Producing method of micromanipulation holding needle

A manufacturing method and a micromanipulation technique, which are applied in the field of the manufacture of micromanipulation holding needles, can solve the problems of porcine oocyte damage, inability to fix, and the holding needles are expensive, and achieve a simple and fast manufacturing method and reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the making of holding fixed needle for micromanipulation

[0025] The manufacturing method of the micromanipulation holding needle provided by the present invention comprises the following steps:

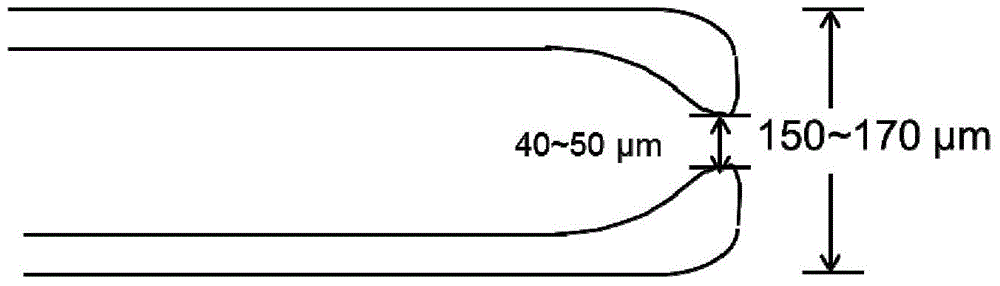

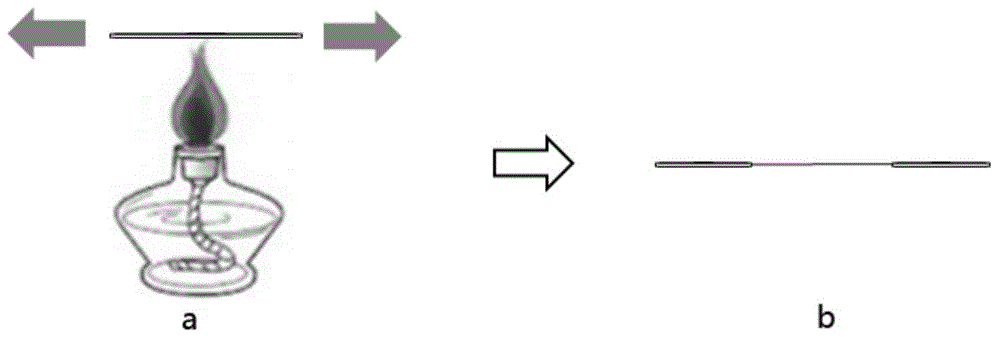

[0026] (1) stretching: such as image 3 As shown, fix the BJ-40 capillary glass tube (outer diameter 1.0mm, inner diameter 0.8mm, length 100mm) with both hands, rotate and heat the middle part on the outer flame of the alcohol lamp, feel the melting force and stretch quickly, and leave the outer flame of the alcohol lamp at the same time flame. Select a part with an outer diameter of 150-170 μm, and use a small grinding wheel to cut off one end.

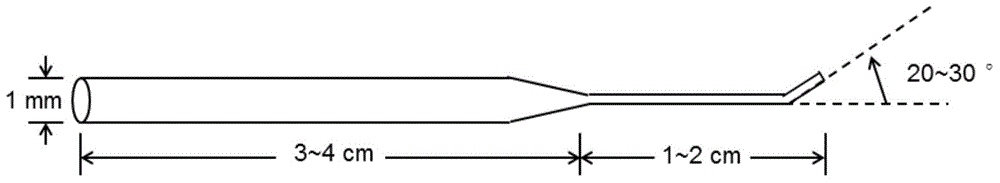

[0027] Such as figure 1 and figure 2 As shown, the outer diameter of the capillary glass tube before stretching is 1.0 mm, and the inner diameter is 0.8 mm; after stretching, the outer diameter of the thinned part is 150-170 μm, and the length is 1-2 cm. If the part with an outer diameter of 150-170 μm cannot be ...

Embodiment 2

[0032] Example 2. Fixing porcine oocytes with micromanipulation needles

[0033] Utilize the holding pins and commercialized holding pins prepared by the manufacturing method provided by the present invention to respectively fix porcine oocytes for micromanipulation, and compare the experimental results:

[0034] Figure 7 Photographs of micromanipulation of porcine oocytes during immobilization using commercially available holding pins, courtesy of Figure 7 As can be seen, Figure 7 (b) and Figure 7 The needle insertion operation in (c) causes the oocyte to slide away from the holding needle, where the arrow in the figure is the direction of sliding; Figure 8 The micromanipulation provided by the present invention holds fixed needle and fixes the photo of porcine oocyte to carry out micromanipulation, by Figure 8 (b) and Figure 8 (c) It can be seen that inserting the needle from the side can make the oocyte rotate in situ, but it will not break away from the holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com