Patents

Literature

66 results about "Silica suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic precipitated silica

Hydrophobic precipitated silica having the physical / chemical parameters:is produced by mixing a precipitated silica suspension with a silane emulsion and drying it. The hydrophobic precipitated silica may be used for the production of defoamers and in papermaking.

Owner:DEGUSSA AG

High transparent polyester film and process for producing the same

The high transparency polyester film contains nano level silica of grain size 20-50 nm and micron level silica of grain size 1.2-2.0 microns. The nano level silica accounts for 50-2000 ppm of total polyester film weight, and the micron level silica 1-300 ppm. The production process of the high transparency polyester film includes the first preparation of silica suspension, the subsequent conventional polymer producing course to produce polyester slice, and final conventional melting extrusion of the slice and bi-directional stretching. The product of the present invention has high transparency, waterproof property, blocking property, heat resistance and antiaging property.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

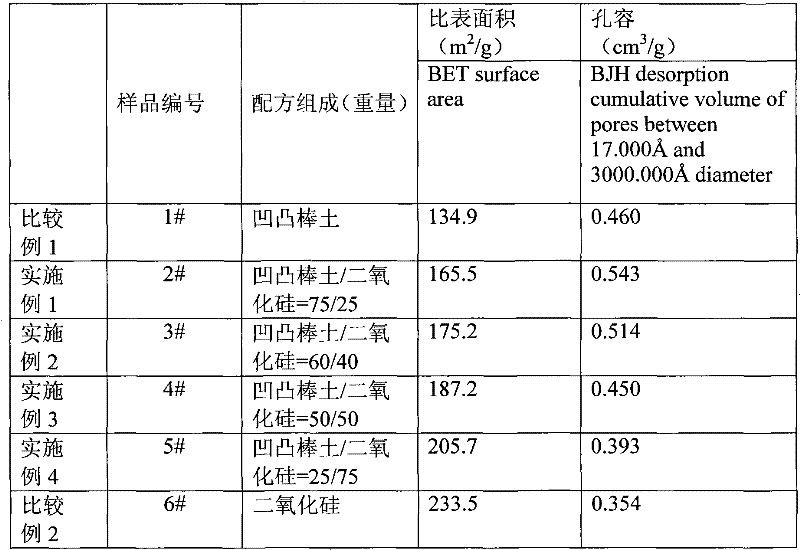

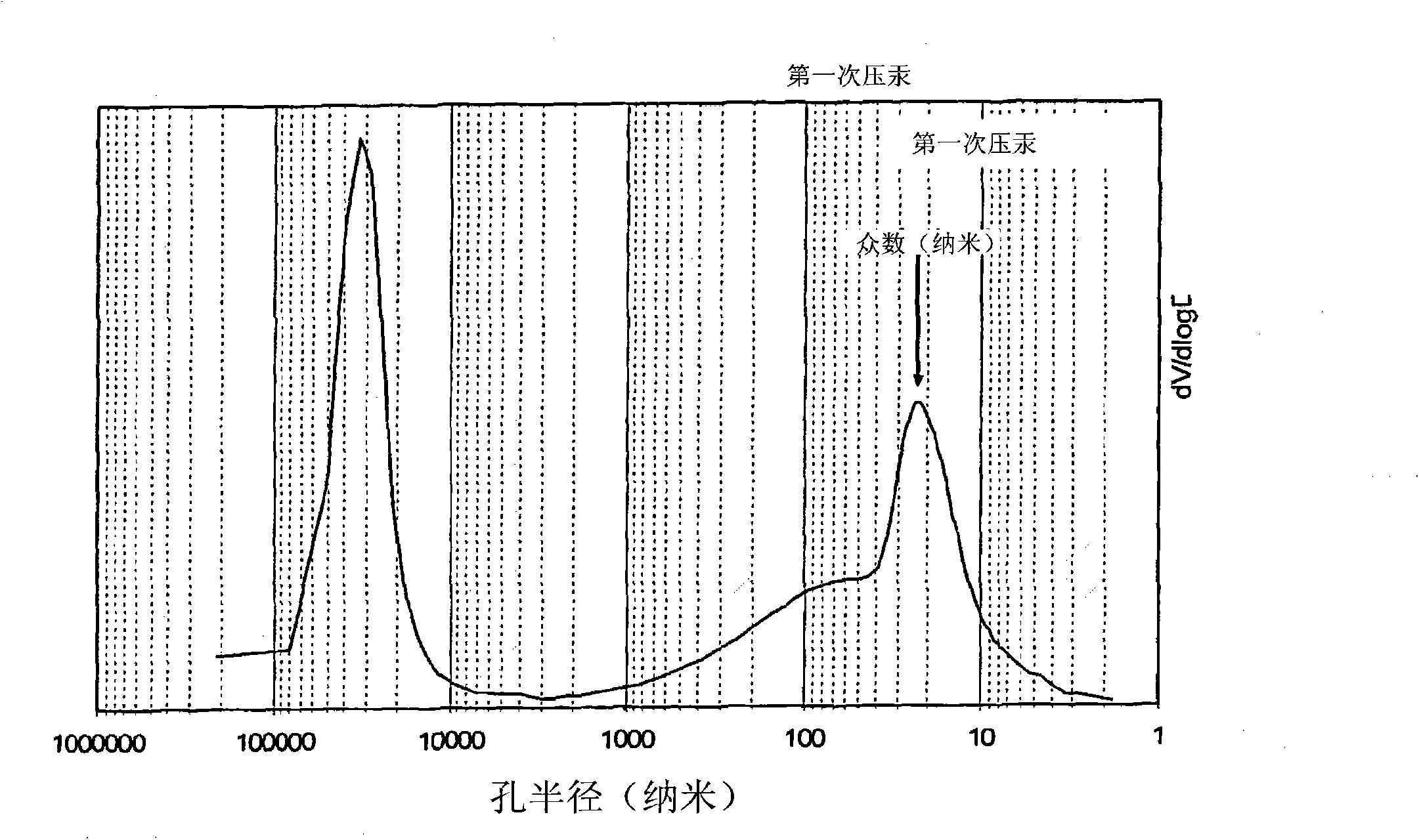

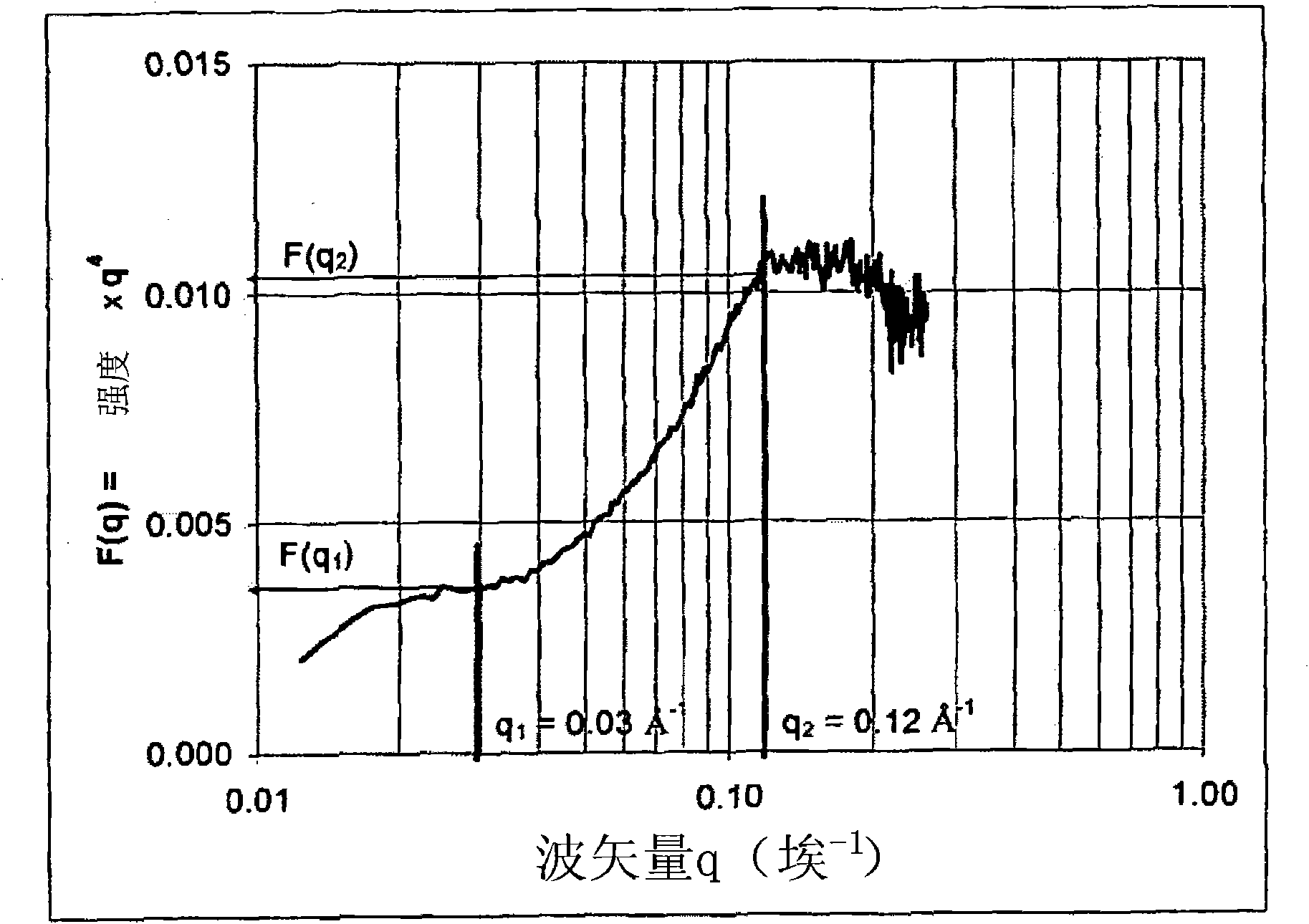

A kind of attapulgite/silicon dioxide composite powder and its preparation method

ActiveCN102284279AIncreased secondary voidsHigh mesopore contentCatalyst carriersOther chemical processesSorbentSilica suspension

The invention discloses an attapulgite / silicon dioxide composite powder and a preparation method thereof. The composite powder comprises attapulgite and silicon dioxide in the weight ratio of 25:75-75:25. The preparation method of the composite powder comprises the following steps of: preparing the attapulgite and water into attapulgite suspension; uniformly mixing the amount of silicon dioxide suspension or silicasol and the attapulgite suspension prepared by the step a to obtain mixed solution; performing spray drying on the obtained mixed solution to obtain the attapulgite / silicon dioxide composite powder. The attapulgite / silicon dioxide composite powder prepared by the invention does not contain organic components and has high adsorption and dispersion performance; the manufacturing cost is greatly reduced; and the attapulgite / silicon dioxide composite powder is an ideal porous inorganic nano-adsorbent and is widely applied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-hydrophobic nano-cellulose membrane and preparation method thereof

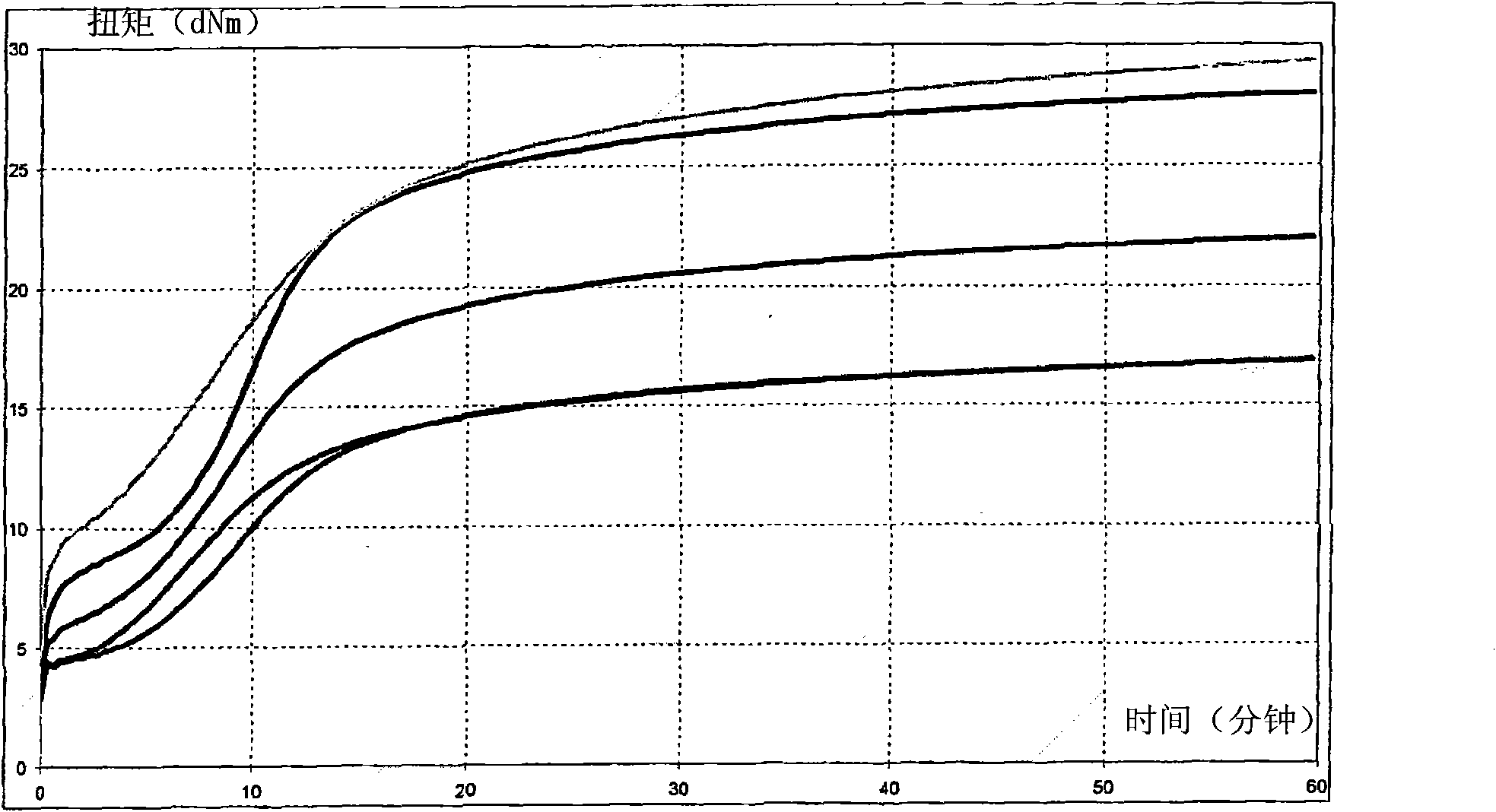

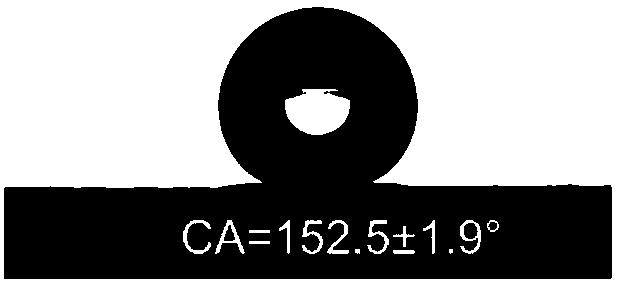

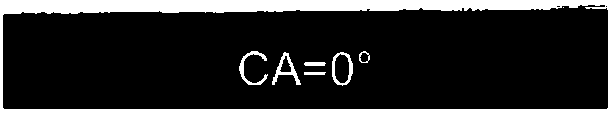

The invention discloses a preparation method for preparing a super-hydrophobic nano-cellulose membrane by using a nano-cellulose membrane impregnated super-hydrophobic nano-silica suspension liquid. The preparation method of the super-hydrophobic nano-cellulose membrane comprises the following steps: (1) preparing a membrane by using cellulose nanofibers; (2) carrying out modification treatment onnano-silica to obtain a super-hydrophobic nano-silica solution; and (3) dipping the cellulose nanofiber membrane by using the super-hydrophobic nano-silica solution, putting the membrane into a drying oven for drying every time when dipping is finished, and repeatedly carrying out dipping and drying to obtain the super-hydrophobic nano-cellulose membrane. The super-hydrophobic nano-cellulose membrane has the advantages that the membrane is high in strength and low in cost, is free of pollution, can be completely degraded, has a simple preparation process, is hydrophobic and environmentally friendly, and can be applied to the fields of food packaging, degradable agricultural membranes, surface modification and the like.

Owner:GUANGXI UNIV

Method for aminolysis of fluorosilicone compounds and separation of fluorine and silicon

InactiveCN1884077AOvercoming the disadvantages of separation methodsImprove conversion rateSilicon halogen compoundsAmmonium halidesPhosphoric acidSilicon tetrafluoride

The invention discloses a separating method of aminolysis and hydrofluosilicic element of silicofluoride, which comprises the following steps: 1. adding solid ammonium fluosilicate or silicon tetrafluoride gas in the saturated ammonium fluoride circulating reacting liquid; putting raw material amino to proceed aminolysis reaction; 2. reducing slurry temperature; screening the reacted slurry; 3. filtering the screened silica suspension and ammonium fluoride crystal slurry to obtain saturated ammonium fluoride solution, silica solid and ammonium fluoride crystal; returning to former procedures as the circulating reacting liquid; washing the ammonium fluoride crystal; drying through normal drying method to obtain high-purity product. The invention can improves technological and economical index, which is fit for wet-producing phosphoric acid, phosphate fertilizer and other phosphor businesses.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

Transparent super-hydrophobic coating as well as preparation method and application thereof

The invention discloses a transparent super-hydrophobic coating as well as a preparation method and application thereof. The preparation method comprises the following steps that (1) polymethyl methacrylate / silicon dioxide microspheres with core / shell structures are subjected to modified treatment by using fluoroalkyl silane so as to form a hydrophobic polymethyl methacrylate / silicon dioxide suspension; and (2) a glass substrate is uniformly coated with a polydimethylsiloxane adhesive, then the polymethyl methacrylate / silicon dioxide suspension is deposited on polydimethylsiloxane by using a scraping rod, and finally, a sample is solidified at room temperature so as to obtain the transparent super-hydrophobic coating. The preparation method for the transparent super-hydrophobic coating issimple; and the transparent super-hydrophobic coating has high light transmittance and good hydrophobic performance and can be applied to the surfaces of various materials.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

Method for preparing a silica suspension in a vulcanisable silicon matrix to form elastomers

InactiveUS6391944B2Easy to useInexpensive and able to be applied on an industrial scaleElastomerParticulates

The invention concerns the preparation of a silica suspension in a silicon fluid, said suspension being used to produce silicon vulcanizable by polyaddition (RTV elastomers). The problem which the invention aims to solve is that of finding a technical compromise between the rheological and mechanical properties of the final RTV. The invention solves the problem by providing a method for preparing a silica suspension treated with hexamethyldisilazane (HMDZ) in a silicon fluid with siloxyl Si-Vinyl function, characterised in that it consists essentially in introducing HMDZ in the preparation medium, before and / or substantially while bringing at least part of the silicon fluid prepared with at least part of the particulate filler used, said introduction being carried out once or several times for a HMDZ fraction corresponding to a proportion not more than 8% by dry weight with respect to the total silica charge and after bringing together the POS and the filler.

Owner:BLUESTAR SILICONES FRANCE SAS

Preparation method of silicon dioxide

The invention discloses a preparation method of silicon dioxide, which sequentially comprises the following steps of: 1, preparing a sodium silicate solution A; 2, sectionally adding a sodium silicate solution B with sodium silicate mass concentration of 22-26 percent in a reaction kettle containing the sodium silicate solution A at a variable speed, controlling and regulating the addition speed of concentrated sulfuric acid at each section so as to keep pH of a reaction medium constant; 3, stopping adding the sodium silicate solution B, continuously adding the concentrated sulfuric acid, regulating the pH of the material obtained from the steps 2 to be 3.0-4.0, and preparing a sediment silicon dioxide suspension; 4, adding an organic surfactant in the suspension obtained in the step 3, ageing; and 5, filtering, washing, drying, post-treating and crushing to prepare the silicon dioxide product. According to the invention, the defect of poor dispersity of silicon dioxide in high-temperature vulcanized silicon rubber is overcome, yellowing performance of the silicon dioxide is improved, filtering and washing efficiencies are increased, washing time is shortened and washing water is saved.

Owner:FUJIAN YUANXIANG CHEM

Precipitated silicas having a narrow particle size distribution

InactiveUS6902715B2Narrow particle size distributionMaterial nanotechnologyPigmenting treatmentSilica particleChemical physics

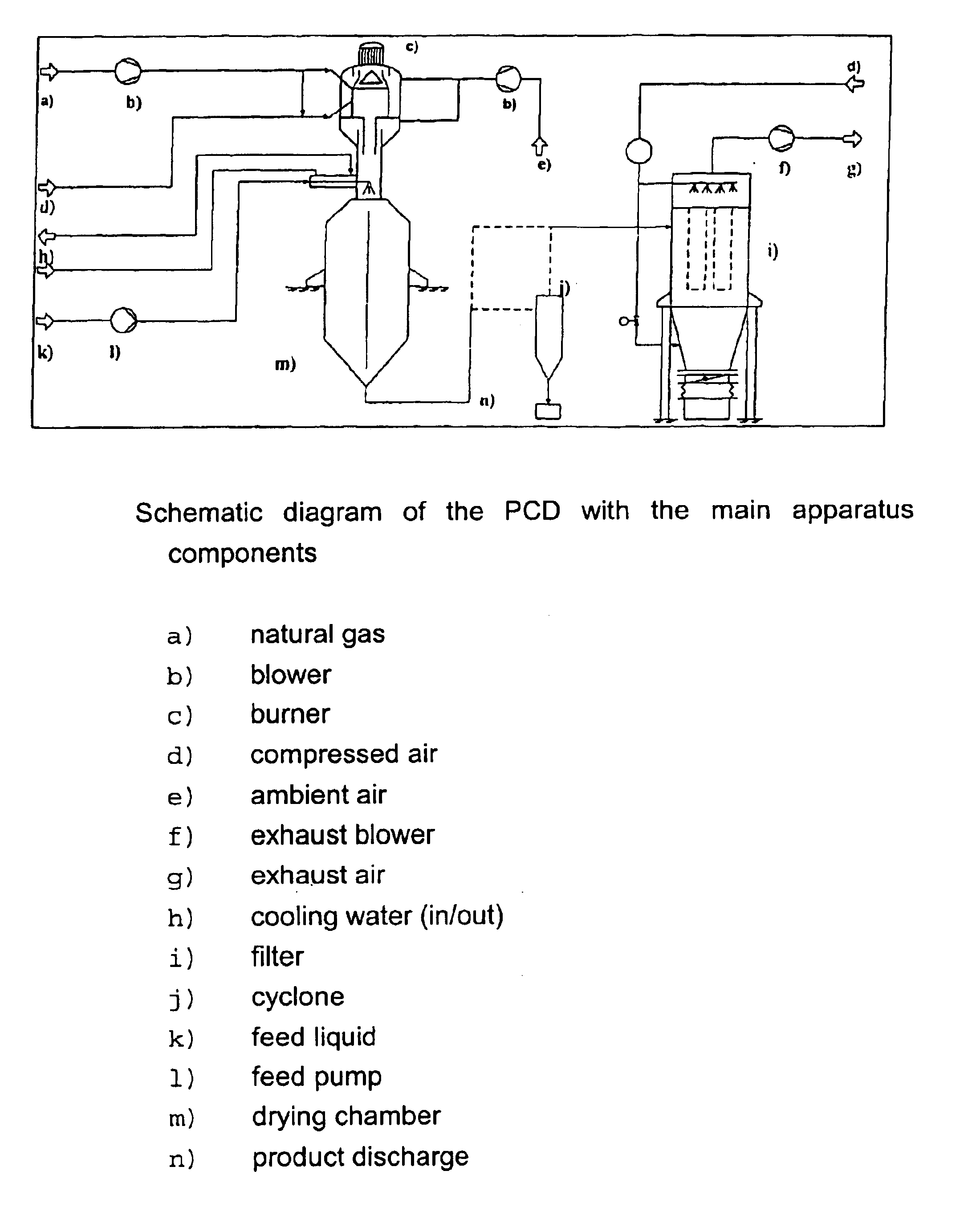

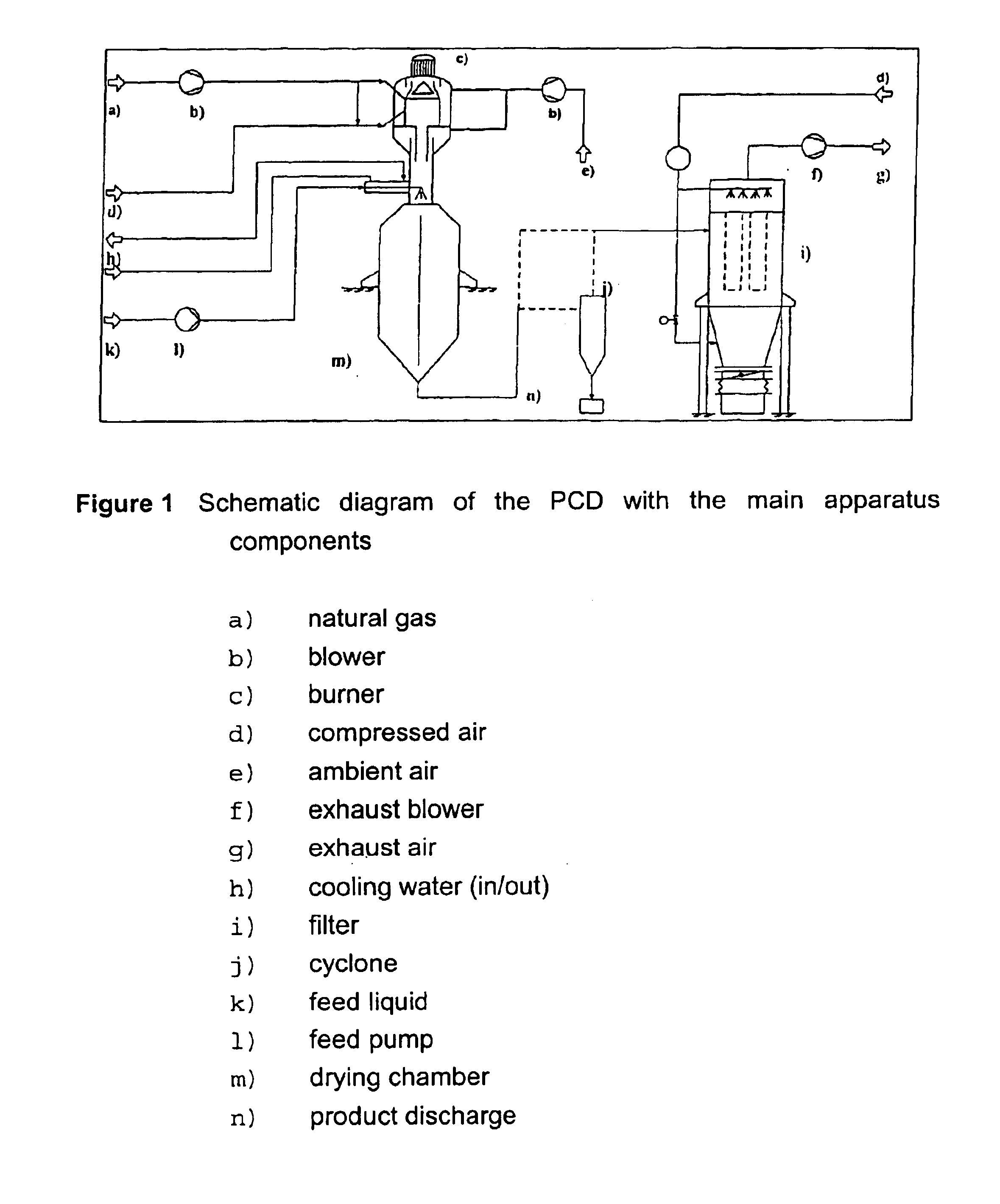

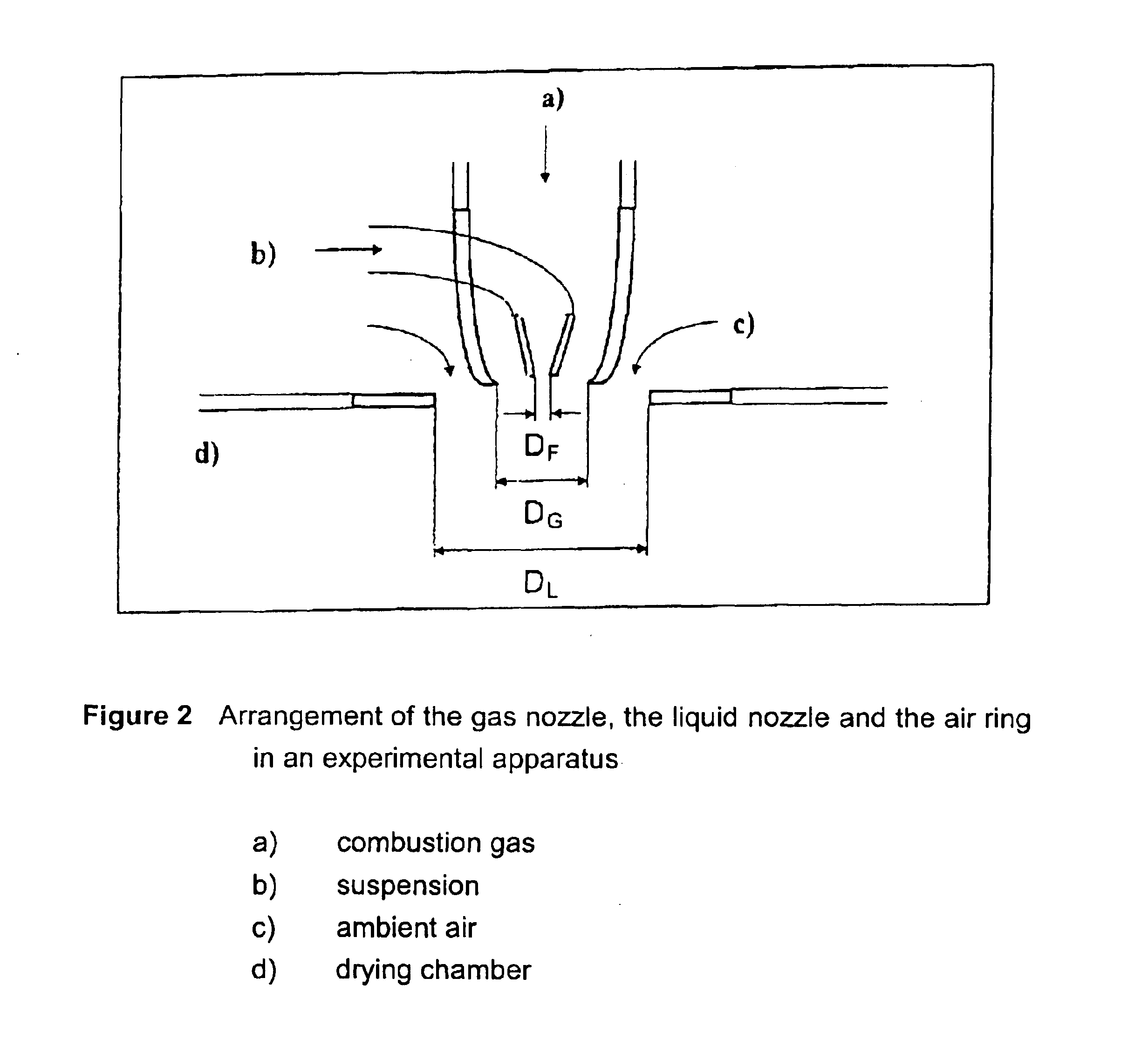

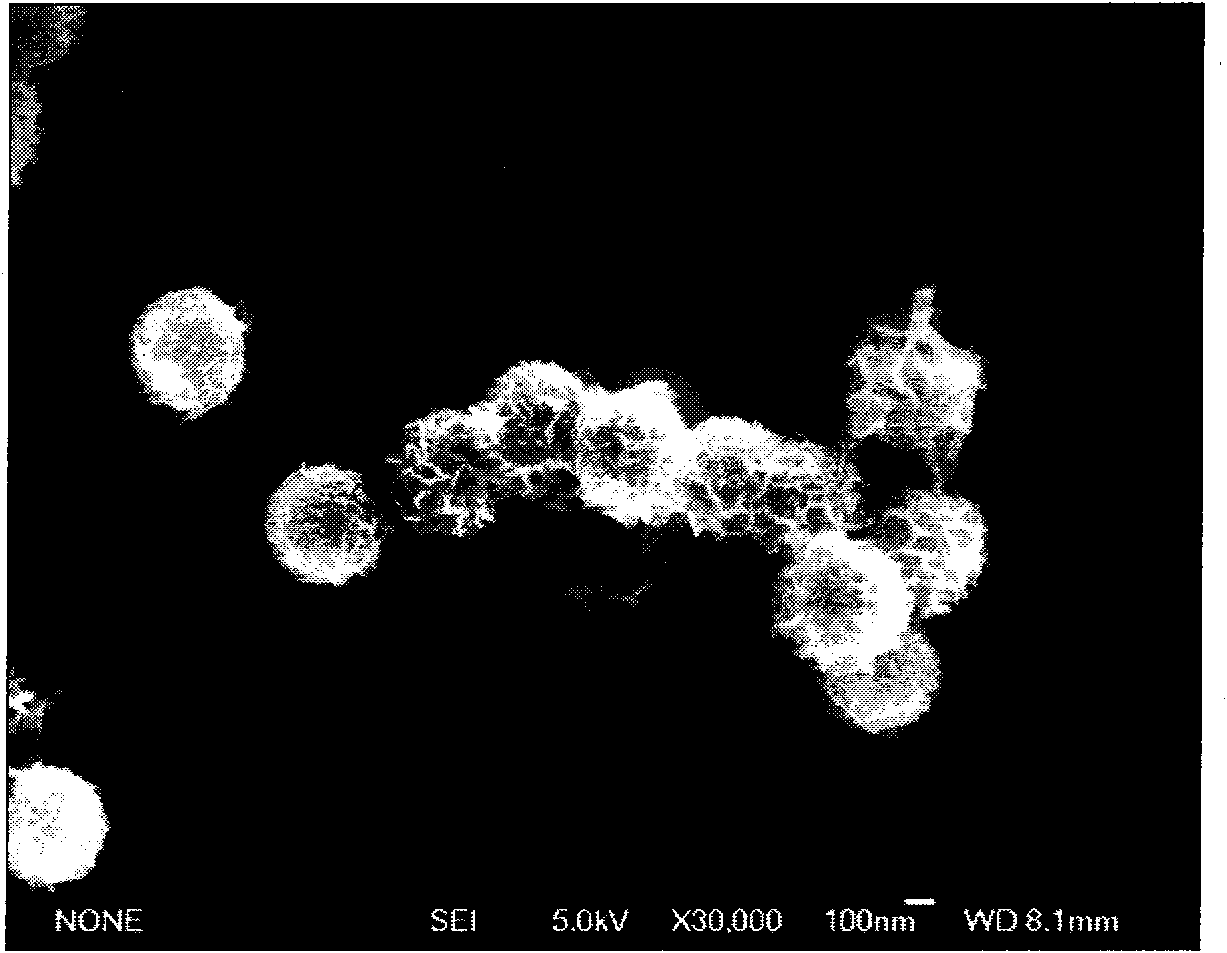

The present invention provides silica particles, which include the following physical properties: BET surface area: 100-700 m2 / g; DBP absorption: 100-500 g / 100 g; tamped density: 100-250 g / l; ALPINE sieve residue>63μ: <5%; and particle sizes (cumulative volume distribution): d95<40 μm; d50<20 μm; and d5<10 μm. The present invention also provides a process for producing silica having a narrow particle size distribution, which includes drying a silica suspension in a pulse combustion dryer to produce silica particles having the following particle size distribution (cumulative volume distribution): d5<10 μm; d50<20 μm; and d95<40 μm.

Owner:EVONIK DEGUSSA GMBH

Method for preparing magnesium hydroxide/silicon dioxide composite inorganic flame retardant

The invention provides a method for preparing a spherical magnesium hydroxide / silicon dioxide composite inorganic flame retardant with a core-shell structure under normal pressure, which comprises the following sequential steps of: (1) hydrolyzing tetraethoxy silane for obtaining amorphous silica microspheres; (2) preparing magnesium salt into a solution with a certain concentration, or taking purified halogen / sea water after purifying treatment as magnesium salt solution for reaction; (3) adding surface active agent into the magnesium salt solution which is then reacted with silica suspension at normal pressure and certain temperature; (4) and fully washing and filtering the precipitate and finally obtaining magnesium hydroxide / silicon dioxide composite inorganic flame retardant powder by drying, sealing and storing. The method is operated under normal pressure, and has simple process, controllable size and appearance of the prepared composite flame retardant, good dispersity, controllability and feasibility of batch preparation.

Owner:QINGDAO UNIV OF SCI & TECH

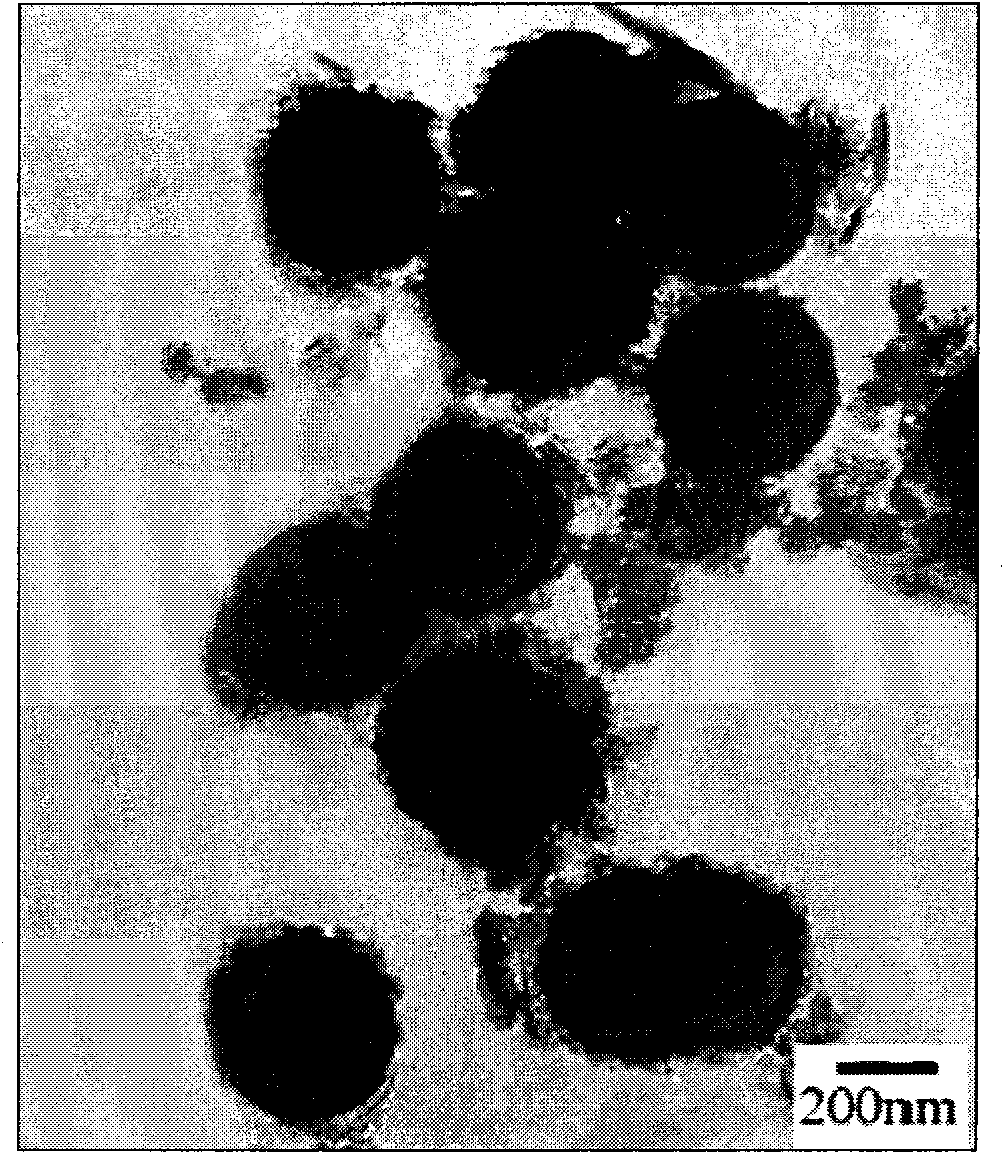

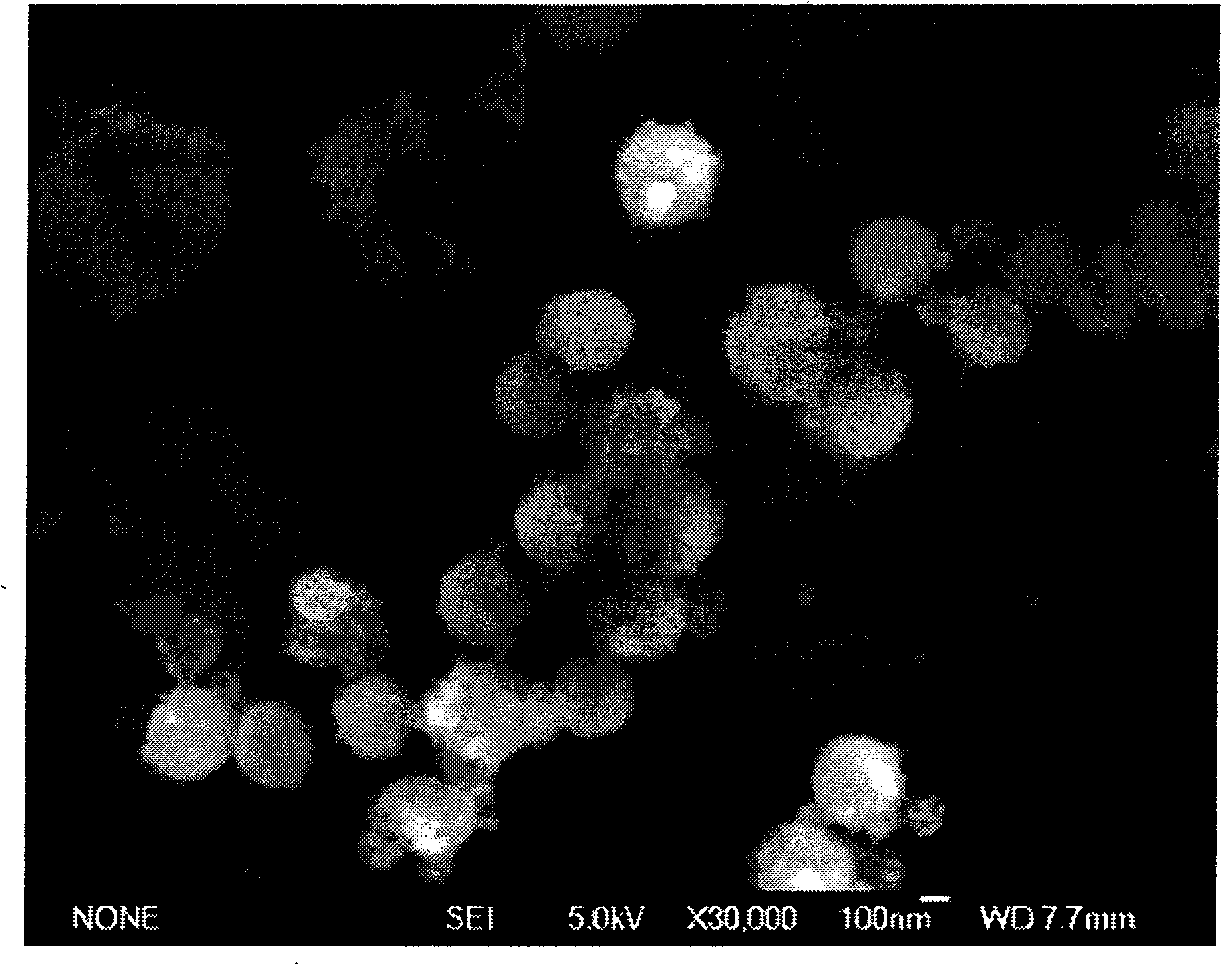

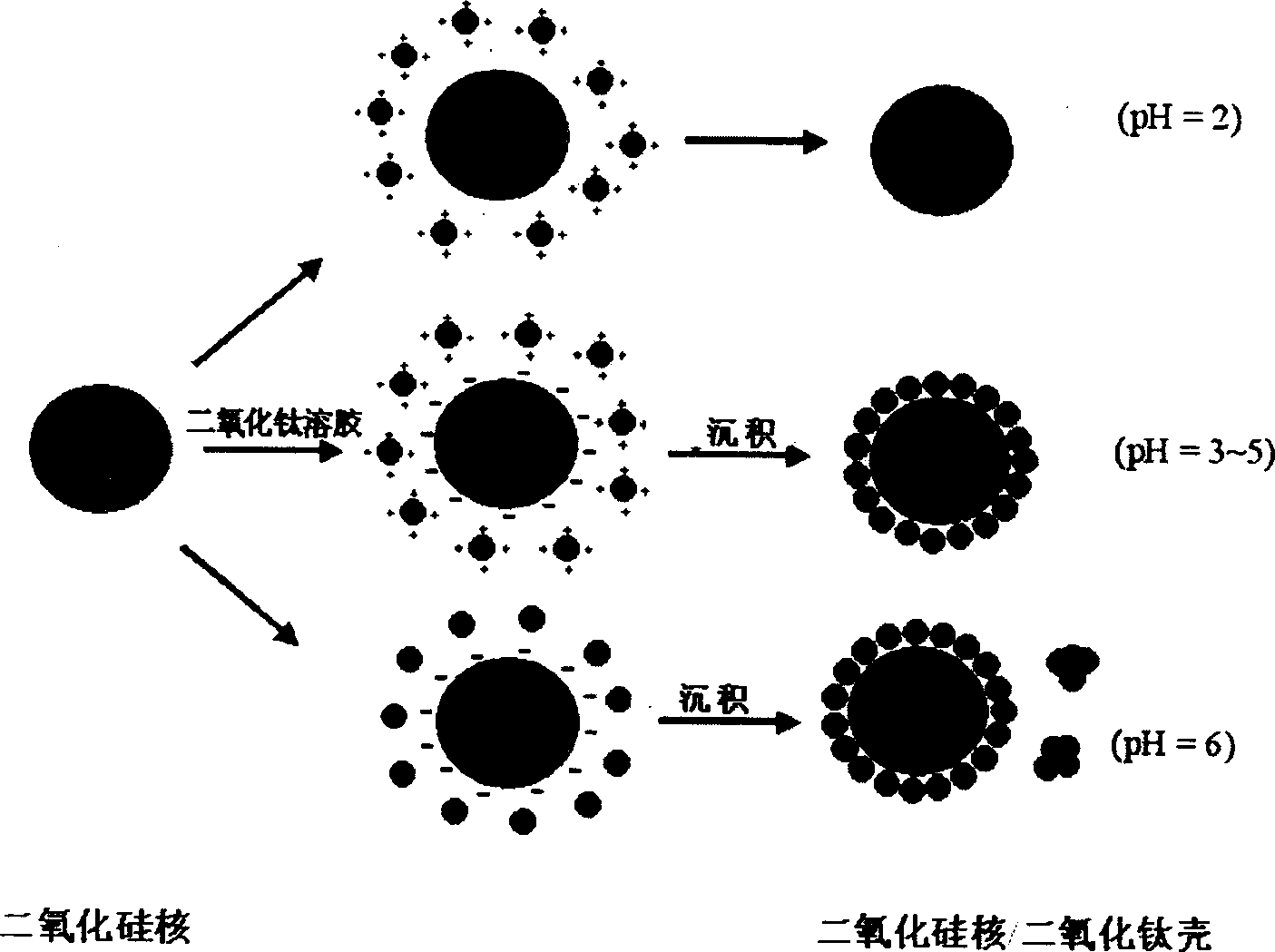

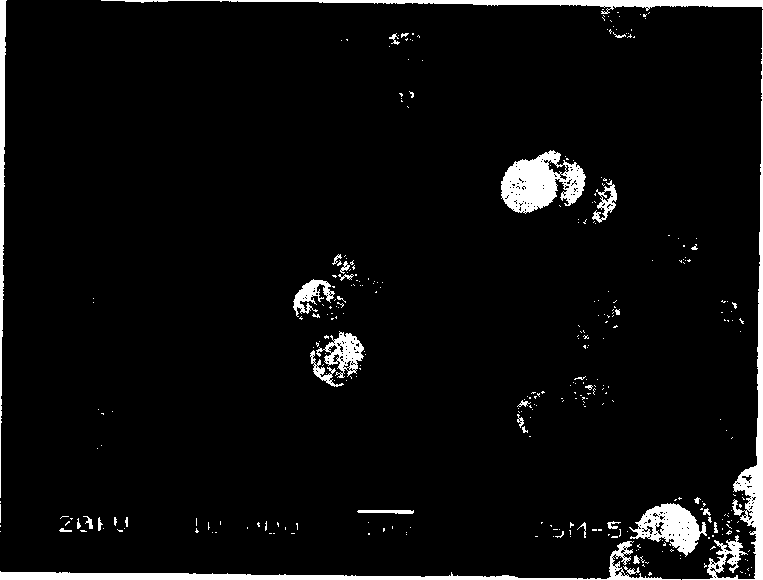

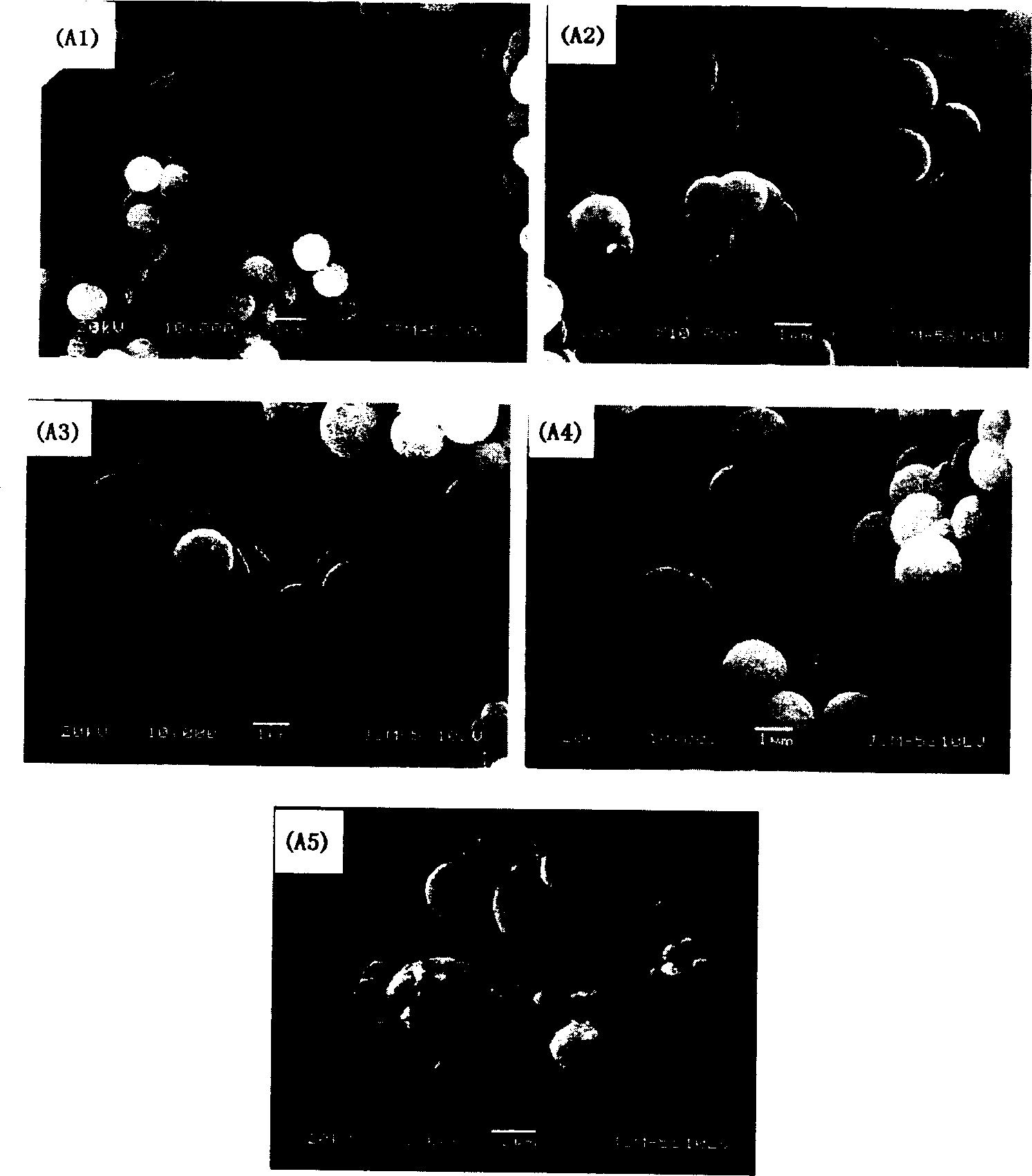

Composite microballoon of monodisperse SiO2 and TiO2 and its prepn process

The preparation process of composite microballoon of monodisperse SiO2 and TiO2 includes the following steps: preparing monodisperse microporous SiO2 microballoon in sol-gel process and preparing TiO2 sol in acid hydrolysis process; ultrasonically dispersing the SiO2 microballoon in distilled water to form suspension, regulating the acidity of suspension with nitric acid for pH value equal that of TiO2 sol, and adding the TiO2 sol into the suspension; stirring to form homogeneous solution, regulating pH value of the mixture solution to 3-5, and forming deposit of composite microballoon of SiO2 and TiO2; and filtering, washing, vacuum drying and high temperature heat treatment to obtain the composite microballoon of monodisperse SiO2 and TiO2 with specific surface area of 400-950 sq m / g.

Owner:WUHAN UNIV OF TECH

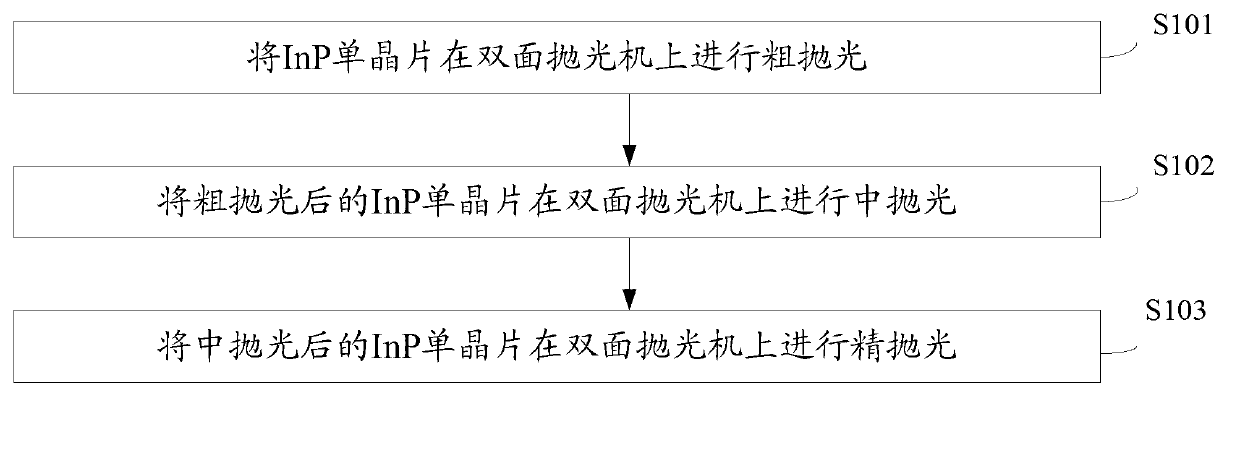

InP single crystal wafer twin polishing method and device

The invention discloses an InP single crystal wafer twin polishing method. The InP single crystal wafer twin polishing method comprises the steps that an InP single crystal wafer sequentially conducts rough polishing, moderate polishing and fine polishing on a twin polishing machine; rough polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium dichloro cyanurate, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: sodium dichloro cyanurate is 1:10:(1.0-1.8), and pondus hydrogenii (PH) value of the rough polishing liquid is 10-11; moderate polishing liquid comprises basoid silicon dioxide suspension liquid, deionized water and sodium hypochlorite, volume ratio of the basoid silicon dioxide suspension liquid: the deionized: the sodium hypochlorite is 1:15:(0.1-0.5), and PH value of the moderate polishing liquid is 8-9; and fine polishing liquid comprises basoid silicon dioxide suspension liquid and deionized water, volume ratio of the basoid silicon dioxide suspension liquid: the deionized is 1: ( 40-60), and PH value of the fine polishing liquid is 7-8. Surface quality of the InP single crystal wafer which is obtained after polishing by adopting of the method is consistent, and the InP single crystal wafer is crocodile-skin-free, scratching-free and mist-free.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Diene rubber composition for tyre including a silica as a reinforcing filler

The invention relates to a diene rubber composition for a tyre that comprises at least: (i) a diene elastomer; (ii) a mineral reinforcing filler; (iii) a binding agent ensuring the bond between the mineral filler and the elastomer; wherein said mineral filler includes at least one silica that may be obtained by the preparation method of the type that comprises reacting a silicate with an acidification agent, thereby providing a silica suspension, and separating and drying said suspension, characterised in that the reaction of the silicate with the acidification agent comprises the following consecutive steps: (i) contacting (mixing) an aqueous suspension of precipitated silica having a pH of between 2.5 and 5.3 with the acidification agent and silicate so that the pH of the reaction medium is maintained between 2.5 and 5.3; and (ii) adding silicate to the obtained reaction medium in order to increase the pH of the reaction medium up to a value between 4.7 and 6.3.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Storable water-silica suspensions and methods

Storable water-silica suspensions and methods of cementing well bores are provided. The storable water-silica suspensions are basically comprised of water, silica and an effective amount of a suspending agent selected from the group consisting of colloidal materials, clays and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

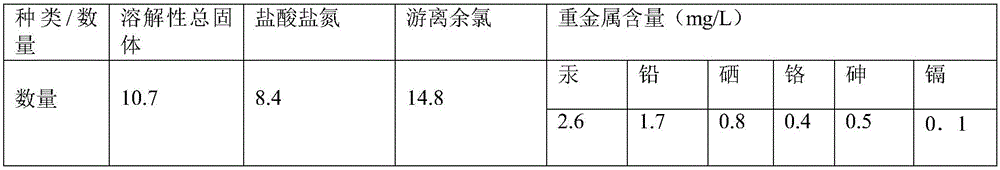

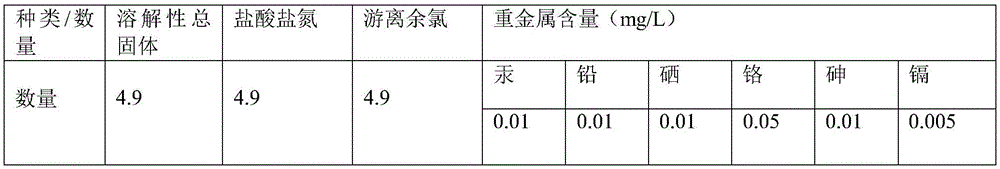

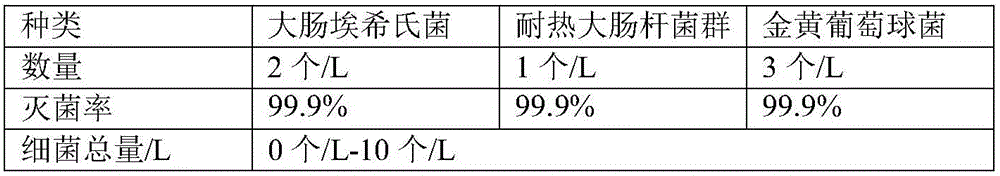

Method for quickly detecting heavy metal in water quality based on ultra-infiltration microchip

ActiveCN108132214ALow costSolve the cumbersome operationMaterial analysis by observing effect on chemical indicatorTesting waterWater qualityHydrophobic silica

The invention discloses a method for quickly detecting heavy metal in water quality based on an ultra-infiltration microchip and belongs to the fields of material preparation and chemical examinationand analysis. The method comprises the following steps: firstly, reacting hydrophobic silica particles with fluorosilane in an ethanol solution to obtain superhydrophobic silica suspension; secondly,coating one side of a double-sided adhesive tape with the suspension to obtain superhydrophobic surface; finally, carrying out plasma etching in a designated area to obtain superhydrophilic microporesand an ultra-infiltration chip; pasting the ultra-infiltration chip on a specific substrate instrument by using the stickiness of the adhesive tape. By use of the ultra-infiltration chip, a color-producing reagent can be concentrated and enriched on the superhydrophilic micropores; the prepared ultra-infiltration chip can fix a detected solution on superhydrophilic sites by simple dipping operation, and colorimetric detection is realized by using a detection reagent on the hydrophilic sites. According to the method, the problems of high cost of a traditional apparatus analysis method and troublesome operation of a chemical analysis method are solved; the method is suitable for quick field detection of an aqueous solution.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing a silica suspension in a vulcanisable silicon matrix to form elastomers

InactiveUS20010034402A1Inexpensive and able to be applied on an industrial scaleEasy to useParticulatesElastomer

The invention concerns the preparation of a silica suspension in a silicon fluid, said suspension being used to produce silicon vulcanisable by polyaddition (RTV elastomers). The problem which the invention aims to solve is that of finding a technical compromise between the rheological and mechanical properties of the final RTV. The invention solves the problem by providing a method for preparing a silica suspension treated with hexamethyldisilazane (HMDZ) in a silicon fluid with siloxyl Si-Vinyl function, characterised in that it consists essentially in introducing HMDZ in the preparation medium, before and / or substantially while bringing at least part of the silicon fluid prepared with at least part of the particulate filler used, said introduction being carried out once or several times for a HMDZ fraction corresponding to a proportion not more than 8% by dry weight with respect to the total silica charge and after bringing together the POS and the filler.

Owner:BLUESTAR SILICONES FRANCE SAS

Hydrophobic and oleophobic polyolefin material and preparation method thereof

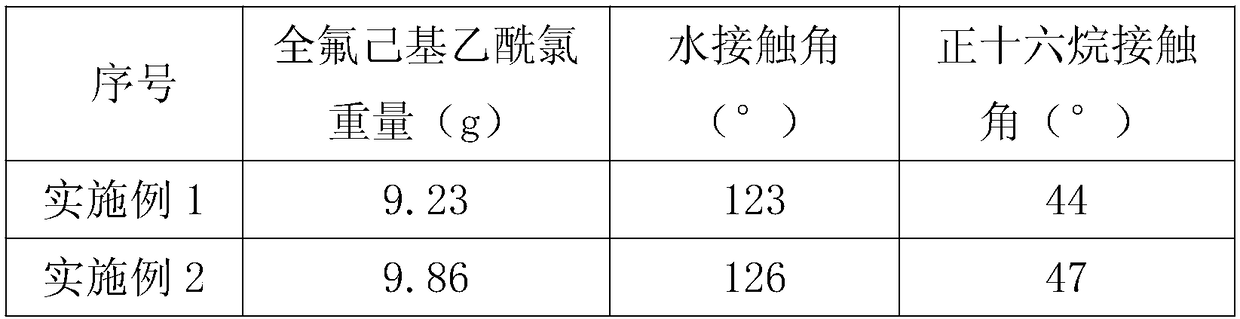

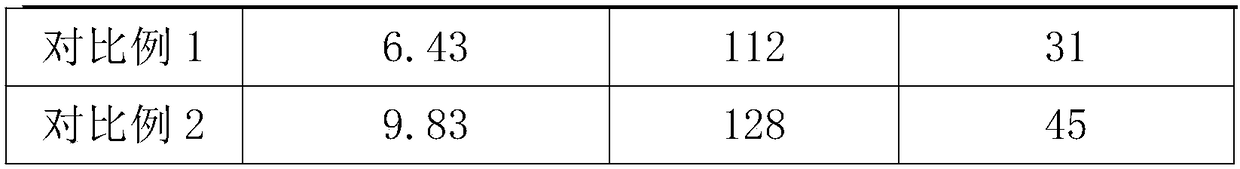

The invention discloses a hydrophobic and oleophobic polyolefin material and a preparation method thereof. The method comprises the following steps: 1) dissolving thionyl chloride in a solvent, addinga catalyst, gradually dropping (perfluorohexyl)acetic acid, stirring the materials, and performing underpressure distillation to obtain perfluor hexyl acetyl chloride; 2) dissolving nano silica in anethanol aqueous solution, performing ultrasonic dispersion for 30 min, gradually dropping an amino silane coupling agent in the above mixed liquor, and heating the materials and stirring the materials to obtain an aminated nano silica fluid suspension; 3) dissolving perfluor hexyl acetyl chloride in an organic solvent, gradually dropping the material in the aminated nano silica fluid suspension,stirring the materials, performing vacuum distillation, performing vacuum drying on the product, and performing ball milling and sealing to obtain the nano silica supported perfluorohexyl acetamide; and 4) uniformly mixing polyolefin resin and nano-silica supported perfluorohexyl acetamide in a high mixer, and then performing melt extruding and granulating to prepare the hydrophobic and oleophobicpolyolefin material. According to the hydrophobic and oleophobic polyolefin material, the surface energy is reduced, the scale is effectively prevented, and energy consumption is saved.

Owner:RIFENG ENTERPRISE GRP CO LTD +2

Preparation method for bacterial cellulose water ultrafiltration adsorption material

InactiveCN103301815AQuick eliminationWon't clogOther chemical processesWater/sewage treatment by sorptionFiberPurification methods

The invention provides a preparation method for a bacterial cellulose water ultrafiltration adsorption material. The preparation method comprises the following steps: processing a bleached wet bacterial cellulose membrane in a pulping machine with a rotating speed of 2, 000 to 100, 000 r / m so as to obtain a bacterial cellulose fiber; subjecting the bacterial cellulose fiber to press filtration by a filter press so as to prepare a superfine bacterial cellulose fiber; treating nanometer bacterial cellulose by using a silicon dioxide suspension liquid with a concentration of 1% through hydro-thermal synthesis so as to obtain tubular silicon oxide coated bacterial cellulose; mixing the obtained tubular silicon oxide coated nanometer bacterial cellulose with boehmite powder and putting an obtained mixture into a die with a transparent pore structure; and activating the mixture by using sinusoidal alternating current with a frequency of 50 Hz so as to form the adsorption material with large eyelets. The bacterial cellulose water ultrafiltration adsorption material prepared in the invention can rapidly remove bacteria in water, does not causes obstruction and enables a simple and low-cost water purification method meeting social demands to be feasible.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Impregnating compound for enhancing quartz fiber tensile strength

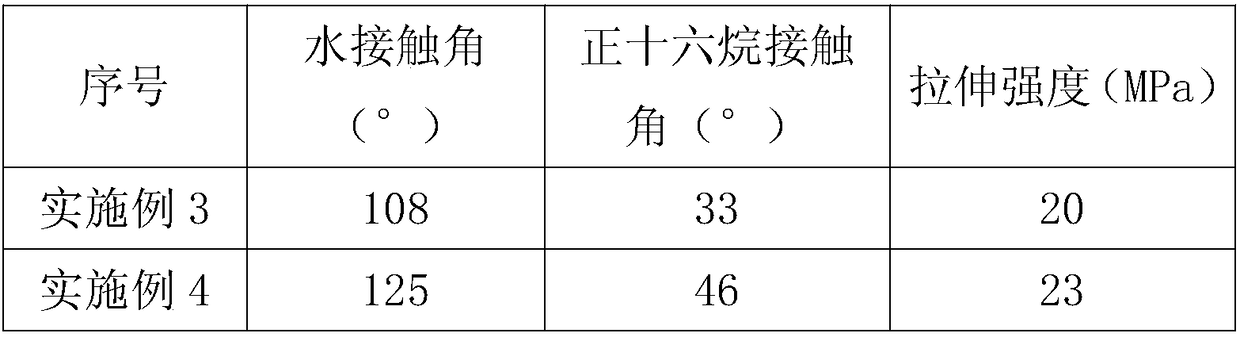

The invention discloses a novel impregnating compound composition for enhancing quartz fiber tensile strength. The impregnating compound is mainly prepared from a main film forming agent water-soluble polyurethane resin emulsion, a water-soluble epoxy resin emulsion, an auxiliary film forming agent water-soluble epoxy resin, a water-soluble lubricant, a water-soluble nano-scale silica suspension, a water-soluble nano-scale alumina suspension, a silane coupling agent, a pH regulator and deionized water. Compared with the prior art, the hairiness amount produced in the quartz fiber monofilament drawing and combining processes is less, the quartz fiber tensile strength is higher under the high temperature condition, and the quartz fiber has good production process properties and application properties.

Owner:天津市硅酸盐研究所有限公司

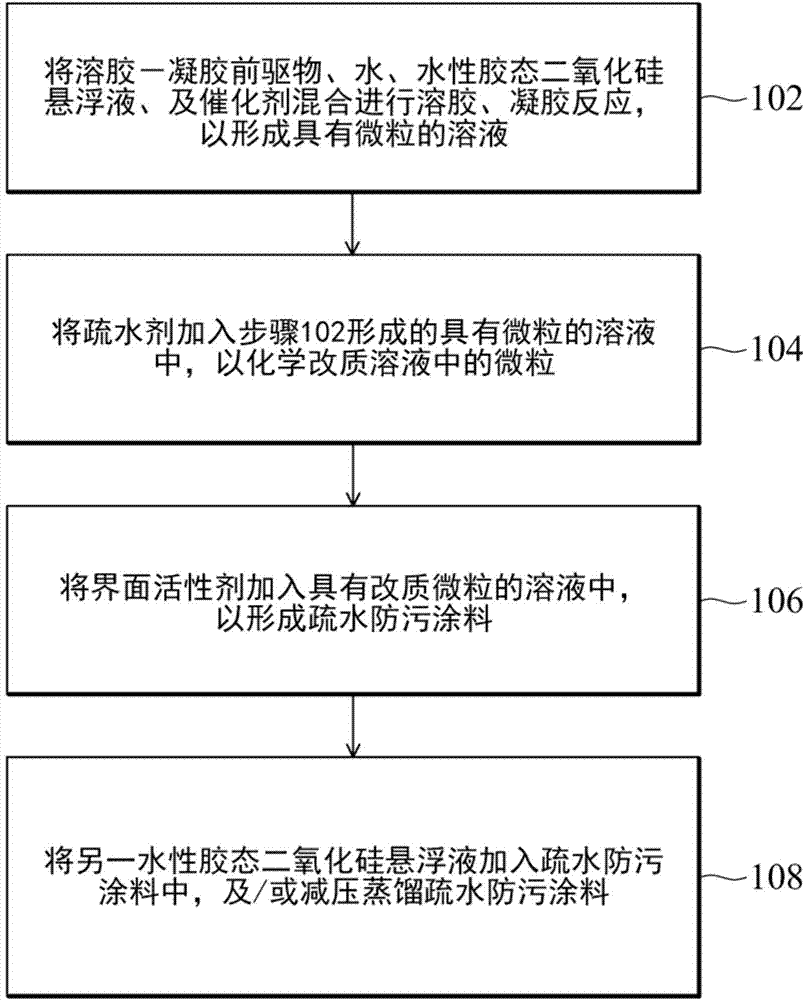

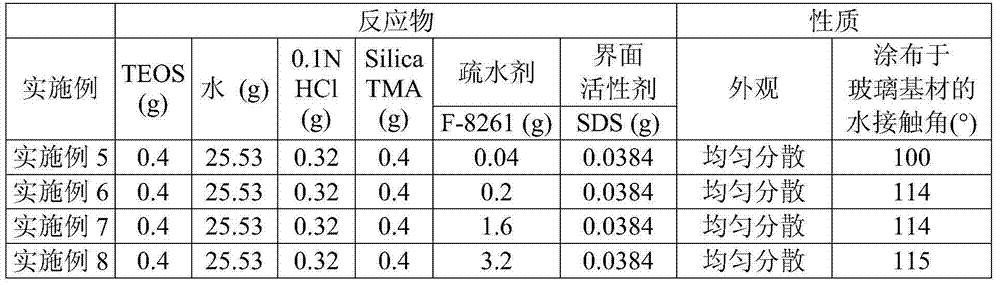

Method of manufacturing hydrophobic antifouling coating material and method of forming hydrophobic antifouling coating film

ActiveCN104744985AReduce VOC valueMeet the needs of environmental protectionAntifouling/underwater paintsPaints with biocidesColloidal silicaOrganic solvent

A method of manufacturing a hydrophobic antifouling coating material, including: (a) mixing a sol-gel precursor, water, an aqueous colloidal silica suspension, and a catalyst to perform a sol-gel reaction to form a solution having particles therein, wherein the sol-gel reaction is performed without addition of any organic solvent; (b) chemically modifying the particles with a hydrophobic agent to form surface-modified particles; and (c) adding a surfactant to the solution containing the surface-modified particles to form a hydrophobic antifouling coating material. The hydrophobic antifouling coating material can be dispersed in an aqueous solution, and has properties such as low VOC (Volatile organic compound) value, high solid content, and high stability.

Owner:IND TECH RES INST +1

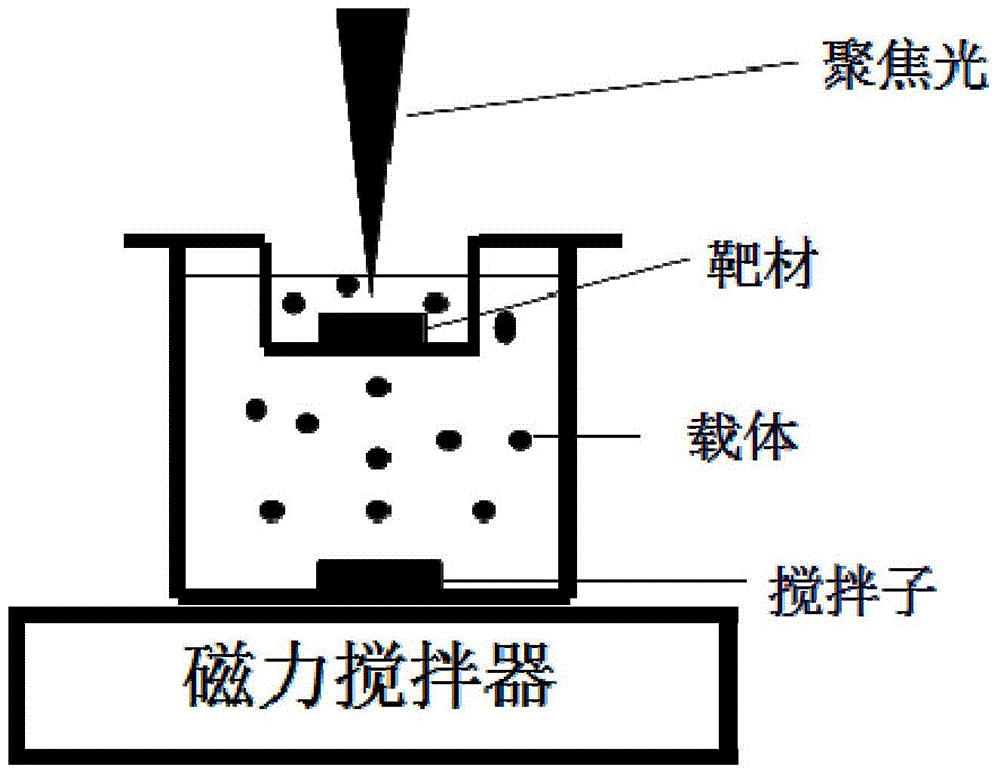

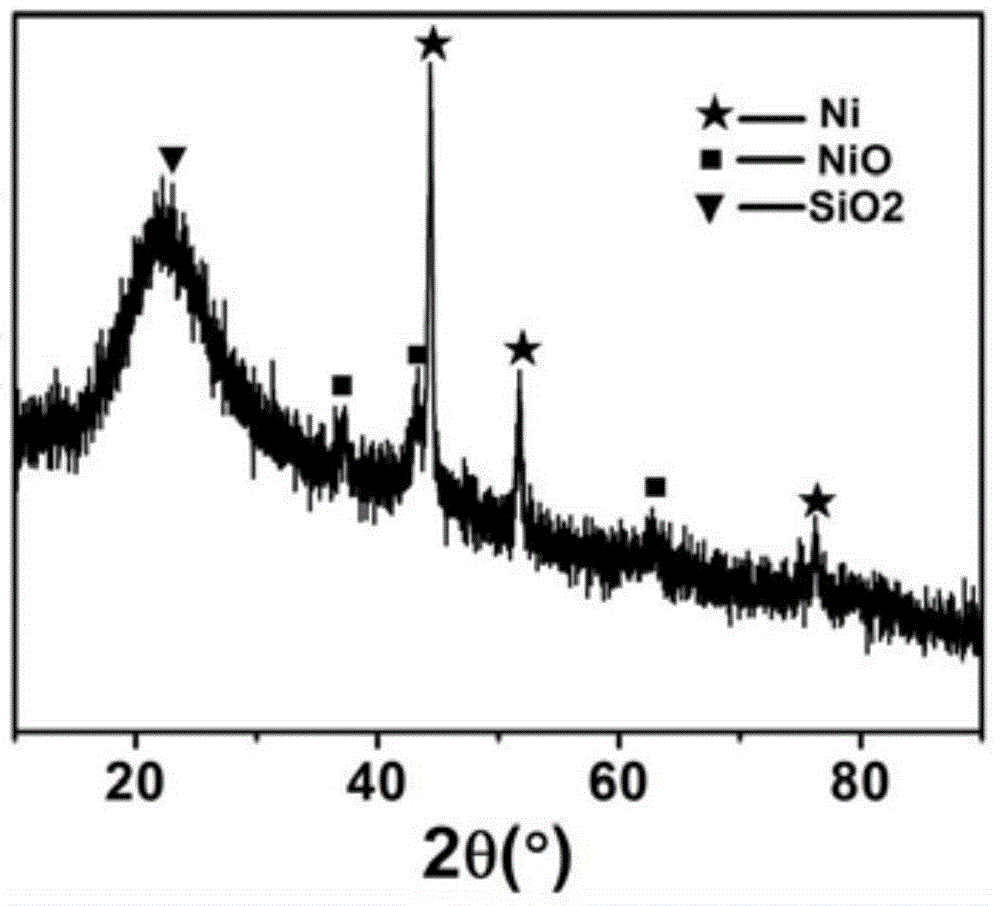

Technological method for preparing nickel/silicon dioxide supported catalyst by laser liquid phase

InactiveCN104549292AThe synthesis method is simpleEasy to operateMetal/metal-oxides/metal-hydroxide catalystsFiltrationSynthesis methods

The invention discloses a technological method for preparing a nickel / silicon dioxide supported catalyst by laser liquid phase. The technological method comprises the following steps of firstly, carrying out polishing and ultrasonic cleaning on a massive metallic nickel target used as a raw material, and blow-drying residual water on the surface of the nickel target; then dispersing silicon dioxide solid powder into deionized water; then putting the treated nickel target into the solution, and adjusting the liquid level height to be greater than 5mm and less than 25mm; ablasting the target by adopting nanosecond focused pulsed laser under the auxiliary action of magnetic stirring and electric translation for 1 hour so as to obtain nickel / silicon dioxide suspension; then carrying out suction filtration on the suspension, and drying so as to obtain the nickel / silicon dioxide powdery supported catalyst. According to the invention, the technological method is simple in synthesis method, is convenient to operate, and is easy to control; byproducts and impurities are not generated; a supported catalyst with small size which is synthesized in a liquid phase by one step at normal temperature and normal pressure is provided; the technological process is an environment-friendly synthesis process.

Owner:TIANJIN UNIV

Multi-ion antibacterial material

The invention relates to the field of antibacterial materials, and discloses a multi-ion antibacterial material. A method for preparing the multi-ion antibacterial material includes (1), respectively mixing silver nitrate, zinc nitrate and magnesium oxide with silicon dioxide suspension to obtain solution and mixing the three types of solution with one another to obtain solution A; (2), melting copper, adding zinc into the copper, melting and mixing the zinc and the copper with each other, adding charcoal powder into the zinc and the copper, uniformly mixing the charcoal powder, the zinc and the copper with one another to obtain mixtures, cooling the mixtures and grinding the mixtures to obtain composite brass powder; (3), mixing the composite brass powder and the solution A with each other to obtain first mixtures, adding the first mixtures into nitric acid solution to obtain second mixtures, heating the second mixtures until the temperature of the second mixtures reaches 100-140 DEG C, adding solution with glacial acetic acid and diethanolamine into the second mixtures, generating precipitates, washing the precipitates, repeatedly heating and washing the precipitates, adding titanium dioxide into solution and drying and cooling the solution to obtain the multi-ion antibacterial material. The multi-ion antibacterial material has the advantages that ion antibacterial principles and micro-magnetic electric field technical principles are utilized, and accordingly the multi-ion antibacterial material is good in stability and high in antibacterial activity and has adsorption capacity; the antibacterial properties of the multi-ion antibacterial material which is a high-polymer material can be effectively improved, and the service life of the high-polymer material can be effectively prolonged.

Owner:ZHEJIANG WATERHOR ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of novel rubber vulcanizing activator

The invention discloses a preparation method of a novel rubber vulcanizing activator. A final product can be applied to the rubber vulcanizing process. The preparation method of the novel rubber vulcanizing activator comprises the following steps of (1) dispersing the ground silicon dioxide powder into an ethyl alcohol solution, and sufficiently stirring at normal temperature, so as to obtain a uniformly-dispersed suspension liquid with certain concentration; (2) adding a zinc sulfate ethyl alcohol solution into the silicon dioxide suspension liquid in step (1), heating, and continuing to stir; (3) adding a sodium hydroxide, water and ethyl alcohol mixed solution into a mixing solution in step (2), stirring for certain time, heating to certain temperature, and aging; (4) washing and filtering the mixing solution, and placing into an oven to dry, so as to obtain a final silicon dioxide-dispersed novel vulcanizing activator. The novel rubber vulcanizing activator has the advantages thatthe novel rubber vulcanizing activator is synthesized at low temperature and is used for replacing the existing vulcanizing activator, the synthesizing method is simple, the usage amount of zinc is reduced, the environment is favorably protected, and the production cost is greatly reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Simple and fast extraction method for DNA in grape wine

InactiveCN101210032AHigh purityHigh yieldSugar derivativesMicrobiological testing/measurementThermal insulationGrape wine

The invention discloses a simple and rapid DNA extraction method in wine, which comprises the following steps: A. 5g Silica is added with 5ml aqueous suspension for Silica precipitation to be evenly mixed after being cleaned by pure water and is set at the temperature of 4 DEG C for standby; B. wine with best adsorption conditions is then produced; C. the DNA of the wine is adsorbed and recycled: (1) Silica suspension is added to the wine mixture; (2) conservation is done for 1-2 hours under the temperature of 4DEG C, with constant shaking and oscillation; (3) centrifugation is done for 5 min under the temperature of 4DEG C with the amount of 5000g; (4) supernatant is removed and the Silica deposit is washed for 1-2 times by using washing fluid containing 0.1M Tris-HCl, pH 8.0, 1 percent of CTAB and 1M NaCl; (5) the centrifugation is done for 5 min with the amount of 5000g to collect the Silica deposit; (6) the Silica deposit is added with the pure water with the equivalent amount as the deposit and then well shaked and done with DNA heat elution after 5-10 min thermal insulation at the temperature of 65 DEG C; (7) centrifugation (10000g, 5min) is done to collect the supernatant containing DNA; (8) the supernatant in step (7) is extracted by chloroform with the same volume and the centrifugation (10000g, 3min) is done to collect top phase containing DNA; (9) the DNA in the supernatant is recycled and concentrated by using isopropanol precipitation; (10) the recycled wine DNA is then dissolved in 50 Mu lota TE (10mM Tris-HCl, pH 8.0) buffering agent.

Owner:HENAN AGRICULTURAL UNIVERSITY

Preparation method of hydrophobic material based on silica

The invention discloses a preparation method of a hydrophobic material based on silica. The preparation method comprises: (1) adding anhydrous ethanol into ethyl orthosilicate as a raw material, stirring the mixture for 20-40min, adding ammonia water to adjust the pH value of the reaction liquid to 8-10 and carrying out stirring for 1-2h to obtain a silica suspension liquid, (2) adding anhydrous ethanol into the silica suspension liquid, carrying out ultrasonic treatment for 1-2h, adding a certain amount of stearic acid into the suspension liquid, carrying out ultrasonic treatment for 20-40min, carrying out magnetic stirring on the mixed solution subjected to ultrasonic treatment at 65-75 DEG C, and carrying out stirring at the room temperature for 5-8h to obtain a product for next use, and (3) adding a certain amount of anhydrous ethanol into the product obtained in the step (2), carrying out uniform stirring, coating the surface of a pretreated metal base with the mixed solution, volatilizing the solvent at 90 DEG C and carrying out drying at 100-120 DEG C for 1-2h to obtain the hydrophobic material based on silica. The hydrophobic material based on silica has superhydrophobic properties and can maintain superhydrophobic properties after being stored at the room temperature for a long time.

Owner:苏州汉力新材料有限公司

Magnesium oxide-silicon dioxide composite catalyst carrier and preparation method thereof

InactiveCN107233928AImprove pore structureImprove adsorption capacityCatalyst carriersWater bathsMagnesium salt

The invention discloses a magnesium oxide-silicon dioxide composite catalyst carrier, and also discloses a preparation method of the composite catalyst carrier. The preparation method comprises the following steps: (1) preparing a silicon dioxide suspension: using tetraethoxysilane as a raw material, adding absolute ethyl alcohol, conducting stirring for 20-40min, then adding ammonia water, and continuing stirring for 1-2h to obtain the silicon dioxide suspension; (2) adding a water-soluble magnesium salt to the silicon dioxide suspension, adding ammonia water for regulating the pH value to 8-9, conducting magnetic stirring for reacting for 20-36h in a water bath of 50-60DEG C to obtain a magnesium oxide-silicon dioxide suspension; and (3) cooling the magnesium oxide-silicon dioxide suspension to room temperature, conducting filtering, washing and baking, and conducting calcining in a 500-600DEG C muffle furnace for 3-6h to obtain the magnesium oxide-silicon dioxide composite catalyst carrier. The method disclosed by the invention is mild in reaction conditions, and the magnesium oxide-silicon dioxide composite catalyst carrier prepared by the method has a good pore structure and adsorption property and can be used as a carrier of a functional material or a metallic catalyst.

Owner:张家港市东威新材料技术开发有限公司

Preparation method of illite-smectite clay intercalated silica dual composite natural rubber

The invention discloses a preparation method for preparing dual composite natural rubber from illite-smectite clay intercalated silica. The method mainly comprises the steps of processing a nano-scale illite-smectite clay material by adopting an intercalating agent, further damaging a close and ordered packed structure of laminar silicate to form layered basic units by peeling, then mixing and melting with a suspension mixed with natural latex and silica, uniformly dispersing in a polymer matrix, finally realizing intercalation composition of a natural rubber high polymer, silica and layered silicate lamellae on nano scale and completing the manufacturing of a finished product through continuous production.

Owner:陈雄

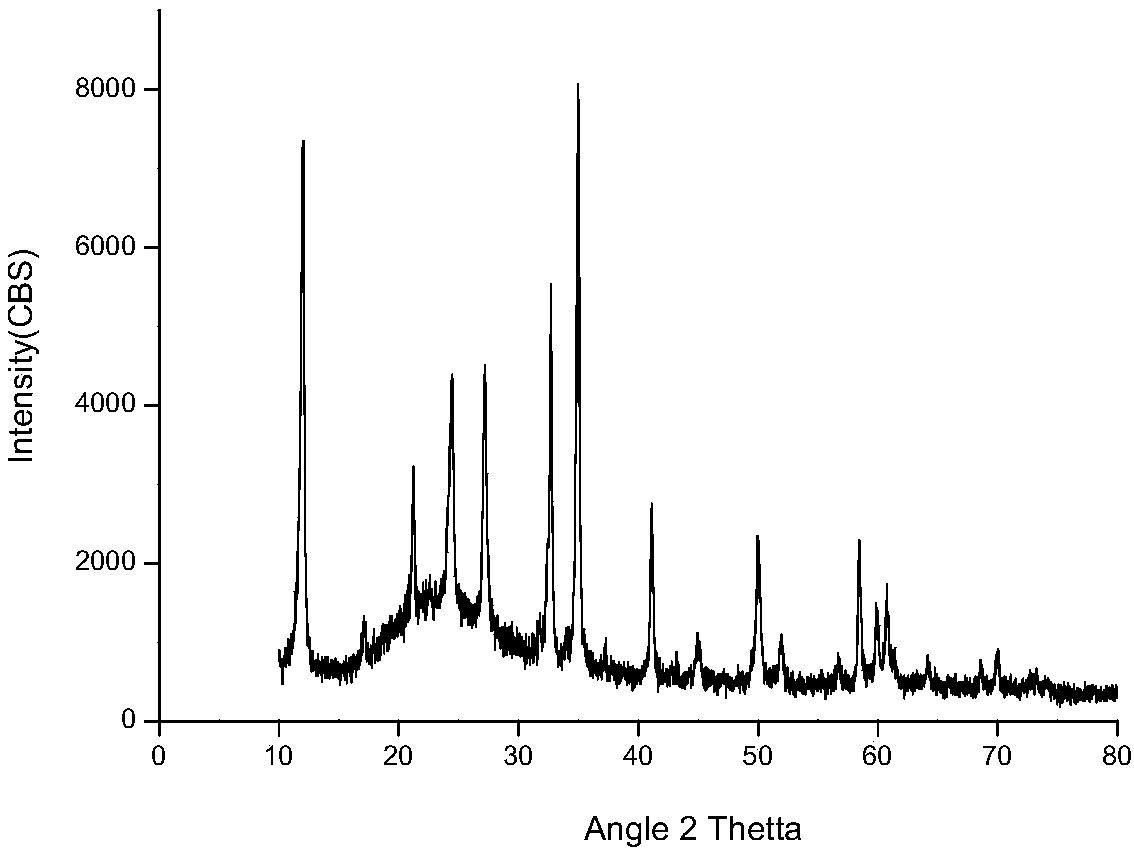

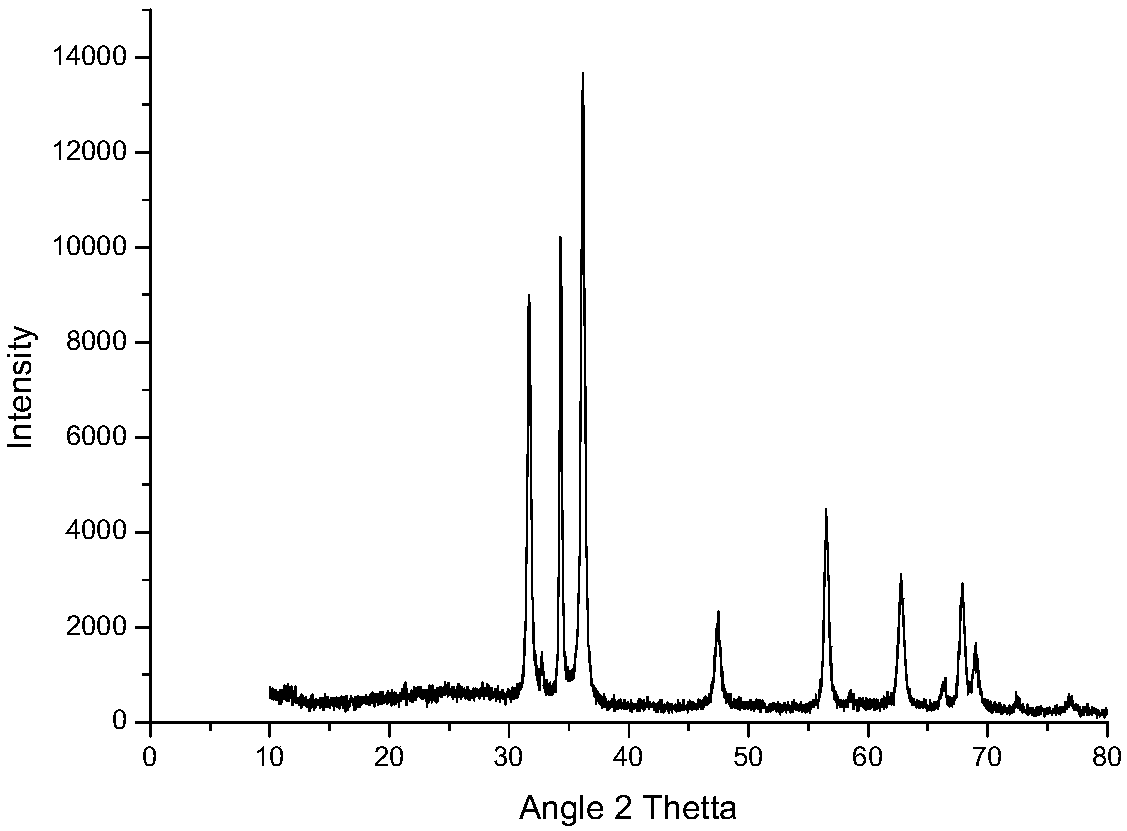

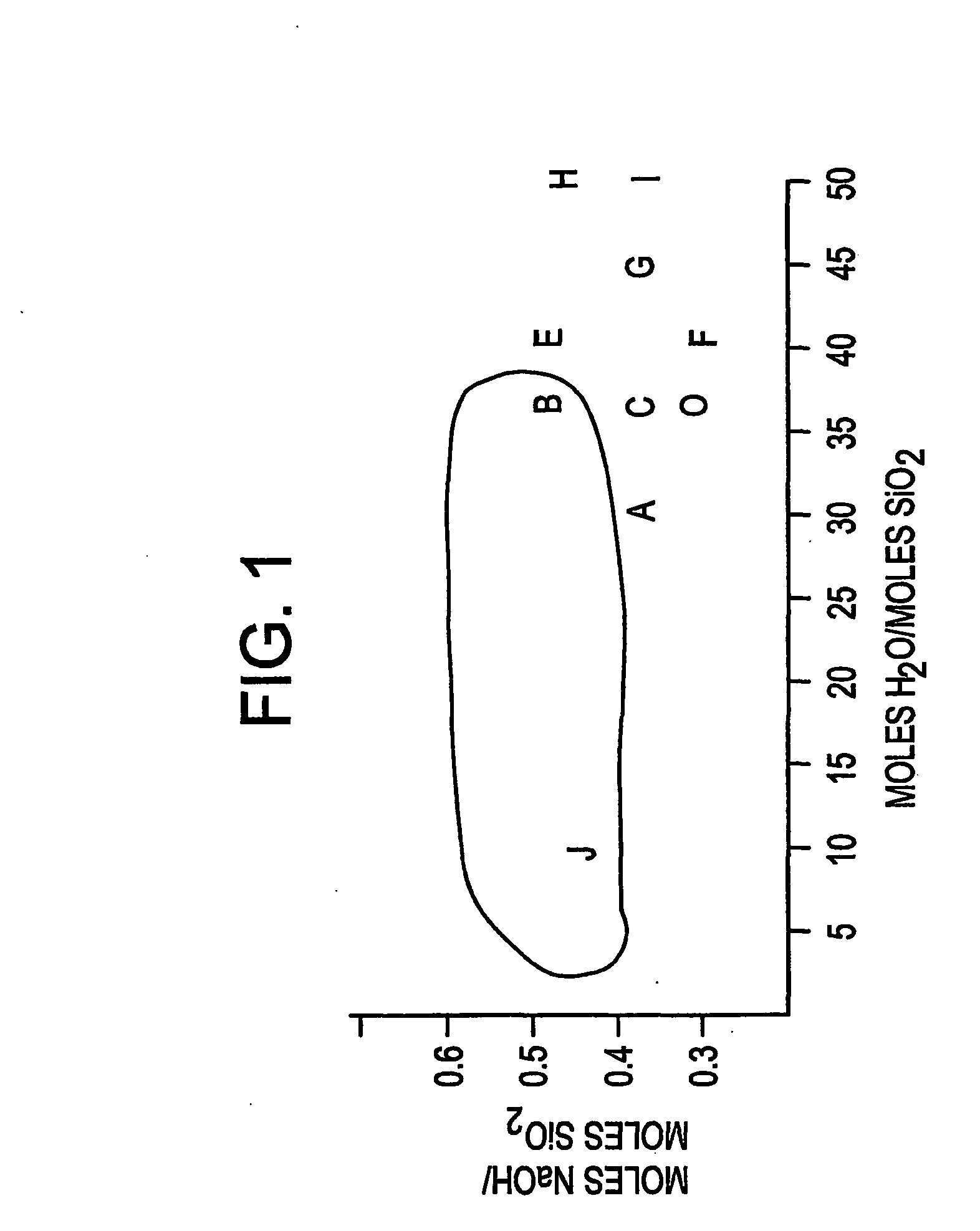

Synthetic platy magadiite and octasilicate

A method for producing synthetic magadiite, including the step of: heating a liquid aqueous colloidal silica suspension, the liquid aqueous colloidal silica suspension having a mole ratio of sodium hydroxide to silica and a mole ratio of water to silica effective to produce a synthetic magadiite wherein more than fifty percent by weight of the synthetic magadiite is platy synthetic magadiite. The synthetic platy magadiite can be converted to the acid form and: (a) heated to produce quartz-like plates; or (b) alkylated to produce an organophilic material. In another aspect, the instant invention is a method for the production of platy sodium octasilicate which includes the step of: heating a liquid aqueous colloidal silica dispersion containing silica, sodium oxide, and water, the mole ratio of the silica to the sodium oxide being in the range of from about 3.5 to about 10. In another aspect, the instant invention is a method for preparing a liquid aqueous colloidal silica dispersion, the dispersion having a mole ratio of silica to sodium oxide of from 3.5 to 10, which includes the step of: mixing a sufficient amount of liquid aqueous colloidal silica suspension with a liquid aqueous sodium silicate suspension to produce the liquid aqueous colloidal silica dispersion, the liquid aqueous colloidal silica suspension having a mole ratio of silica to sodium oxide of more than 20, the liquid aqueous sodium silicate suspension having a mole ratio of silica to sodium oxide of less than 3.5, the rate of mixing being effective to prevent the gellation or solidification of the liquid aqueous colloidal silica dispersion.

Owner:THE DOW CHEM CO

Austenite alloy EBSD sample preparation method

InactiveCN109855931AShort manufacturing timeReduce preparationPreparing sample for investigationSilica suspensionAlloy

The invention discloses an austenite alloy EBSD sample preparation method. The preparation method comprises austenite alloy sample preparation, grinding, polishing, fine polishing, two-step ultrasonictreatment and drying steps, wherein for the fine polishing step, in the fine polishing process, silica suspension liquid with particle size of 20-50nm is used, the rotation speed of a metallographical polishing machine is smaller than or equal to 100 turn / min, and fine polishing time is larger than or equal to 10 min; and for the two-step ultrasonic treatment step, the first ultrasonic treatmentstep is characterized by placing the samples in a 10%NaOH aqueous solution, which is 10-45 DEG C, for ultrasonic cleaning, the cleaning time being larger than or equal to 3 min. Compared with the national standard GBT19501, the method does not need the electropolishing process and does not need to purchase special equipment, thereby reducing preparation steps, making preparation simple and convenient and reducing cost; and the problems that an existing electropolishing method needs special equipment, is high in sample preparation cost and is long in polishing process exploration time, and electrolyte pollutes the environment and the like are overcome effectively.

Owner:HEBEI IRON AND STEEL

Process for producing spherical composite cured melamine resin particles

InactiveUS7115303B2Easy to separateSuppress particleLiquid surface applicatorsCoatingsColloidal silicaSilica suspension

A process for producing spherical composite cured melamine resin particles excellent in water resistance, in which colloidal silica is localized near the surface thereof, comprising (a) a step of reacting a melamine compound with an aldehyde compound in an aqueous medium under a basic condition in the presence of a suspension of colloidal silica having an average particle size of 5 to 70 nm to produce an aqueous solution of a precondensate of water-soluble melamine resin; and (b) a step of adding an acid catalyst to the aqueous solution produced in the step (a) to separate out spherical composite cured melamine resin particles.

Owner:NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com