Static electricity spinning prepared fixed enzymic electrode and method thereof

An electrospinning and enzyme electrode technology is applied in the field of immobilized enzyme electrodes and immobilized enzyme electrodes to achieve the effects of simple preparation method, good response performance and improved electron transport capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use Al with uniform particle size for the gold substrate 2 O 3The powder is polished on deer skin, washed repeatedly with twice distilled water, and then placed in a phosphate buffer solution (PBS) with pH=6.8 and scanned by cyclic voltammetry until it is stable. Weigh the PVA into deionized water, heat and stir in a water bath to completely dissolve the PVA, and cool to room temperature under stirring to prepare a PVA aqueous solution with a concentration mass volume ratio of 8%. Take 5ml of the prepared PVA aqueous solution and add 198μL of glucose oxidase to ensure that the GOD concentration in the solution is 200U / ml. 120μL of nano-gold solution was added to the PVA aqueous solution. The PVA / glucose oxidase mixed solution added with the nano gold solution is injected into a syringe with a needle, and the syringe is fixed on the syringe pump. Place a grounded receiving screen (aluminum foil) at a distance of 10 cm from the needle, and open a hole in the center of the alu...

Embodiment 2

[0031] The copper electrode was used as the base electrode of the working electrode, and the others were the same as in Example 1.

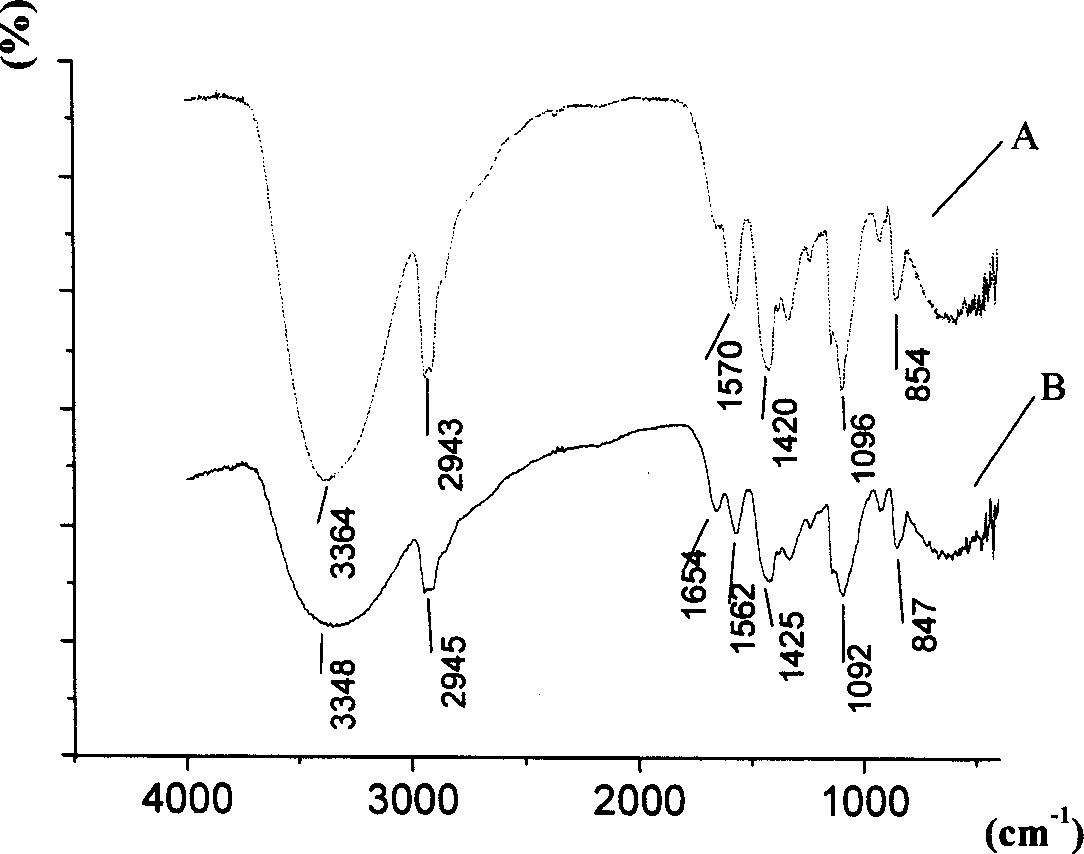

[0032] image 3 This is a comparison between the electrode without enzyme and the electrode with enzyme on the copper electrode substrate. (A) Upper 3364cm -1 The broad peaks on the left and right are the stretching vibration peaks of O-H in PVA, and are also the characteristic absorption peaks of PVA; 2943cm -1 Left and right are -CH 2 Peak of stretching vibration; 1420cm -1 Left and right are O-H and C-H bending vibration and -CH 2 Absorption peak caused by bending vibration; 1096cm -1 Left and right are the absorption peaks of C-O (multi-associative) single bond stretching and O-H bending vibration, 854cm -1 The left and right are characteristic peaks related to the isotactic sequence. The characteristic absorption peak of PVA appears on the PVA / GOD spectrum [Figure (B)]. At the same time, since the stretching vibration peak of N-H in the glucose...

Embodiment 3

[0034] The platinum electrode is used as the base electrode of the working electrode, and the other is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com