Silicon dioxide modified carbon dot fluorescent powder and fluorescent silicone rubber

A silicon dioxide and phosphor technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of polluted environment, high price, harmful to human body, etc., achieve excellent fluorescence performance, improve thermal stability and anti-aging performance, Simple and quick preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a carbon dot phosphor modified by silica, which is prepared by the following steps:

[0030] Dissolve 4.8g of WL-180 type silicon dioxide in 100ml of deionized water, stir evenly to obtain a silicon dioxide suspension, and set aside; take 0.5g of citric acid, 10ml of KH792, and 140ml of deionized water, mix and stir for 30min, and then add the aforementioned two The silicon oxide suspension was stirred for 30 minutes to obtain a mixed solution; the mixed solution was put into a tetrafluoroethylene reactor, heated to 180°C under vacuum, and after 6 hours of reaction, centrifuged 3 times with deionized water at a speed of 8000r / min time 10min, then vacuum dry.

Embodiment 2

[0032] This embodiment provides a carbon dot phosphor modified by silica, which is prepared by the following steps:

[0033] Dissolve 3g of WL-180 type silica in 100ml of deionized water, stir well to obtain a silica suspension, and set aside; take 0.1g of citric acid, 5ml of KH792, and 140ml of deionized water, mix and stir for 30min, then add the aforementioned silica Stir the silicon suspension for 30 minutes to obtain a mixed solution; put the mixed solution into a tetrafluoroethylene reactor, heat it to 150°C under vacuum, react for 3 hours, and centrifuge 3 times with deionized water at a speed of 8000r / The min time is 10min, and it is vacuum-dried.

Embodiment 3

[0035] This embodiment provides a carbon dot phosphor modified by silica, which is prepared by the following steps:

[0036] Dissolve 6g of WL-180 silicon dioxide in 100ml of deionized water, stir well to obtain a silicon dioxide suspension, and set aside; take 2g of citric acid, 15ml of KH792, and 140ml of deionized water, mix and stir for 30min, then add the aforementioned silicon dioxide The suspension was stirred for 30 minutes to obtain a mixed solution; the mixed solution was put into a tetrafluoroethylene reactor, heated to 200°C under vacuum, and after 12 hours of reaction, centrifuged 3 times with deionized water at a speed of 8000r / min The time is 10 minutes, and vacuum drying is obtained.

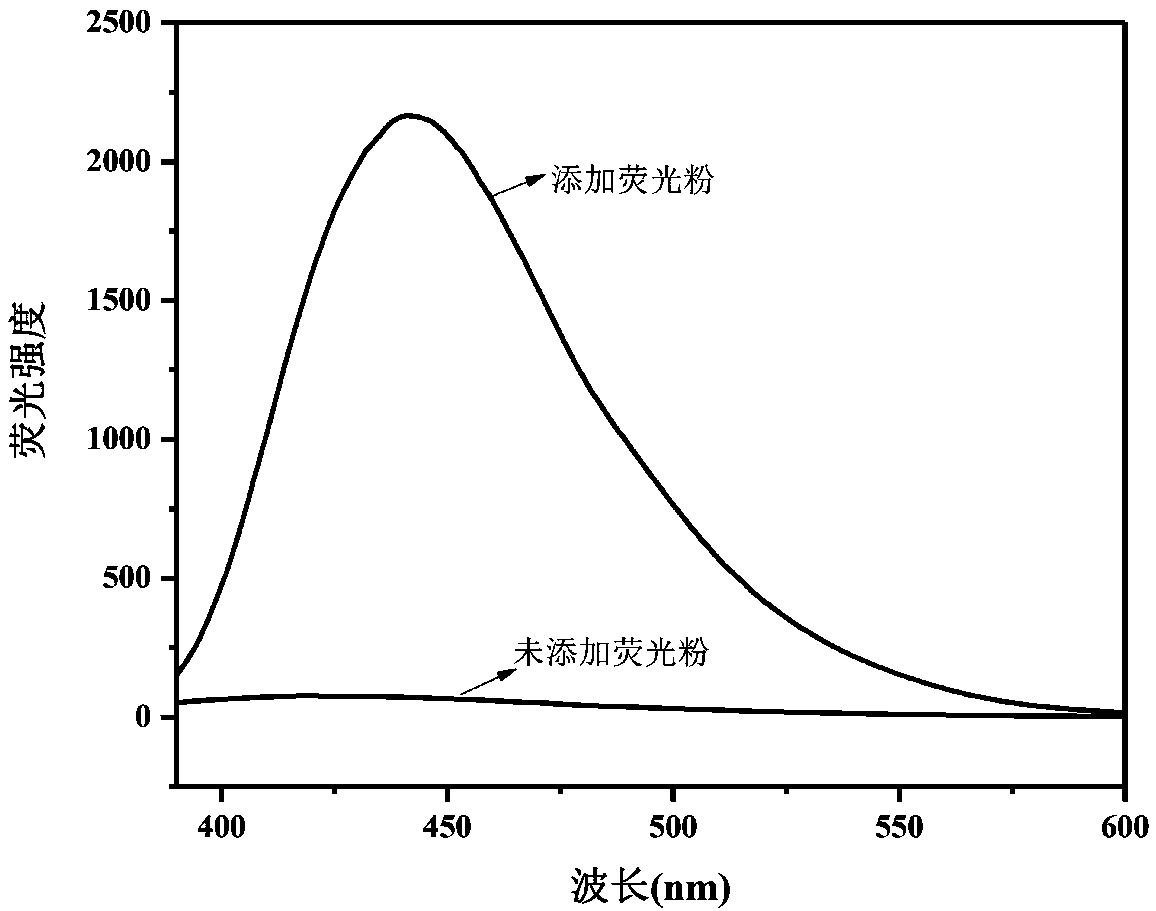

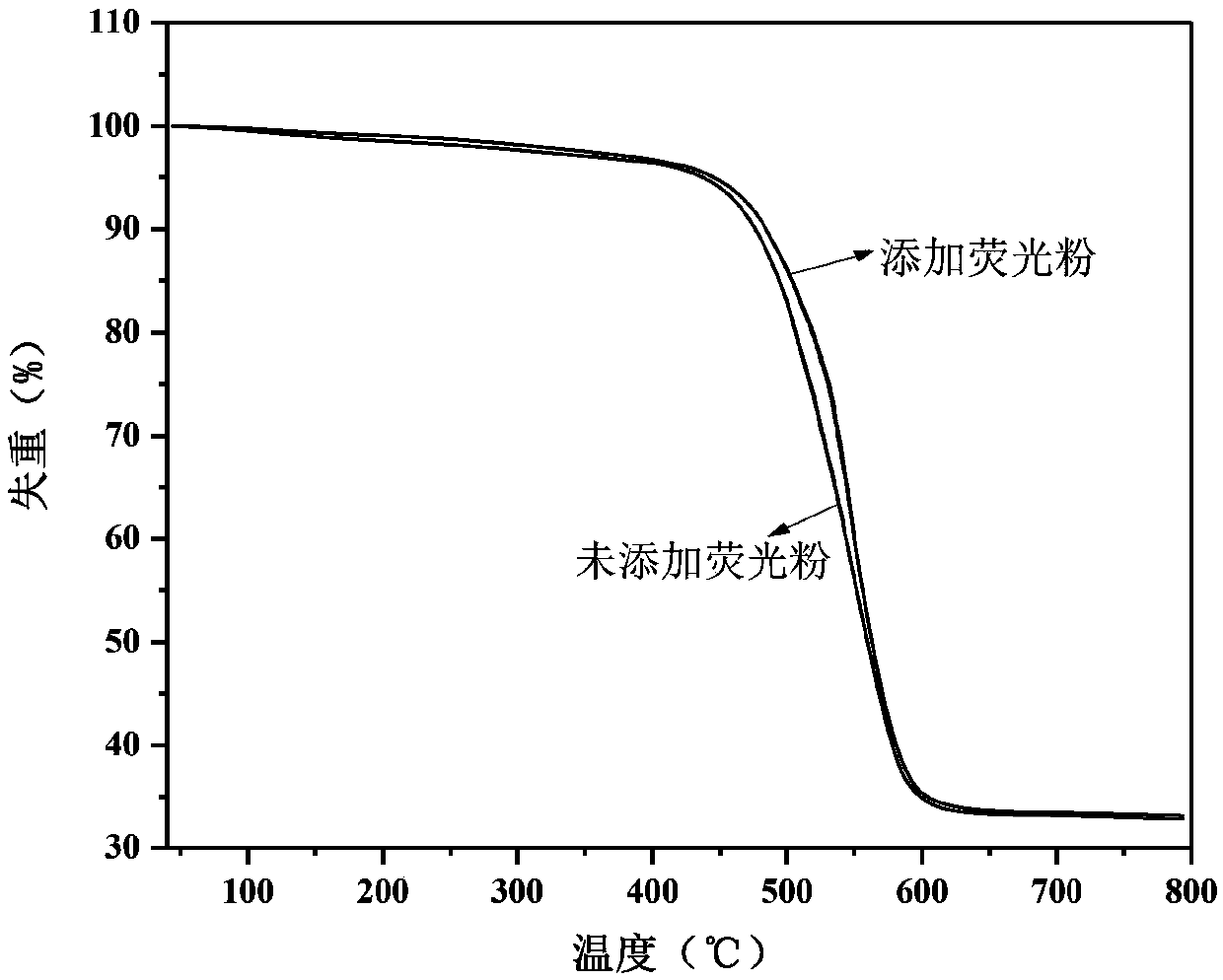

[0037] The silica-modified carbon-dot phosphors provided in Examples 1 to 3 above are all white powders with strong fluorescent effects; among them, the fluorescent effect and particle size uniformity of the carbon-dot phosphors provided in Example 1 optimal. The transmission e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com