Janus particle with double properties and preparation method thereof

A particle and colloidal particle technology, applied in the field of materials, can solve the problems of incomplete phase separation, Janus particles cannot be called real Janus particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

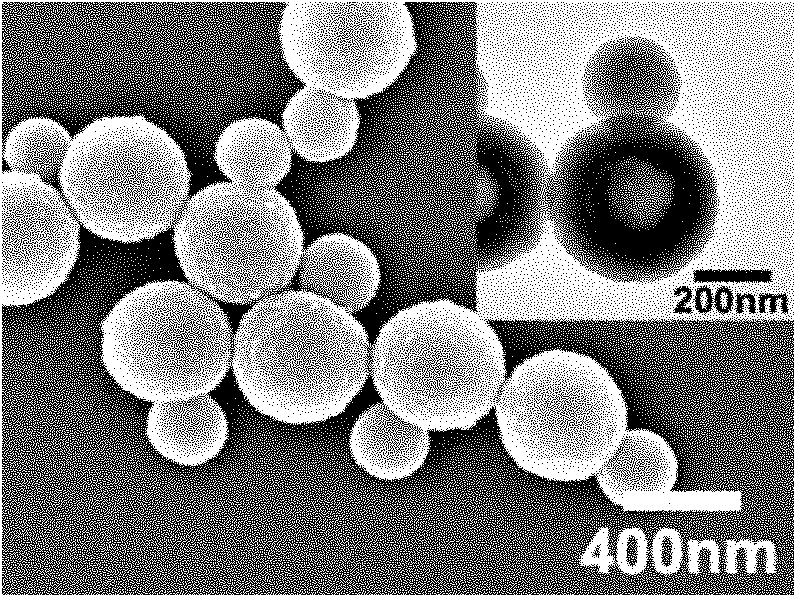

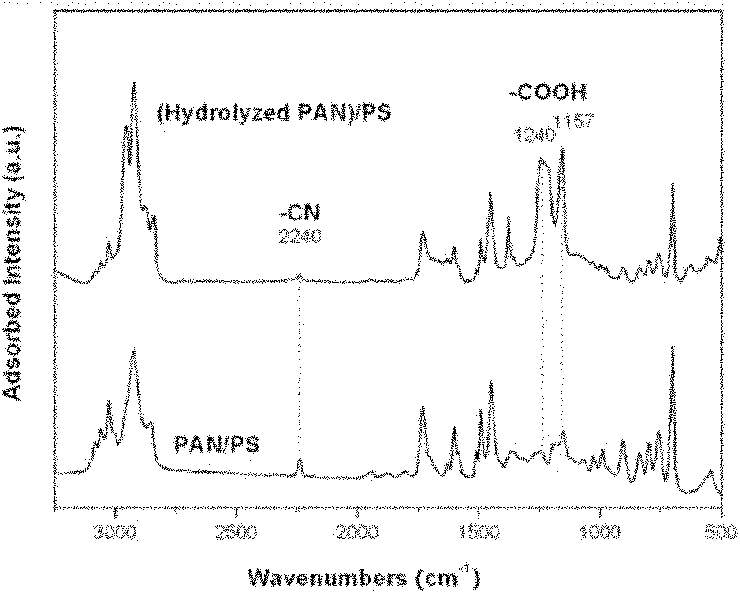

[0042] Embodiment 1, mass preparation Janus particles

[0043] Disperse 0.5 g of cross-linked polyacrylonitrile hollow spherical particles with a diameter of 400 nm and a degree of cross-linking of 50% (thickness of the shell layer is 100 nm) in 15 g of water, and ultrasonically disperse evenly to obtain a seed solution with a concentration of 3.2% by mass; in addition , 0.25g monomer styrene (St), 0.75g crosslinking agent divinylbenzene (DVB), 0.5g emulsifier sodium dodecylsulfonate (SDS), 0.5g mass percent concentration of 1% The aqueous solution of the potassium persulfate (KPS) as initiator and 15g water, mix supersonic emulsification, obtain emulsion system, in this emulsion system, the mass percent concentration of monomer styrene is 1.5%, the cross-linking agent divinylbenzene The mass percentage concentration is 4.4%, the mass percentage concentration of emulsifier sodium dodecylsulfonate is 2.9%, and the mass percentage concentration of initiator potassium persulfate ...

Embodiment 2

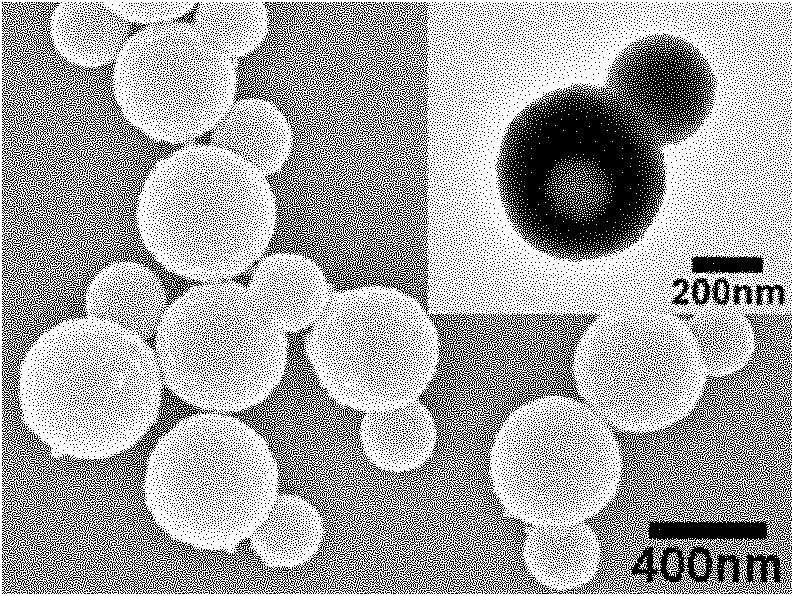

[0045] Embodiment 2, mass preparation Janus particles

[0046] Disperse 0.5 g of cross-linked polyacrylonitrile solid spherical particles with a diameter of 1 μm and a cross-linking degree of 50% in 15 g of water, and ultrasonically disperse them uniformly to obtain a seed solution with a concentration of 3.2% by mass; in addition, 0.25 g of monomeric benzene Ethylene (St), 0.75g crosslinking agent divinylbenzene (DVB), 0.5g emulsifier sodium dodecylsulfonate (SDS), 0.5g mass percent concentration is 1% potassium persulfate as initiator The aqueous solution of (KPS) and 15g water are mixed and ultrasonically emulsified to obtain an emulsion system. In this emulsion system, the mass percent concentration of monomer styrene is 1.5%, and the mass percent concentration of crosslinking agent divinylbenzene is 4.4%. , the mass percent concentration of emulsifier sodium dodecyl sulfonate is 2.9%, the mass percent concentration of initiator potassium persulfate is 0.03%; above-mention...

Embodiment 3

[0047] Embodiment 3, mass preparation Janus particles

[0048] Disperse 0.5g of crosslinked polymethyl methacrylate hollow spherical particles (shell thickness of 100nm) with a diameter of 400nm and a crosslinking degree of 50% in 15g of water, and ultrasonically disperse them uniformly to obtain seeds with a mass percentage concentration of 3.2%. Solution; In addition, with 0.25g monomer styrene (St), 0.75g crosslinking agent divinylbenzene (DVB), 0.5g emulsifier sodium dodecylsulfonate (SDS), 0.5g mass percent concentration is The aqueous solution of 1% potassium persulfate (KPS) as initiator and 15g water, mixing supersonic emulsification, obtain emulsion system, in this emulsion system, the mass percent concentration of monomer styrene is 1.5%, crosslinking agent divinyl The mass percent concentration of basebenzene is 4.4%, the mass percent concentration of emulsifier sodium dodecylsulfonate is 2.9%, and the mass percent concentration of initiator potassium persulfate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com