Positive electrode protective material of lithium sulfur battery and application thereof

A technology for lithium-sulfur batteries and protective materials, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as weak force, high capacity of weakened materials, and difficulty in large-scale expansion, so as to suppress loss and increase energy Effects of conversion efficiency, rate performance, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The embodiment of the present invention also provides a method for preparing a positive electrode of a lithium-sulfur battery with a protective layer, comprising the following steps:

[0095] (1) Take the current collector, and prepare a positive electrode active material layer on the current collector;

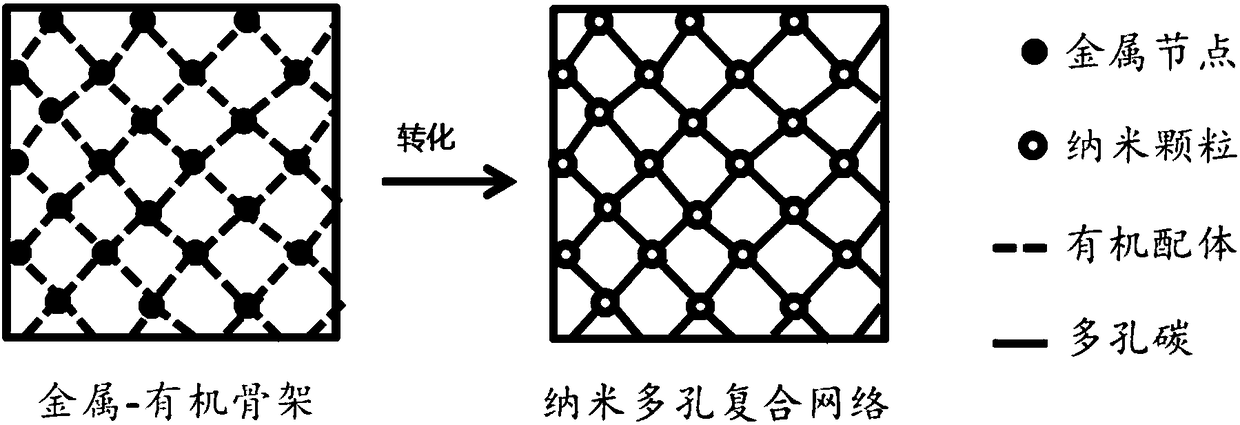

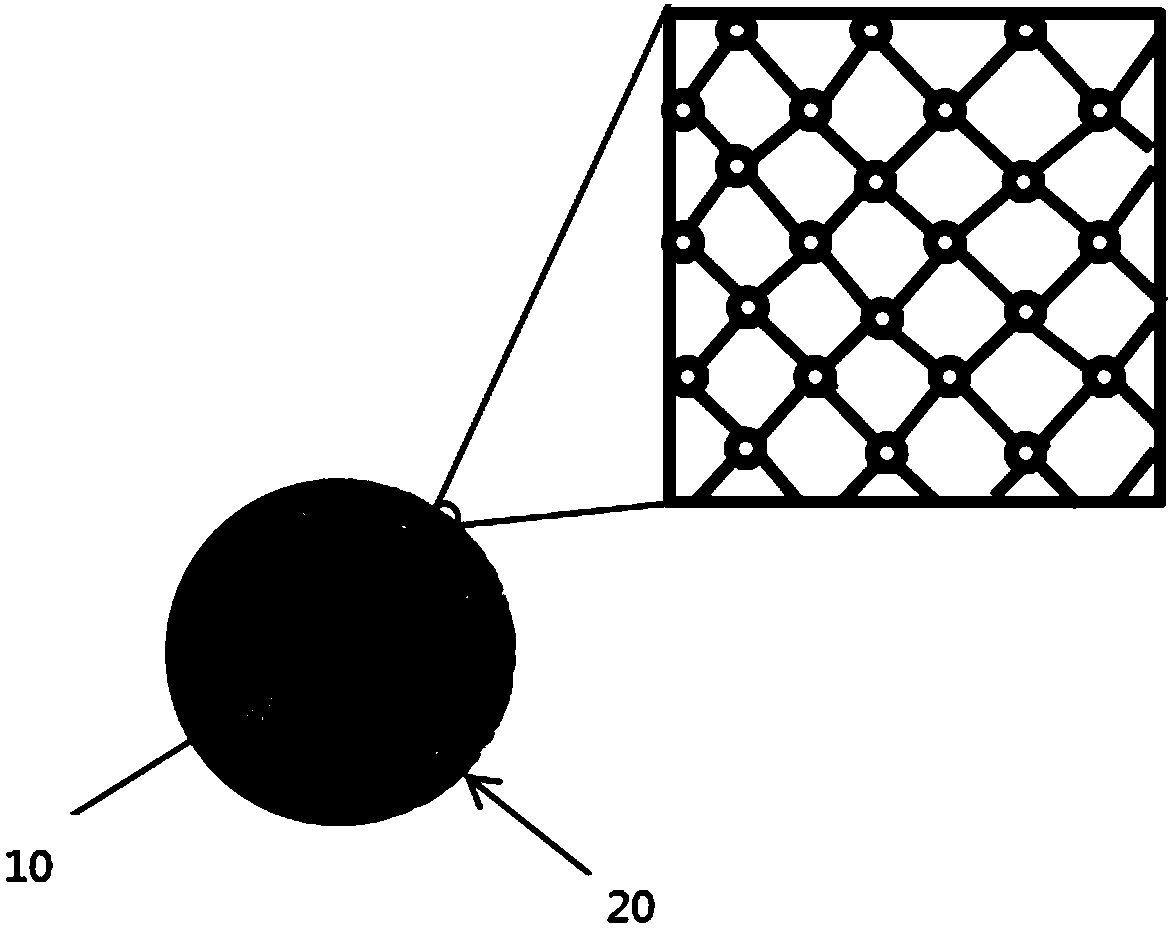

[0096] (2) Under an inert atmosphere, the metal-organic framework is subjected to a heat treatment at 500-1200° C., so that the metal-organic framework is converted into a nanoporous carbon network embedded with metal nanoparticles, and then the metal nanoparticle embedded The nanoporous carbon network is subjected to oxidation, vulcanization, nitriding or phosphating treatment, so that the metal nanoparticles undergo a compound reaction to form metal compound nanoparticles or metal-metal compound composite nanoparticles, that is, the positive electrode protection material for lithium-sulfur batteries is obtained. The lithium-sulfur battery cathode protection material ...

Embodiment 1

[0129] A method for preparing a lithium-sulfur battery positive electrode material with a protective layer by a coating method, comprising the following steps:

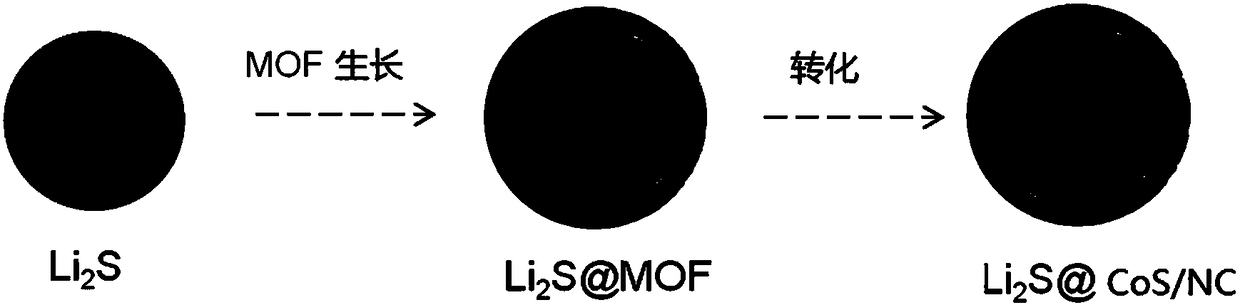

[0130] (1) Weigh 1.44g of Co(NO 3 ) 2 ·6H 2 O and 3.24g of dimethylimidazole were dissolved in 100mL of ethanol to obtain Co(NO 3 ) 2 ·6H 2 O ethanol solution and dimethylimidazole ethanol solution; 5g lithium sulfide (Li 2 S) the powder is dispersed in the dimethylimidazole ethanol solution, and 5wt% polyvinylpyrrolidone (PVP) is added to obtain a mixed solution; the gained mixed solution is mixed with the above-mentioned Co(NO 3 ) 2 ·6H 2 The O ethanol solution was mixed and stirred for 10 minutes and then allowed to stand for 8 hours. The precipitate was filtered, washed with ethanol, and then dried in vacuum at 80°C for 12 hours to obtain a lithium sulfide composite material (Li 2 S@MOF).

[0131] (2) the above product Li 2 S@MOF was placed in a crucible in a tube furnace, and the sample was heated to 60...

Embodiment 2

[0136] A method for preparing a lithium-sulfur battery positive electrode material with a protective layer by a filling method, comprising the following steps:

[0137] (1) Weigh 0.74g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50mL ethanol to obtain A solution, and 0.72g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 50mL ethanol to obtain B solution, 3.24g of dimethylimidazole was dissolved in 100mL ethanol to obtain C solution, then A and C solutions were mixed, after stirring for 20 minutes, B solution was added to the mixed solution, and the stirring was continued for 20 minutes After 2 minutes of standing still for 2 hours, the obtained purple precipitate was filtered, washed and then dried in vacuum at 80°C for 12 hours to obtain a composite metal-organic framework ZnCo-mIM material; the obtained composite metal-organic framework material was placed in a crucible in a tube furnace In , the sample was heated to 910°C at a heating rate of 10°C / min under a nitrogen atmosphere, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com