Preparation method of metal-nonmetal hollow Janus particles

A non-metallic, hollow technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of inapplicable large particle size Janus particle preparation, complex preparation process, etc., and achieve simple and fast preparation method , high activity, high metal activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention discloses a method for preparing metal-nonmetal hollow Janus particles. The method mainly includes the following steps:

[0034] Step 1: Pretreat the hollow glass microspheres, the pretreatment process is:

[0035] Flotation treatment: the hollow glass beads are subjected to ultrasonic and centrifugal static treatment to reduce the impact of debris on the quality of subsequent coating particles;

[0036] Hydroxylation treatment: add the flotation hollow glass microspheres into the NaOH solution, heat and stir at 40-120°C for 20-60 minutes, stand still to take the upper layer mixture, and filter until the filtered water is neutral; among them, the NaOH solution The concentration is 20-40g / L;

[0037] Amination treatment: Add the hydroxylated hollow glass microspheres to the mixture of silane coupling agent, ethanol and deionized water, stir at 30-100°C for 40-90min, after the reaction is completed, filter and wash with ethanol , and then cleaned with deio...

Embodiment 1

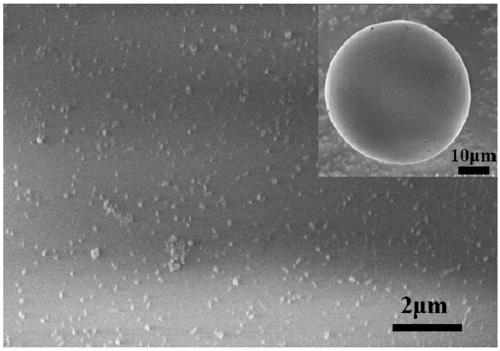

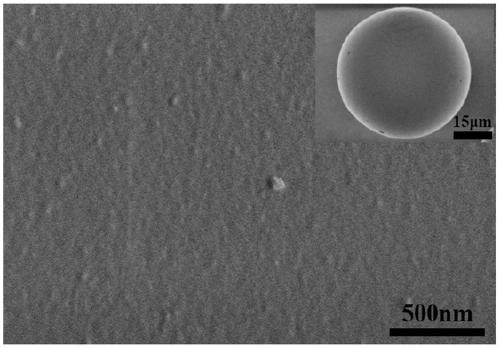

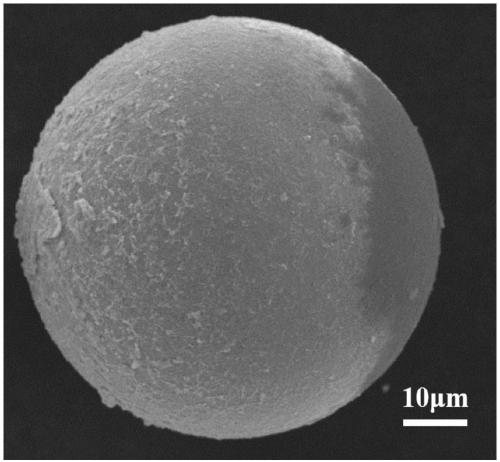

[0045] Weigh 10 g of hollow glass microspheres with a diameter distribution of φ40-120 μm (H60, Sinosteel Ma’anshan Mining Institute New Material Technology Co., Ltd.), add the hollow glass microspheres to deionized water and ultrasonicate for 5 minutes to form a milky suspension. Centrifuge and separate, take the upper layer of glass microbead mixture, and dry it at 110°C for later use. Add the dried hollow glass microspheres into 250ml, 30g / L NaOH solution, heat and stir, and treat at 80°C for 40min. Stand still to take the upper layer mixture, and filter it with deionized water until the filtered water is neutral, and dry the glass beads for later use. Then the hydroxylated hollow glass microspheres are added to the mixed solution of silane coupling agent, ethanol and deionized water, wherein the amount of silane coupling agent Kh550 is 1% of the mass of hollow glass microspheres, ethanol and deionized water The volume ratio of water is 1:1, and it is stirred at 60°C for 6...

Embodiment 2

[0057] The difference between this example and Example 1 is that the silane coupling agent is Kh560, and the morphology and properties of the prepared Janus particles are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com