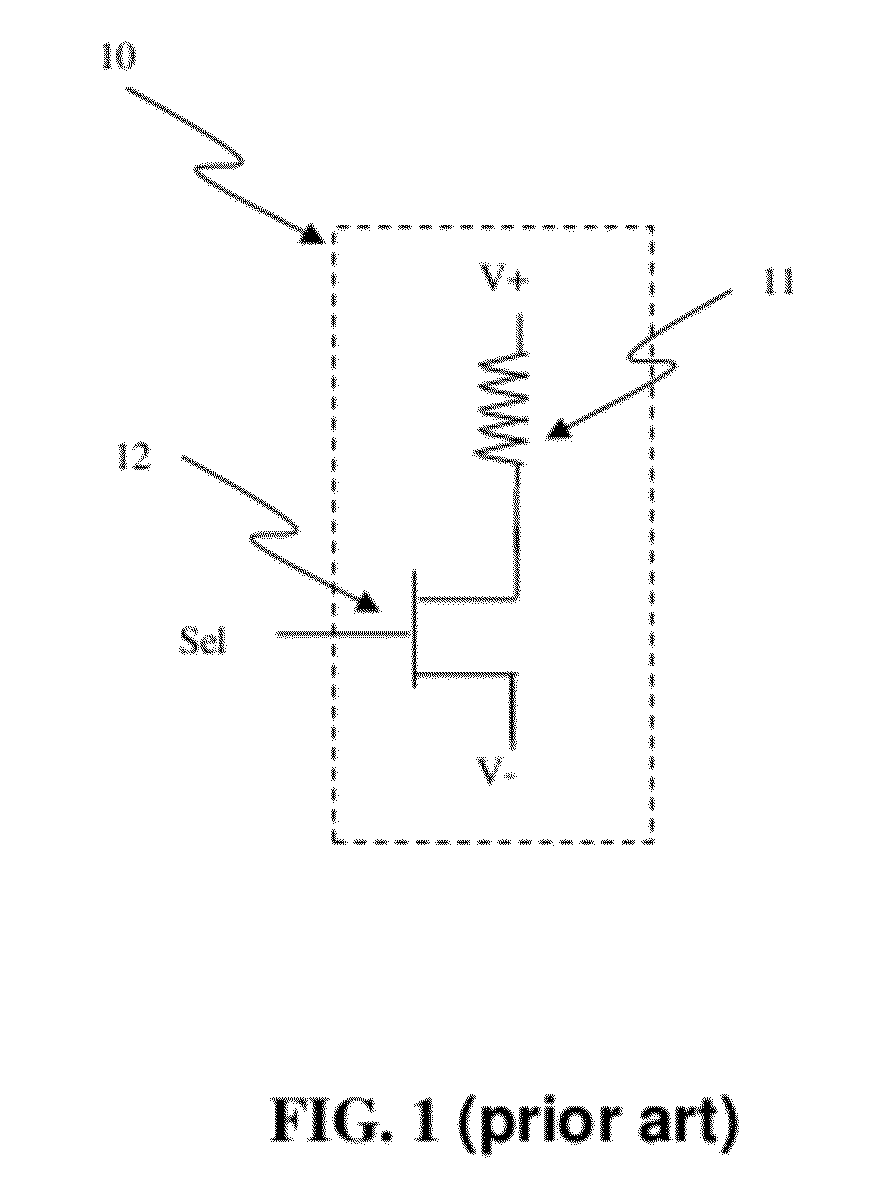

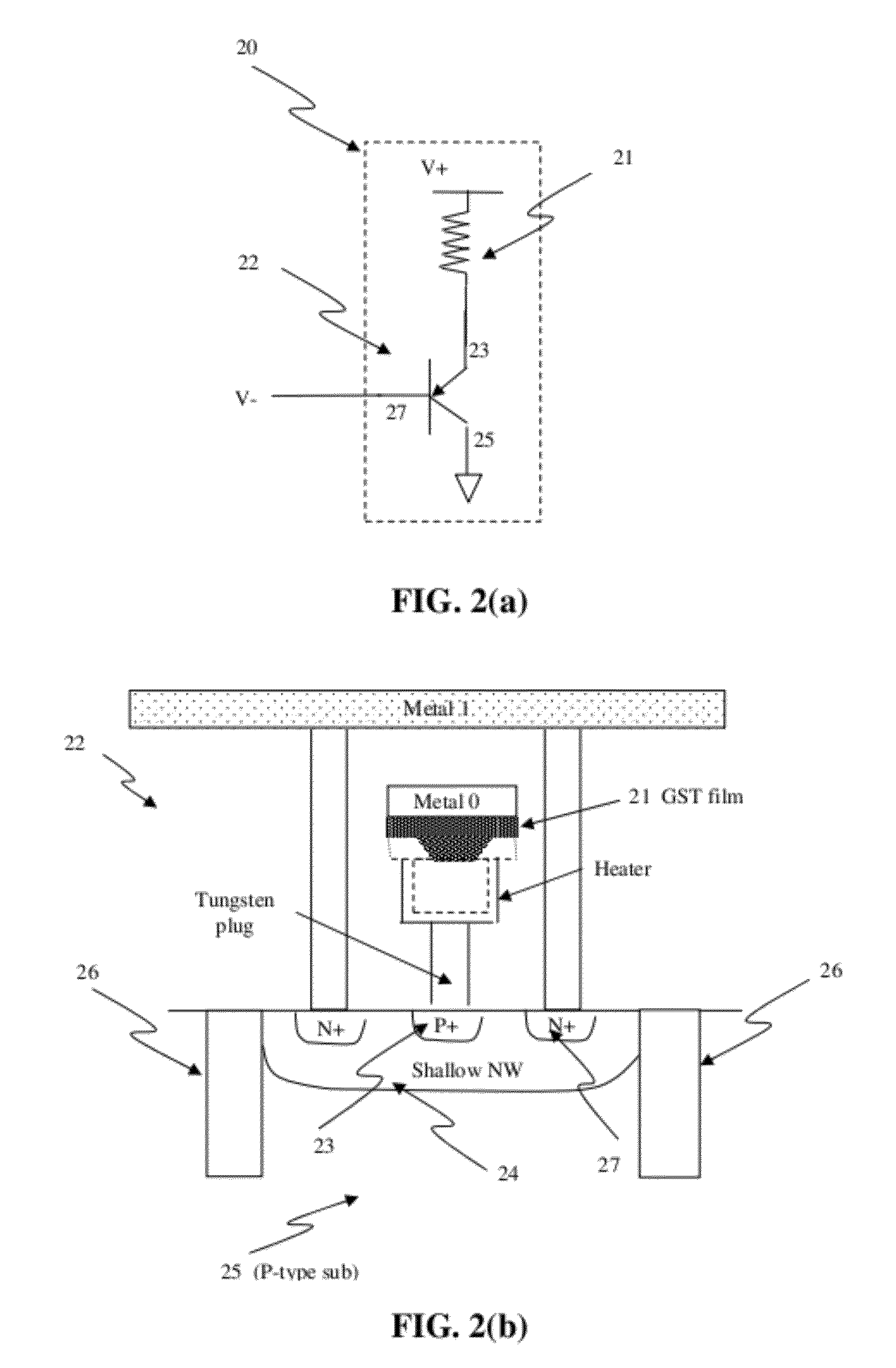

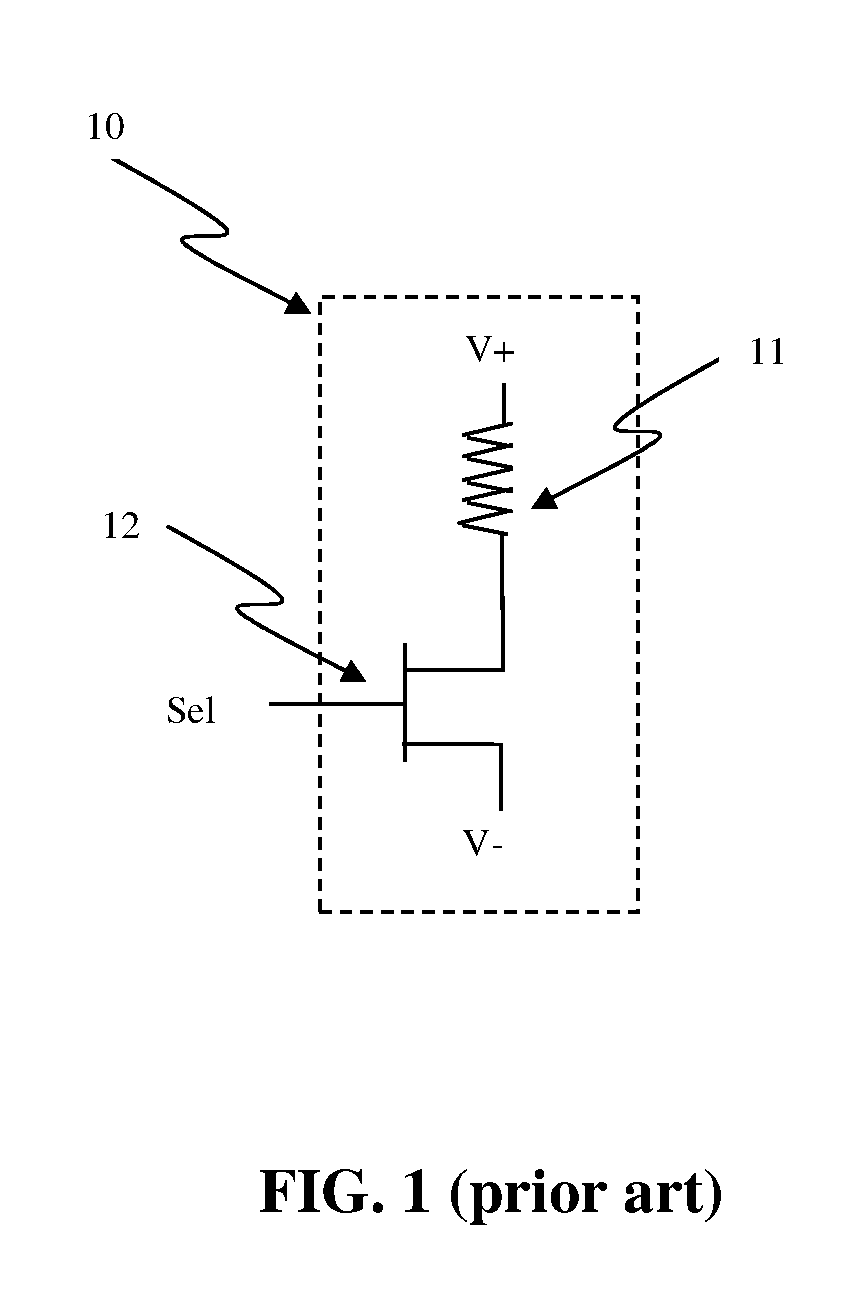

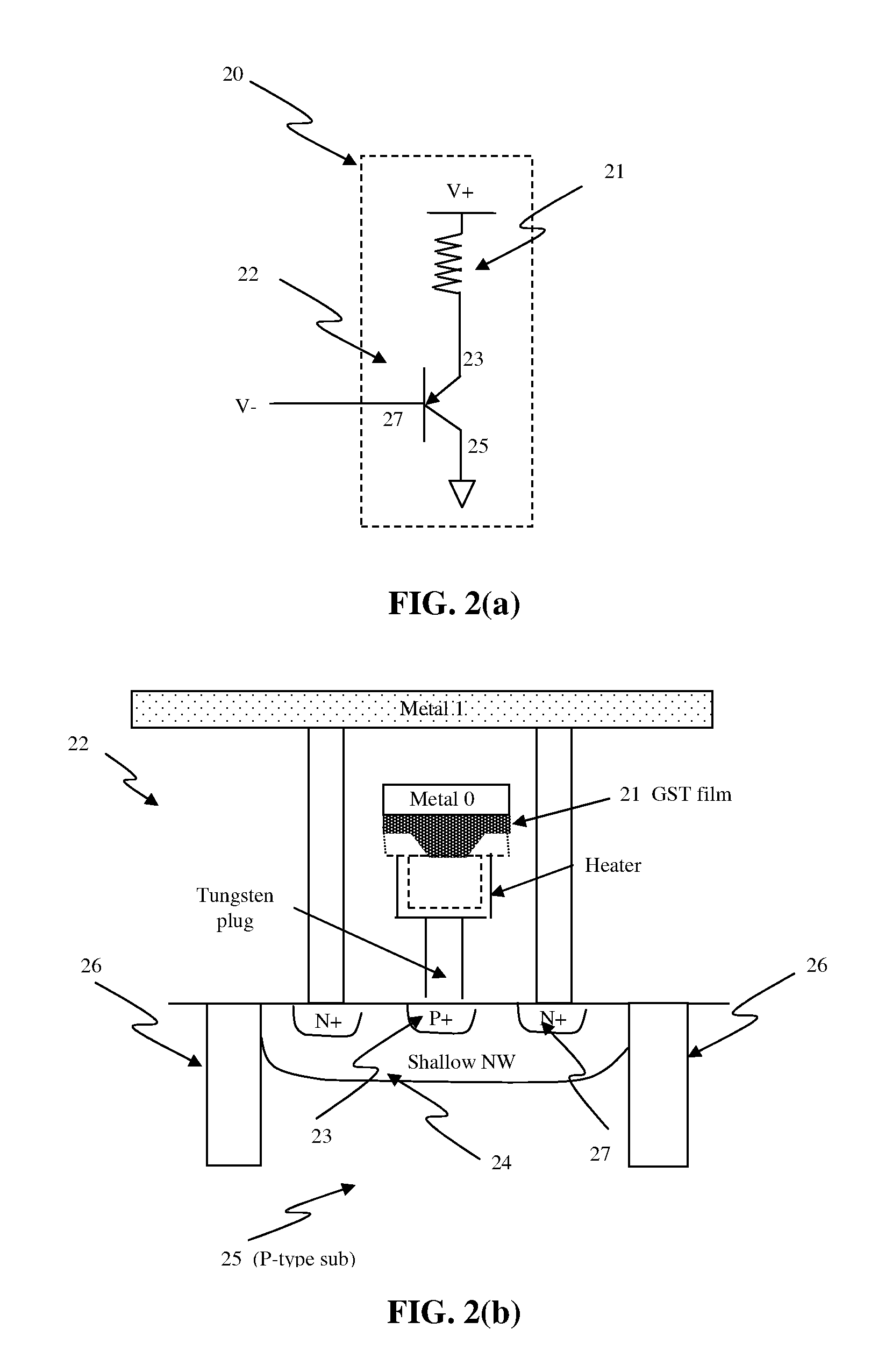

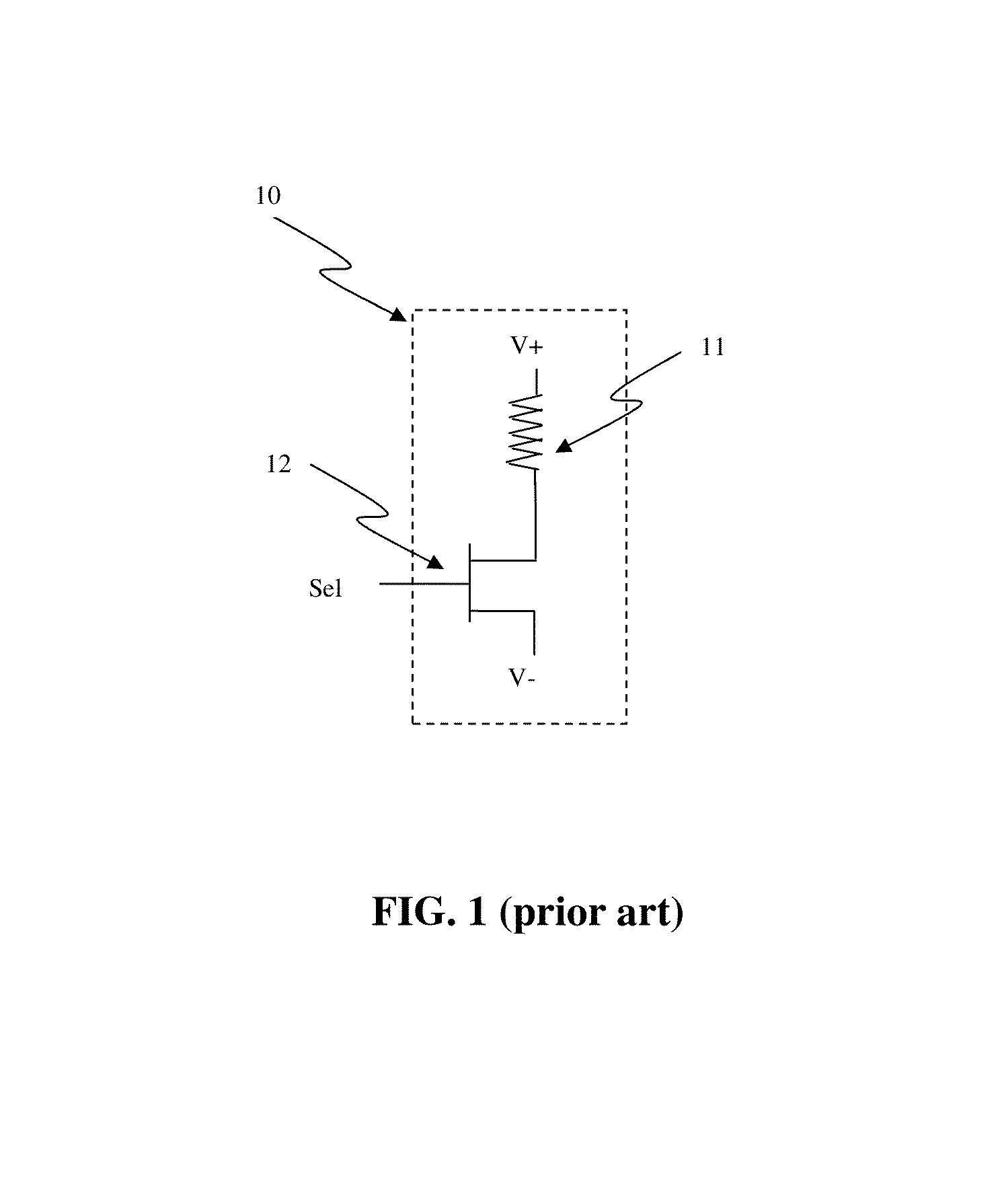

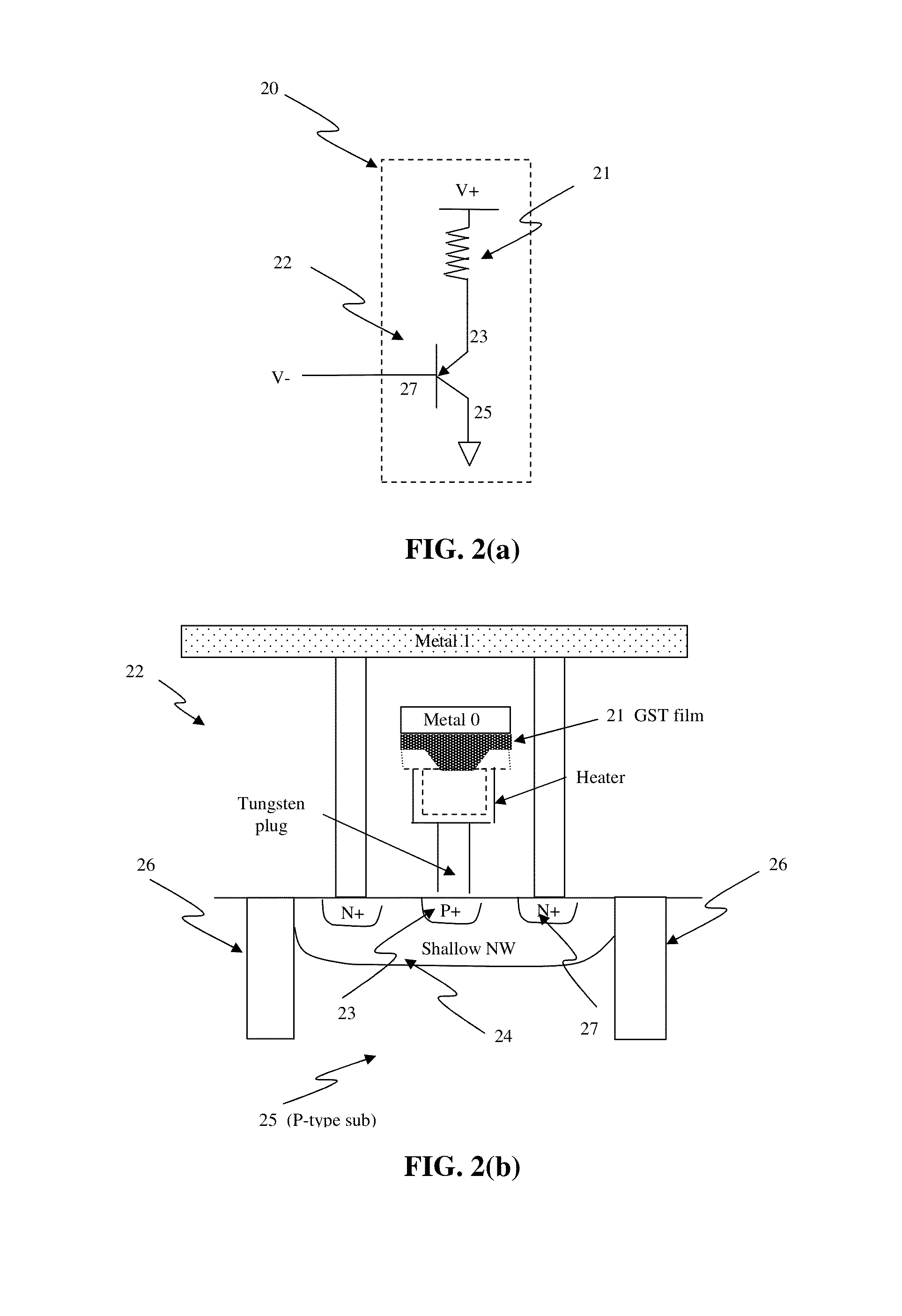

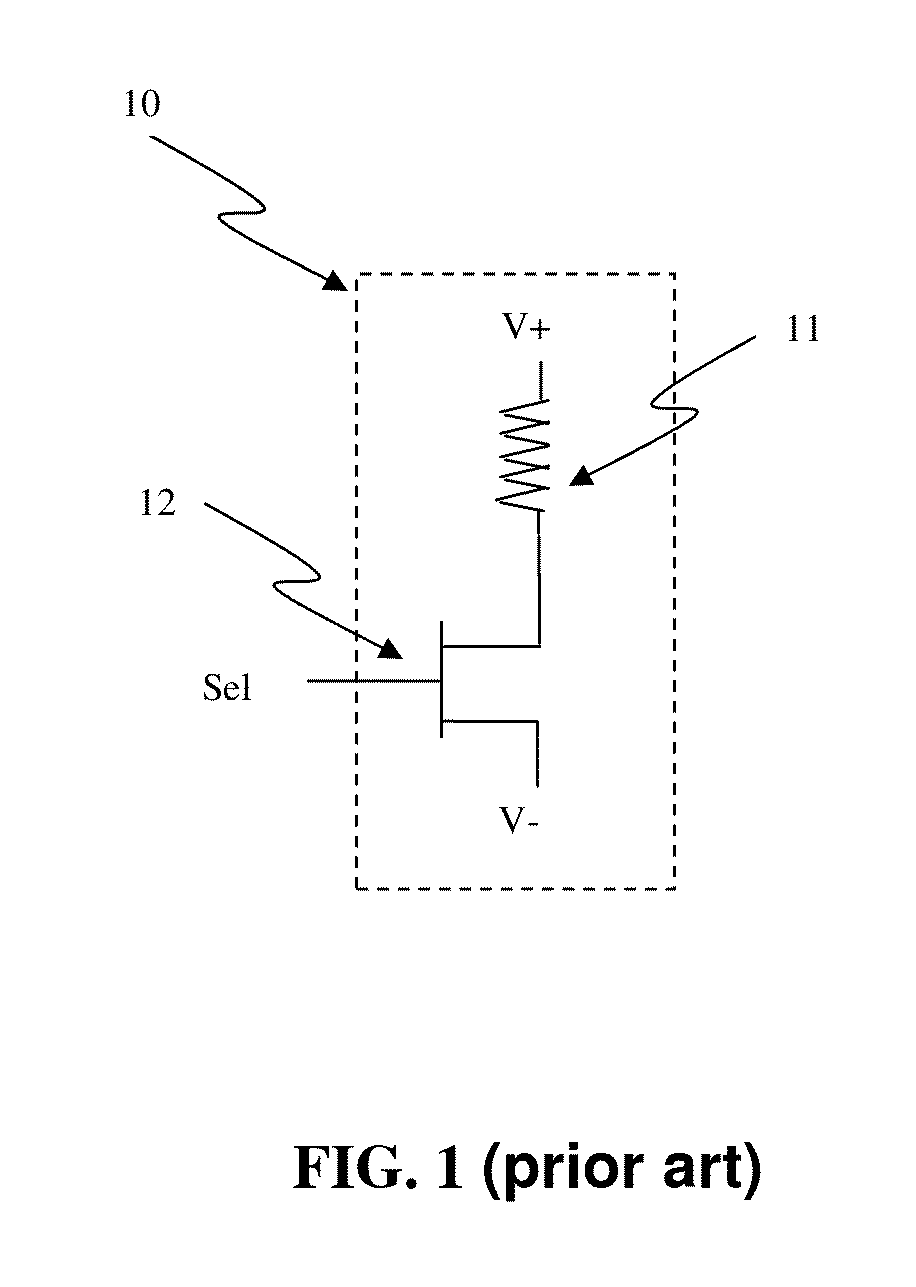

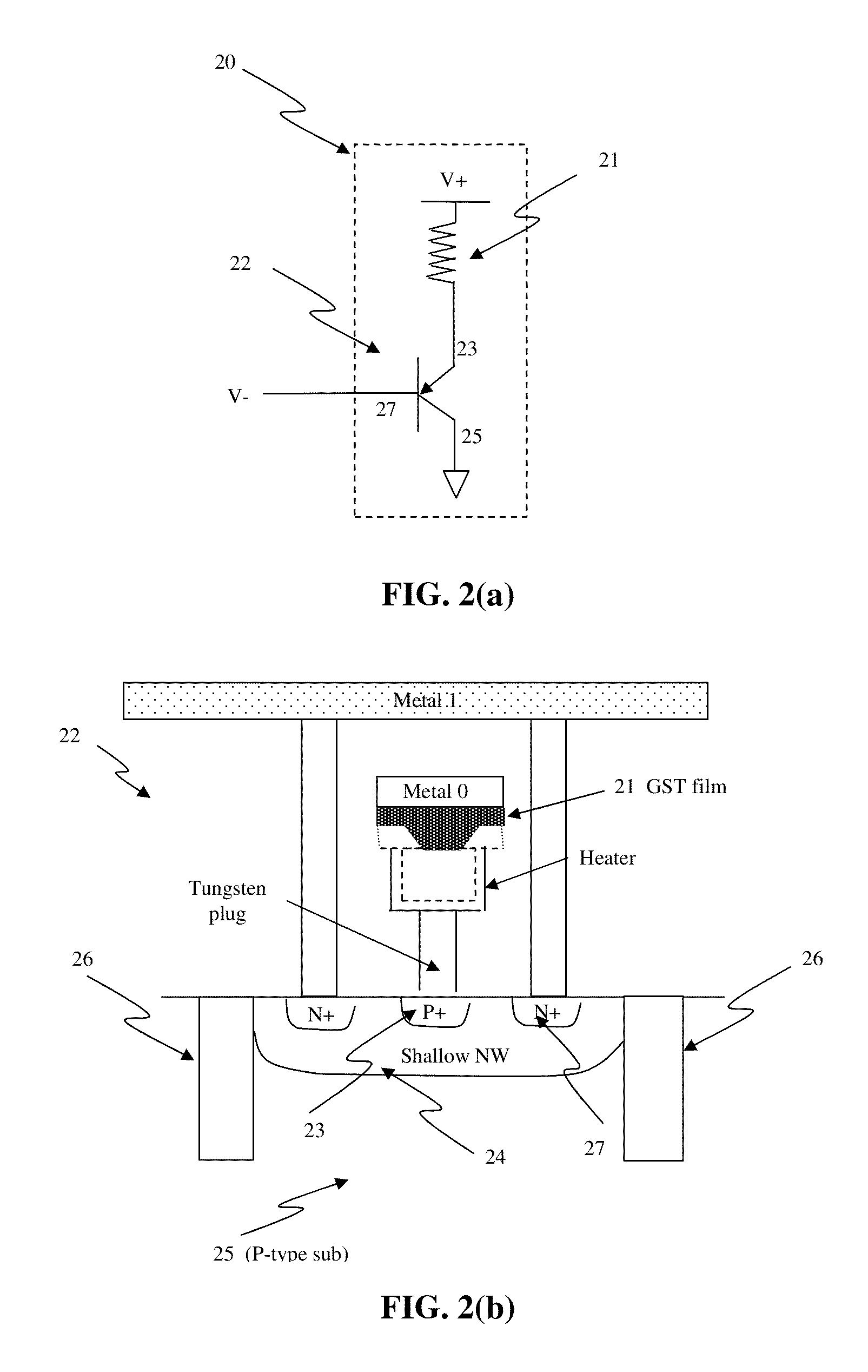

Circuit and System of Using Junction Diode as Program Selector for One-Time Programmable Devices

ActiveUS20120224406A1Small cell sizeLow costMagnetic-field-controlled resistorsSolid-state devicesHemt circuitsEngineering

Junction diodes fabricated in standard CMOS logic processes can be used as program selectors for One-Time Programmable (OTP) devices, such as electrical fuse, contact / via fuse, contact / via anti-fuse, or gate-oxide breakdown anti-fuse, etc. The OTP device has at least one OTP element coupled to at least one diode in a memory cell. The diode can be constructed by P+ and N+ active regions in a CMOS N well, or on an isolated active region as the P and N terminals of the diode. The isolation between P+ and the N+ active regions of the diode in a cell or between cells can be provided by dummy MOS gate, SBL, or STI / LOCOS isolations. The OTP element can be polysilicon, silicided polysilicon, silicide, metal, metal alloy, local interconnect, thermally isolated active region, CMOS gate, or combination thereof.

Owner:ATTOPSEMI TECH CO LTD

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS20090043136A1Physical/chemical process catalystsPreparation by hydrogen halide split-offHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

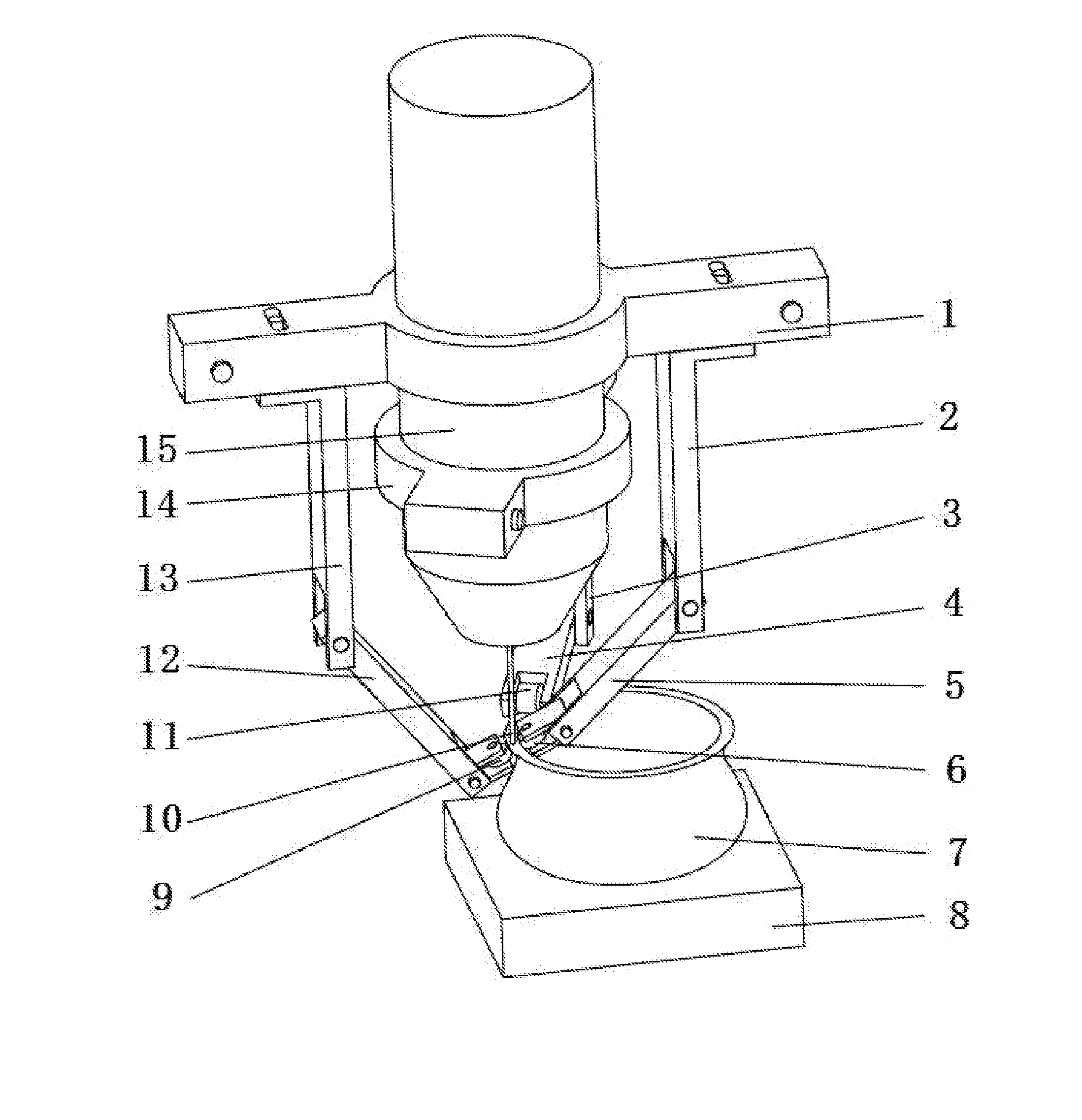

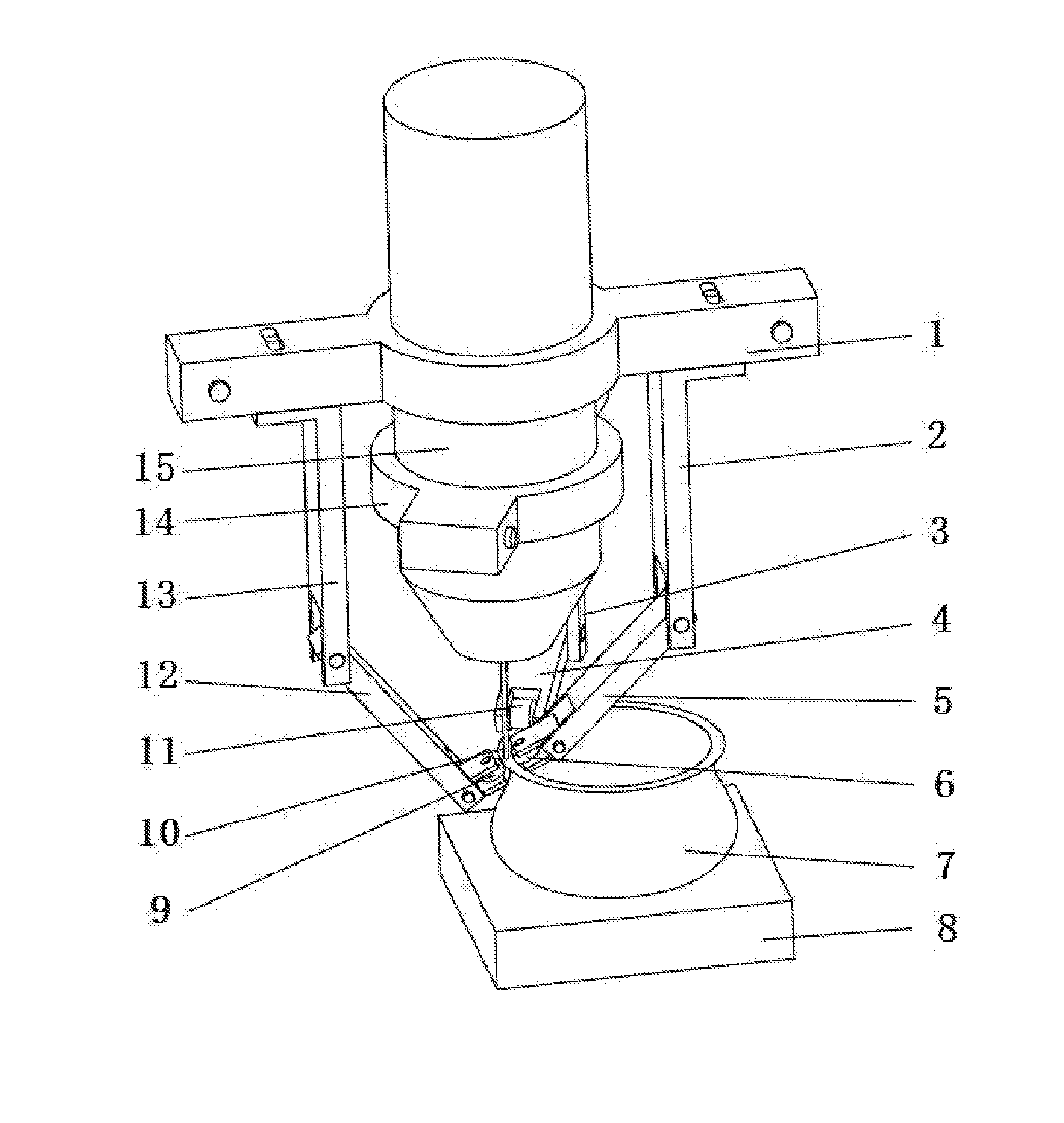

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

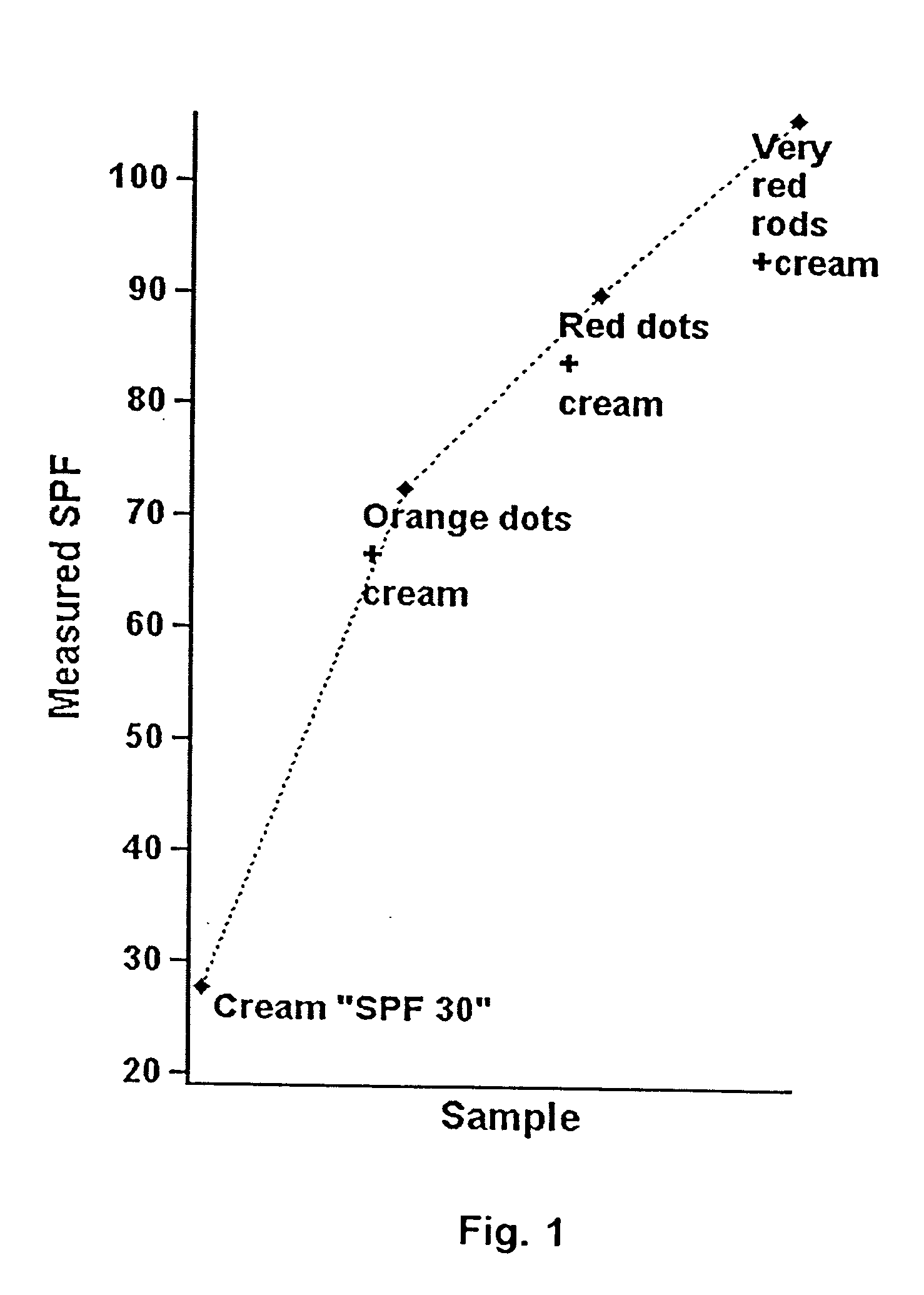

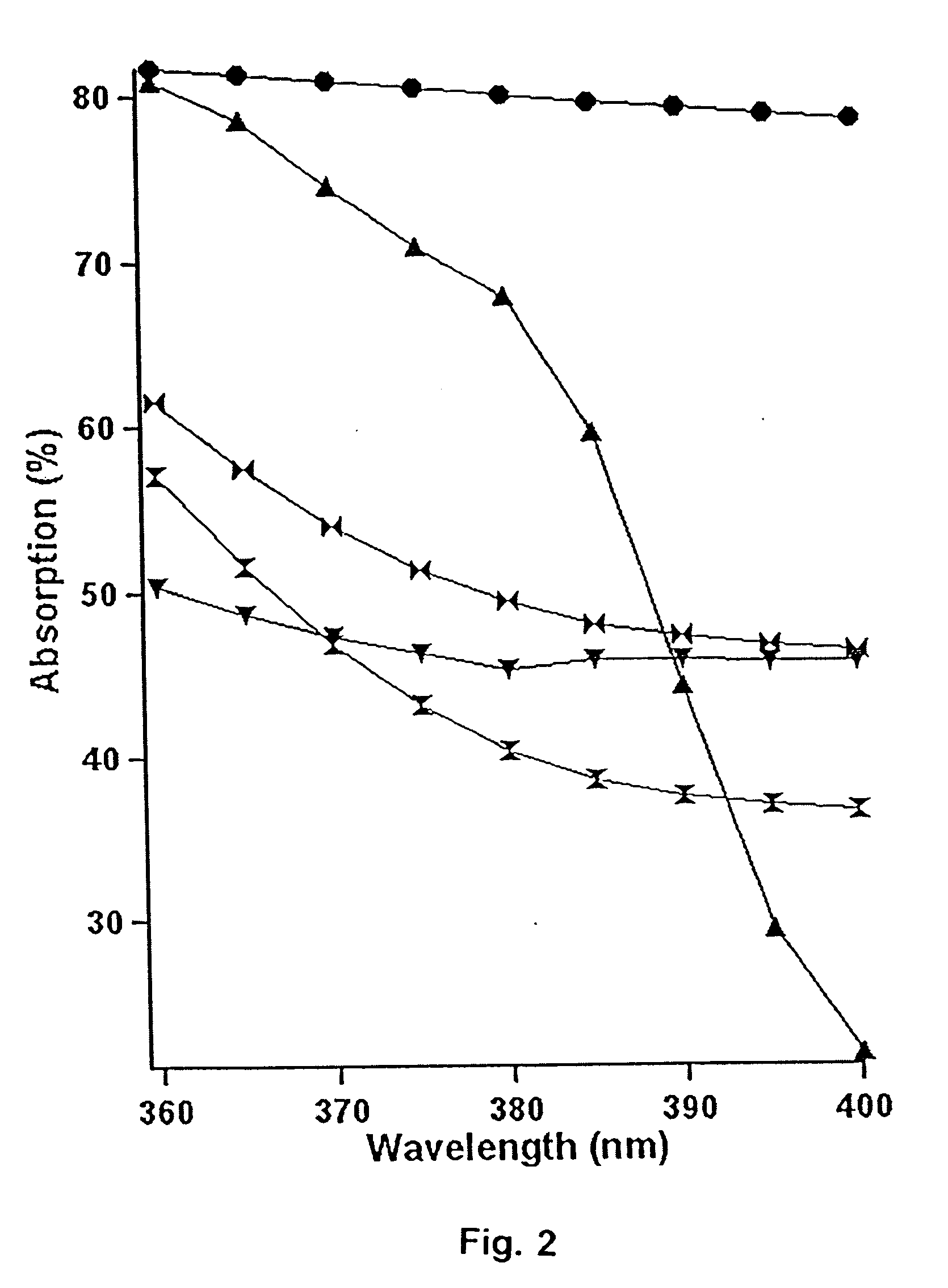

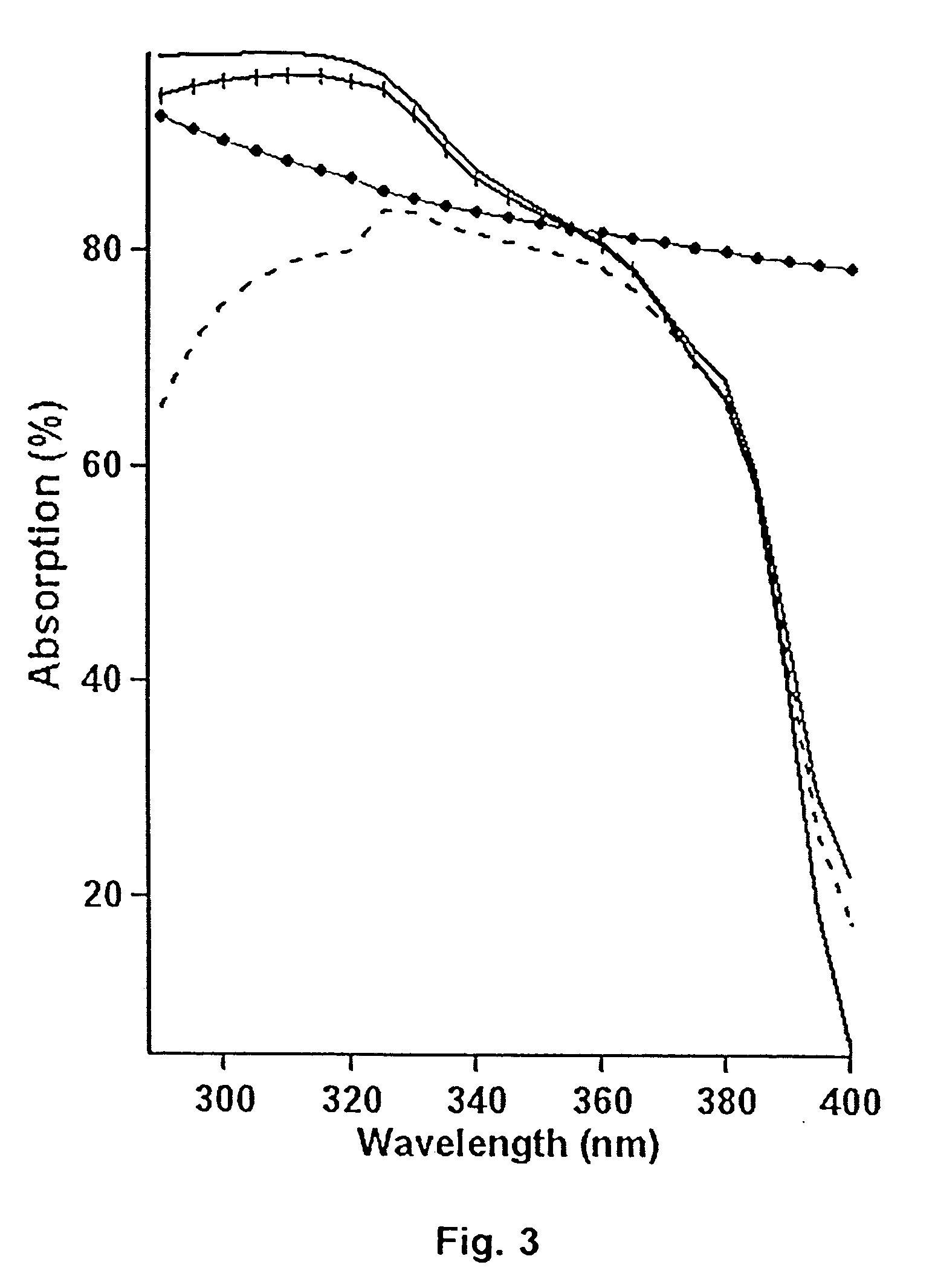

Semiconductor nanocrystal quantum dots and metallic nanocrystals as UV blockers and colorants for suncreens and/or sunless tanning compositions

InactiveUS20050265935A1Eliminate the effects ofCosmetic preparationsToilet preparationsBroadband absorptionPhoto stability

The present invention is directed to photostable sunscreen and / or artificial tanning compositions including quantum dot nanocrystals of a material selected from semiconductor nanocrystals, modified semiconductor nanocrystals, multicomponent semiconductor / semiconductor nanocrystals, and hybrid semiconductor / metal nanocrystals, the quantum dot nanocrystals having an absorption band gap occurring at wavelengths higher than 400 nm whereby the quantum dot nanocrystals have substantial broadband absorption properties of ultraviolet light at wavelengths across the range of both UV-A (320-400 nm) and UV-B (280-320 nm), and a dermatologically acceptable carrier for the quantum dot nanocrystals. The present invention is further directed to photostable sunscreen and / or artificial tanning compositions including a material selected from metallic nanocrystals, multicomponent metal / metal nanocrystals, and alloyed metal nanocrystals, the metallic material having a surface plasmon resonance occurring sufficiently into the visible or infrared spectral region whereby broad absorption features due to electronic transitions, the broad absorption features located at higher energies, provide substantial broadband absorption properties of ultraviolet light at wavelengths across the range of both UV-A (320-400 nm) and UV-B (280-320 nm), and a dermatologically acceptable carrier for the metallic material.

Owner:LOS ALAMOS NATIONAL SECURITY

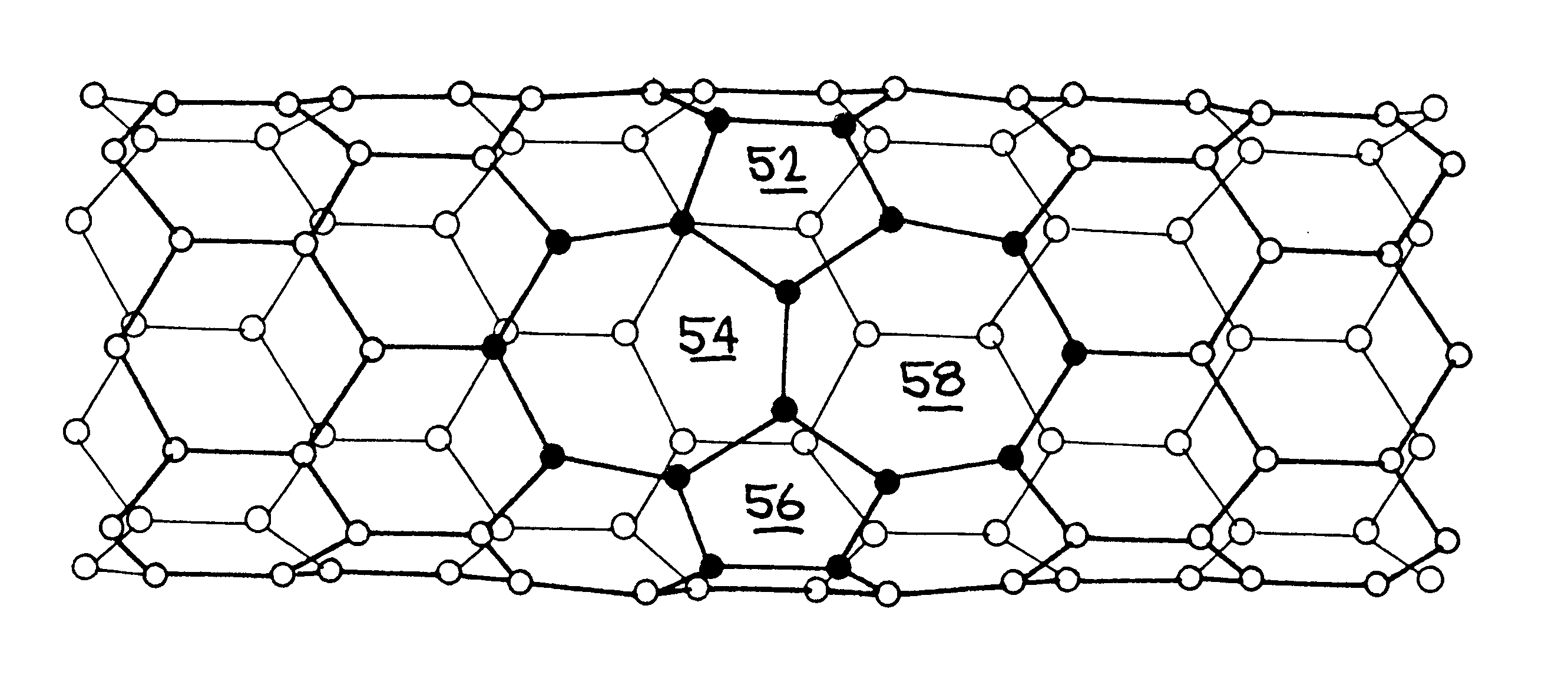

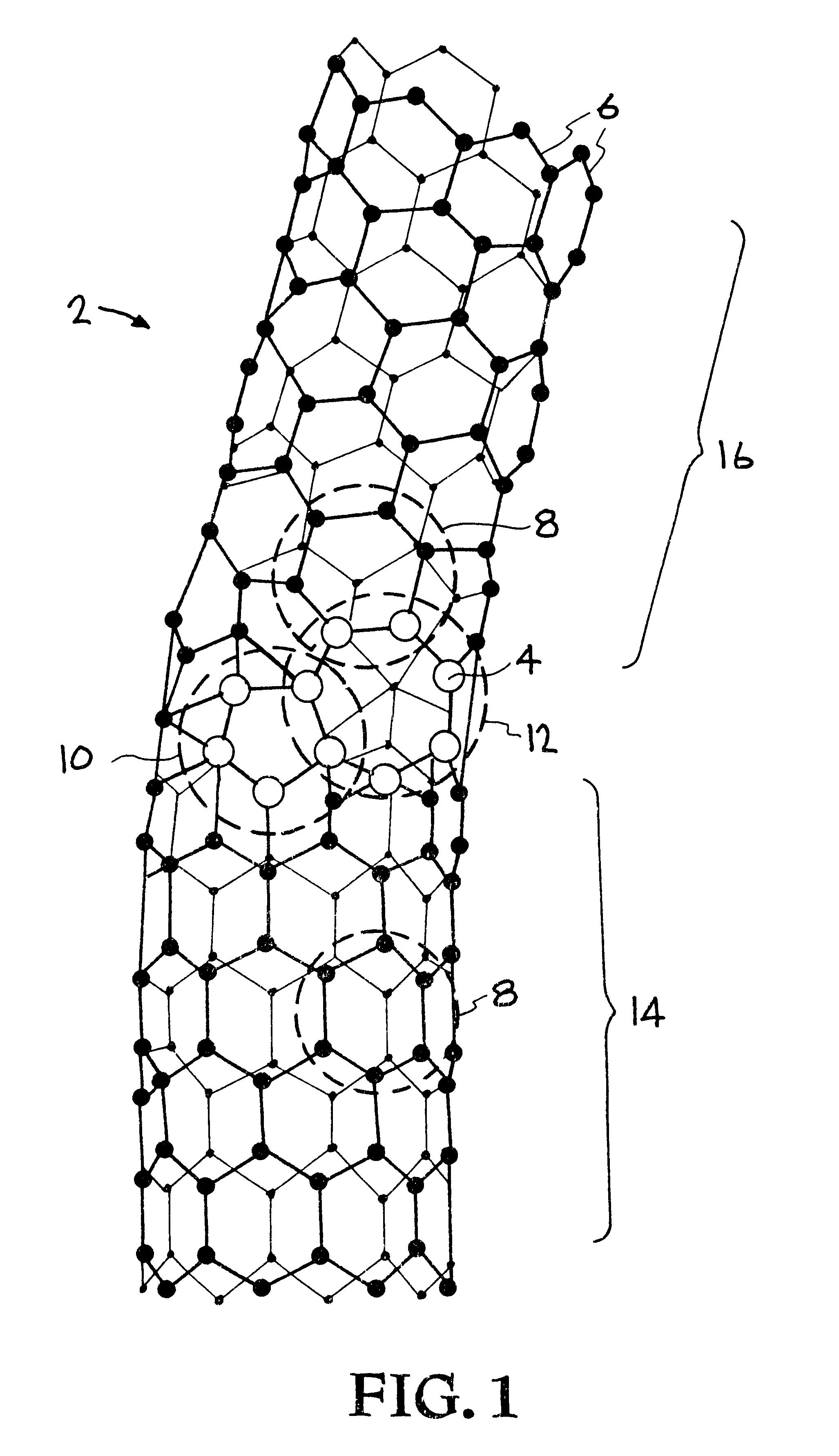

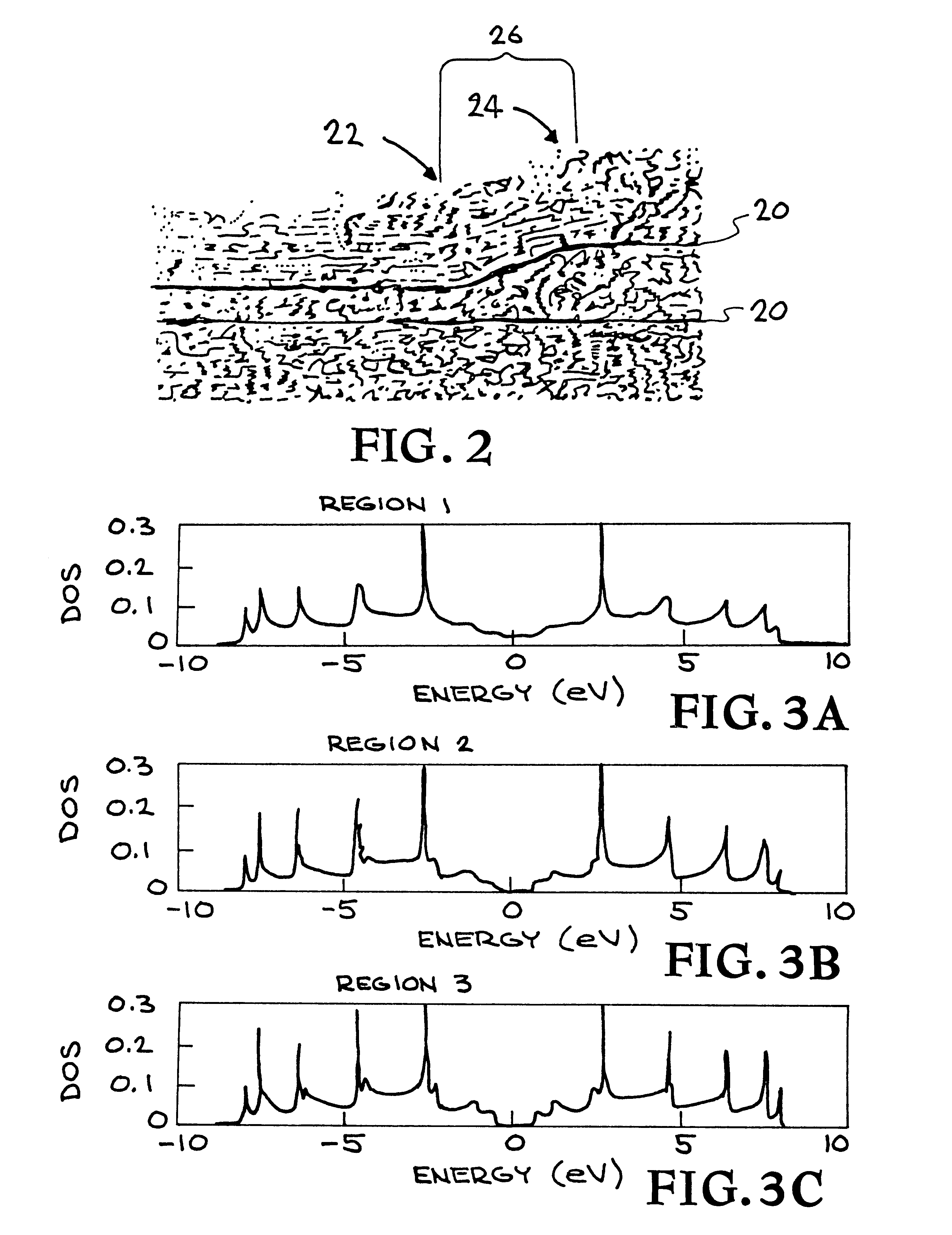

Nanotube junctions

The present invention comprises a new nanoscale metal-semiconductor, semiconductor-semiconductor, or metal-metal junction, designed by introducing topological or chemical defects in the atomic structure of the nanotube. Nanotubes comprising adjacent sections having differing electrical properties are described. These nanotubes can be constructed from combinations of carbon, boron, nitrogen and other elements. The nanotube can be designed having different indices on either side of a junction point in a continuous tube so that the electrical properties on either side of the junction vary in a useful fashion. For example, the inventive nanotube may be electrically conducting on one side of a junction and semiconducting on the other side. An example of a semiconductor-metal junction is a Schottky barrier. Alternatively, the nanotube may exhibit different semiconductor properties on either side of the junction. Nanotubes containing heterojunctions, Schottky barriers, and metal-metal junctions are useful for microcircuitry.

Owner:RGT UNIV OF CALIFORNIA

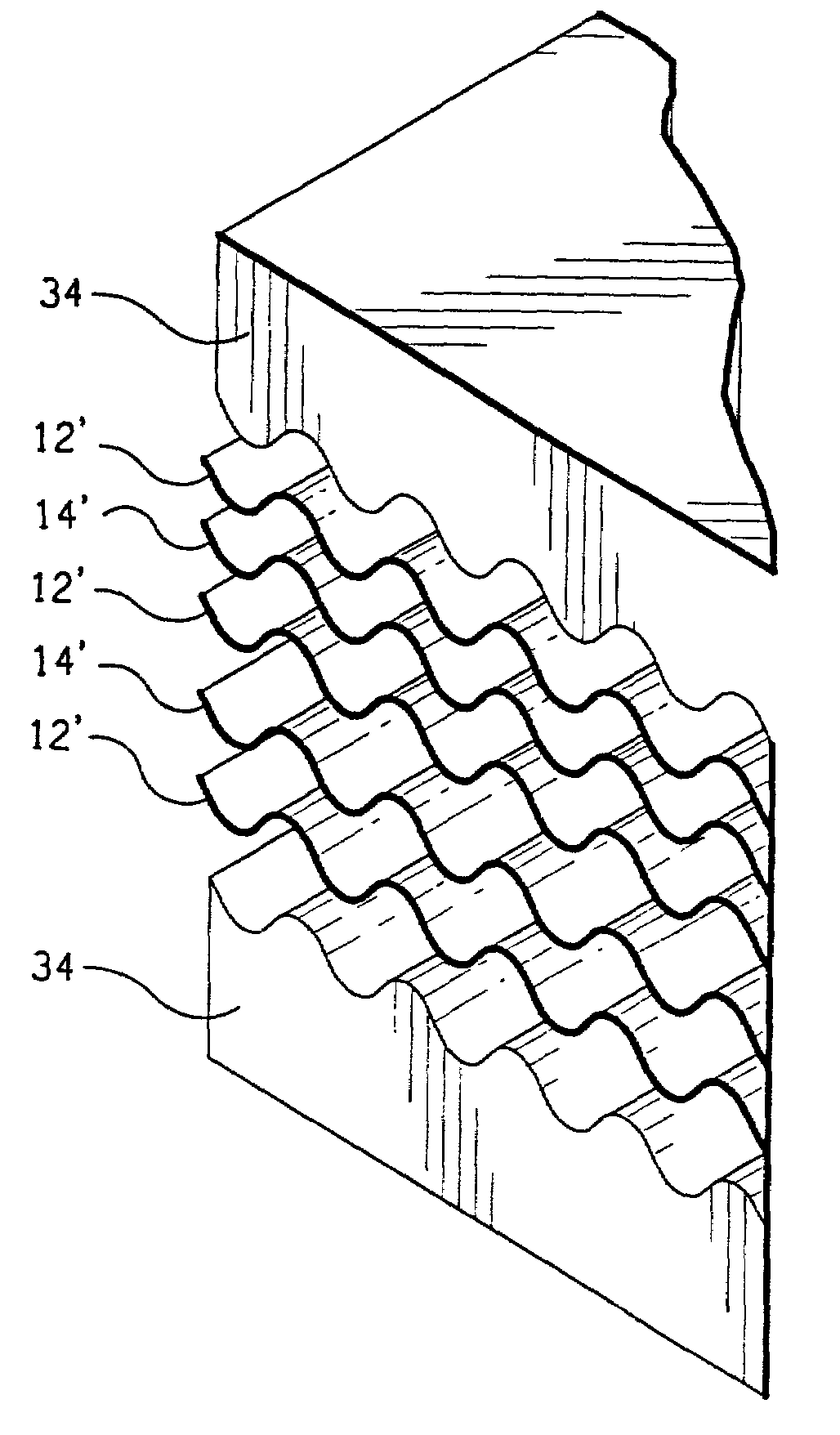

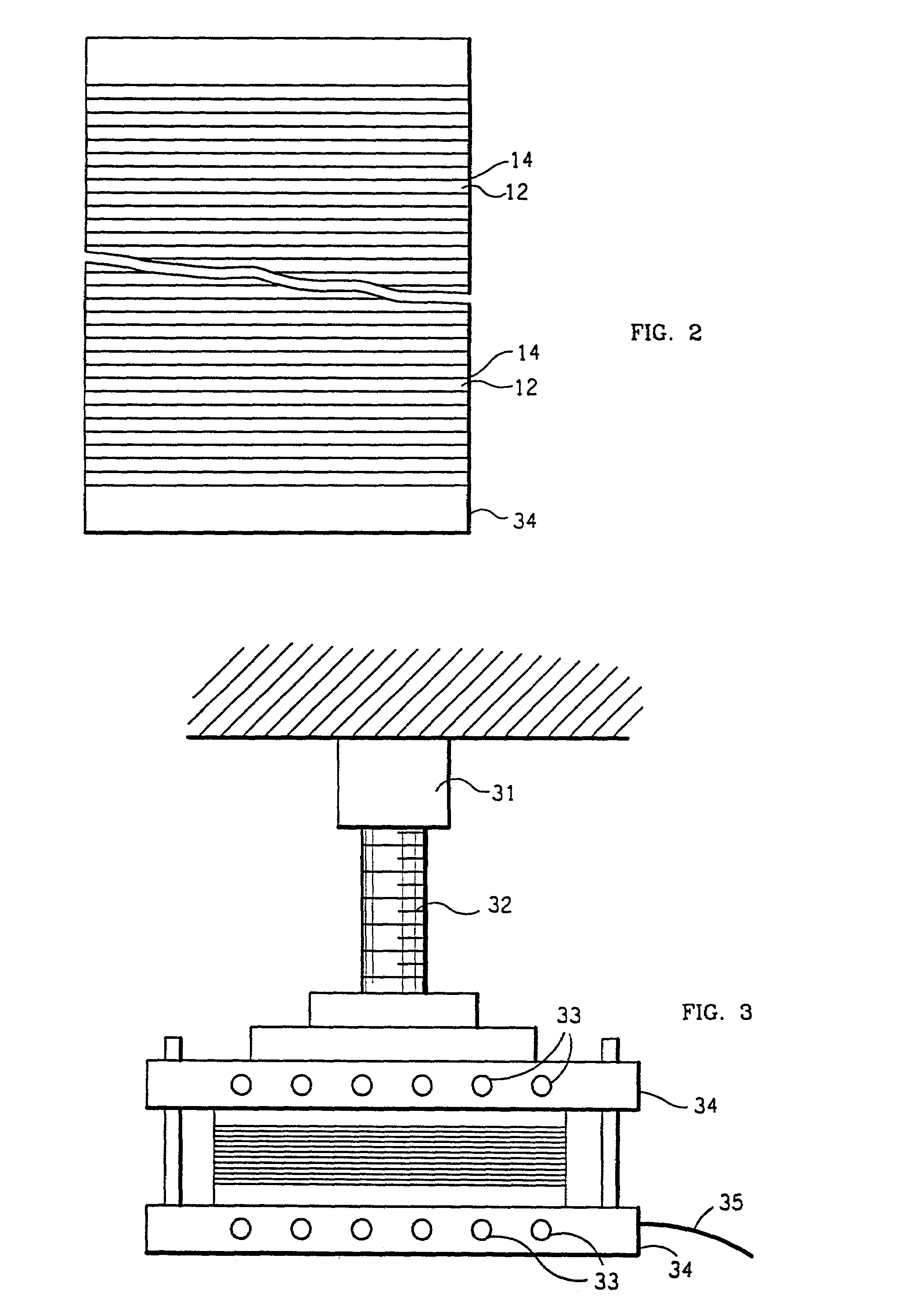

Fabrication of interleaved metallic and intermetallic composite laminate materials

InactiveUS7188559B1Well formedLimit cracking and fracturingWeapon componentsDomestic articlesGramComposite laminates

Typically 20–40 films of a tough first metal, normally 0.1–1.0 mm thick films of titanium, nickel, vanadium, and / or steel (iron) and alloys thereof, interleaved with a like number of films of a second metal, normally 0.1–1.0 mm thick films of aluminum or alloys thereof, are pressed together in a stack at less than 6 MPa and normally at various pressures 2–4 MPa while being gradually heated in the presence of atmospheric gases to 600–800° C. over a period of, typically, 10+ hours until the second metal is completely compounded; forming thus a metallic-intermetallic laminate composite material having (i) tough first-metal layers separated by (ii) hard, Vickers microhardness of 400 kg / mm2+, intermetallic regions consisting of an intermetallic compound of the first and the second metals. The resulting composite material is inexpensive, lightweight with a density of typically 3 to 4.5 grams / cubic centimeter, and very hard and very tough to serve as, among other applications, lightweight armor. Upon projectile impact (i) the hard intermetallic, ceramic-like, layers are confined by the tough metal layers while (ii) cracking and fracturing is blunted and channeled in directions orthogonal to the axis of impact.

Owner:RGT UNIV OF CALIFORNIA

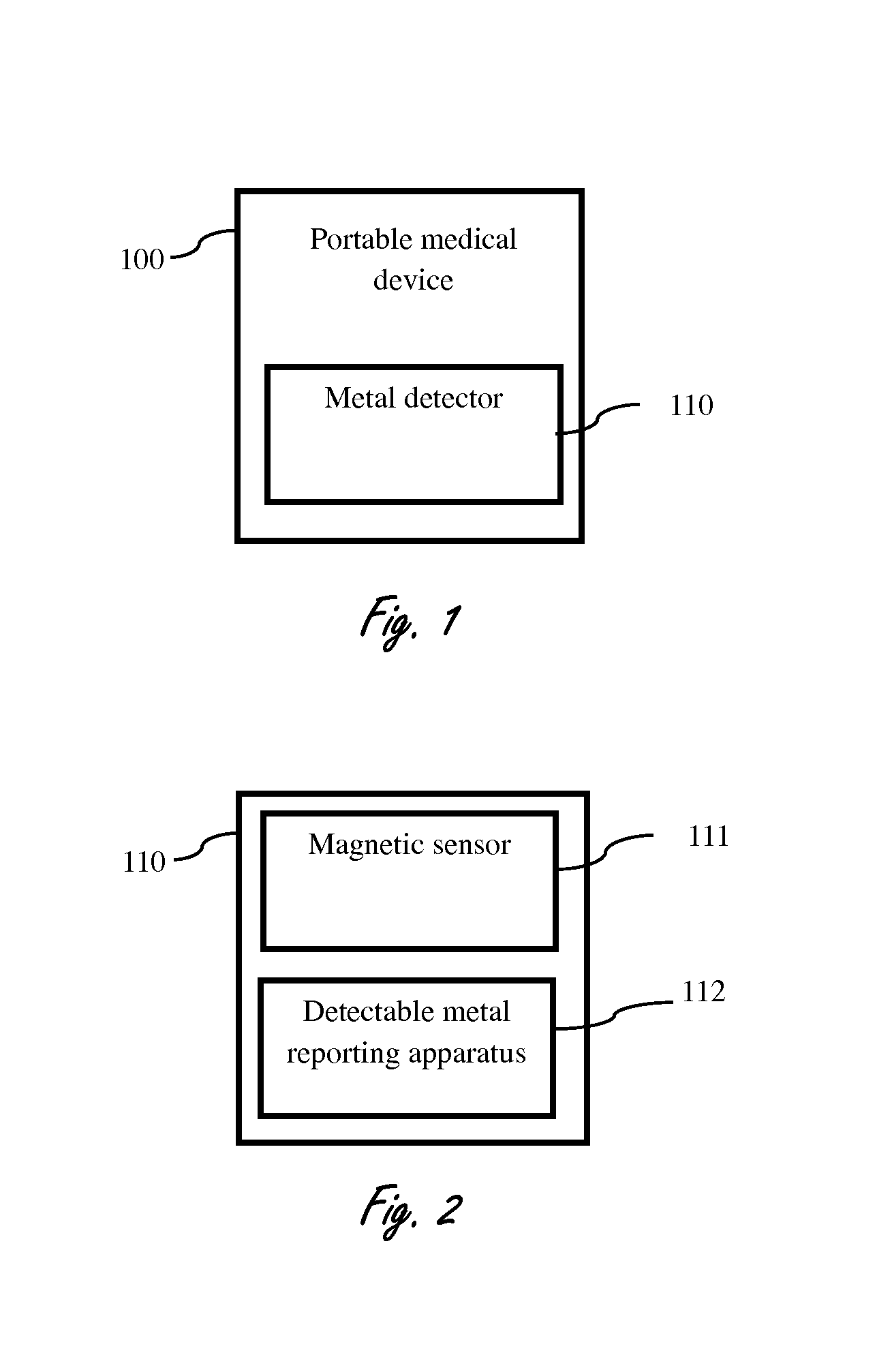

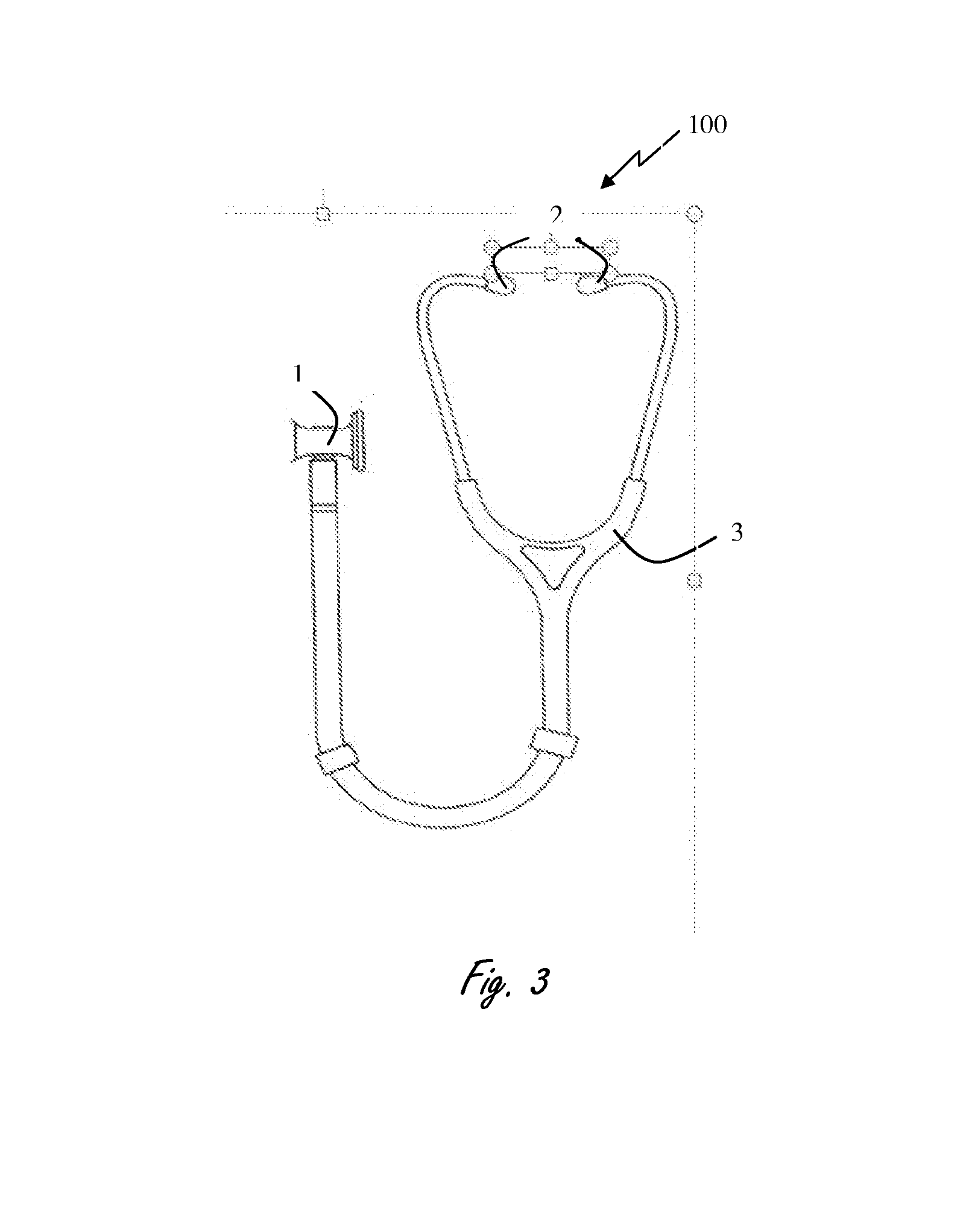

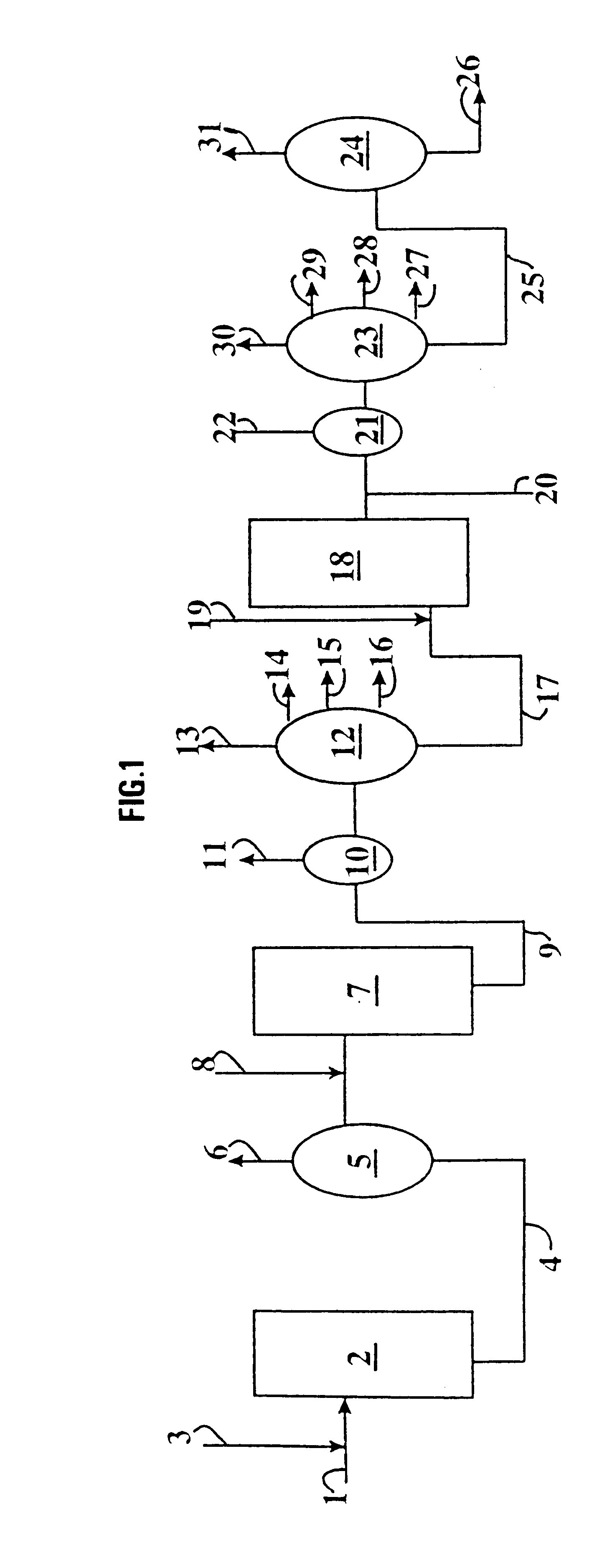

Integrated metal detector-portable medical device

An integrated metal detector-portable medical device adapted to identify metals in a human body, where the metal detector is in connection with the portable medical device. The metal detector includes: at least one transmitting means adapted to generate a second magnetic field so as to induce a magnetic field generated by a metal; at least one sensor adapted to detect a magnetic field generated by the metals to be detected; and at least one signaling means adapted, upon detection of a magnetic field, to alert the identification of metals, if the intensity of a magnetic field is above a predetermined value.

Owner:ASPECT IMAGING

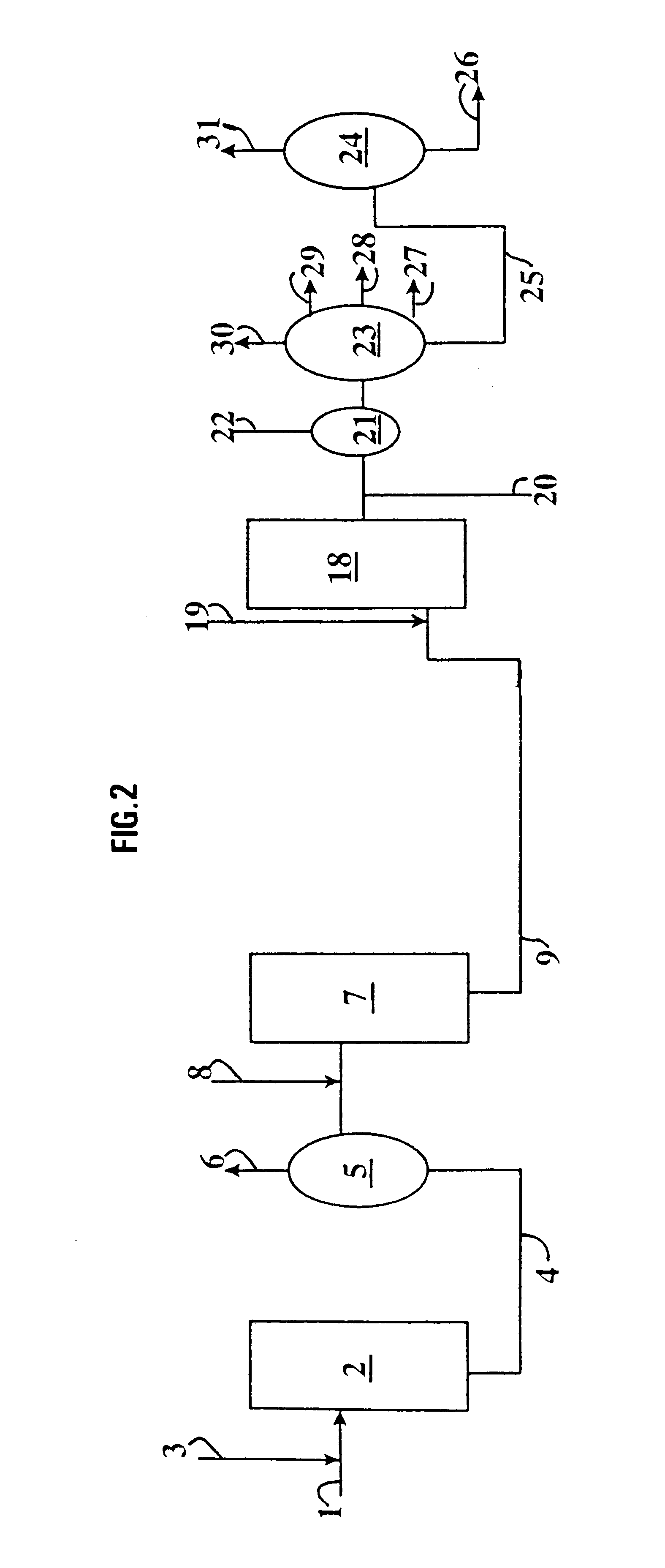

Flexible process for producing base stock and distillates by conversion-hydroisomerisation using a catalyst with low dispersion followed by catalytic dewaxing

InactiveUS6602402B1Facility of preparationImprove hydrogenation activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonPtru catalystEngineering

An improved process for producing very high quality base stock and for simultaneous production of high quality middle distallates, comprising successive hydroisomerisation and catalystic dewaxing steps wherein hydroisomerisation is carried out in the presence of a catalyst containing at least one noble metal deposited on an amorphous acidic support, the dispersion of the metal being less than 20%. The support is preferably an amorphous silica-alumina. Catalytic dewaxing is carried out in the presence of a catalyst containing at least one hydrodehydrogenating element (group VIII) and at least one molecular sieve (preferably zeolite). The sieve is preferable selected from NU-10, EU-1, EU-13, zeolite and ferrierite.

Owner:INST FR DU PETROLE

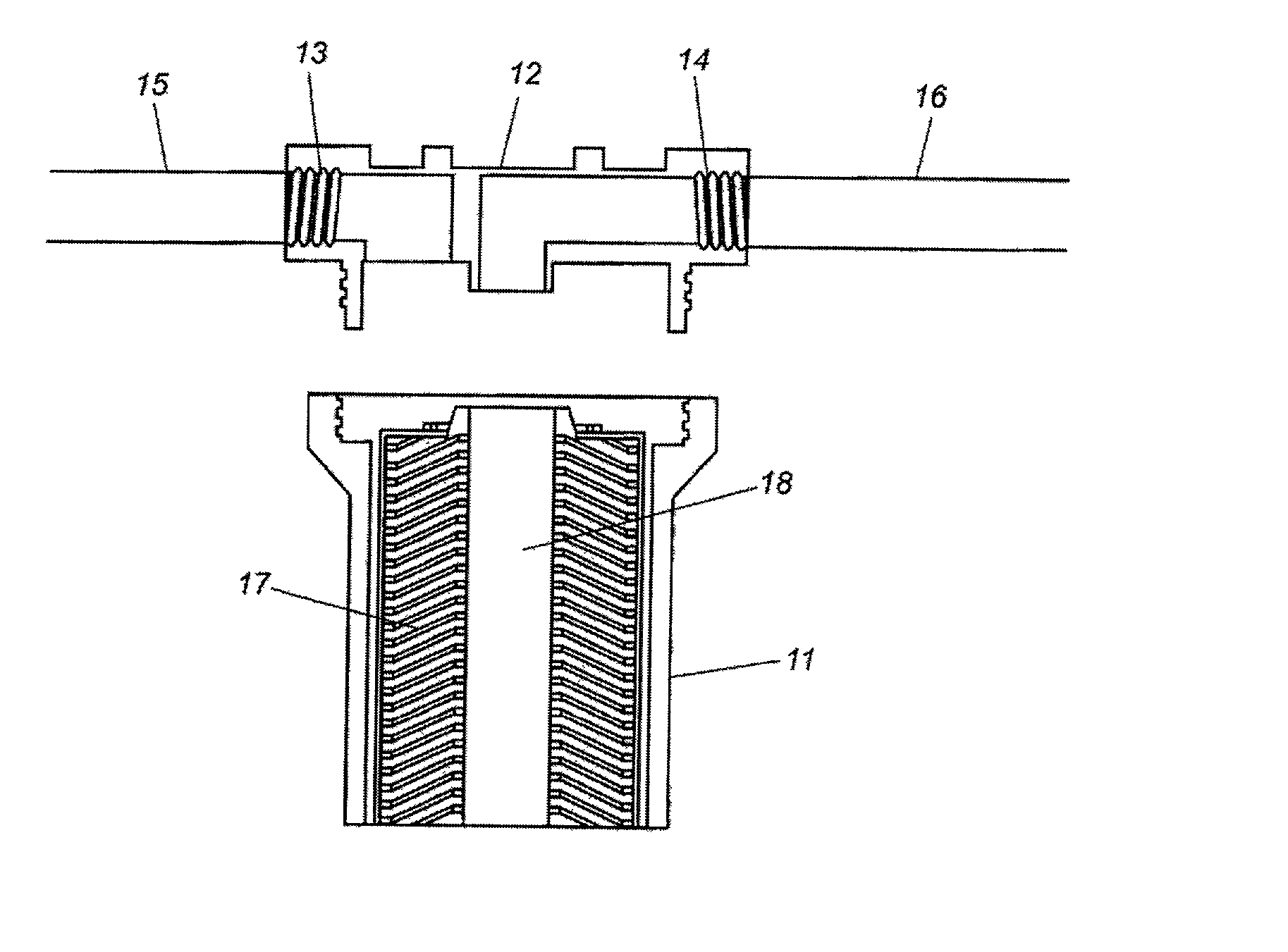

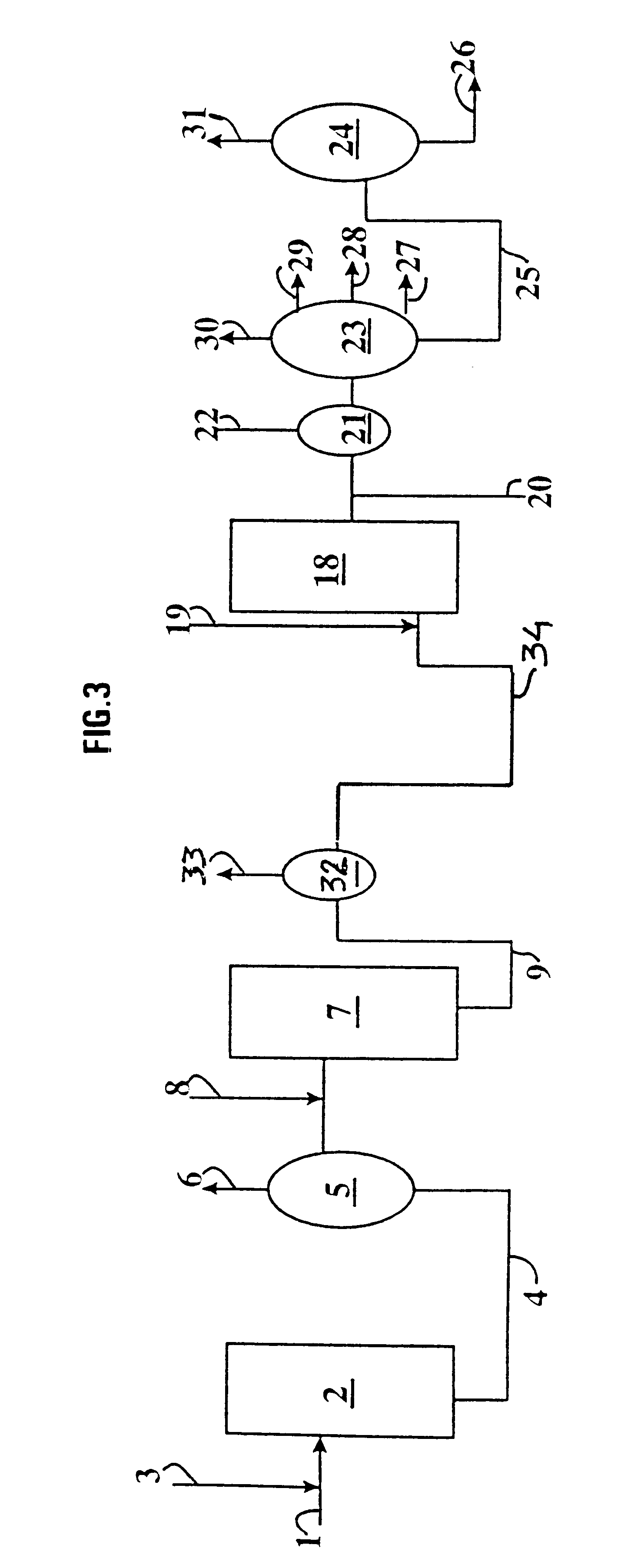

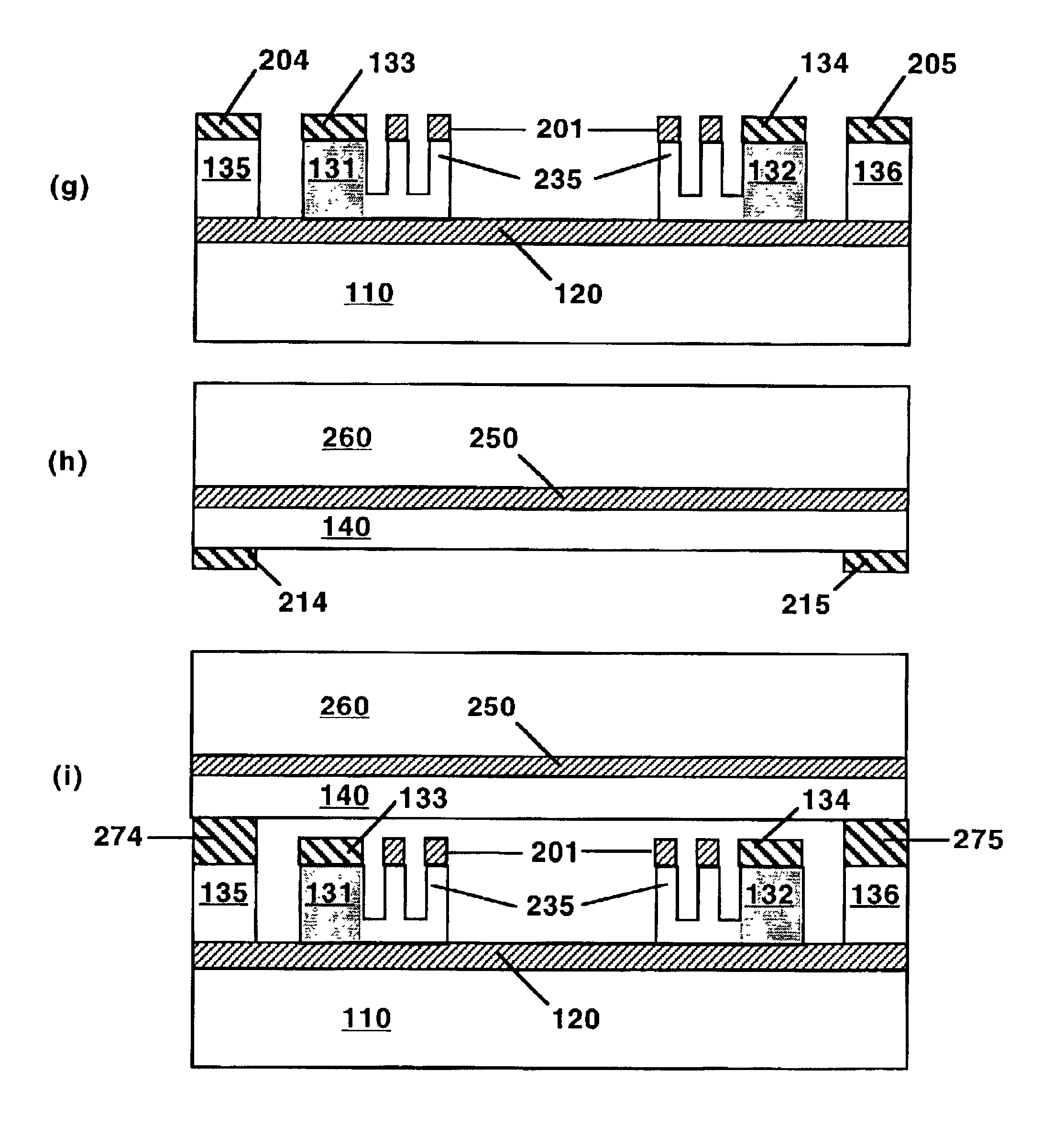

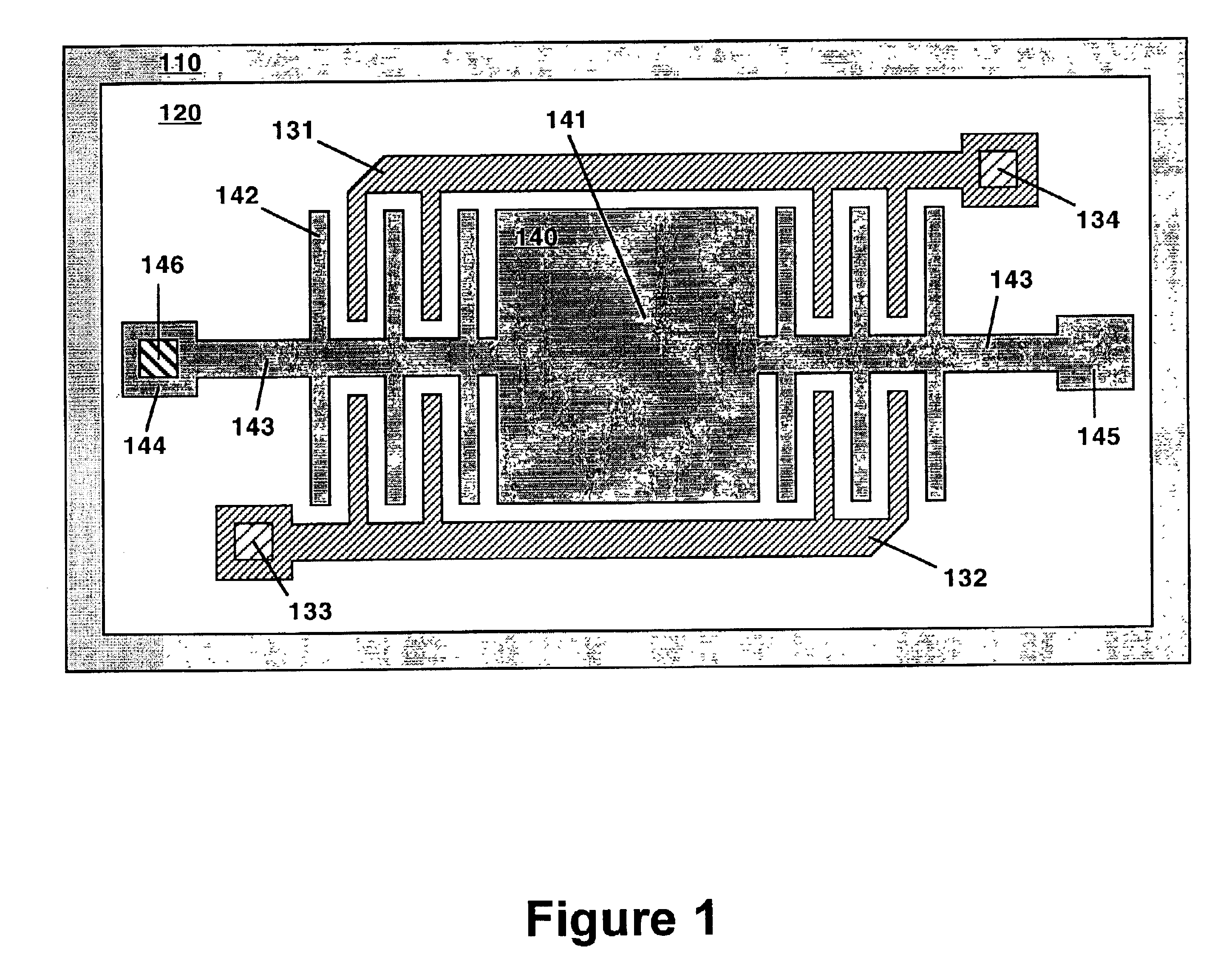

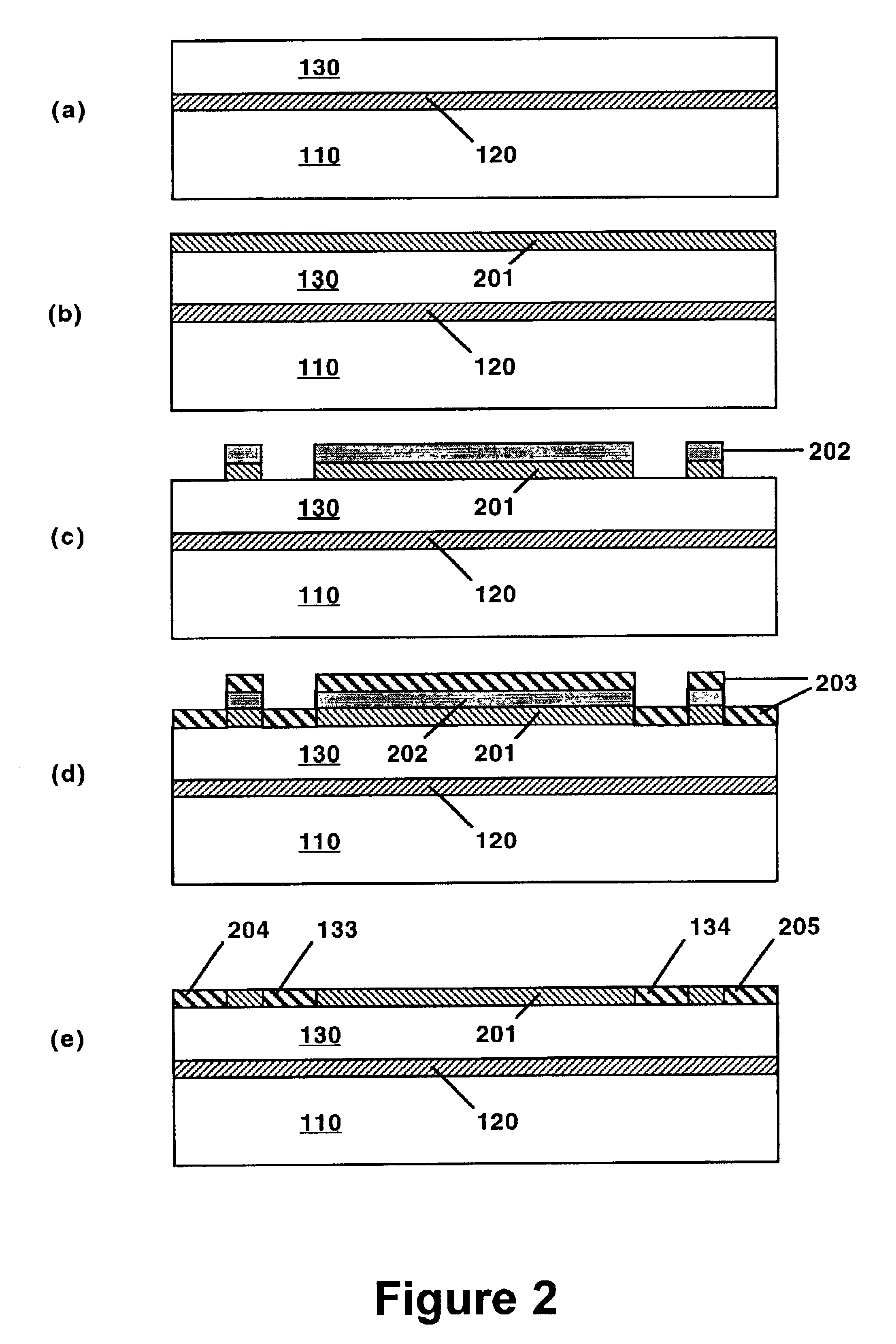

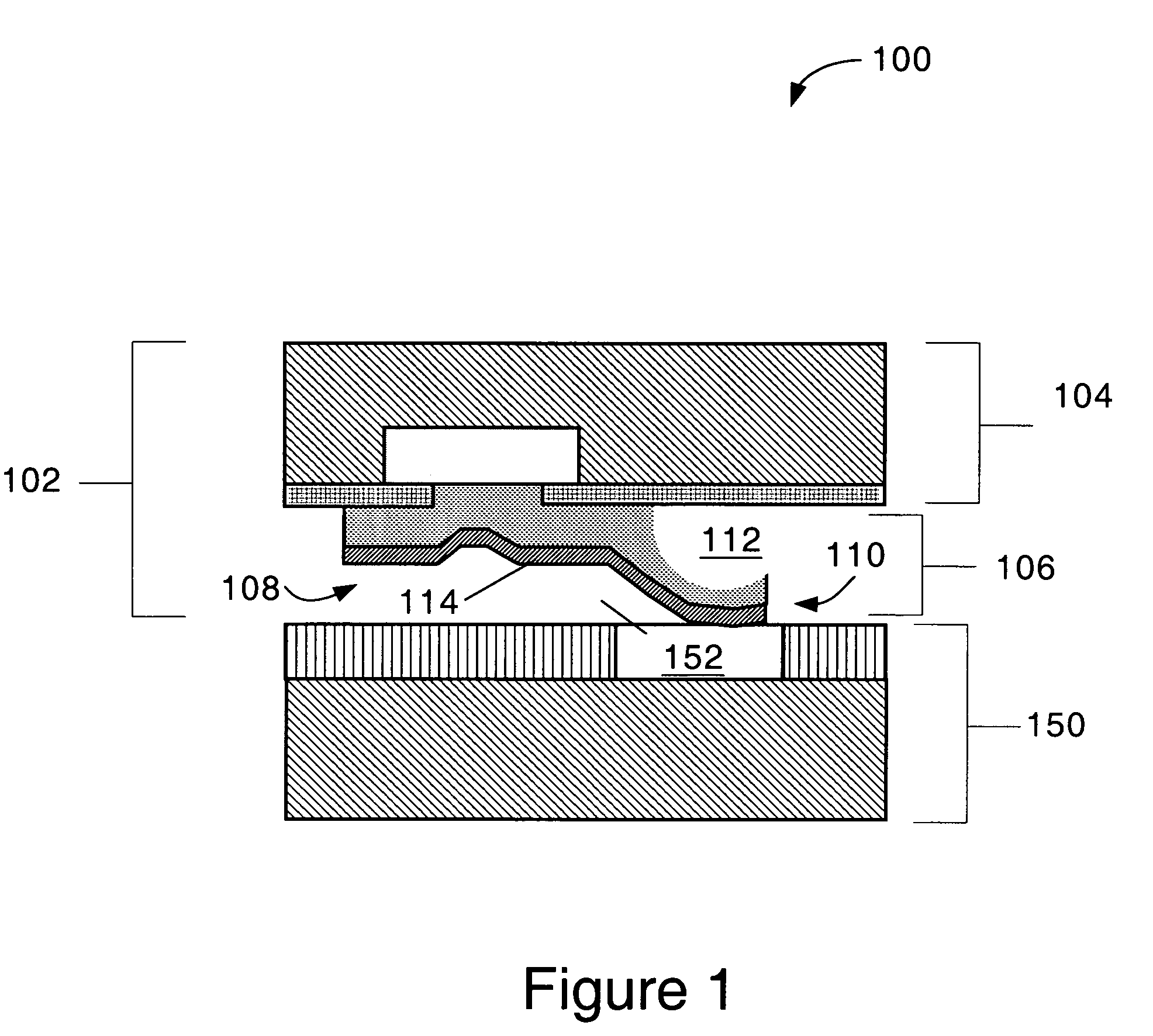

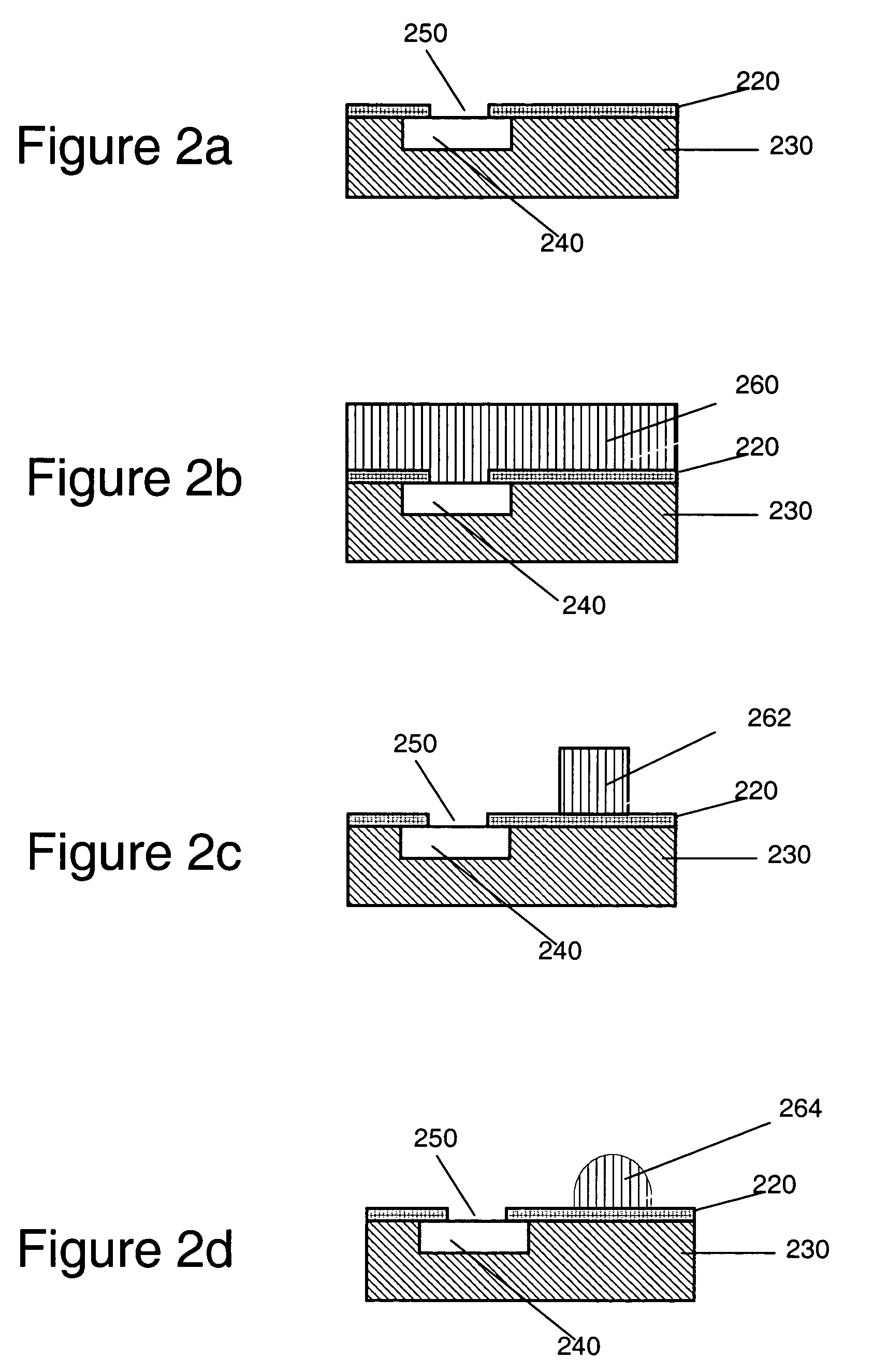

Process for high yield fabrication of MEMS devices

ActiveUS6872319B2Thickness minimizationExceptionally precise layer to layer alignmentSemi-permeable membranesPrecision positioning equipmentEngineeringSilicon

A MEMS fabrication process eliminates through-wafer etching, minimizes the thickness of silicon device layers and the required etch times, provides exceptionally precise layer to layer alignment, does not require a wet etch to release the moveable device structure, employs a supporting substrate having no device features on one side, and utilizes low-temperature metal-metal bonding which is relatively insensitive to environmental particulates. This process provided almost 100% yield of scanning micromirror devices exhibiting scanning over a 12° optical range and a mechanical angle of ±3° at a high resonant frequency of 2.5 kHz with an operating voltage of only 20 VDC.

Owner:TELEDYNE SCI & IMAGING

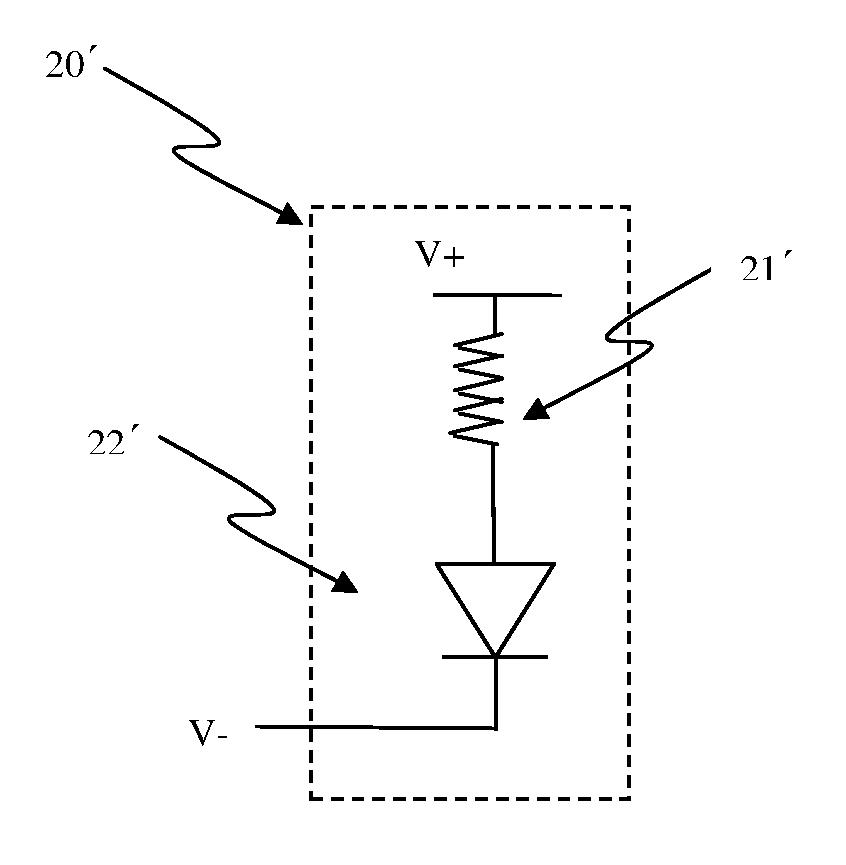

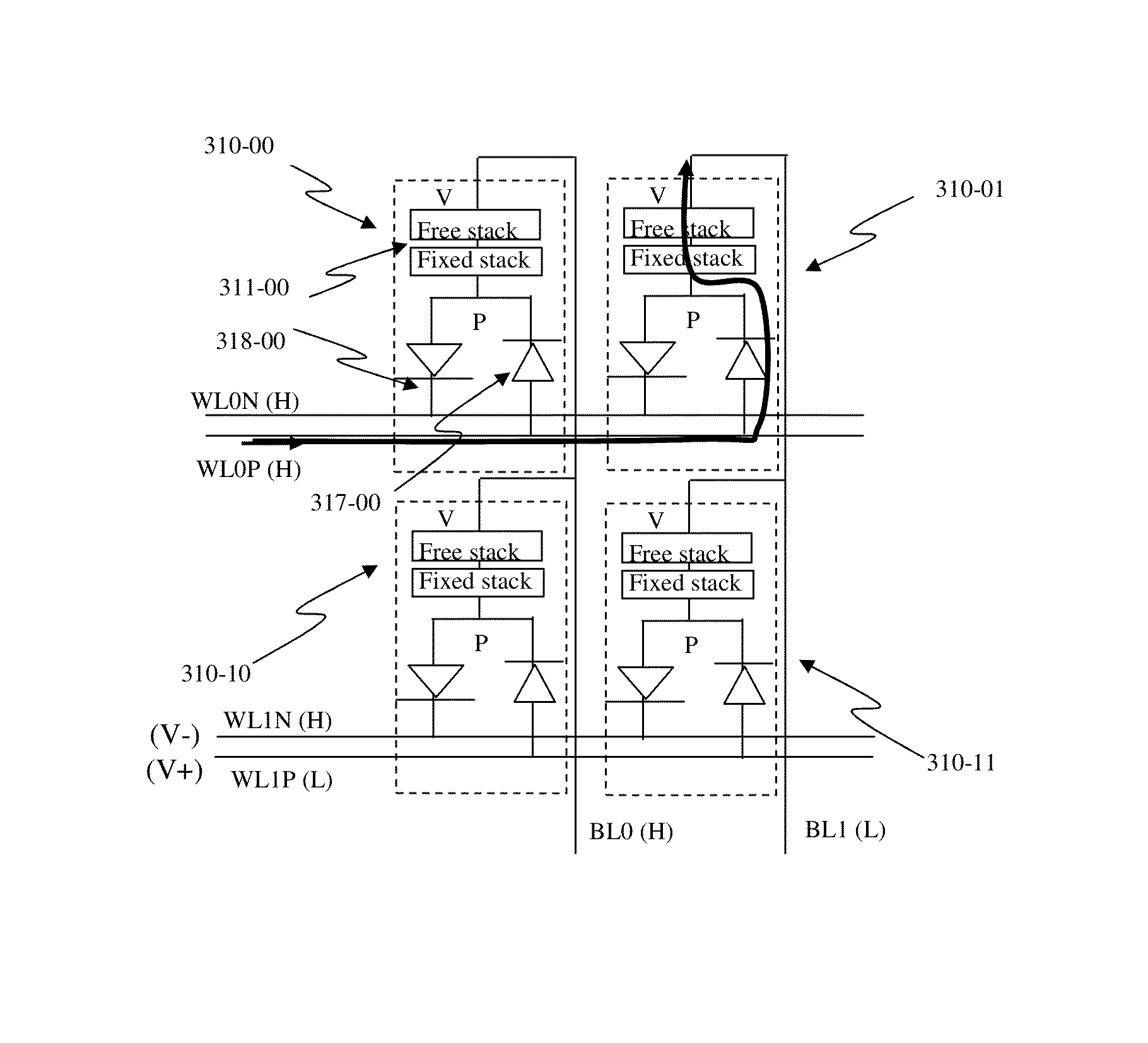

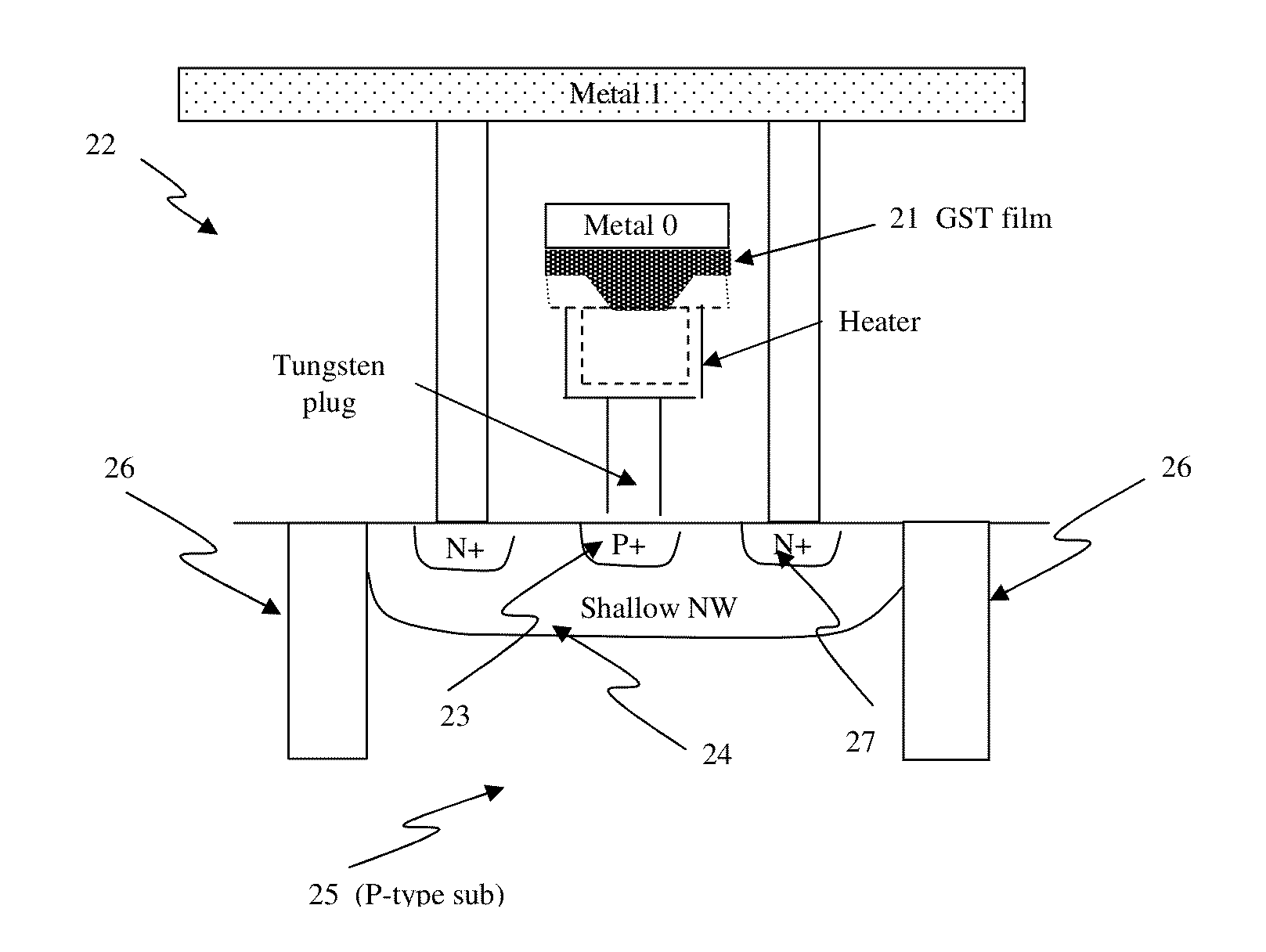

Circuit and system of using junction diode as program selector and mos as read selector for one-time programmable devices

Junction diodes fabricated in standard CMOS logic processes can be used as program selectors for One-Time Programmable (OTP) devices, such as electrical fuse, contact / via fuse, contact / via anti-fuse, or gate-oxide breakdown anti-fuse, etc. The OTP device has at least one OTP element coupled to at least one diode in a memory cell. The diode can be constructed by P+ and N+ active regions in a CMOS N well, or on an isolated active region as the P and N terminals of the diode. The isolation between P+ and the N+ active regions of the diode in a cell or between cells can be provided by dummy MOS gate, SBL, or STI / LOCOS isolations. The OTP cell can have a MOS in series with the OTP element as a read selector. The OTP element can be polysilicon, silicided polysilicon, silicide, polymetal, metal-0, metal, metal alloy, local interconnect, thermally isolated active region, CMOS gate, or combination thereof.

Owner:ATTOPSEMI TECH CO LTD

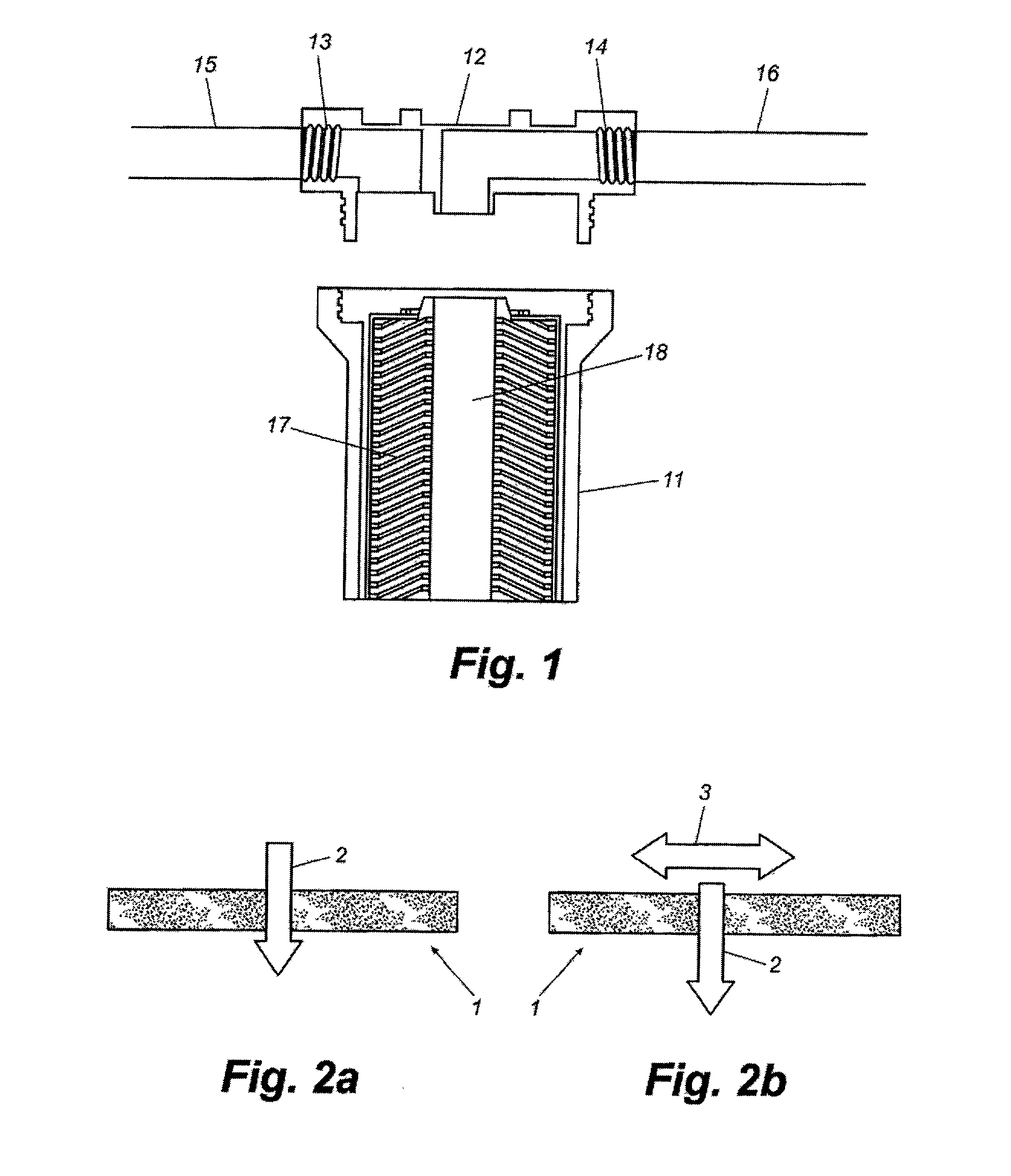

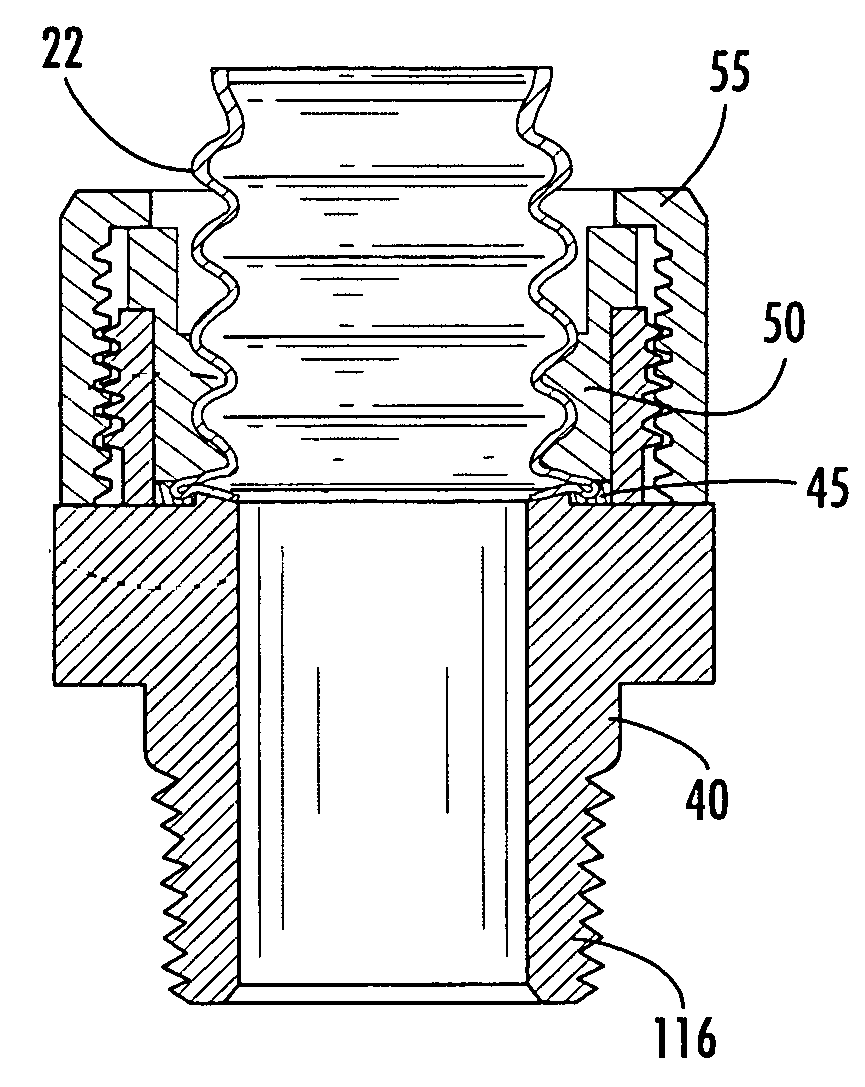

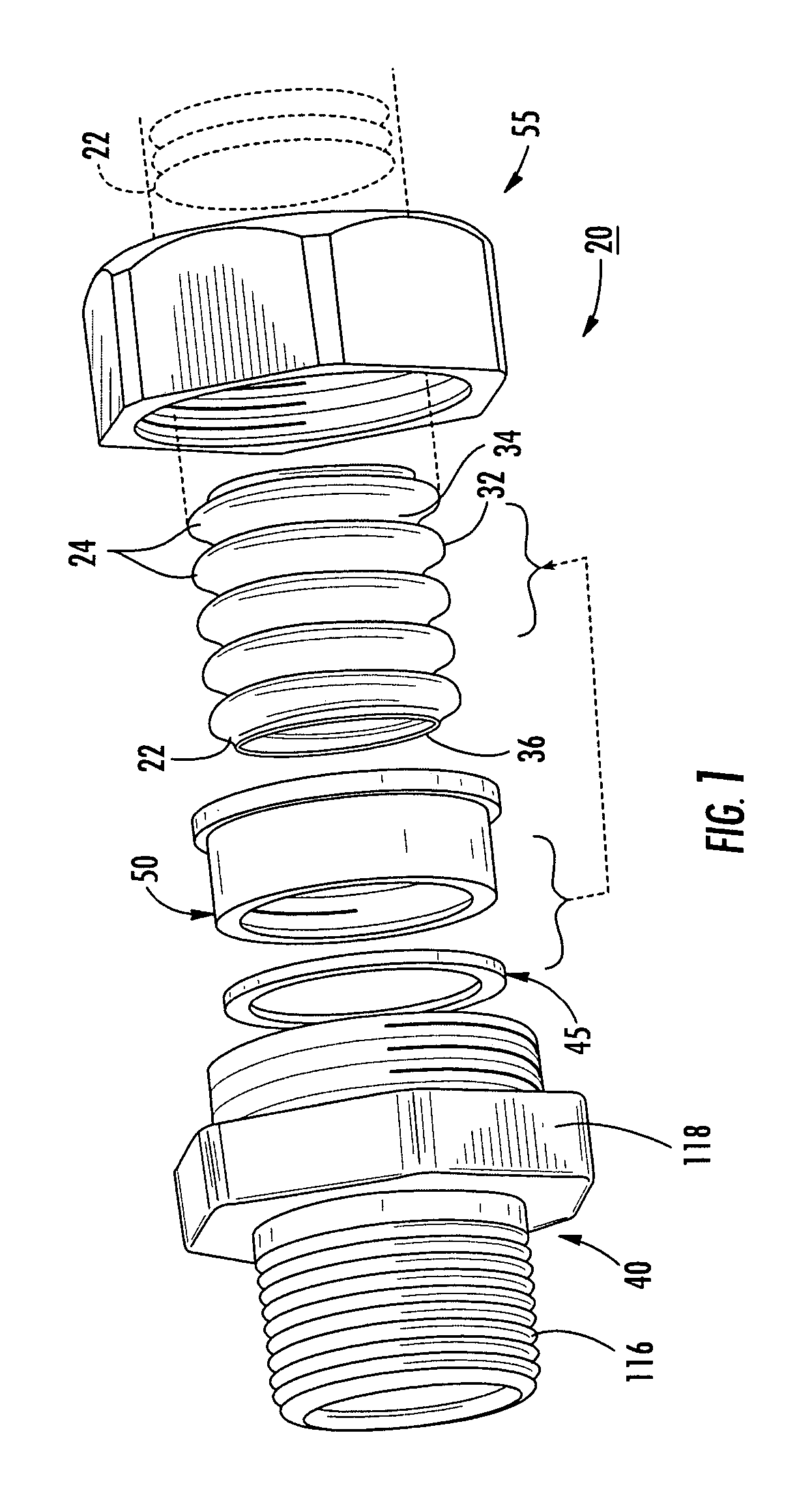

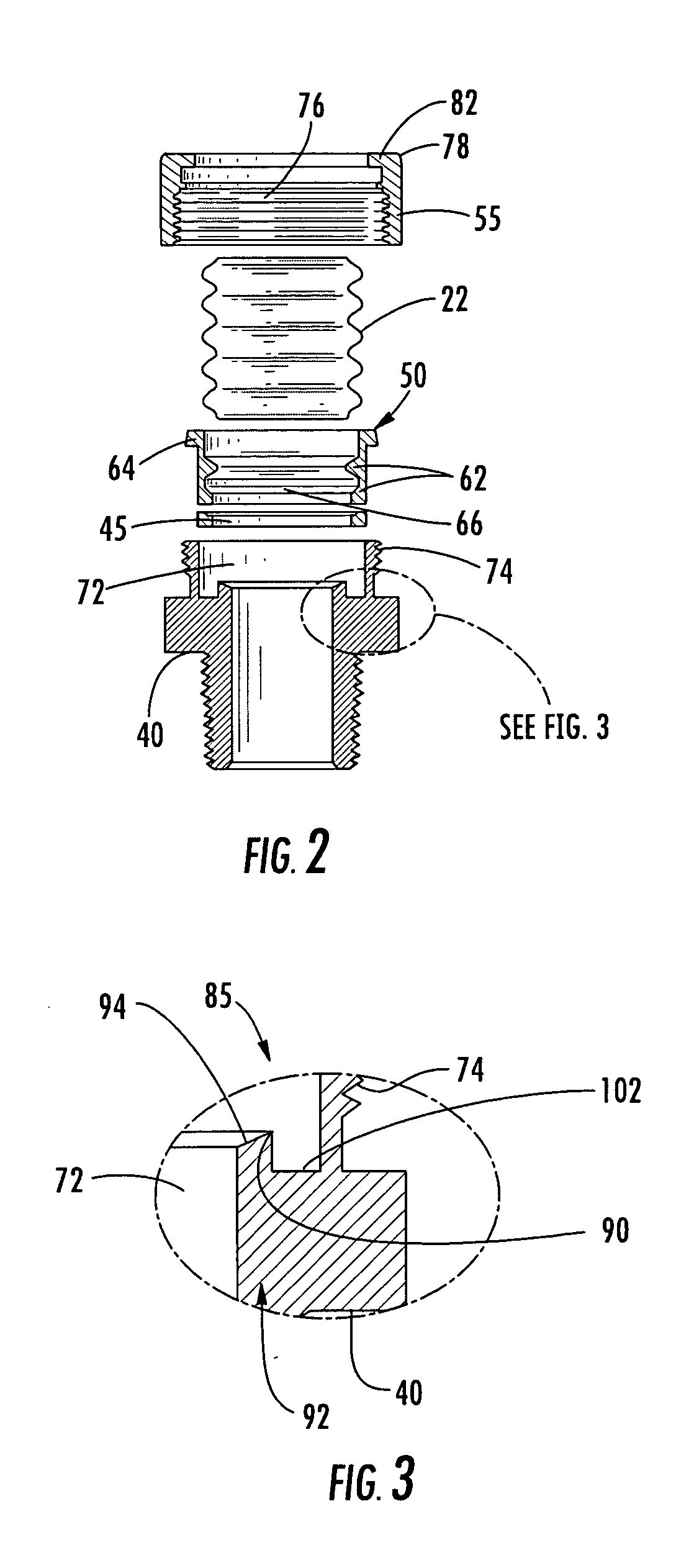

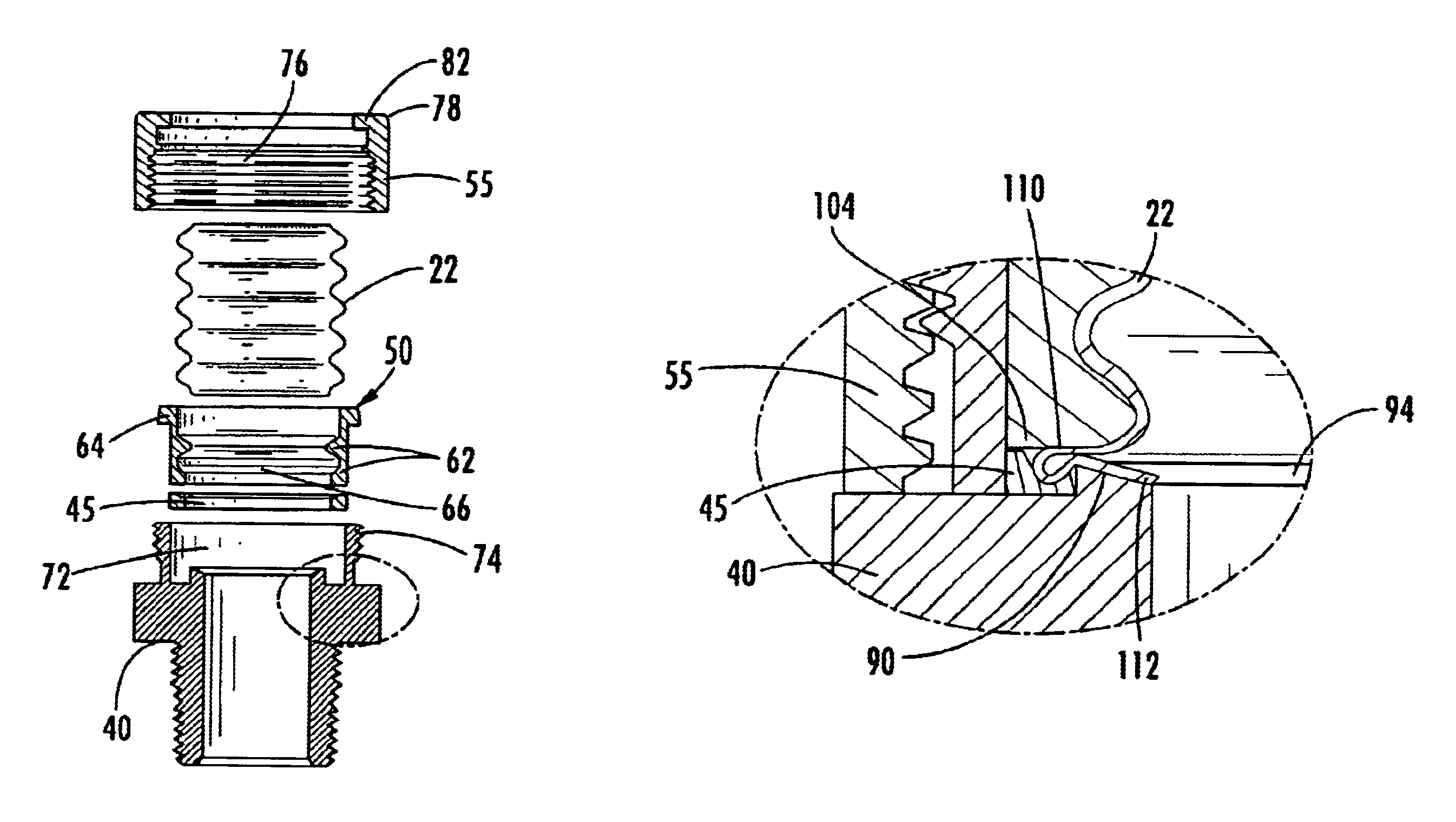

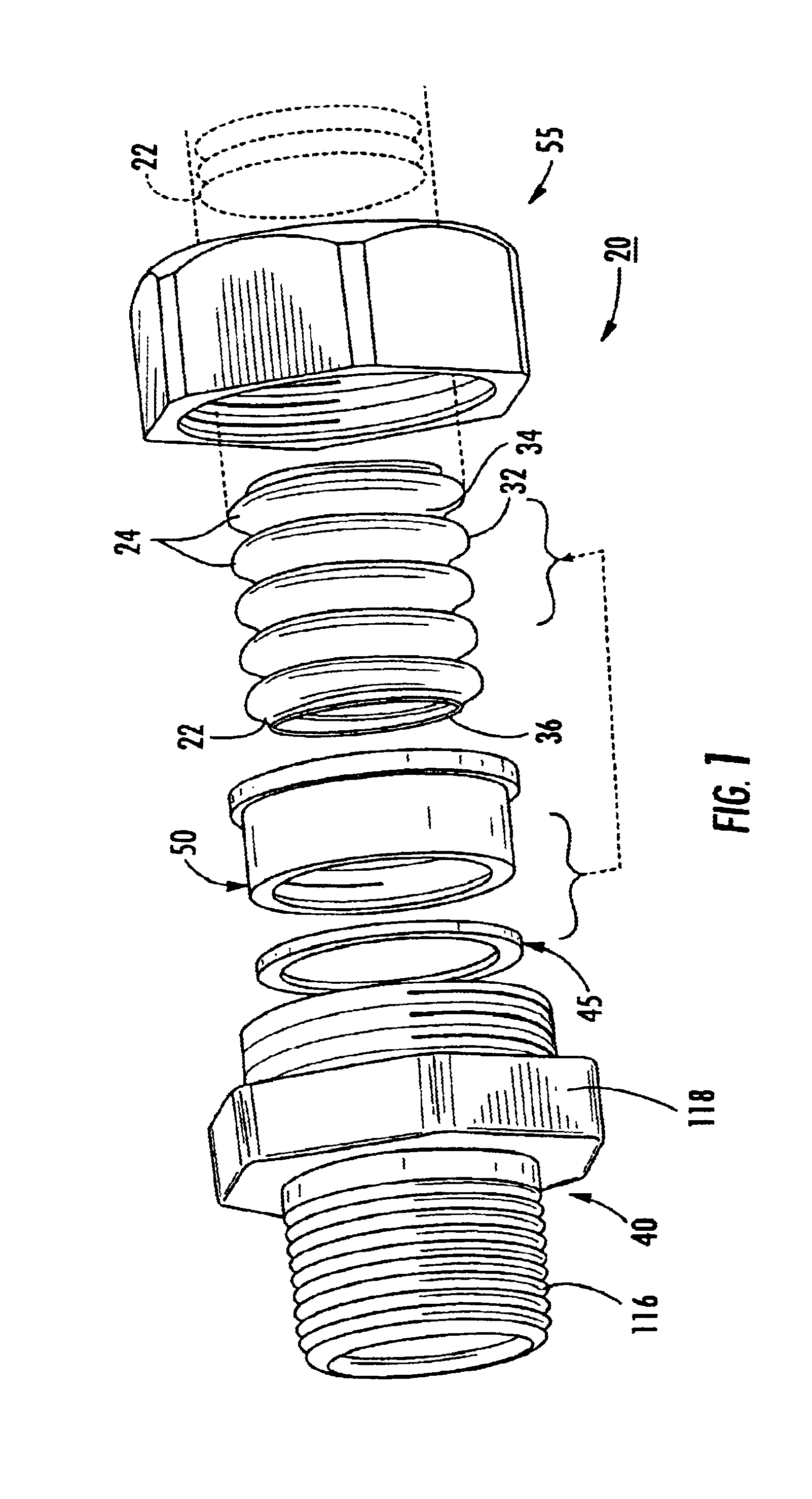

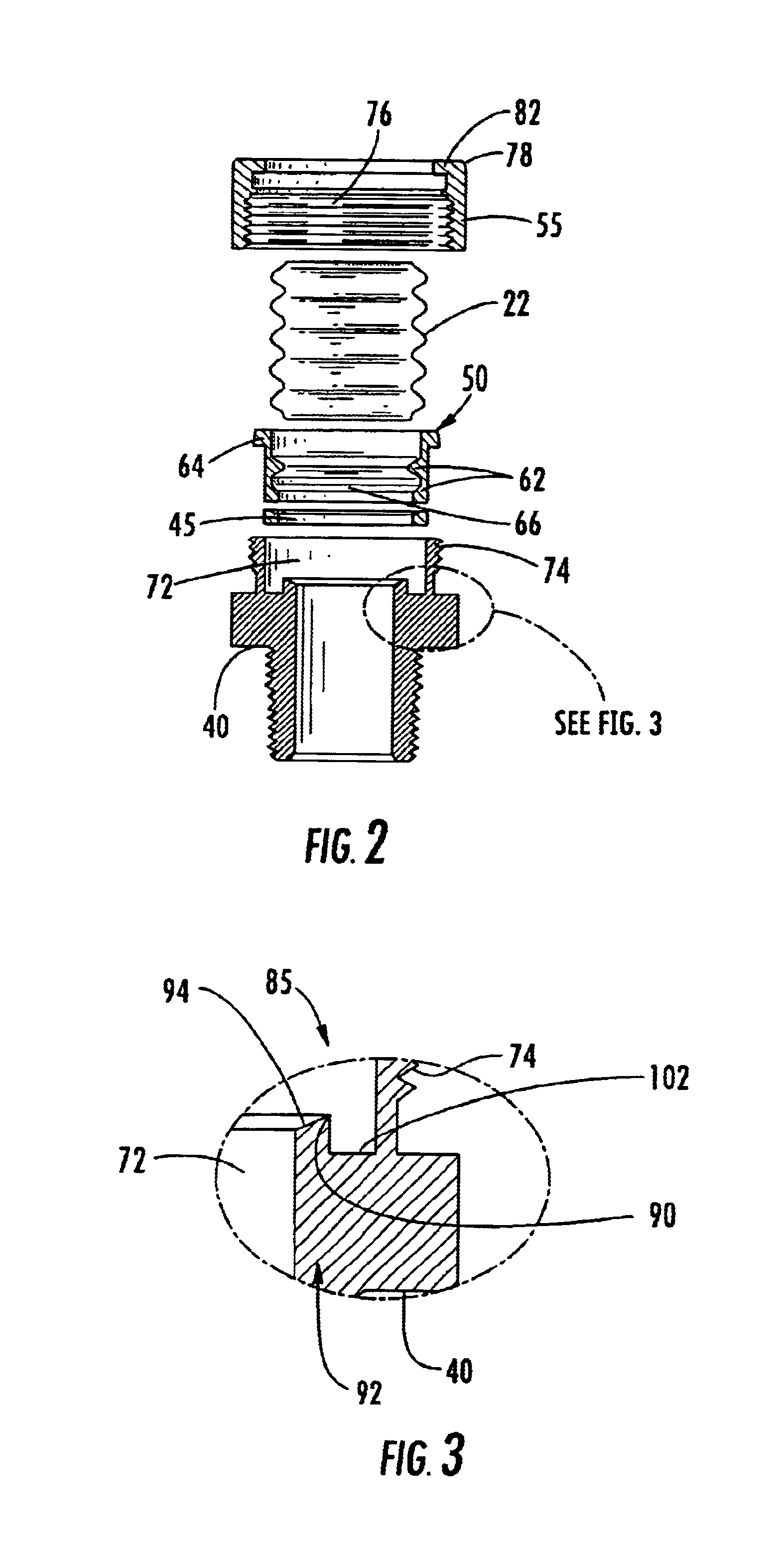

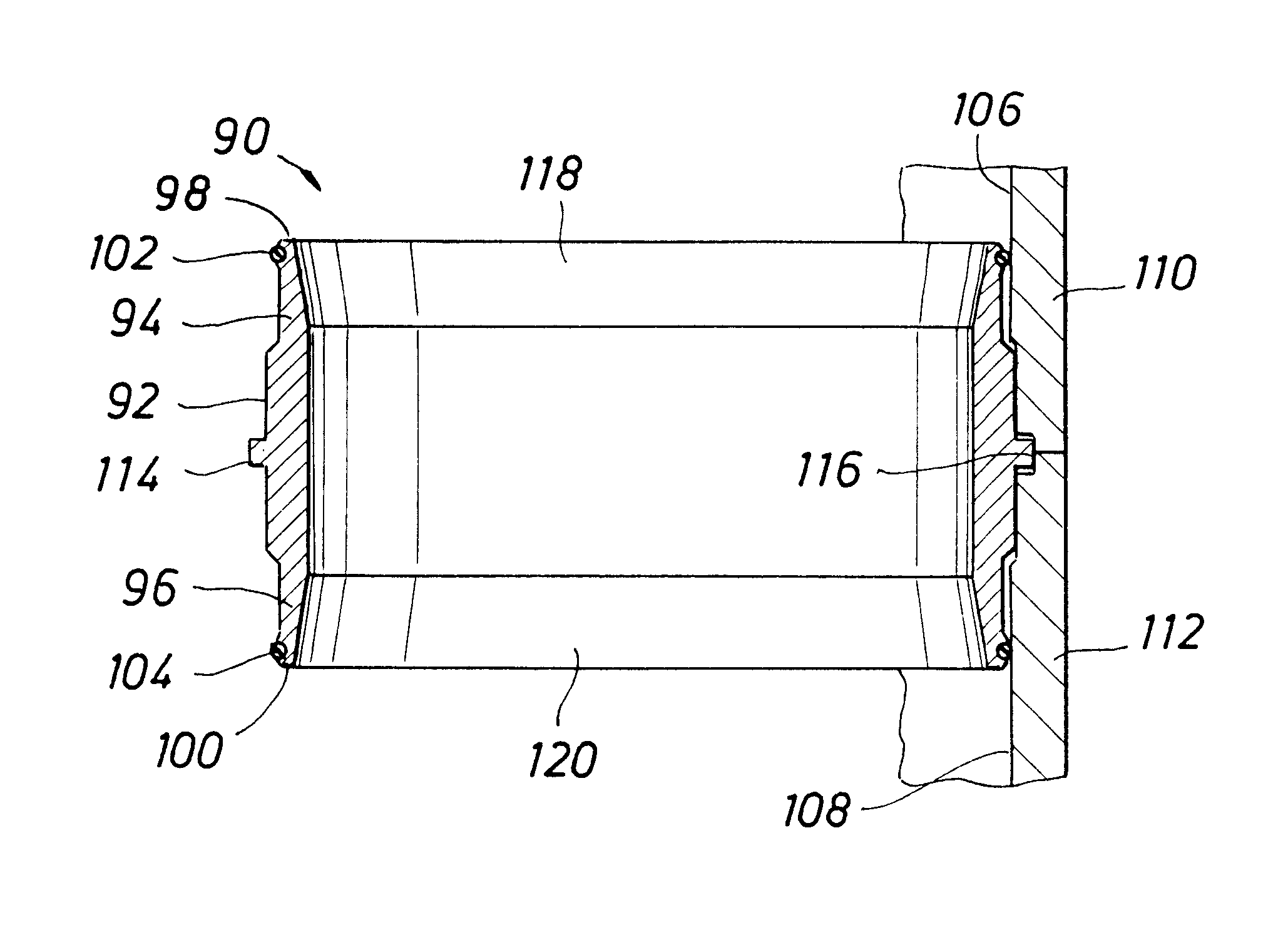

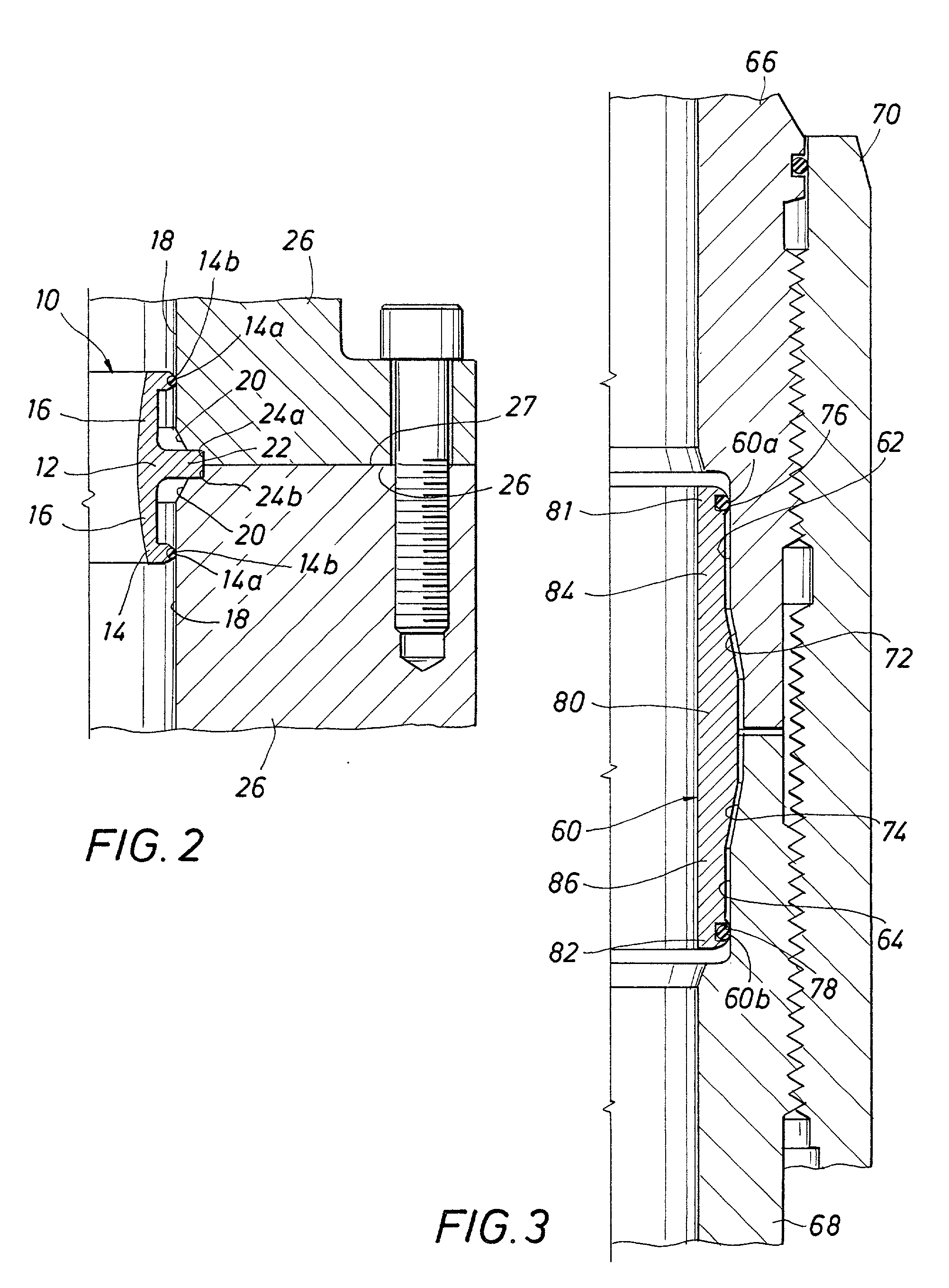

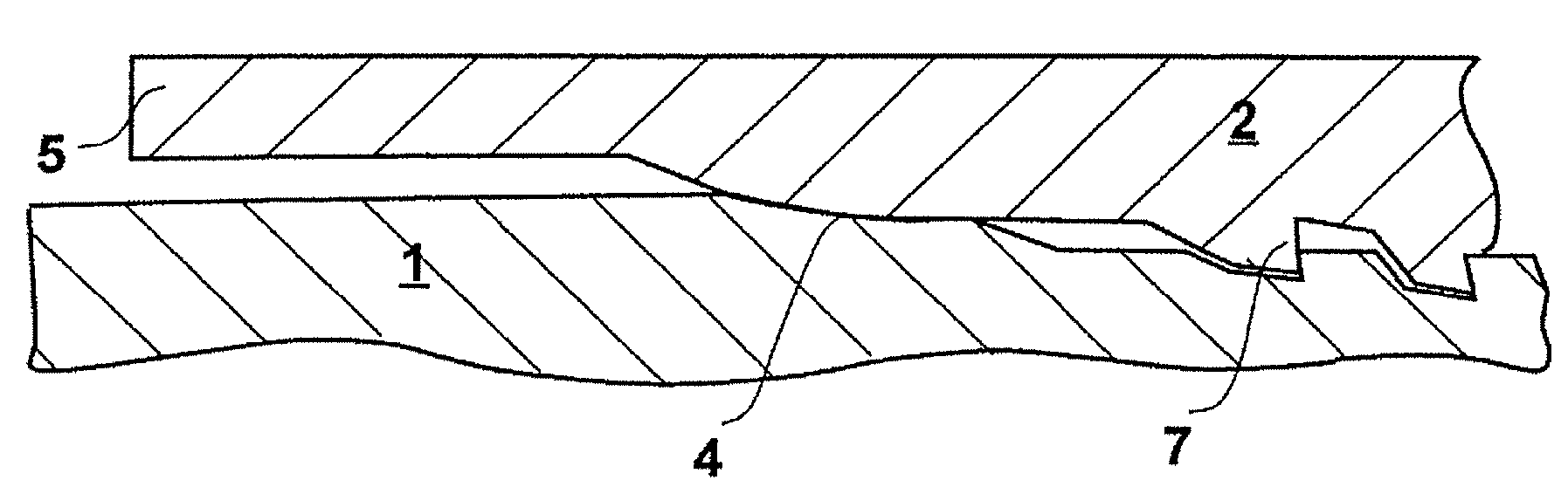

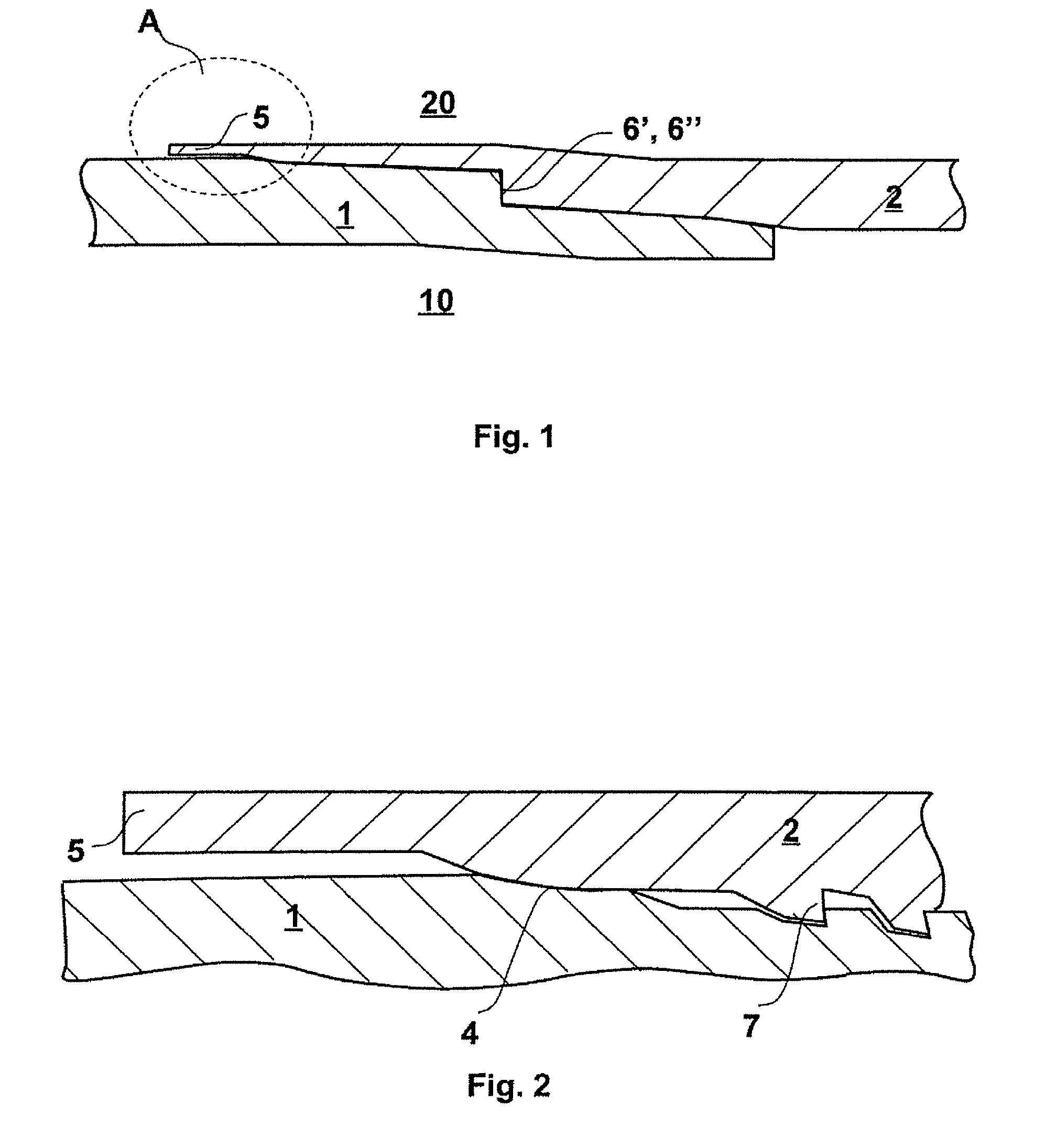

Corrugated tube fitting

InactiveUS20050023832A1Improve mechanical strength performanceImproved sealing performanceSleeve/socket jointsFluid pressure sealed jointsEngineeringMetal metal

A fitting for an end of a length of corrugated tubing has a split retainer that grips the tubing corrugations, and is engaged between a fitting body and a nut. Upon tightening the nut on the fitting body, the endmost corrugation is compressed between the retainer and a sealing seat on the fitting body arranged to provide a narrow metal-metal sealing junction and also a gasket seal. The fitting body has an inwardly tapered conical surface with a circular outer radius surrounded by an annular groove, thus forming a sealing edge, and the annular groove carries a gasket. The conical surface is dimensioned so that the sealing edge falls between the maximum and minimum diameters of the endmost corrugation. As the fitting is tightened, the endmost corrugation is collapsed between the sealing edge and the retainer, providing a metal / metal clamped sealing junction. The outer diameter part of the endmost corrugation is wrapped into a bead or torus that compresses the gasket, forming a metal / gasket additional seal.

Owner:HIGHLANDS CORP

Corrugated tube fitting

InactiveUS6877781B2Improve performanceHigh strengthSleeve/socket jointsFluid pressure sealed jointsEngineeringMetal metal

A fitting for an end of a length of corrugated tubing has a split retainer that grips the tubing corrugations, and is engaged between a fitting body and a nut. Upon tightening the nut on the fitting body, the endmost corrugation is compressed between the retainer and a sealing seat on the fitting body arranged to provide a narrow metal-metal sealing junction and also a gasket seal. The fitting body has an inwardly tapered conical surface with a circular outer radius surrounded by an annular groove, thus forming a sealing edge, and the annular groove carries a gasket. The conical surface is dimensioned so that the sealing edge falls between the maximum and minimum diameters of the endmost corrugation. As the fitting is tightened, the endmost corrugation is collapsed between the sealing edge and the retainer, providing a metal / metal clamped sealing junction. The outer diameter part of the endmost corrugation is wrapped into a bead or torus that compresses the gasket, forming a metal / gasket additional seal.

Owner:HIGHLANDS CORP

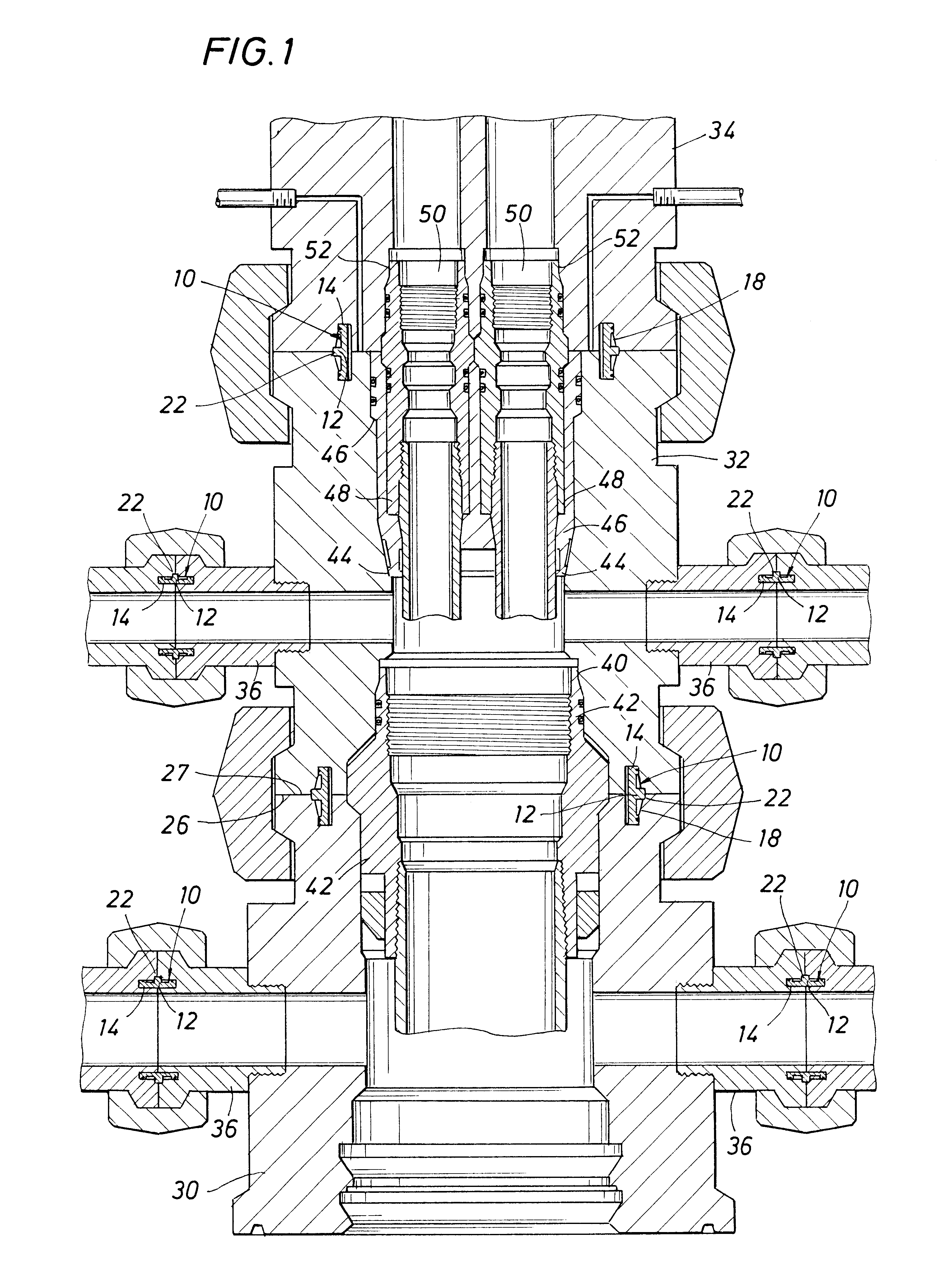

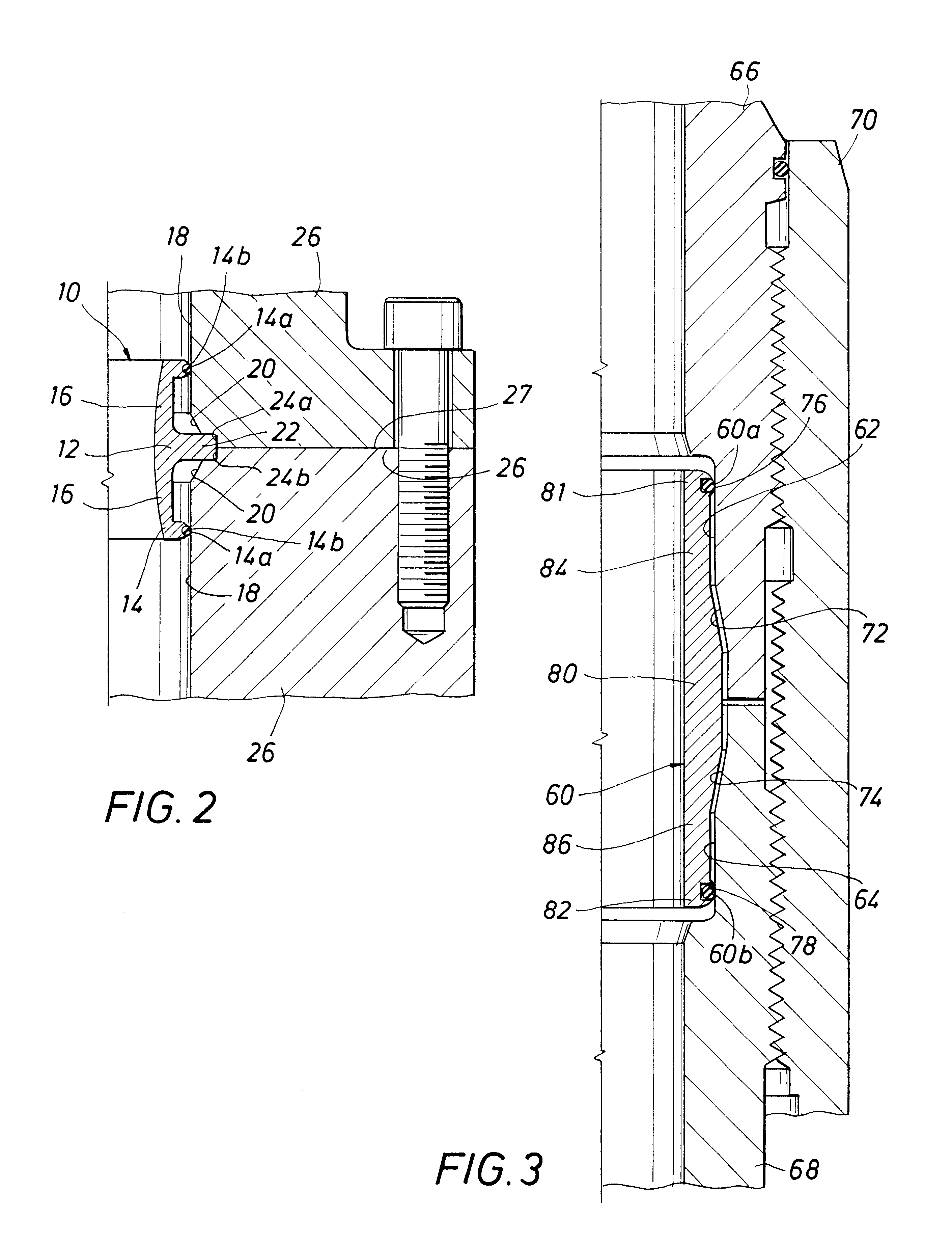

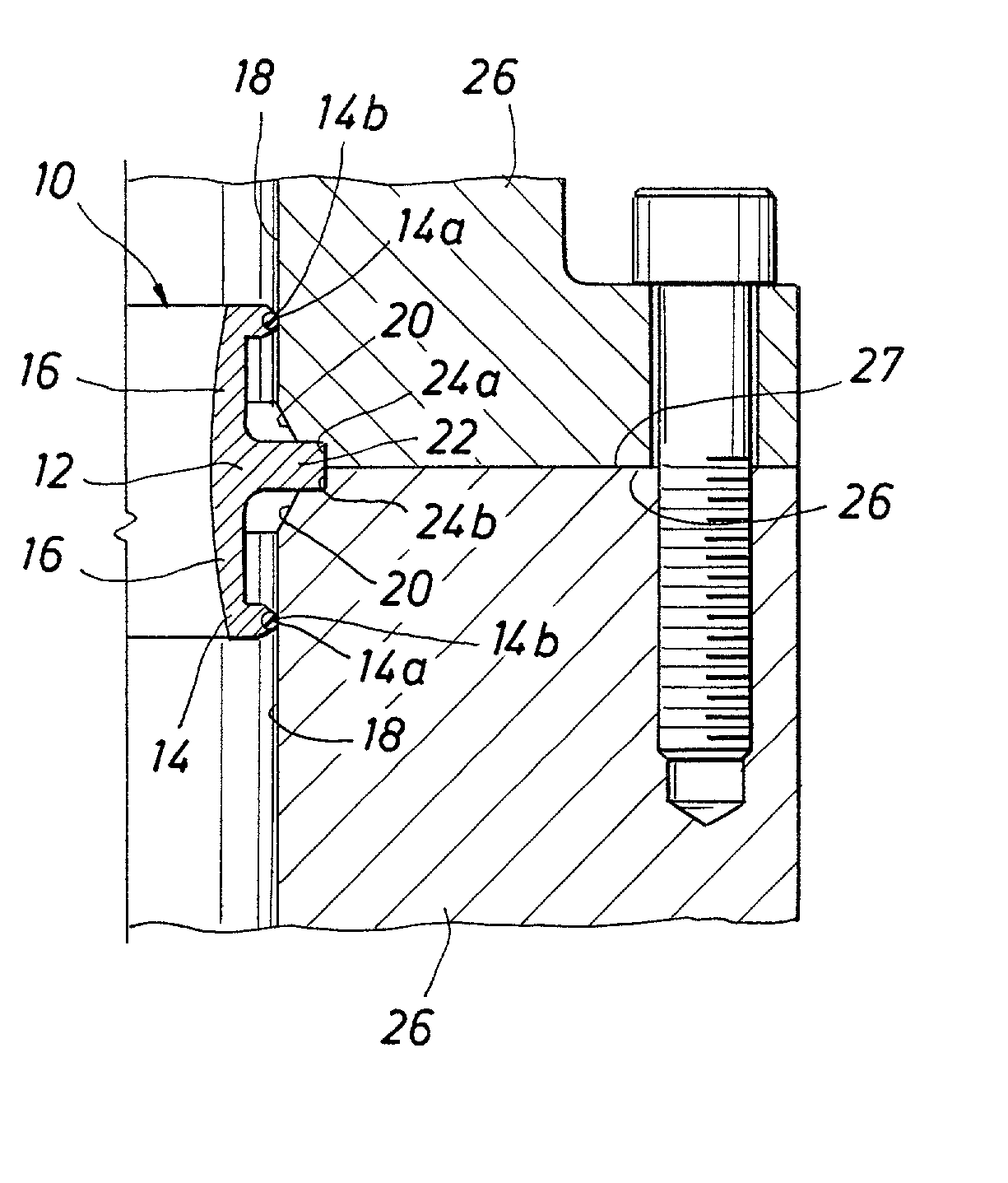

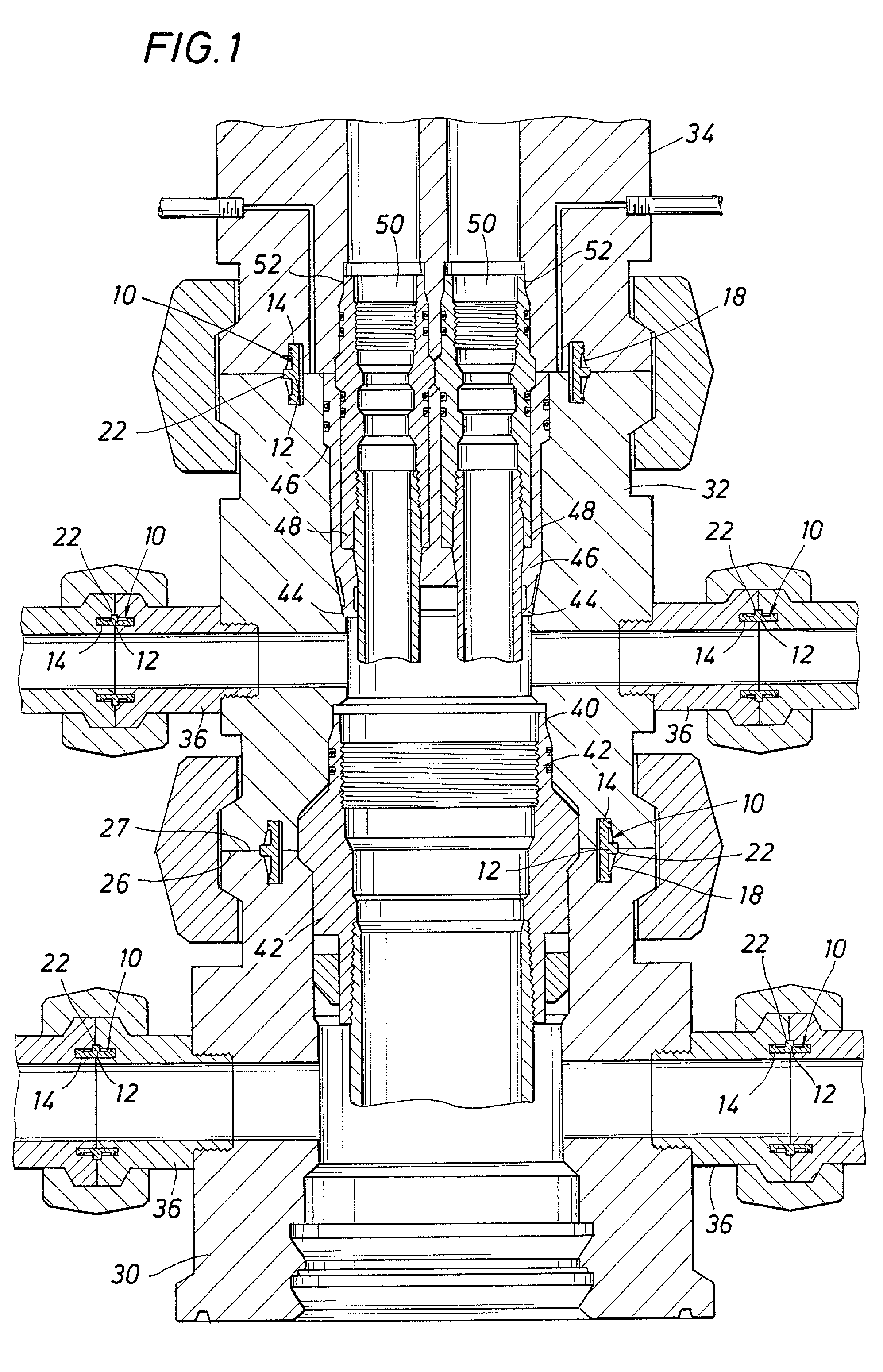

Metal-to-metal seal with soft metal insert

An annular metal-to-metal sealing system, for use in wellhead systems and having many other uses, has a metal member defining an annular internal or external sealing surface for which sealing is intended. An annular seal body composed of high strength metal material is positioned in concentric relation with the annular sealing surface and is sufficient flexible to become spring loaded, typically during assembly, for continuous application of a spring force. The annular seal body defines one or more annular seal retainer grooves each having an annular soft metal sealing insert therein, with a portion thereof exposed for sealing engagement with the annular sealing surface. The spring loaded characteristic of the annular seal body applies constant force to maintain the soft metal seal insert in constantly energized sealing relation with the annular sealing surface and maintains effective sealing even when dimensional changes to the sealing surface occur due to temperature or pressure changes.

Owner:FMC CORP

Circuit and system of using junction diode as program selector and MOS as read selector for one-time programmable devices

Junction diodes fabricated in standard CMOS logic processes can be used as program selectors for One-Time Programmable (OTP) devices, such as electrical fuse, contact / via fuse, contact / via anti-fuse, or gate-oxide breakdown anti-fuse, etc. The OTP device has at least one OTP element coupled to at least one diode in a memory cell. The diode can be constructed by P+ and N+ active regions in a CMOS N well, or on an isolated active region as the P and N terminals of the diode. The isolation between P+ and the N+ active regions of the diode in a cell or between cells can be provided by dummy MOS gate, SBL, or STI / LOCOS isolations. The OTP cell can have a MOS in series with the OTP element as a read selector. The OTP element can be polysilicon, silicided polysilicon, silicide, polymetal, metal-0, metal, metal alloy, local interconnect, thermally isolated active region, CMOS gate, or combination thereof.

Owner:ATTOPSEMI TECH CO LTD

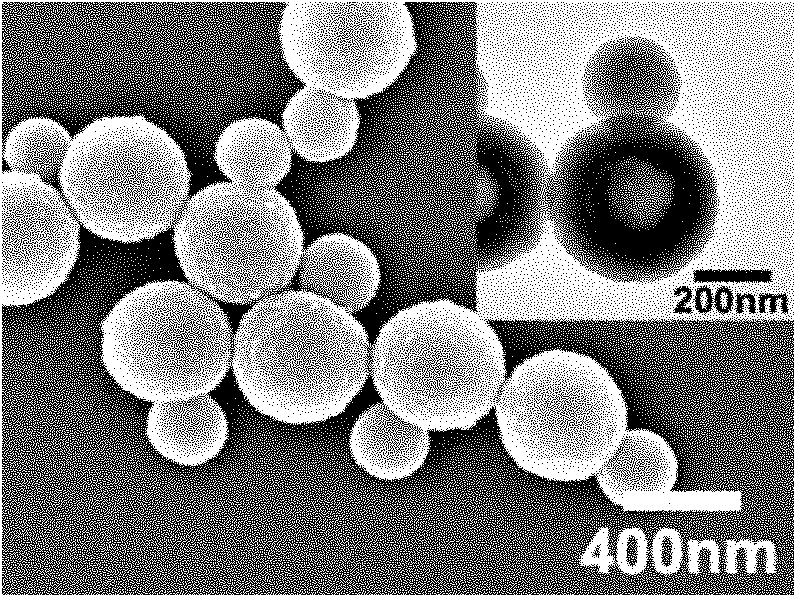

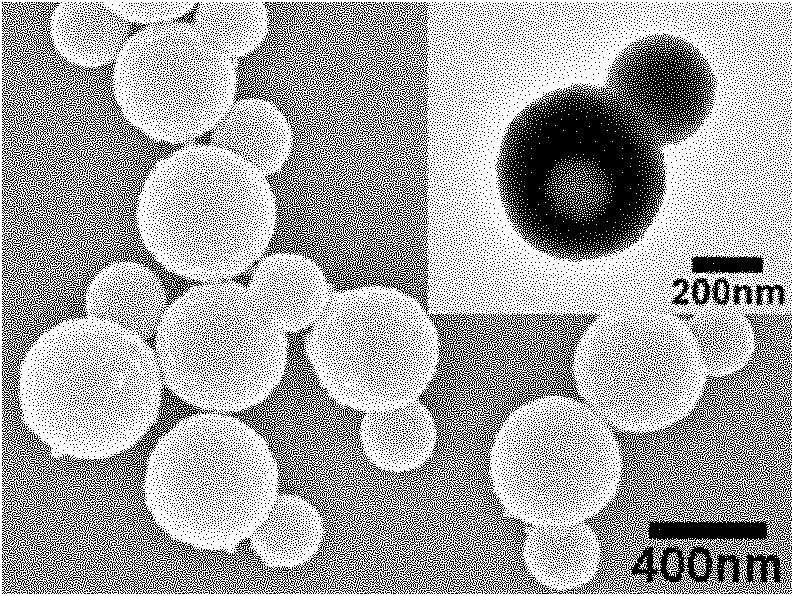

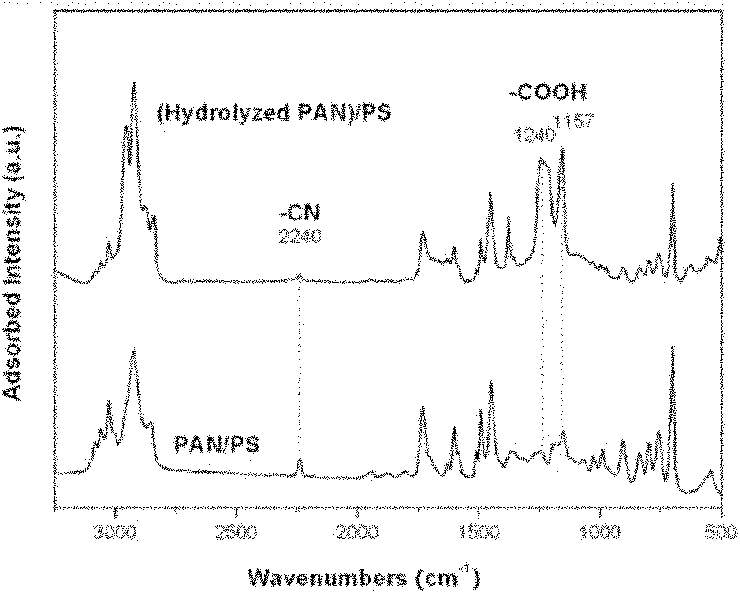

Janus particle with double properties and preparation method thereof

The invention discloses a Janus particle with double properties and a preparation method thereof. By employing cross-linked polymer colloidal particles as seeds and through a seed emulsion polymerization method, Janus particles with double properties are obtained on the basis of a phase separation mechanism; inorganic, metal and metal oxide compounded Janus particles with electrical, magnetic, optical properties are obtained through functional group modification and composition of function materials and can be used for the material field. The Janus particles have an emulsifying property in organic, inorganic dispersed phases or different organic dispersed phases and meanwhile the Janus particles have a great application prospect in the aspects of self-assembly, superhydrophobicity, nanomotor and the like. The preparation method provided by the invention is easy to operate, has the feasibility of mass production and can adapt to different needs by modification and composition of function materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ccircuit and system of using junction diode as program selector for metal fuses for one-time programmable devices

Junction diodes fabricated in standard CMOS logic processes can be used as program selectors for One-Time Programmable (OTP) devices. An OTP device can have at least one OTP element coupled to at least one diode in a memory cell. With a metal fuse is used by the OTP element, at least one contact and / or a plurality of vias can be built (possibly with use of one or more jumpers) in the program path to generate more Joule heat to assist with programming. The jumpers are conductive and can be formed of metal, metal gate, local interconnect, polymetal, etc. The metal fuse can also have an extended area that is longer than required by design rules for enhanced programmability. The OTP element can be polysilicon, silicided polysilicon, silicide, polymetal, metal, metal alloy, local interconnect, thermally isolated active region, CMOS gate, or combination thereof.

Owner:ATTOPSEMI TECH CO LTD

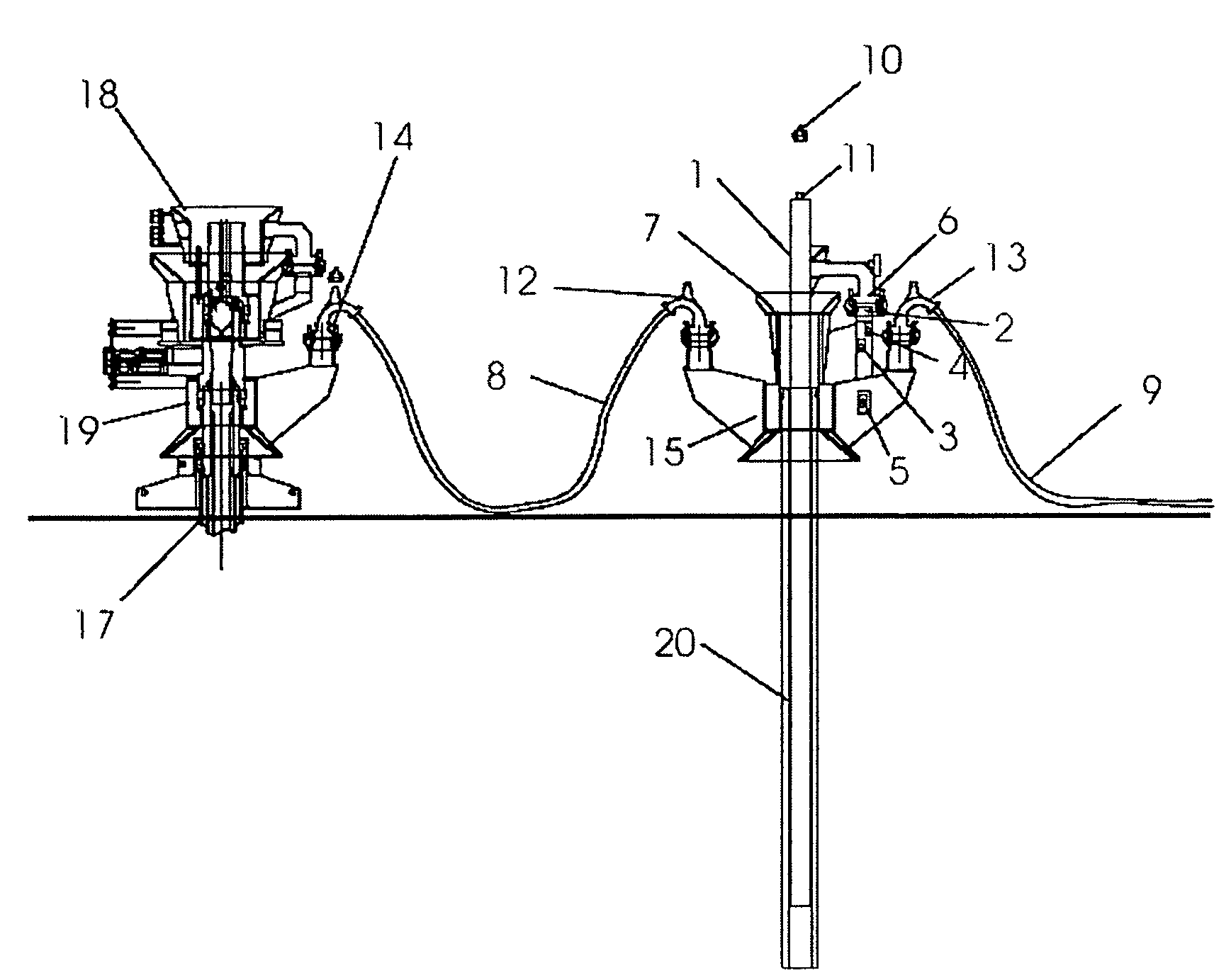

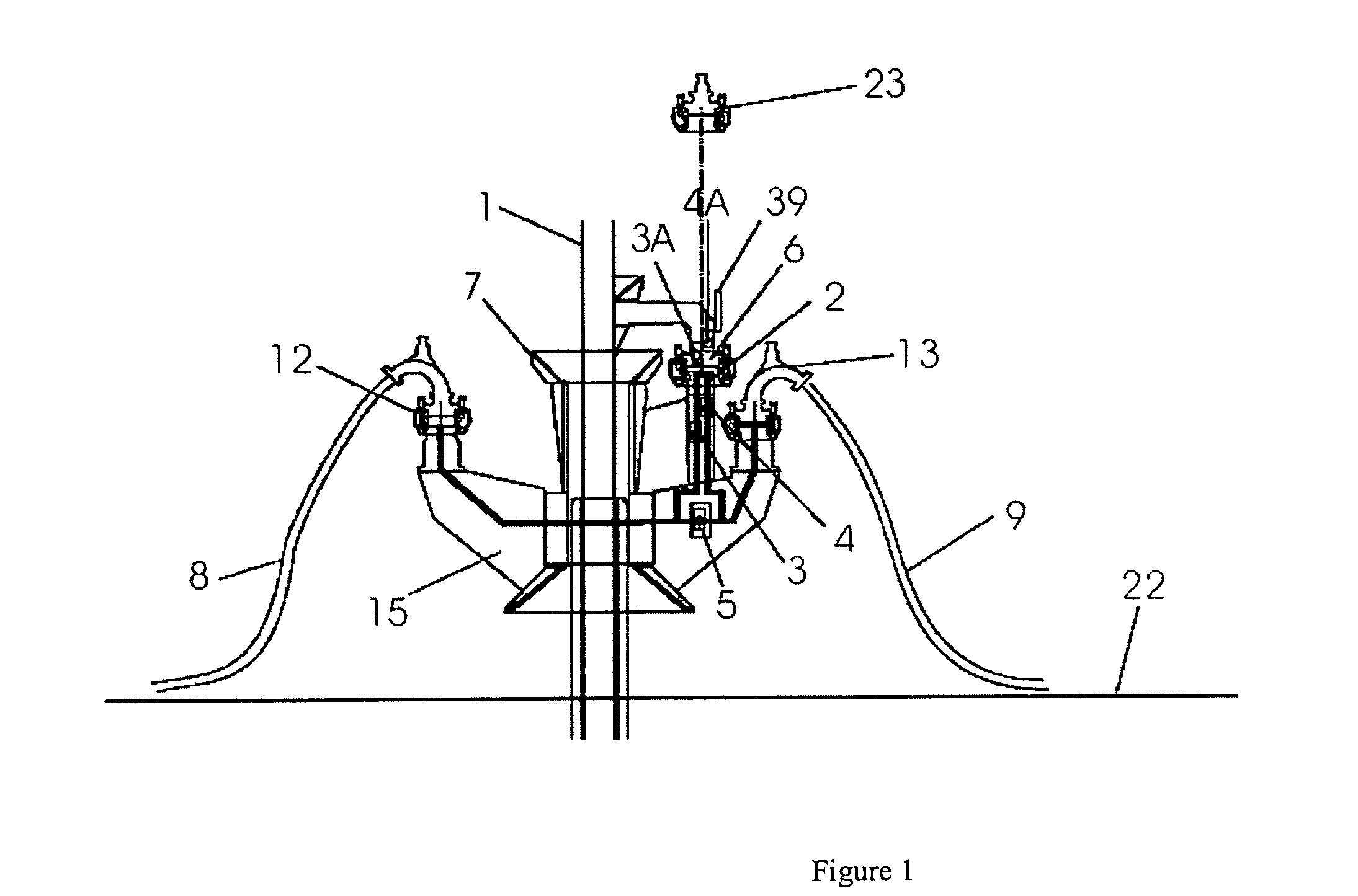

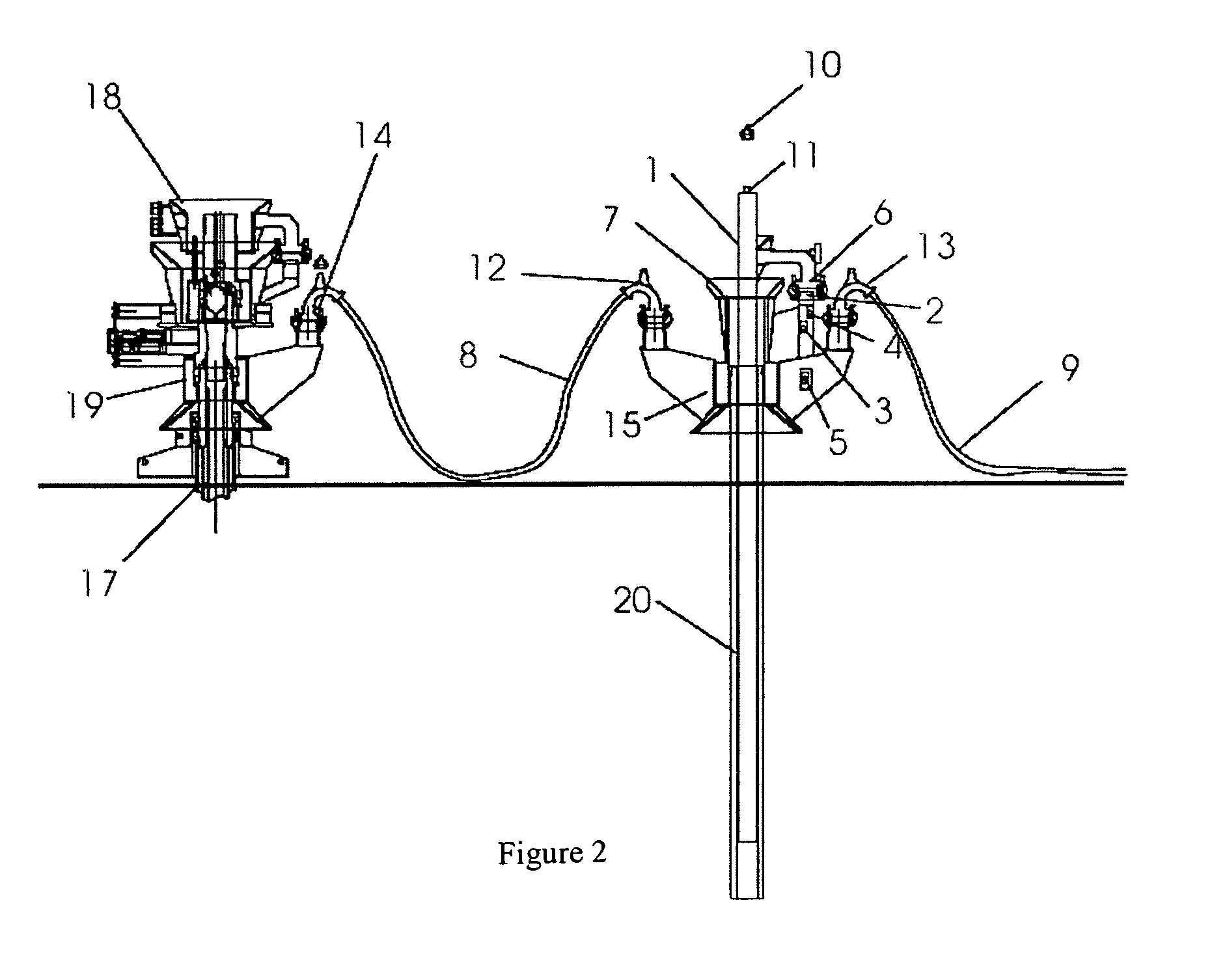

Subsea pumping module system and installation method

ActiveUS7314084B2Reduce riskEasy to disassembleFluid removalUnderwater drillingOcean bottomLine tubing

The present invention contemplates a system comprising a pumping module coupled to an intermediate flow inlet (IFI) wherein said IFI is coupled to a base structure disposed on the flow line that routes production from one or more oil wells, allowing for the quick and easy installation or recovery of a subsea pumping module by cable from an inexpensive vessel. The present invention also allows for the hydraulic isolation of the subsea pumping module by means of on-off valves on the IFI whereby the pumping module can be easily installed or removed without causing underwater oil spills. Sealing of the connection is of the metal-metal type. It is also possible to pass a pig through the present system for clearing the flow lines.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Metal-to-metal seal with soft metal insert

An annular metal-to-metal sealing system, for use in wellhead systems and having many other uses, has a metal member defining an annular internal or external sealing surface for which sealing is intended. An annular seal body composed of high strength metal material is positioned in concentric relation with the annular sealing surface and is sufficient flexible to become spring loaded, typically during assembly, for continuous application of a spring force. The annular seal body defines one or more annular seal retainer grooves each having an annular soft metal sealing insert therein, with a portion thereof exposed for sealing engagement with the annular sealing surface. The spring loaded characteristic of the annular seal body applies constant force to maintain the soft metal seal insert in constantly energized sealing relation with the annular sealing surface and maintains effective sealing even when dimensional changes to the sealing surface occur due to temperature or pressure changes.

Owner:FMC CORP

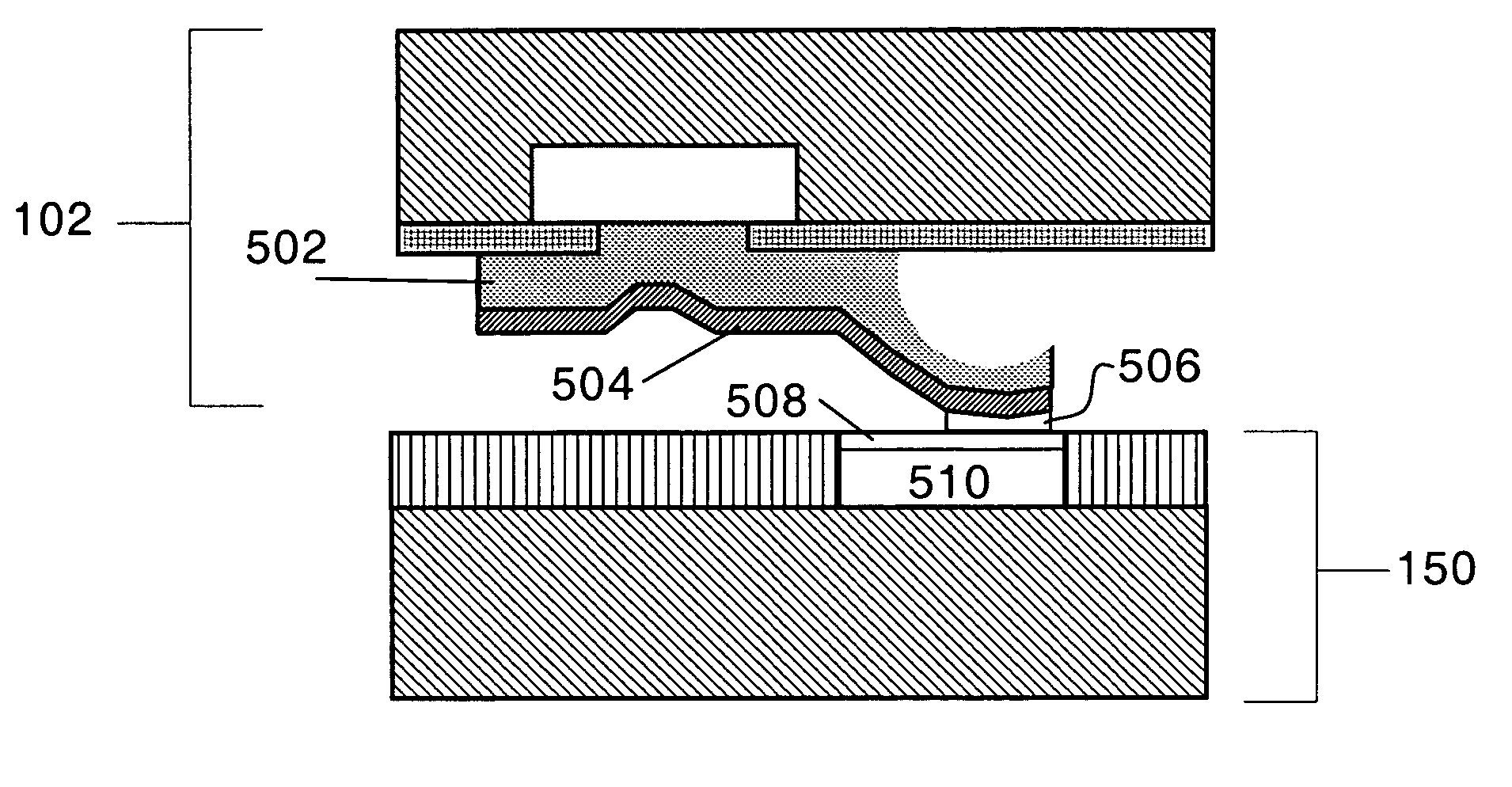

Metal-metal bonding of compliant interconnect

ActiveUS7750487B2Semiconductor/solid-state device detailsSolid-state devicesMetal metalMaterials science

Owner:INTEL CORP

Threaded joint for pipes provided with seal

ActiveUS7506900B2Rigid enoughIncreasing the thicknessJoints with sealing surfacesHose connectionsEngineeringScrew thread

A threaded joint for pipes comprising at least one seal of the metal-metal interference type arranged externally to the female thread. The joint has an extension of the box beyond the seal which produces an elastic tightening band effect on the seal so that excessive interference on the seal is not necessary, thus favoring correct making up.

Owner:TENARIS CONNECTIONS

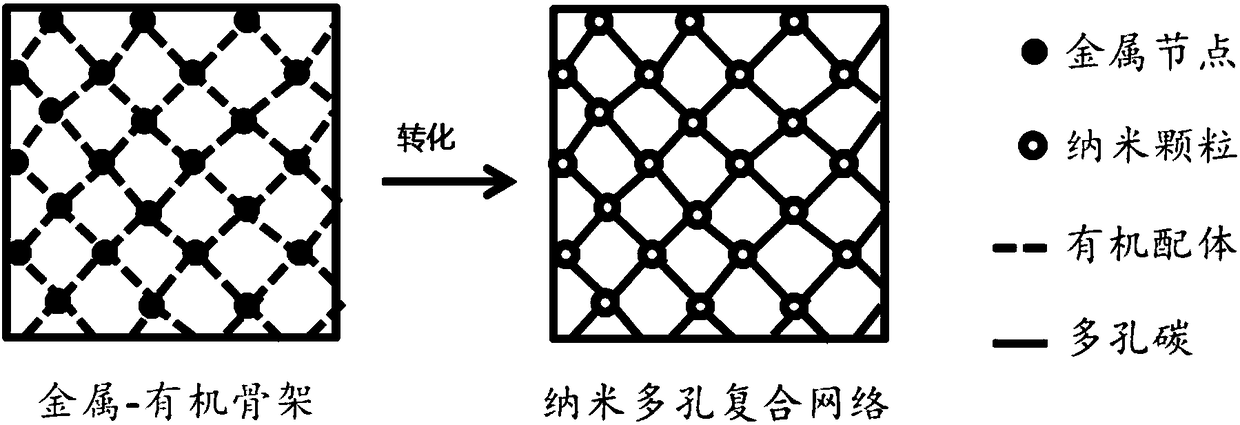

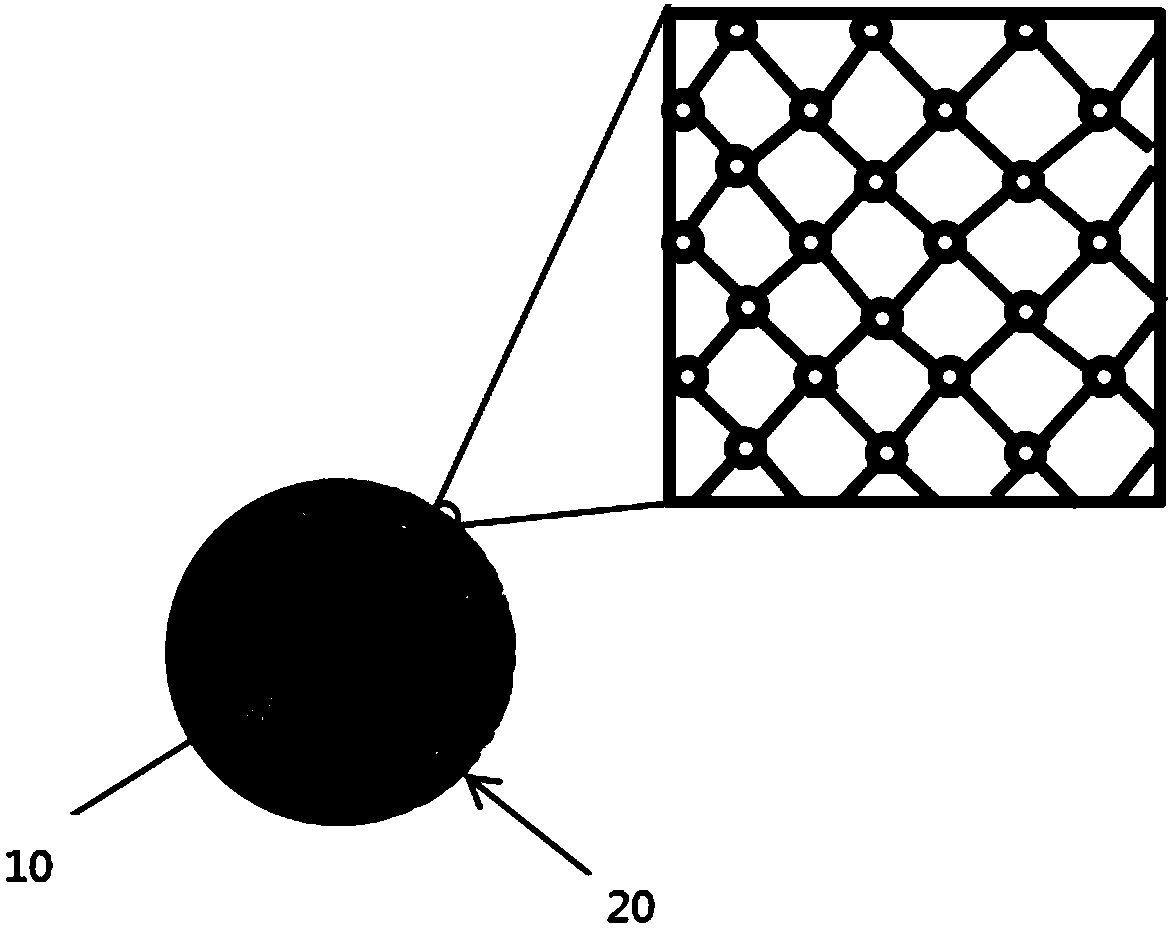

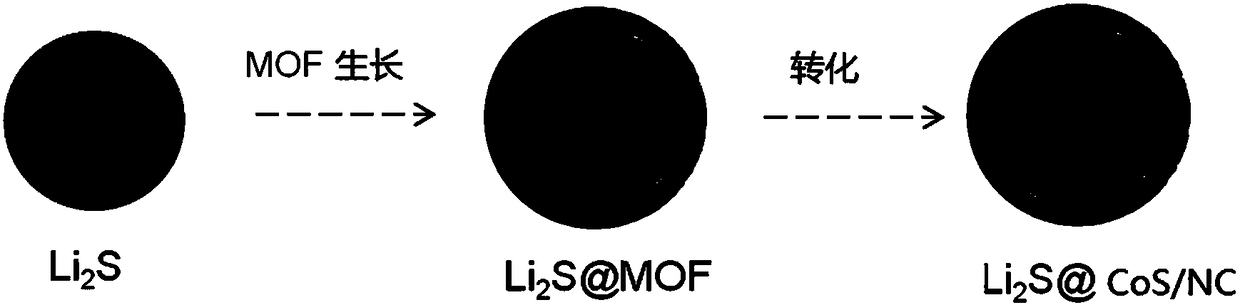

Positive electrode protective material of lithium sulfur battery and application thereof

InactiveCN108336308APromote circulationCurb churnMaterial nanotechnologyCell electrodesHigh energyNanoporous carbon

In one embodiment, the invention provides a positive electrode protective material of a lithium sulfur battery. The material includes a nano-porous carbon network and inorganic nano-particles uniformly distributed therein. Distance of any two adjacent inorganic nano-particles is 3-50 nm. The inorganic nano-particles are metal compound nano-particles or metal-metal compound composite nano-particles. The nano-porous carbon network and the inorganic nano-particles can form an integrated three-dimensional nano-porous composite network. The positive electrode protective material has physical and chemical dual-adsorption effect and can constrain lithium polysulfide to nearby the positive electrode, thus effectively inhibiting loss of a positive active material in the lithium sulfur battery. Meanwhile, the material can accelerate conversion from soluble lithium polysulfide to indissolvable Li2S2 or Li2S, thus greatly improving energy conversion efficiency and rate capability of the lithium sulfur battery and achieving excellent cycle performance under high energy density. The invention also provides a practical application of the positive electrode protective material in the lithium sulfur battery.

Owner:HUAWEI TECH CO LTD

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

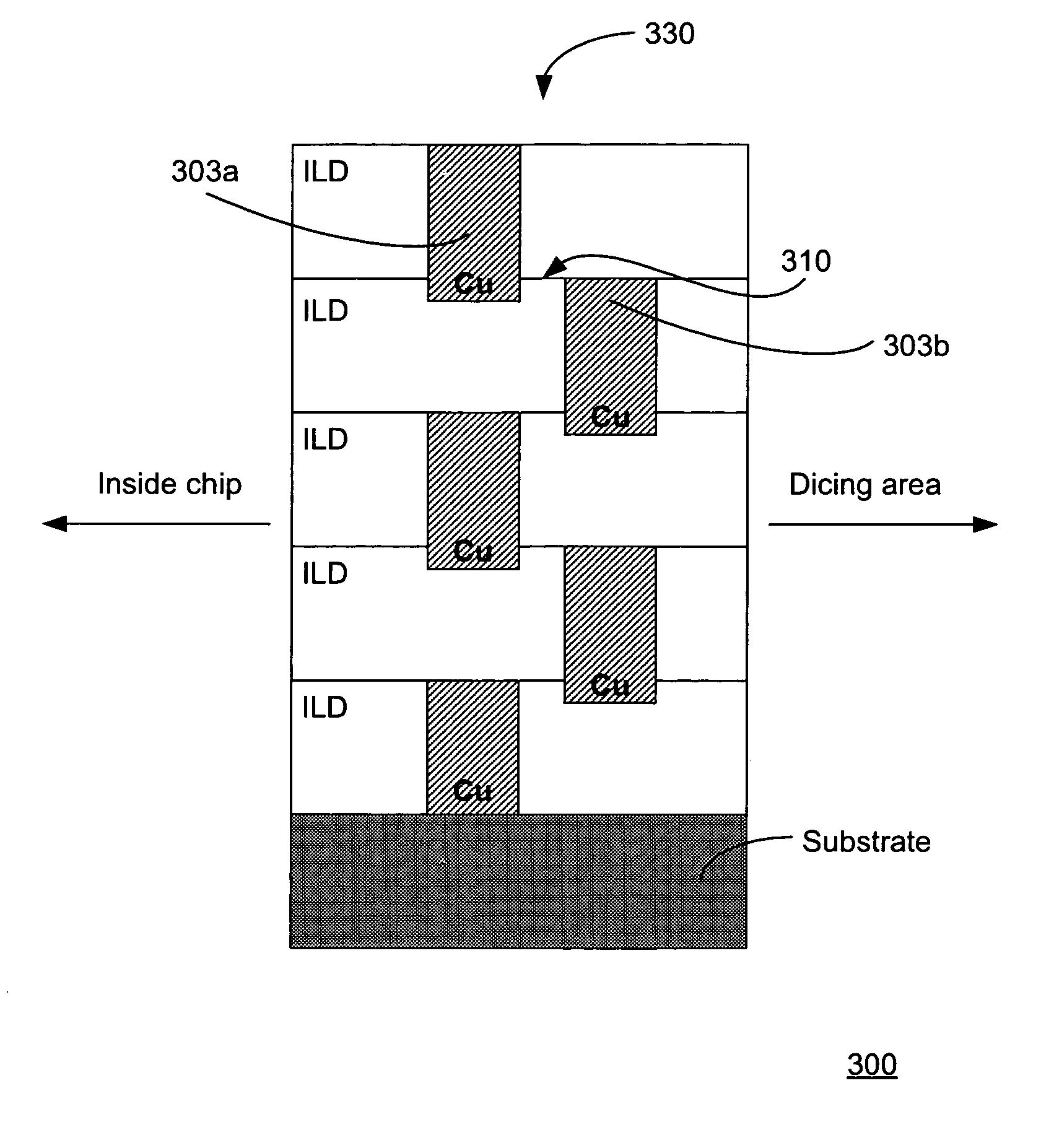

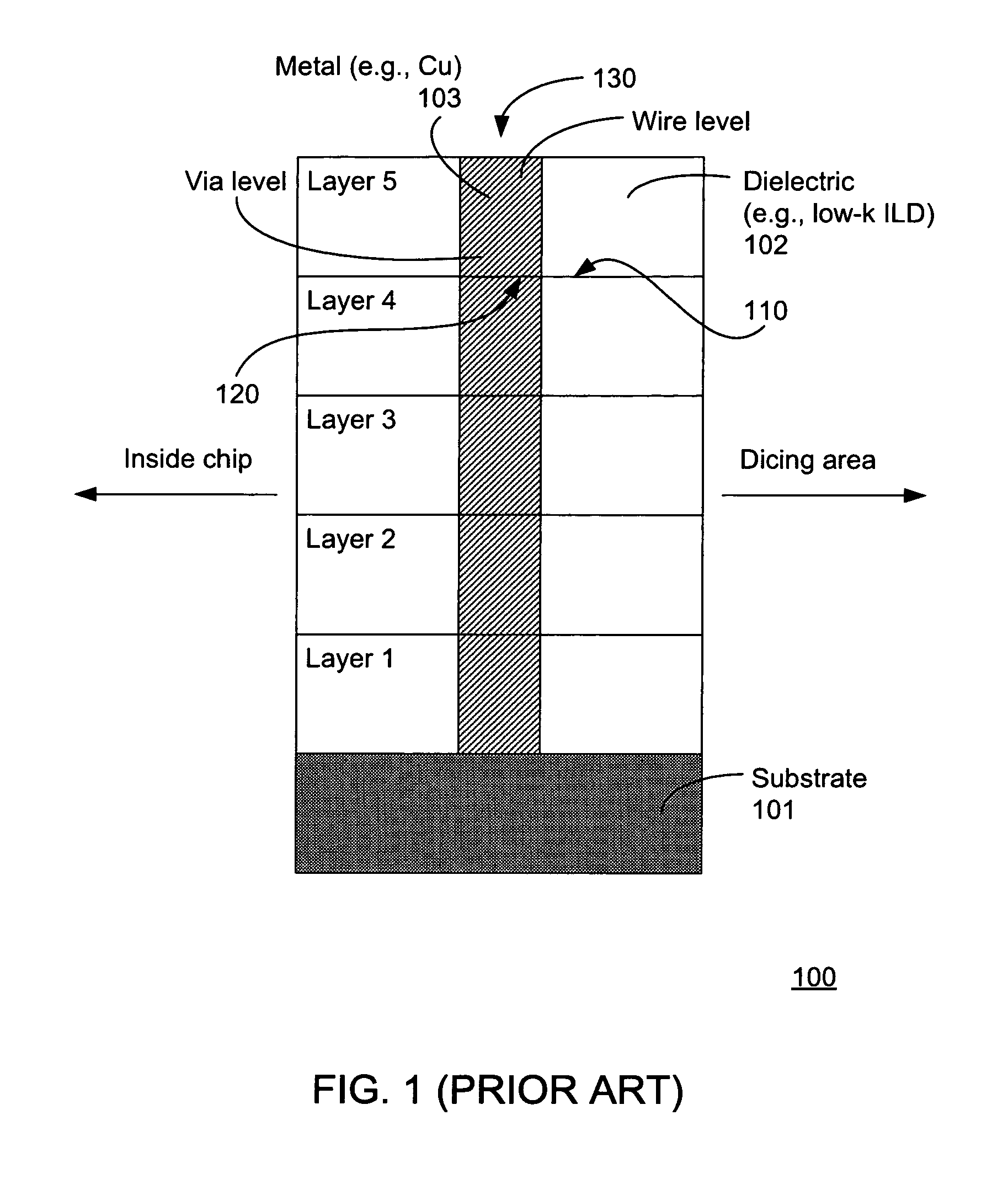

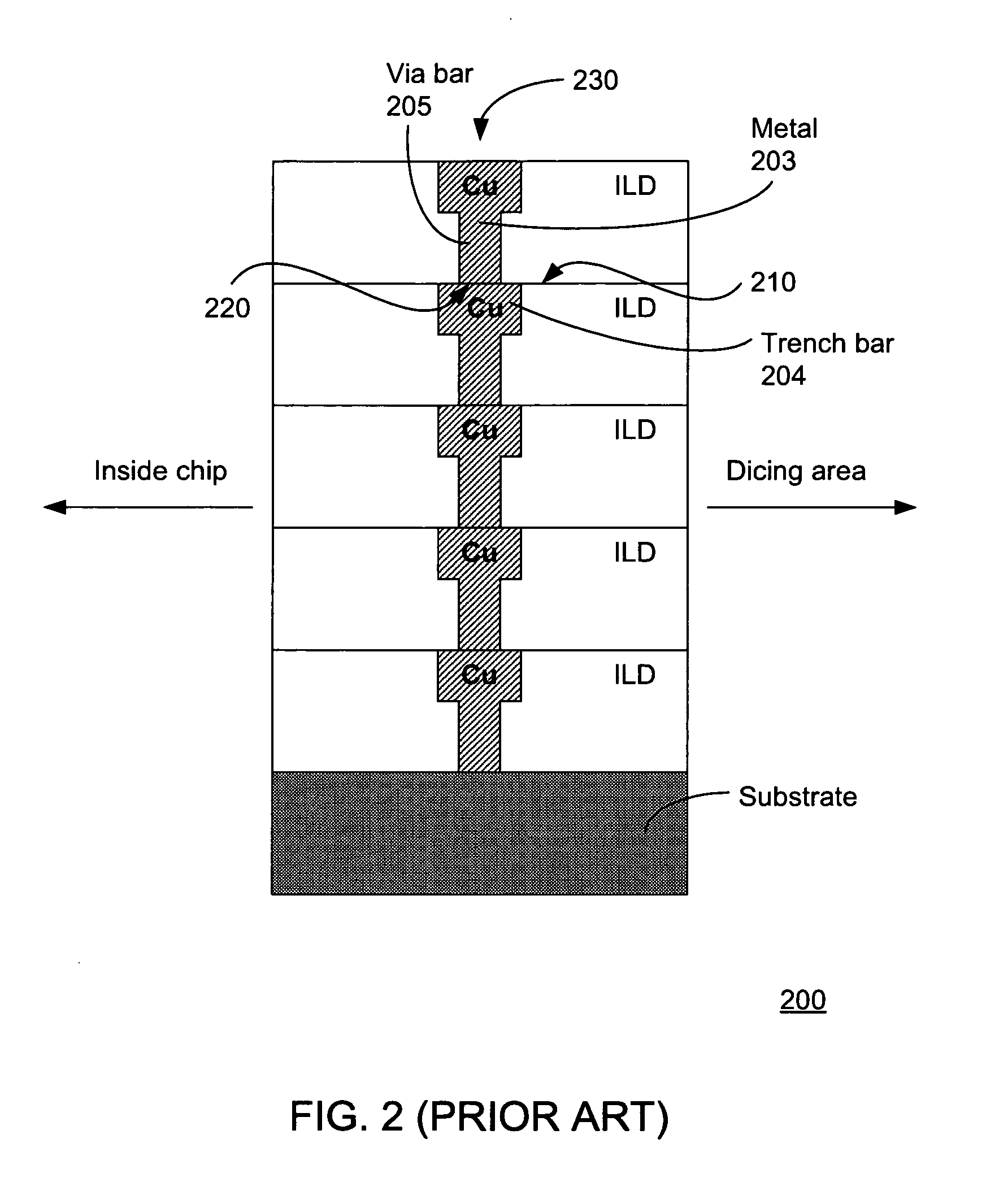

Staggered guard ring structure

InactiveUS20080099884A1Effectively stopAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Embodiments of the present invention provide staggered guard ring structures for stopping cracks from propagating during a dicing operation or by suffering mechanical stress after packaging. In one embodiment, a guard ring structure may comprise staggered metal bars, each of which extends into the ILD underneath it. In one embodiment, the extended portion of a metal bar may overlap a portion of another metal bar underneath it. In one embodiment, the bottom portion of a metal bar extends into the underlying substrate. In all embodiments of the invention, the metal-metal interfaces and the ILD-ILD interfaces do not lie on the same plane, effectively stopping cracks from propagating into the active circuit area through delaminated interfaces.

Owner:KK TOSHIBA

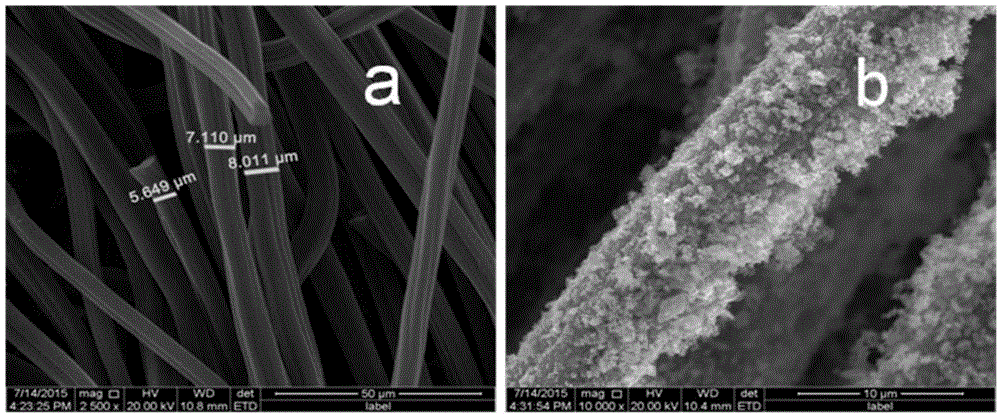

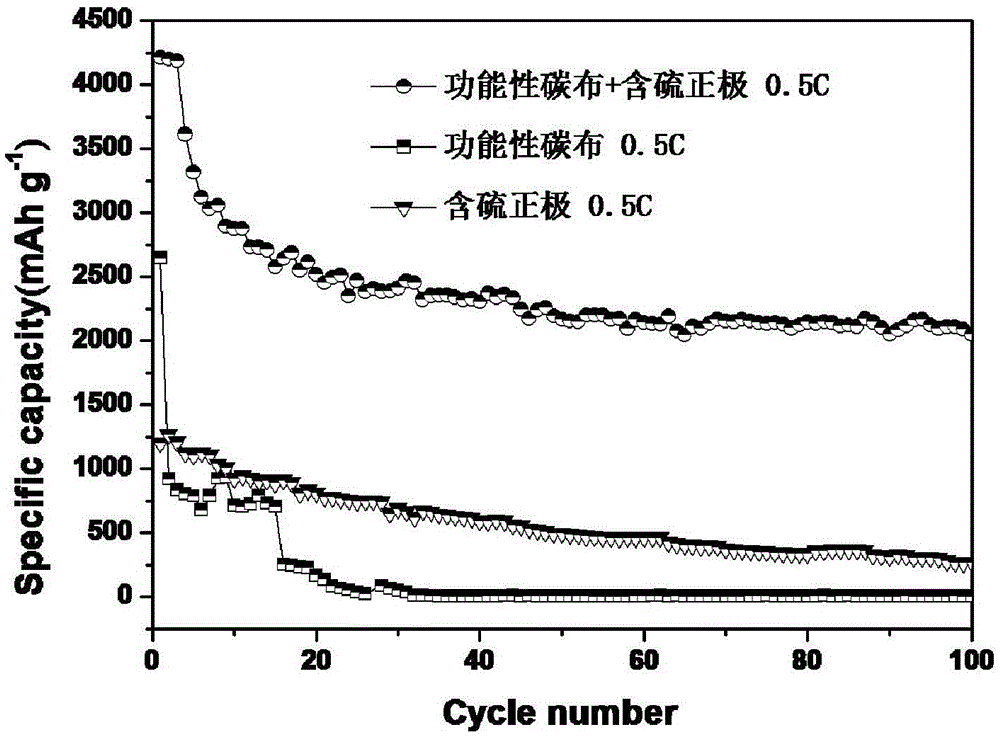

Lithium-sulfur battery based on functional carbon fiber cloth as positive electrode barrier layer

ActiveCN105552282AHigh specific capacityImprove cycle performanceLi-accumulatorsCell component detailsFiberLithium–sulfur battery

The invention relates to a lithium-sulfur battery based on a functional carbon fiber cloth as a positive electrode barrier layer, and belongs to the field of electrochemical batteries. The lithium-sulfur battery based on a functional carbon fiber cloth as a positive electrode barrier layer comprises a sulfur-containing active material positive electrode, a diaphragm, an electrolyte, a metal lithium negative electrode and a foam nickel current collector, and a barrier layer is arranged between the sulfur-containing active material positive electrode and the diaphragm; and the barrier layer is obtained through compounding one or more of metal oxide, metal, metal alloy or metal hydroxide on the surface of the carbon fiber cloth. The above functional substance having catalysis activity and adsorption ability or capable of improving the electrochemical functions of the battery is introduced with the help of the good conductive performance and the three dimensional structure of the carbon fiber cloth, so polysulfide can be effectively intercepted and adsorbed, a shuttle effect is inhibited, and the practical specific capacity and the cycle performances of the lithium-sulfur battery are substantially improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Flexible method for producing oil bases and middle distillates with hydroisomerization-conversion followed by catalytic dewaxing

InactiveUS7267758B2Facility of preparationImprove hydrogenation activityTreatment with plural serial cracking stages onlyMolecular sieve catalystsMolecular sievePtru catalyst

For producing very high quality base stock and for simultaneously producing high quality middle distillates, successive hydroisomerisation and catalytic dewaxmg steps are employed wherein the hydroisomerisation is carried out in the presence of a catalyst containing at least one noble metal deposited on an amorphous acidic support, the dispersion of the metal being 20%-100%. The support is preferably an amorphous silica-alumina. Catalytic dewaxing is carried out in the presence of a catalyst containing at least one hydrodehydrogenating element (group VIII) and at least one molecular sieve selected from ZBM-30, EU-2 and EU-11.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com