Lithium-sulfur battery based on functional carbon fiber cloth as positive electrode barrier layer

A carbon fiber cloth and lithium-sulfur battery technology, applied in the field of electrochemical batteries, can solve the problems of inconvenient large-scale production, defects in preparation and operation, complex preparation, etc., achieve significant value, good application prospects, and increase the effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation method of sulfur-containing positive electrode:

[0029] Sulfur powder is a sulfur-containing active material, conductive carbon black (Super-P) is a conductive agent, and PVDF (5%) NMP solution is a binder, and are mixed at a mass ratio of 4:5:1. After the materials were mixed, they were placed on a magnetic stirrer and stirred at a medium speed for 12 h. After the stirring is completed, the obtained viscous slurry is coated on the aluminum foil of the current collector, and then dried in a vacuum oven at 60° C. for 12 hours, and weighed for later use.

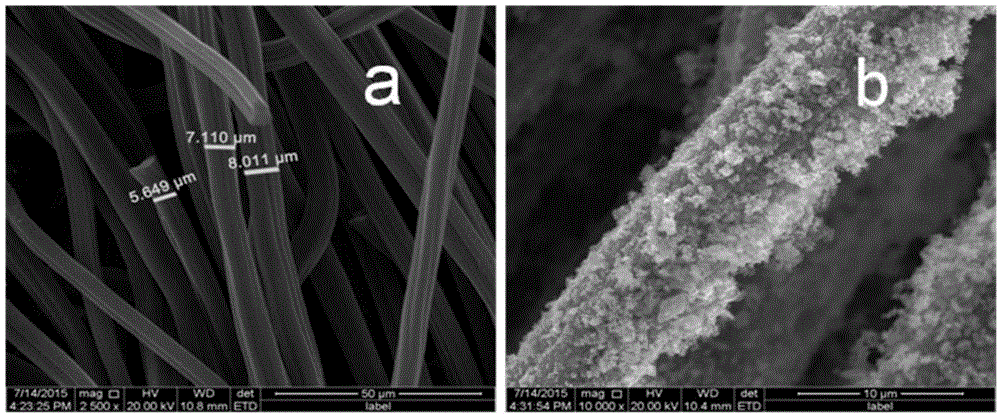

[0030] Pretreatment of carbon fiber cloth:

[0031] The carbon fiber cloth was ultrasonically soaked and washed with 10% dilute nitric acid, deionized water and ethanol for 20 min, respectively. It was then dried in a vacuum oven at 50°C for 12 hours. Finally, the carbon fiber cloth was cleaned with a plasma cleaning machine. During the cleaning process, the working voltage was set to 700V, and the oxyge...

Embodiment 2

[0039] The pretreatment of the carbon fiber cloth barrier layer and the preparation method of the sulfur-containing positive electrode are the same as in Example 1.

[0040] Preparation of functional carbon fiber cloth barrier layer:

[0041] According to titanium hydroxide (Ti(OH) 4 ) and carbon fiber cloth at a mass ratio of 1:8 to weigh titanium hydroxide, mix titanium hydroxide and PVDF (5%) NMP solution at a mass ratio of 4:1, and stir for 5 hours at a medium speed. After the slurry reaches an appropriate viscosity, it is coated on carbon fiber cloth and dried in a vacuum oven at 40°C for 24 hours to obtain a functional carbon fiber cloth. Then the functional carbon fiber cloth was cut into 12mm discs, weighed and vacuum dried again.

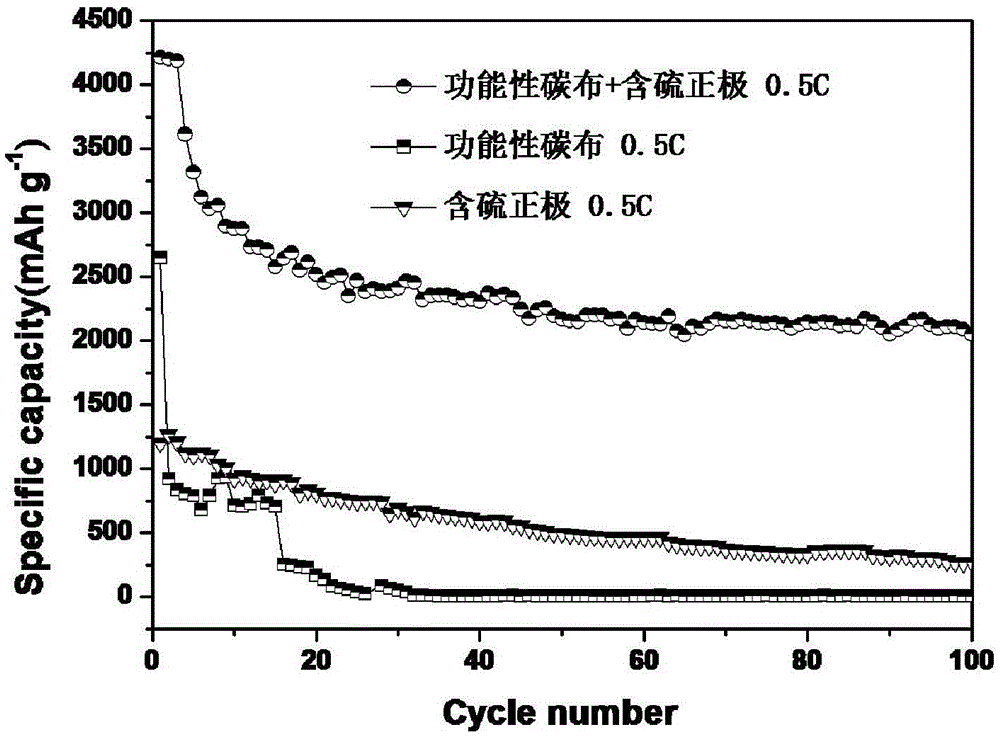

[0042] When the battery is assembled, the battery without the functional carbon fiber cloth barrier layer without the sulfur-containing positive electrode and the battery without the functional carbon fiber cloth barrier layer with the su...

Embodiment 3

[0045] The pretreatment of the carbon fiber cloth barrier layer is consistent with Example 1.

[0046] Preparation method of sulfur-containing positive electrode:

[0047] Sulfur powder is a sulfur-containing active material, acetylene black is a conductive agent, and PVDF (5%) NMP solution is a binder, mixed at a mass ratio of 7:2:1. After the materials were mixed, they were placed on a magnetic stirrer and stirred at a medium speed for 12 h. After the stirring is completed, the obtained viscous slurry is coated on the aluminum foil of the current collector, and then dried in a vacuum oven at 60° C. for 12 hours, and weighed for later use.

[0048] Preparation of functional carbon fiber cloth barrier layer:

[0049] Cobalt tetroxide (Co 3 o 4 ) was ultrasonically dispersed in ethanol to obtain a suspension. And under vacuum filtration, compound tricobalt tetroxide and carbon fiber cloth at a mass ratio of 1:5, and dry in a vacuum oven at 60°C for 16 hours to obtain funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com