Patents

Literature

260results about How to "Meet the needs of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical method for silver coating on copper powder surface

The invention relates to a method for copper powder surface chemical plating silver, belonging to field of chemical silver plating. Said method comprises following steps: putting copper powder into diluted acid of 5-10% to remove oxide on surface of copper powder; adding disperser of 1-30% of copper powder by weight, stabilizer of 10-60% of copper powder by weight into deionized water to form reducing liquid, adding copper powder and stirring; adding silver nitrate into deionized water, adding ammonia, stirring and adding sodium-hydroxide and getting silver amine solvent; adding silver amine solvent into reducing liquid under stirring, finishing chemical silver plating of copper surface 10-50 minutes later; filtering, separating and washing, vacuum drying and getting silver-coated copper powder. The process is characterized by simple preparation and raw material, reduced silver-plated layer on container wall by adding silver amine solvent into reducing liquid, high silver converting rate. The electrical resistance of got copper powder is smaller than 2*10-4 omegacm.

Owner:TSINGHUA UNIV

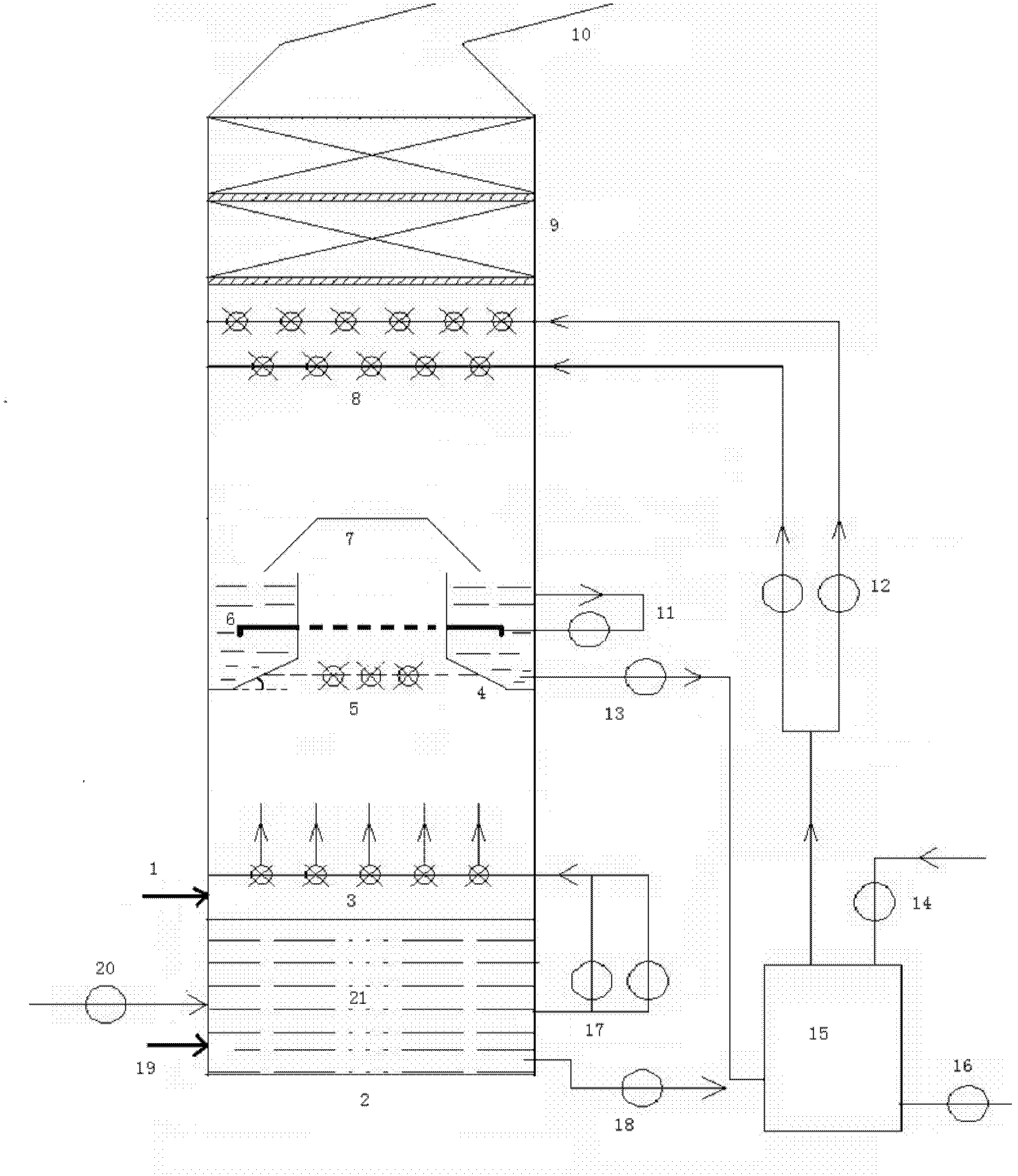

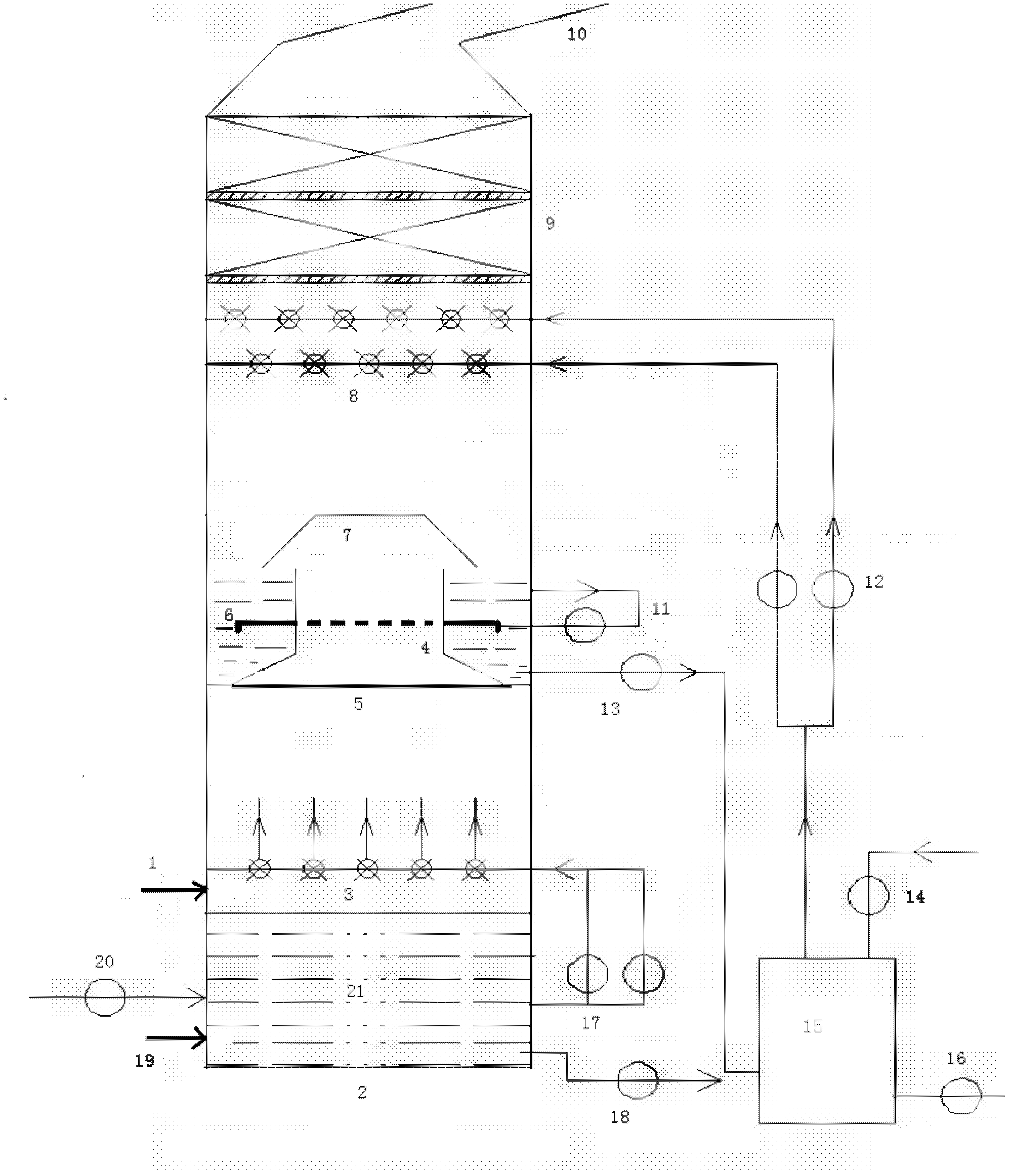

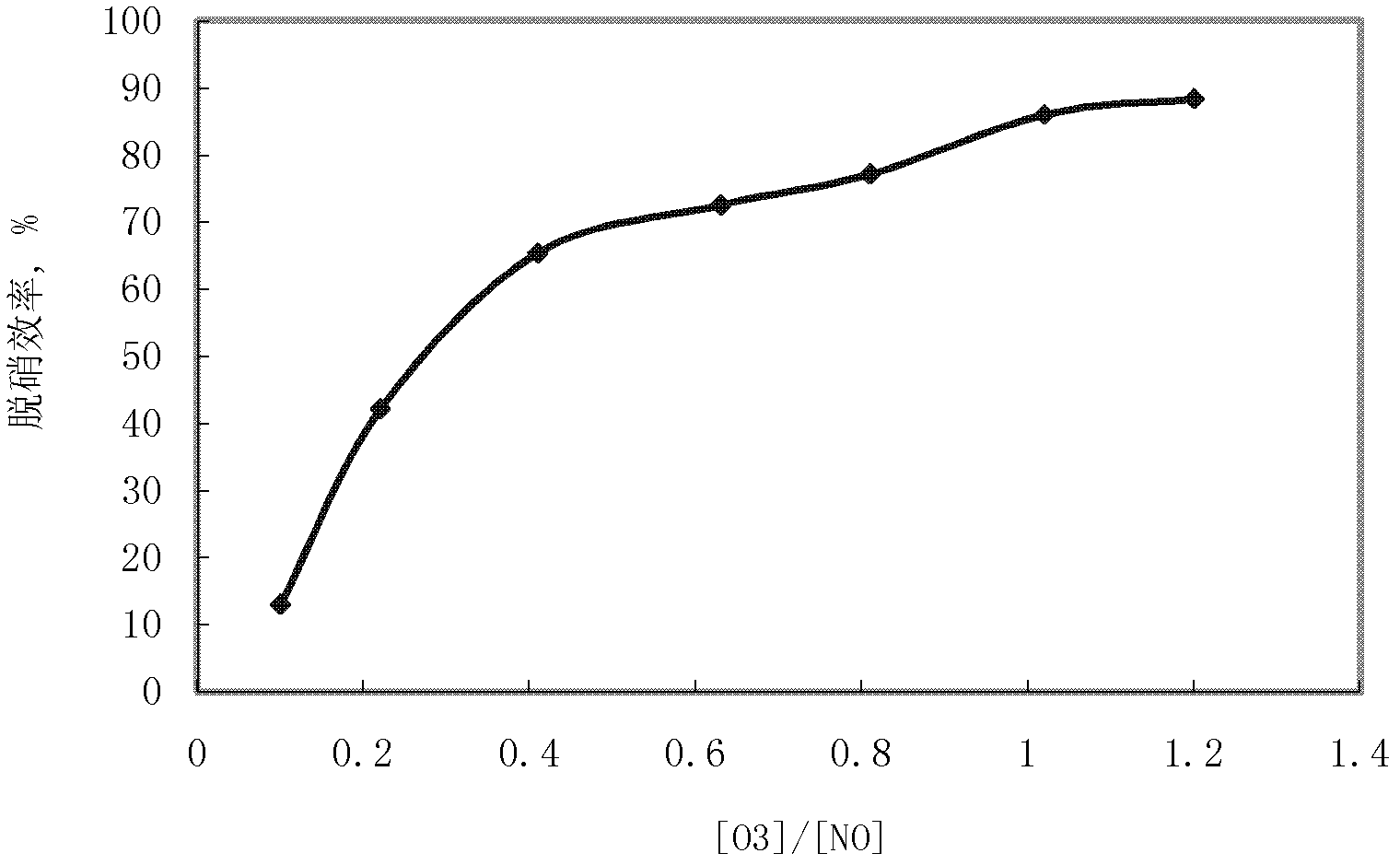

Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

InactiveCN102553428AAchieve removalUnique structureDispersed particle separationAir quality improvementOxidation zoneSlurry

The invention discloses an absorption tower for desulfurization and denitrification combined with an oxidant in forward-flow and back-flow spraying mode and a method. The absorption tower includes two washing sections: a first section is a desulfurization loop and arranged on the lower portion of the absorption tower, and sulfur dioxide and hydrogen chloride are removed through slurry forward-flow and back-flow and smoke contact cleaning; a second section cleans oxidized smoke pollutants in slurry back-flow and smoke contact mode mainly for removing oxynitride and heavy metal mercury. A slurry divider is arranged between the two cleaning sections, the bottom of the slurry divider is an oxidization area, and strong oxidant is sprayed in the area. For reducing consumption of the oxidant, a catalyst is added in second-loop slurry for achieving auxiliary oxidization. Sulfur dioxide, oxynitride, heavy metal mercury and the like can be removed simultaneously in a washing tower by the technology, and the absorption tower has the advantages of being high in efficient and simple and suitable for various combustion devices including fuel coal power stations, refuse incineration plants, organic and inorganic production enterprises and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

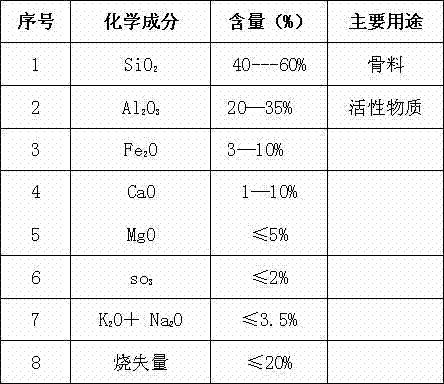

Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

InactiveCN103193447AStable compressive strength"Light weightSolid waste managementCeramicwareBrickAluminium powder

The invention provides an autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and a preparation method thereof. The brick is prepared from the following materials by weight percent: 65%-68% of pulverized fuel ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurization gypsum, 1%-1.5% of water-soluble aluminum powder, 0.5% of fatty acid soap and 0.5% of gleditsia sinensis powder. The preparation method comprises steps of: adding water to pulverized fuel ash and desulfurization gypsum which are screened mechanically and grinding together to form slurry, wherein the fineness of the pulverized fuel ash has to reach the condition that the residual of a 0.08mm square hoe sieve is not more than 15%; carrying out stirring, pouring, cutting and thermal, static and suspension curing on the slurry together with the lime, the cement and the aluminum powder suspension liquid which are weighed according to a weight ratio of a formula; utilizing an autoclave with good sealing for heating with 180-200 DEG C saturated steam under proper pressure (1.0-1.2Mpa); and steam curing for 8-10 hours so as to produce the aerated concrete brick. The aerated concrete brick has the characteristics of light weight, high strength, good heat insulation performance, good fire resistance and sound absorption, labor saving and energy saving, waste recycling and the like; and the aerated concrete brick meets constructional engineering requirements and environment protection requirements, and the wastes of enterprises are reasonably used.

Owner:SHIYAN JINSHA WALL MATERIALS

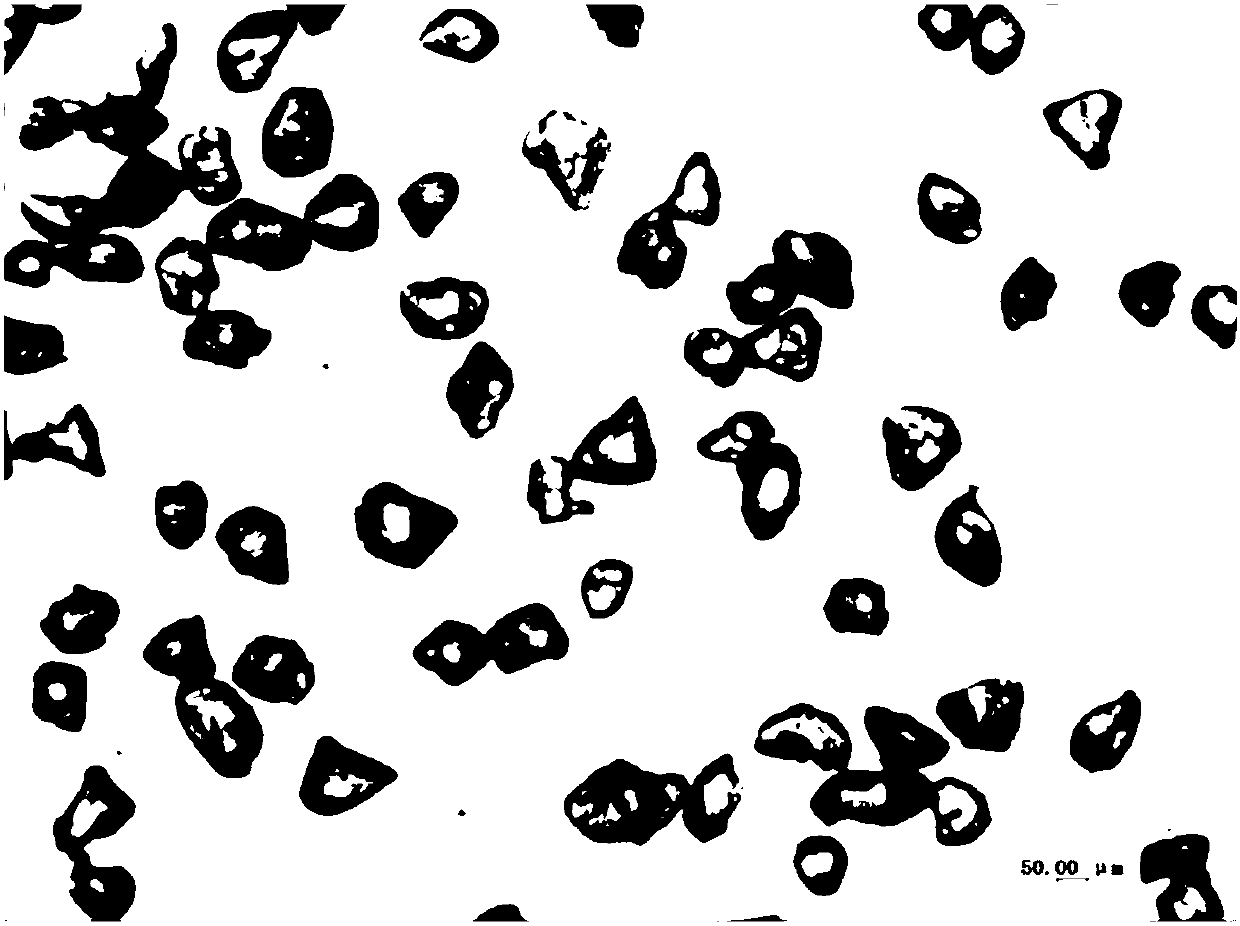

Preparation method of silver coated copper powder for electronic slurry

InactiveCN102328076ARaw material components are simpleThe process steps are simpleLiquid/solution decomposition chemical coatingIonAmmonium hydroxide

The invention provides a preparation method of silver coated copper powder for electronic slurry, which comprises the following operation steps of: (1) adding a certain mass of copper powder raw materials into a reaction container, adding acid solution, carrying out ultrasonic stirring for 5 to 15 min, filtering materials, and collecting filter residue; (2) weighing a proper amount of complexing agents, adding the complexing agents into deionized water, then, adding copper powder after acid washing, carrying out stirring dispersion, and obtaining reducing liquid; (3) weighing a proper amount of silver nitrate, adding the silver nitrate into the deionized water, adding ammonia water, stirring the solution until the solution is transparent, and obtaining silver-ammonia solution; (4) adding the silver-ammonia solution into the reducing liquid for taking reaction under the dispersion stirring of an ultrasonic dispersing device; and (5) filtering the solution after the reaction, washing the filter residue by the deionized water and / or absolute ethyl alcohol, carrying out vacuum drying, and obtaining the product of the silver coated copper powder for the electronic slurry. The preparation method has the advantages that the raw material ingredients are simple, the technical steps are simple, the preparation method can be used for large-scale production, and in addition, a silver layer can not be deposited on the surface of the reaction container.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

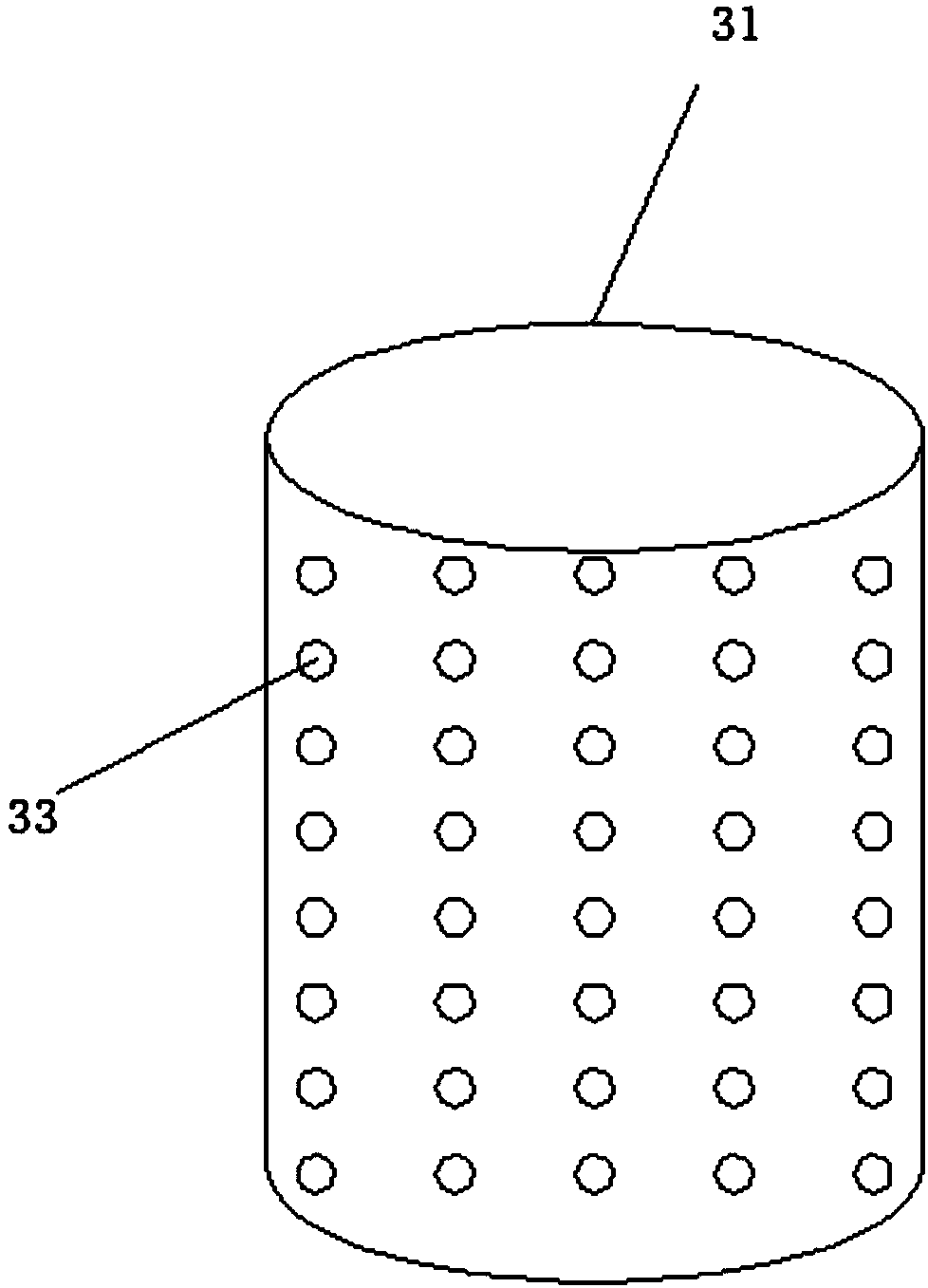

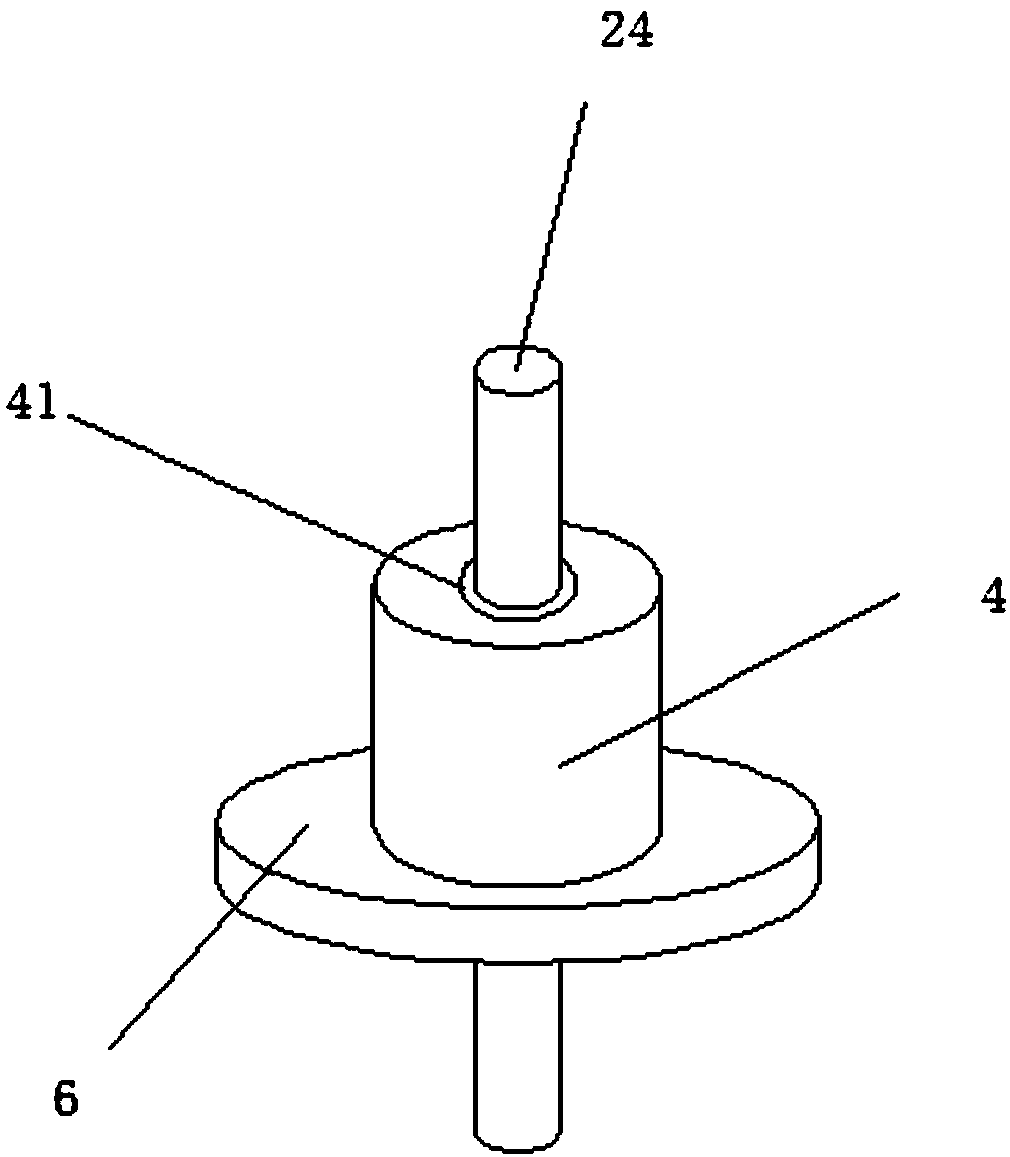

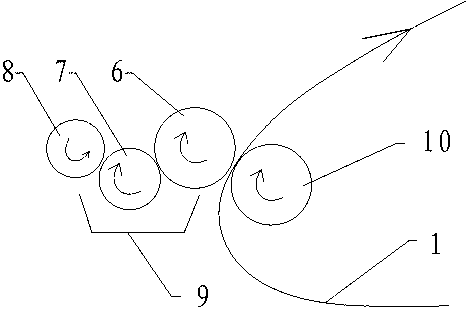

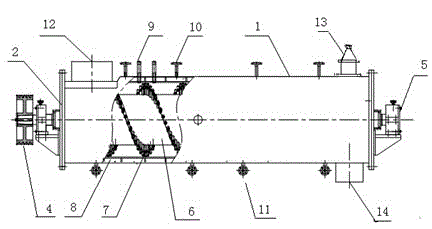

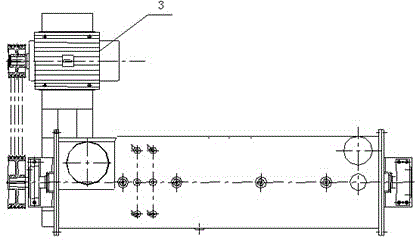

Roller centrifugal type environment-friendly treatment device for sludge dewatering

InactiveCN108033664AReasonable structureInnovative designSludge treatment by de-watering/drying/thickeningRotary centrifugesDrive shaftEngineering

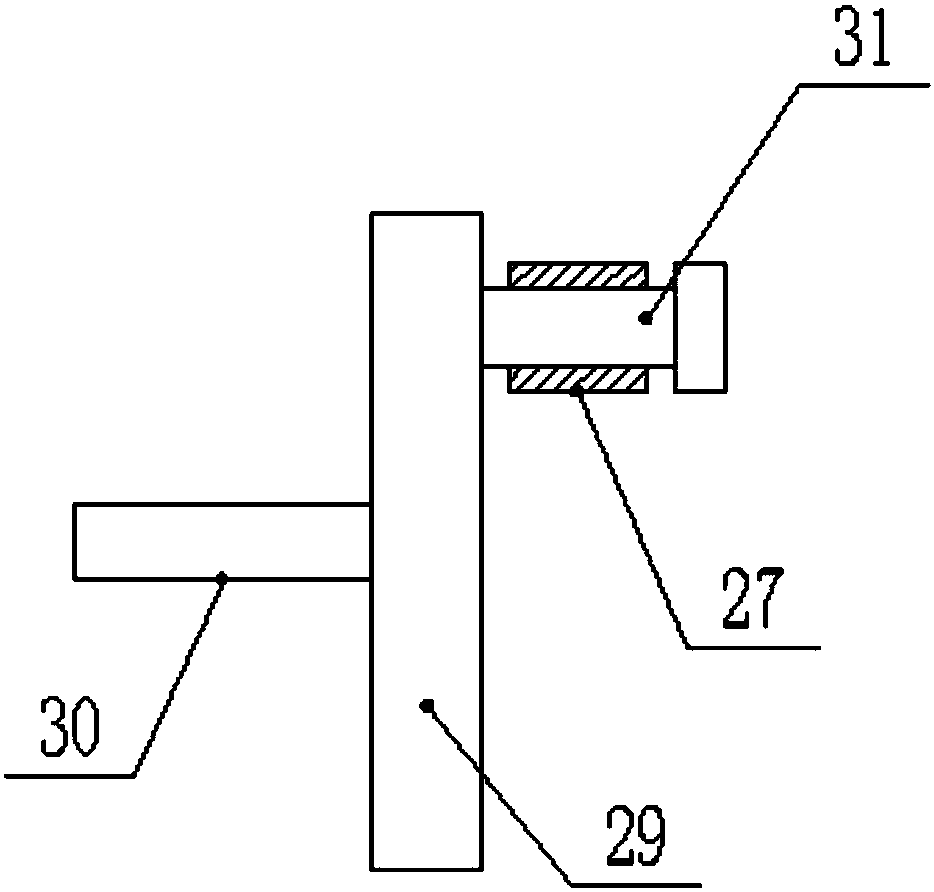

The invention discloses a roller centrifugal type environment-friendly treatment device for sludge dewatering. The device comprises a fixing base plate; a first supporting frame is arranged on the left side of the upper end of the fixing base plate; a guide base is arranged at the upper end of the first supporting frame; a driving shaft is arranged in the middle of the guide base; a first rotatingdisc is arranged at the right end of the driving shaft; a second supporting frame is arranged on the right side of the upper end of the fixing base plate; a driven shaft is arranged in the middle ofthe second supporting frame through a bearing; a second rotating disc is arranged at the left end of the driven shaft; an outer cylinder is arranged between the first rotating disc and the second rotating disc; a first motor is arranged on the left side of the lower end of the outer cylinder; a driving belt wheel is arranged at the upper end of the first motor; a driven belt wheel is connected tothe right end of the driving belt wheel through a belt; a main shaft is arranged at the upper end of the driven belt wheel; an inner cylinder is arranged at the upper end of the main shaft; and a counter shaft is arranged in the main shaft. According to the device, sludge can be efficiently dewatered by utilizing the centrifugal force, the dewatering efficiency of the sludge can be improved, and meanwhile, the dewatered sludge can be quickly poured out.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Natural macromolecular composite aqueous polyurethane bond and its preparation method

InactiveCN1876746AHigh bonding strengthImprove water resistanceProtein adhesivesPolyureas/polyurethane adhesivesWater basedEmulsion

The invention relates the natural high polymer composite water-based polyurethane binder and preparing method. The high polymer composite water-based polyurethane binder comprises 40-100% A water solution and 10-25% water-based polyurethane emulsion. The mass ratio of A mass percent and solid constituent is 20-80%, and the ratio of water-based polyurethane emulsion and solid constituent is 20-80%. The mass ratio of A and water-based polyurethane emulsion is 30-40%. The A comprises fecula, soy protein, modified starch, and modified soy protein. The product has the advantages of high bonding capacity, low cost, biodegradability, environmental protection and simple technology.

Owner:WUHAN UNIV OF TECH

Short fiber of polyethylene terephthalate and method for producing same

ActiveCN101525782AImprove performanceImprove breathabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention discloses short fiber of polyethylene terephthalate and a method for producing the same. A raw material for preparing the polyethylene terephthalate is glycol, wherein a carbon element of the glycol comes from a biological material. The cutting length of the short fiber obtained by adopting a conventional pre-spinning and post-spinning process is between 4 and 10 mm; the titer is between 6.5 and 6.8 dtex; the strength is between 3.0 and 4.0 cN / dtex; and the elongation is between 20 and 40 percent. Compared with the prior short fiber, the preparation of the short fiber of the polyethylene terephthalate utilizes bio-based glycol to replace glycol as a conventional petroleum source, reduces dependence on petroleum, relieves energy crisis, simultaneously improves the utilization of crops and achieves the effects of increment and profit generation.

Owner:TORAY IND INC

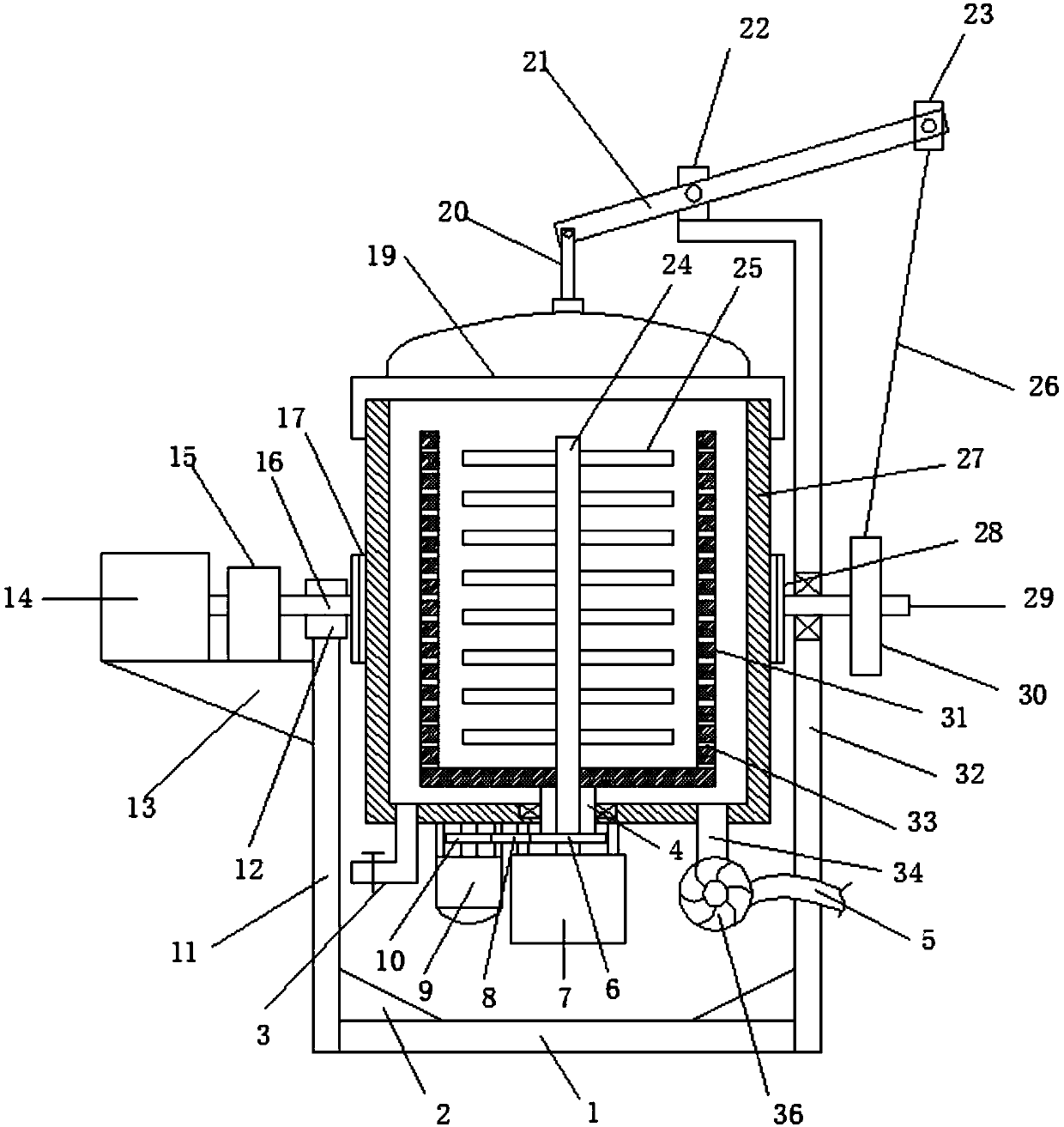

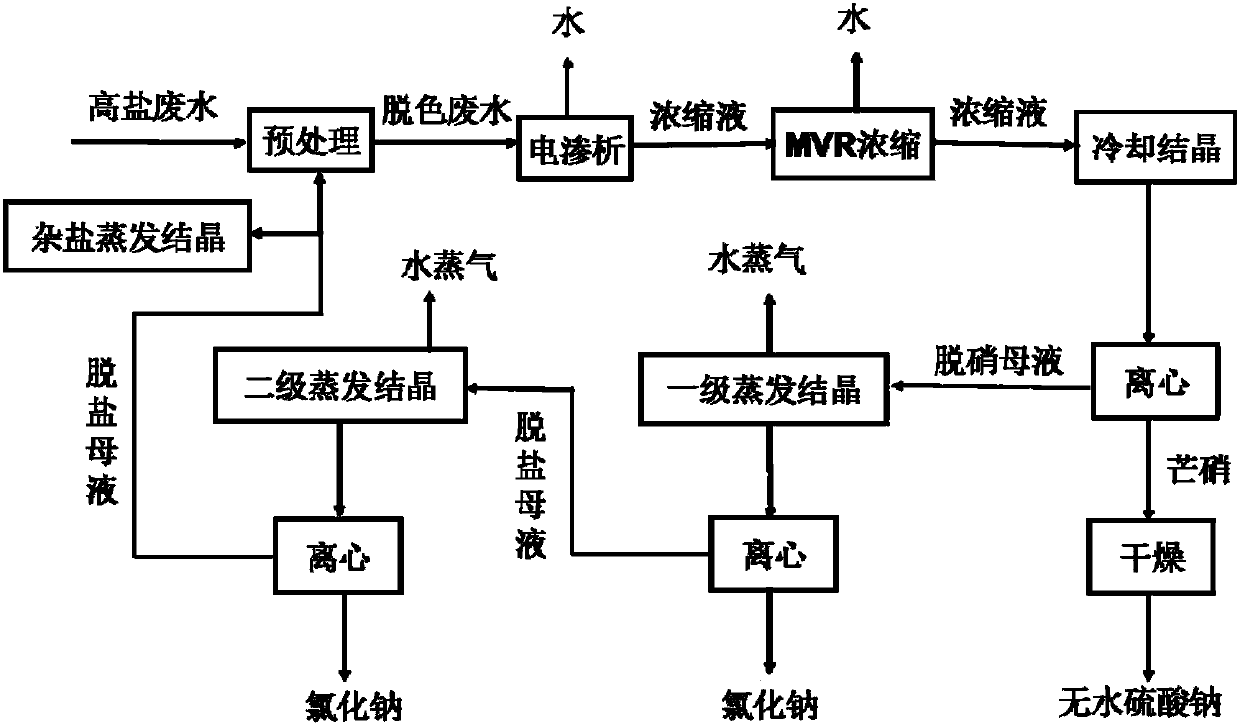

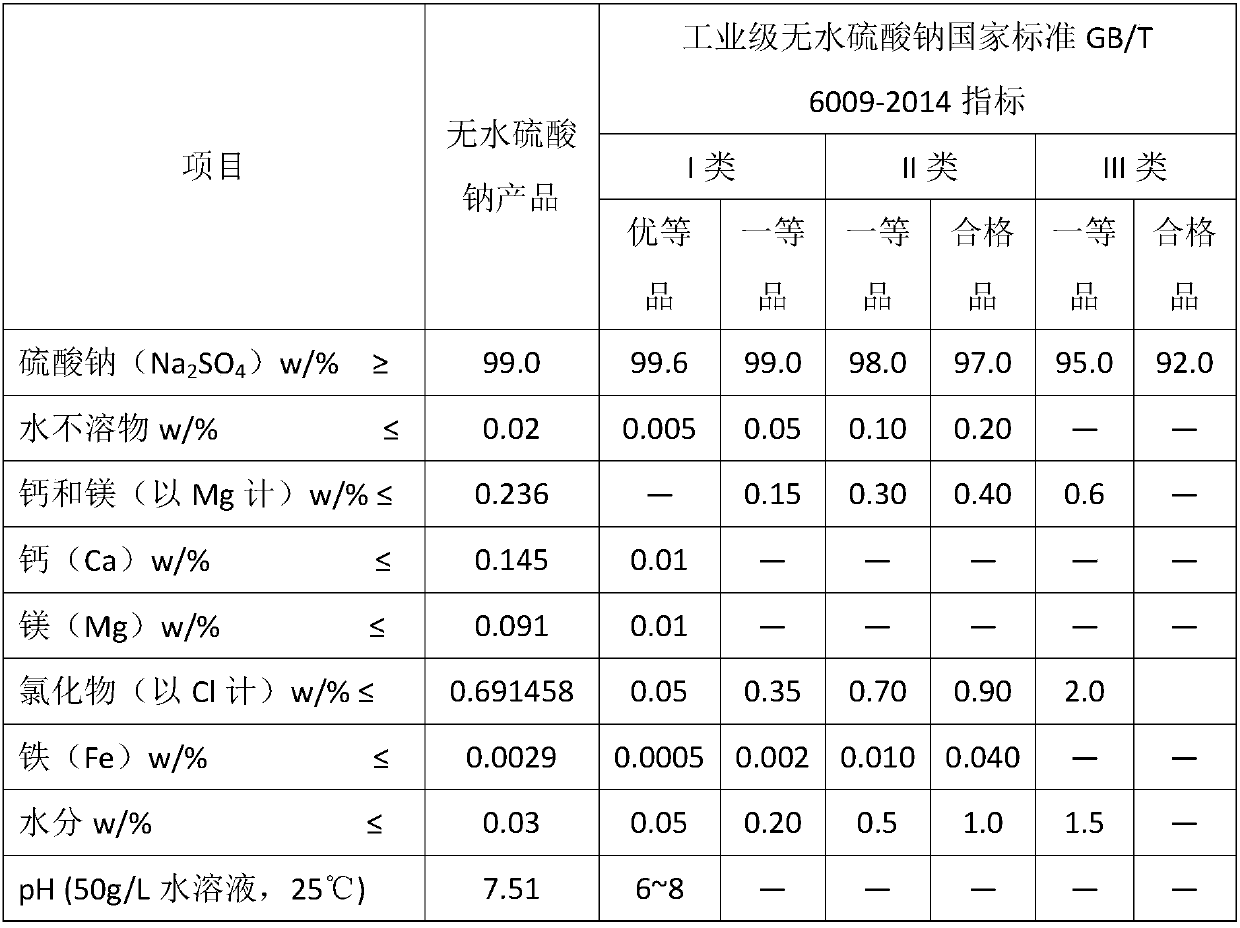

Separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater

ActiveCN107867707AAchieve zero discharge treatmentReduce processing costsWater contaminantsMultistage water/sewage treatmentActivated carbonEvaporation

The invention relates to a separate crystallization method for extracting recyclable high-purity sodium sulfate and sodium chloride from high-salinity wastewater. Activated carbon is adopted for decolorization pretreatment, the COD can be significantly reduced, and insoluble impurities and soluble substances such as Ca<2+>, Mg<2+>, silicate and the like can be removed simultaneously; after pretreatment, the wastewater is sent to electrodialysis and mechanical steam recompression devices sequentially for concentration, and sodium sulfate and sodium chloride are approximately saturated through concentration according to the initial composition of sodium sulfate and sodium chloride in the wastewater; the concentrated wastewater is sent to a crystallizer, sodium sulfate is obtained cooling crystallization, directly extracted, washed and dried, and an anhydrous sodium sulfate product is obtained; a concentrated solution of denitration mother liquor is subjected to two-stage evaporative crystallization, and the sodium chloride product is directly extracted, washed and dried; part of mother liquor obtained after two-stage evaporation salt removal returns to the system and is mixed with fed wastewater to be recycled, the rest mother liquor is sent to a mixed salt evaporative crystallizer. The sodium sulfate and sodium chloride products reaching the national standard are obtained.

Owner:TIANJIN UNIV

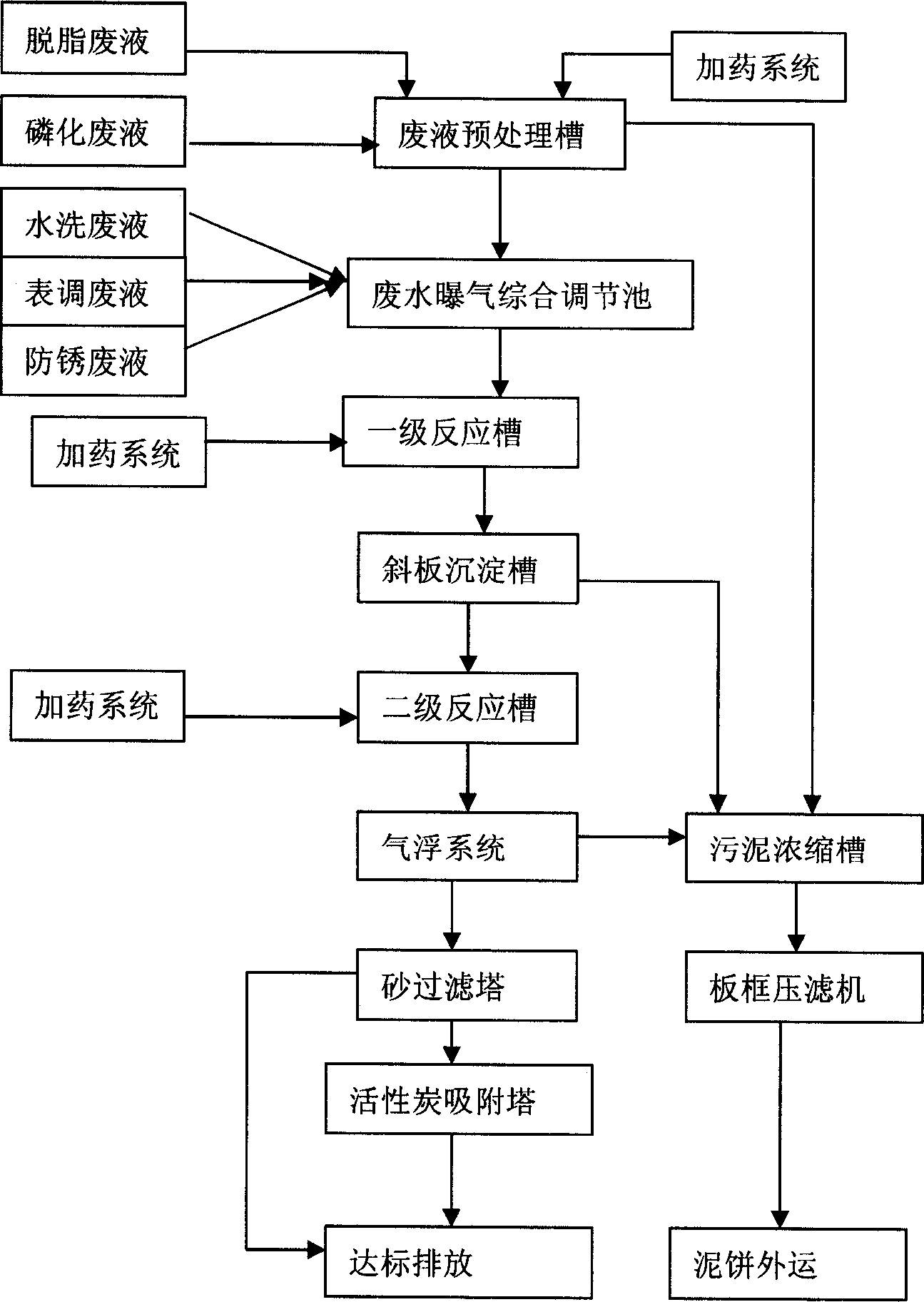

Method for treating manganese-series phosphorized waste water

ActiveCN101168463APrevent sudden load changesImprove buffering effectWater aerationMultistage water/sewage treatmentLiquid wasteSurface cleaning

The invention discloses a process for treating manganese phosphate waste water, which combines independent pretreatment and continuous treatment on output solution. The inventive process comprises processing acidifying demulsifying pretreatment on the cleaning waste liquid of degreasing slot independently, and processing coagulation deposition pretreatment on the cleaning waste liquid of phosphating slot, then combining the pretreated degreasing waste liquid and phosphating waste liquid , with normal-overflow washing waste liquid and other surface cleaning waste liquid and cleaning waste liquid without pretreatment to enter into following treatment, wherein the following treatment comprises aeration integral adjustment, first deposition reaction, inclined plate deposition separation, second coagulation reaction, air-float separation, sand filtration, and active carbon adsorption. The invention can effectively resolve the problems of phosphating waste liquid as instable water quality and high fluctuation impact load, with simple operation, high reliability, low cost, and environment protection.

Owner:BAOSHAN IRON & STEEL CO LTD

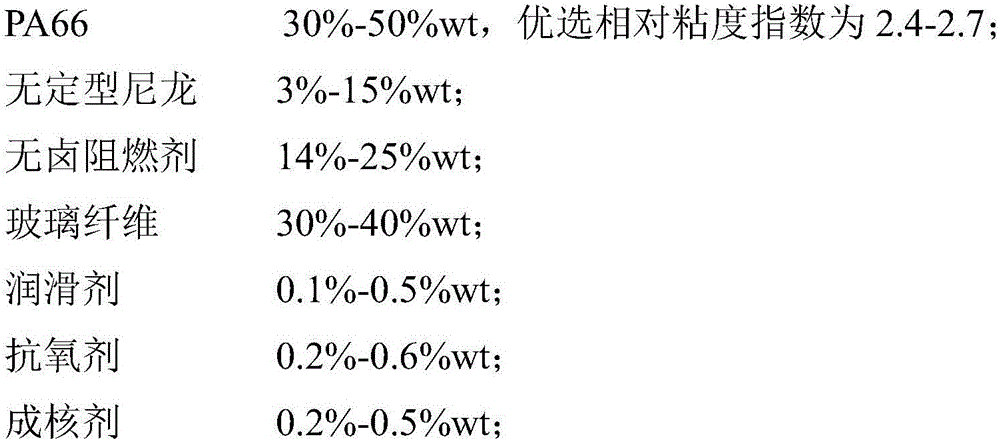

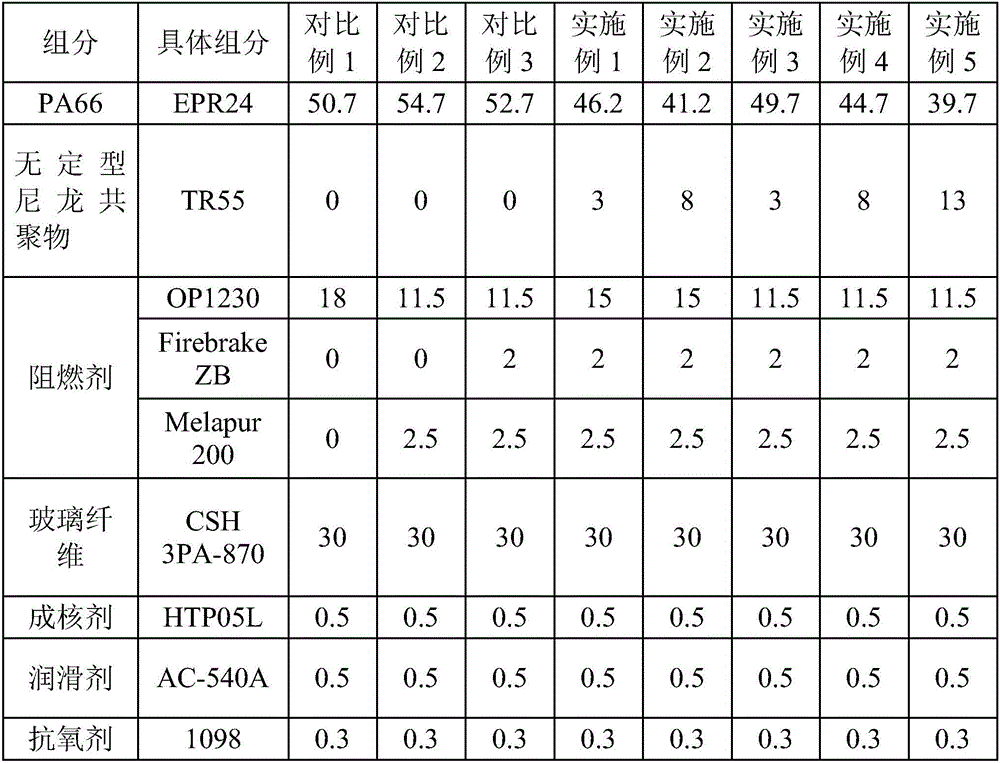

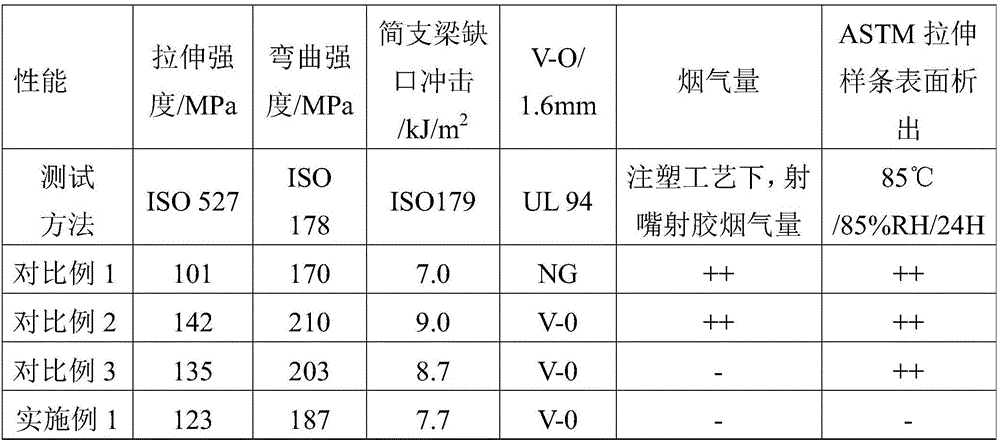

Halogen-free flame retardant glass fiber reinforced nylon as well as preparation method and application thereof

The invention belongs to an electricity & electronics industry, and provides halogen-free flame retardant glass fiber reinforced nylon. The halogen-free flame retardant glass fiber reinforced nylon is prepared from the following materials in percentage by weight: 30 to 50 percent of PA66, 3 to 15 percent of amorphous nylon, 14 to 25 percent of a halogen-free flame retardant, 30 to 40 percent of glass fiber, 0.1 to 0.5 percent of a lubricating agent, 0.2 to 0.6 percent of an antioxidant and 0.2 to 0.5 percent of a nucleating agent, wherein the halogen-free flame retardant is a composition of alkyl aluminum phosphate (OP), zinc borate and melamine pyrophosphate (MPP). A preparation method, provided by the invention, of the halogen-free flame retardant glass fiber reinforced nylon comprises the following steps: adding all the raw materials into a high-speed stirring machine for full and uniform mixing; after the raw materials are completely mixed, conveying the materials into a double-screw extruder through a metering material conveying device, setting the temperature of each region to be 240 to 285 DEG C, fully fusing the materials under shearing, mixing and conveying of screws, and finally performing extrusion, drawing and cooling to prepare a granular finished product. The halogen-free flame retardant glass fiber reinforced nylon provided by the invention is high in flame retardancy under an OP and MPP compound system, and the problem of separation out of the flame retardant under a wet environment is solved.

Owner:江苏晋伦塑料科技有限公司

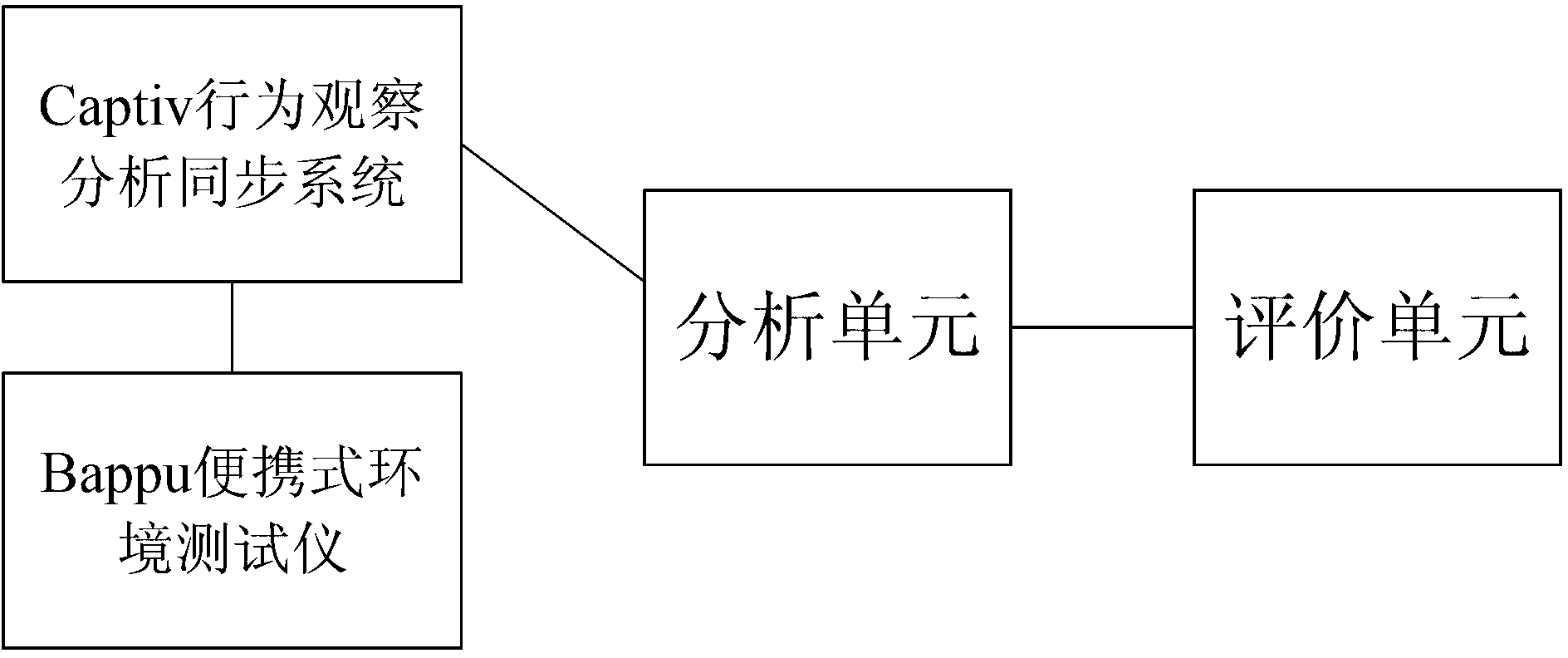

Assessment test method and device of timber architecture room environment

ActiveCN103218759AImprove superiorityImprove the living environmentData processing applicationsLife qualityStatistical analysis

The invention relates to an assessment test method and a device of a timber architecture room environment. The assessment test method includes that physical indexes of the timber architecture room environment and physiological indexes of a testee in the timber architecture room environment are synchronously tested, and physical index data and physiological index data are obtained, wherein the physical indexes include noise, lighting, a temperature and humidity, and the physiological indexes include electrocardio, a heart rate, respiration, a skin temperature, skin conductivity and surface myoelectricity of the testee; and statistic analysis is carried out on the physical index data and the physiological index data to obtain assessment test results. The invention further provides an assessment test device. According to the assessment test method, an assessment and / or comparation system of the timber architecture room environment is built, living environment, working environment and life quality of human beings are beneficially improved, and superiority of different kinds of timber architectures is beneficially and deeply developed.

Owner:INT CENT FOR BAMBOO & RATTAN

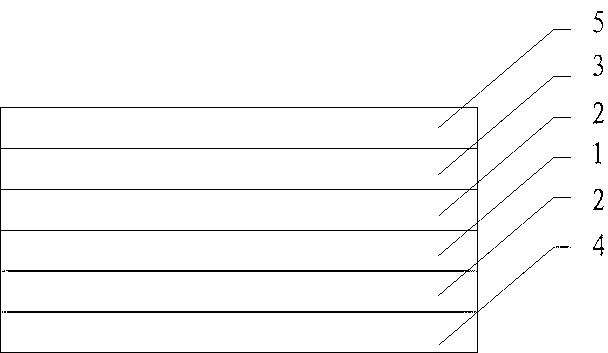

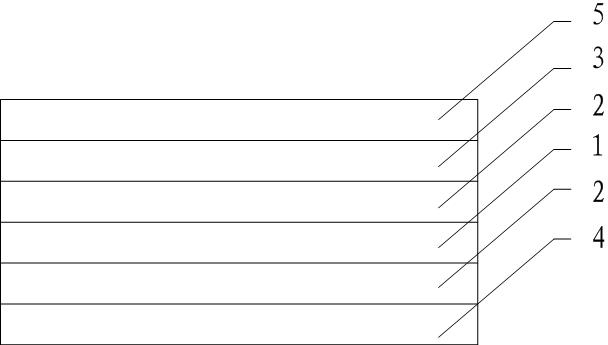

Preparation method of vertical texture colorful board as well as colorful board manufactured by using preparation method

ActiveCN102698949AUniform colorStable mechanical propertiesSpecial ornamental structuresPretreated surfacesChemical treatmentMetallurgy

The invention provides a preparation method of a vertical texture colorful board as well as a colorful board manufactured by using the preparation method, and solves the problem that the conventional colorful coating steel board has relatively poor surface anti-scratching capability and simple appearance effect. According to the technical scheme, the preparation method of the vertical texture colorful board comprises the following process steps of: manufacturing a substrate, degreasing, washing with water, carrying out chemical treatment on the surface of a steel board, roasting the surface of the steel board, coating primer on the surface of the steel board, curing the primer at a high temperature, and coating finish paint on the surface of the steel board; and meanwhile, coating back paint on the back surface of the steel board, drying the finish paint at the high temperature, and adhering a protection film on the front surface of the steel board. The invention further provides the colorful board manufactured by using the preparation method. The surface of the vertical texture colorful board has the advantages of high rigidity, high scoring resistance and high scratching resistance, and can be used for products with the high scoring resistance and the high scratching resistance, such as a refrigerator and an air conditioner. With the adoption of the preparation method of the vertical texture colorful board, the fingerprint resistance is improved, so that the 3D (three-dimensional) vertical texture effect is realized. Therefore, the vertical texture colorful board meets various requirements of a user in the market.

Owner:合肥河钢新材料科技有限公司

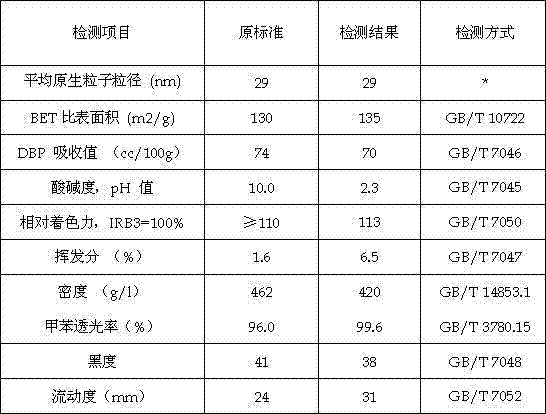

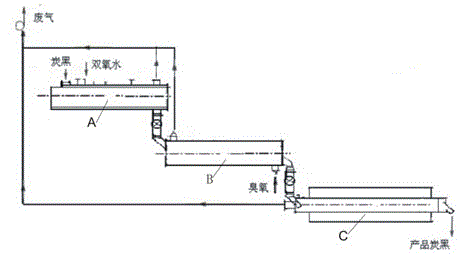

Production method of environment-friendly and safe furnace carbon black and carbon black product

ActiveCN104725899AExtended stayPromote graphitizationPigmenting treatmentExhaust fumesProcess engineering

The invention discloses a production method of environment-friendly and safe furnace carbon black and a carbon black product. The production method comprises the following steps: preheating raw material oil after fractioning treatment, then spraying the preheated raw material oil into a furnace carbon black reaction furnace with an ultra-long retention section from a throat pipe section, and strictly controlling the purity of the raw material entering the furnace to prepare carbon black smoke gas; collecting the carbon black in the carbon black smoke gas by a main bag filter; crushing the carbon black by a micron crushing machine, then sending the carbon black to a collection cyclone separator and an exhaust bag filter by a wind-sending fan, exhausting waste gas, collecting carbon black powder to a carbon black storage tank, and meanwhile, introducing one part of preheated hot air to a conveying pipeline from the wind-sending fan to the collection cyclone separator; sending the powdery carbon black in the carbon black storage tank to at least one oxidation-granulation unit for oxidation and granulation; sending the prepared oxidized carbon black into a roller rotary drying machine for drying; and drying and packaging a finished product. The process disclosed by the invention is safe and reliable, and the produced pigment carbon black can meet various international environment-friendly and safe requirements of the carbon black products.

Owner:安徽黑猫新材料有限公司

Non-radiation ceramic tile with high whiteness and manufacturing technique thereof

The invention discloses a ceramic tile with a high whiteness and no radiation as well as the manufacturing method thereof. The weight percents of the main raw materials of the ceramic tile is: 15-60 wt.% of burning talcum, 15-30 wt.% of feldspar, 5-30 wt.% of porcelain sand, 20-28 wt.% of black mud. The steps of manufacturing method is as follows: (1) calcining the talcum; (2) the manufacturing process is: raw materialsbatchingball millingremoving zirconiumspraying and millingmouldingdryingpenetratingburningpolishing; (3) doing a strict anti-pollution treatment after polishing. The calcining temperature of the talcum is: 1200 DEG C; the calcining temperature of the ceramic tile is 1210-1230 DEG C; burning period is: 60-80 minutes; whiteness is: about 80 DEG. The invention firstly does a pre-burning treatment to the talcum material in 1200 DEG C, thus it manages its sheet structure and removes volatile with a high temperature. The disposed material is without greasy texture and the dosage will not influence the products molding.

Owner:GUANGDONG WINTO CERAMICS

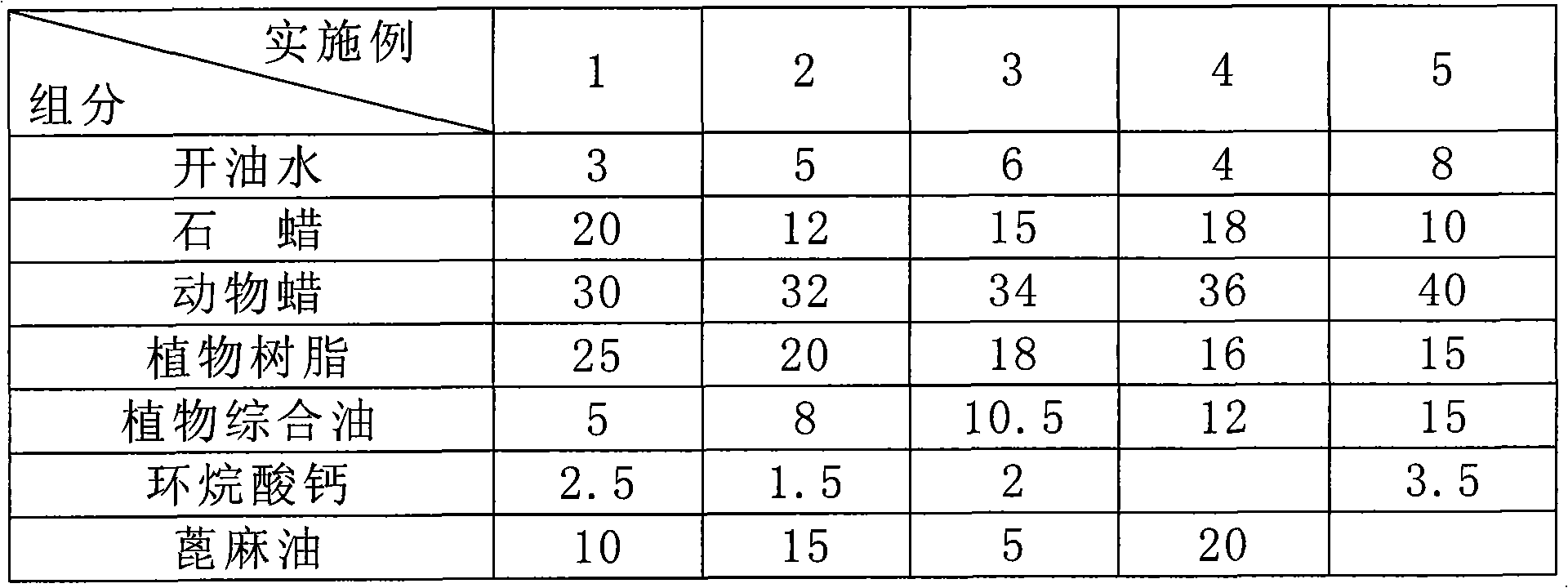

Environmental protection type wood wax oil and preparation method thereof

InactiveCN101659832AWide variety of sourcesLow priceWax coatingsNatural resin coatingsParaffin waxPropolis

The invention provides an environmental protection type wood wax oil and a preparation method thereof, belonging to the technical field of chemical products. The wood wax oil and the preparation method solve the problems that the existing wood wax oil has higher production cost, unreasonable compatibility between raw materials, and poorer uniformity after being mixed. The wood wax oil is preparedby the following components according to part by weight: 3-8 parts of boiled oil water, 10-20 parts of paraffin wax, 30-40 parts of animal wax, 15-25 parts of propolis and 5-15 parts of plant composite oil. The preparation method has simple process flow, few steps, wide raw material sources and low cost; and the prepared product has better uniformity, low toxicity, no pollution and the effects ofmould proof, moisture proof, damp proof, moth proof, surface conservation, beautification and the like.

Owner:王增平

Polypropylene composite material for automotive interior parts and production process of polypropylene composite material for automotive interior parts

ActiveCN108047560AImprove mechanical propertiesImprove antibacterial propertiesPolypropylene compositesAntioxidant

The invention discloses a polypropylene composite material for automotive interior parts and a production process of the polypropylene composite material for the automotive interior parts. The polypropylene composite material for the automotive interior parts is prepared from, by weight, 55-80 parts of homo-polypropylene, 6-12 parts of ethylene-propylene-diene monomer rubber, 15-25 parts of talcumpowder, 0.2-0.8 part of a light stabilizer, 5-7 parts of a compatibilizer, 0.8-1.2 parts of a coupling agent, 0.3-0.6 part of an antioxidant, 5-8 parts of a flame retardant, 3-6 parts of an antibacterial and 0.2-2.1 parts of an adsorbent. Compared with the prior art, the polypropylene composite material for the automotive interior parts has advantages of great antibacterial and fame retardation performances, low VOC (volatile organic compound) and the like. In addition, the polypropylene composite material for the automotive interior parts has appearance and performances of rubber and can bemade into the automobile interior parts such as driver's seat outer lateral plates, small cover caps, lateral plate inner plates, inner lateral plate plastic parts, passenger seat outer lateral plates, door sheet armrest frameworks, door embedded decorative plate frameworks, door embedded decorative plates and the like through an injection molding process.

Owner:湖北瀚氏汽车零部件有限公司

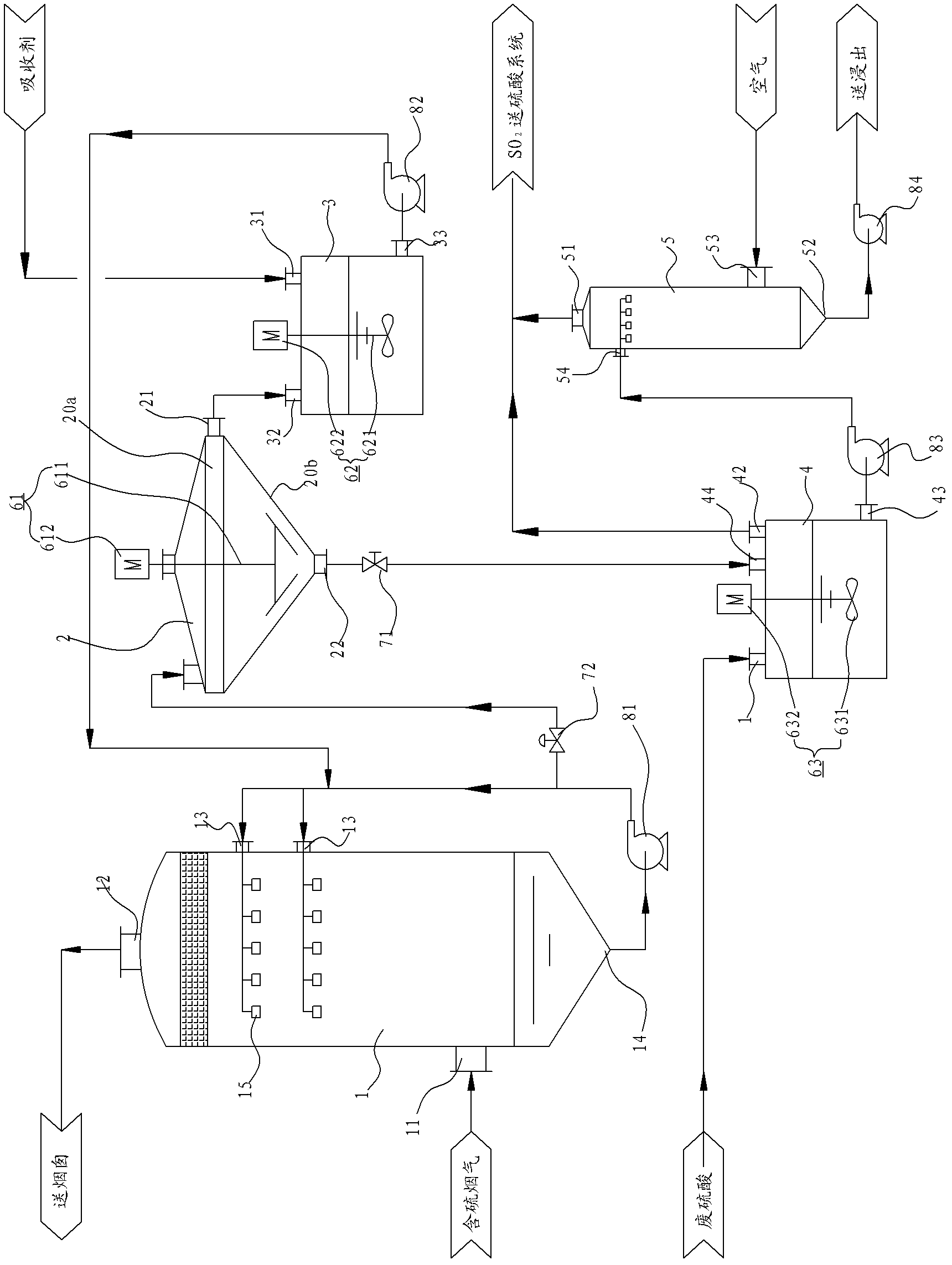

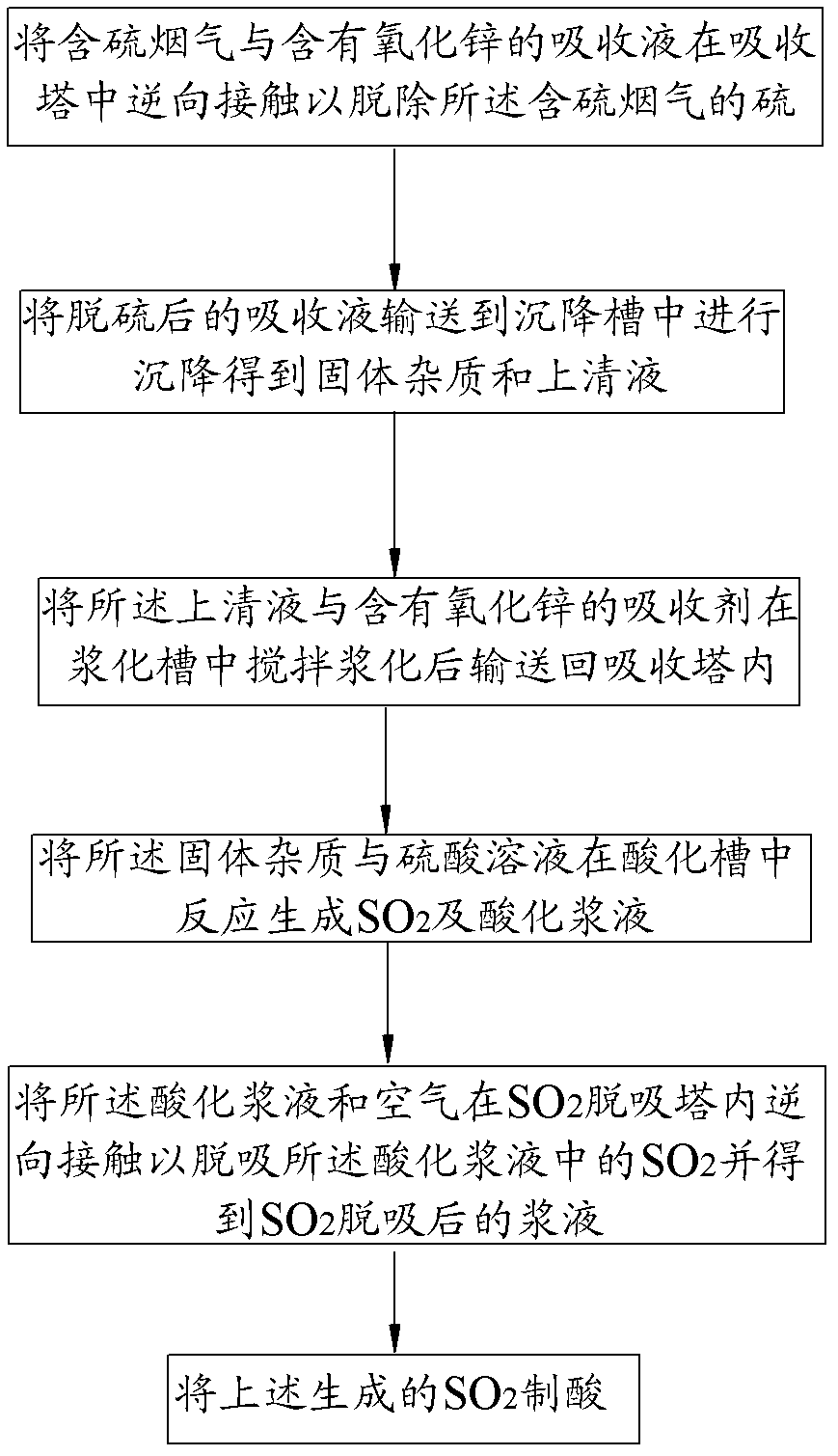

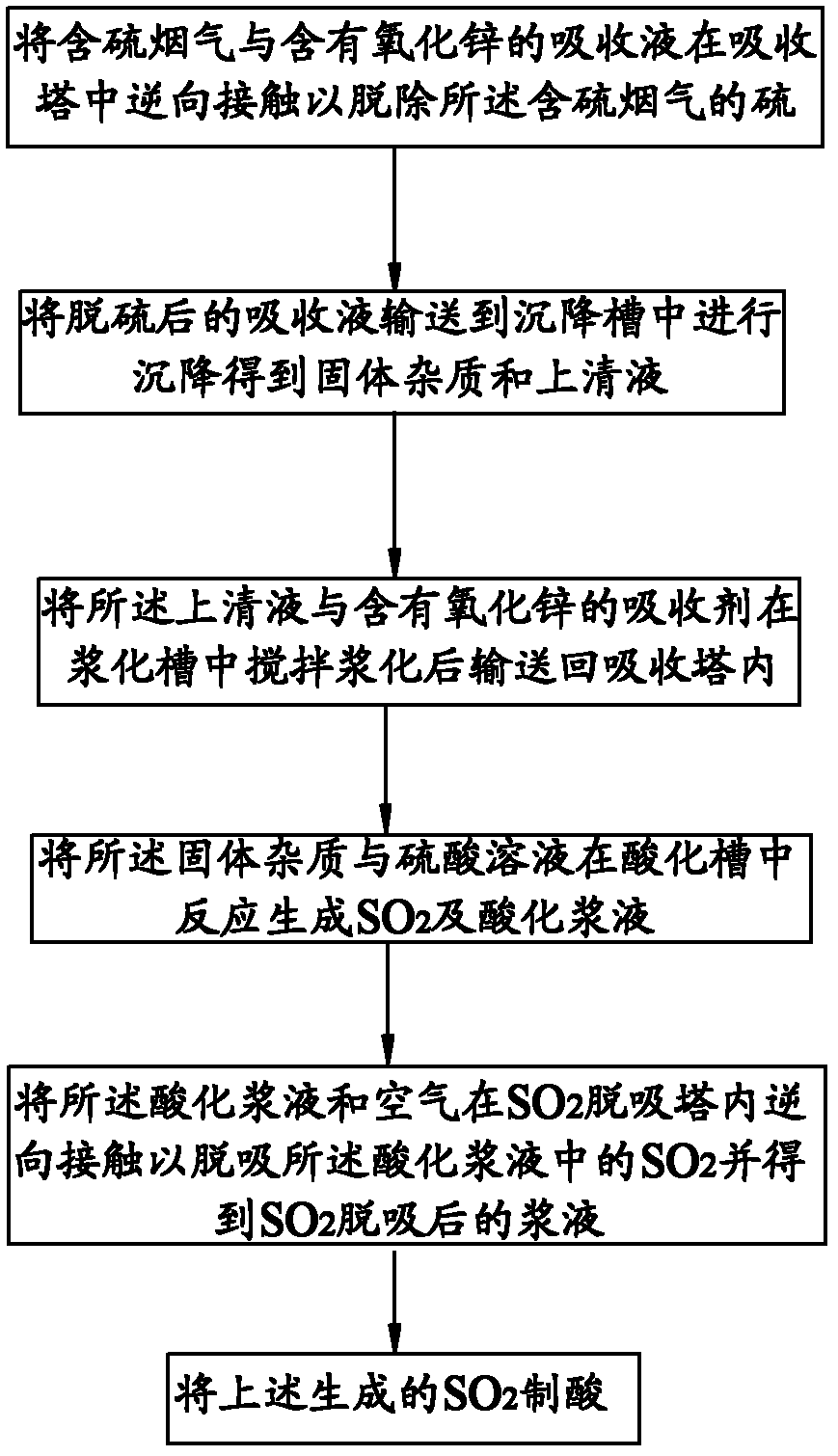

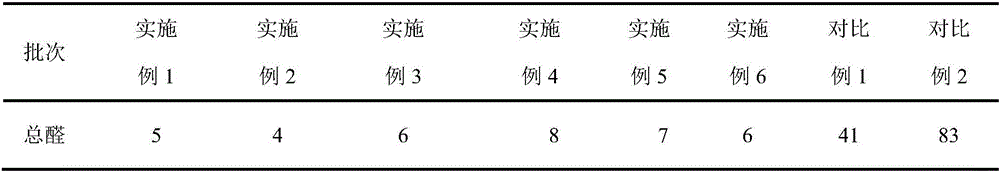

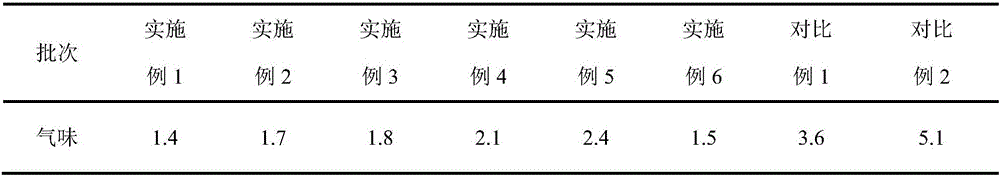

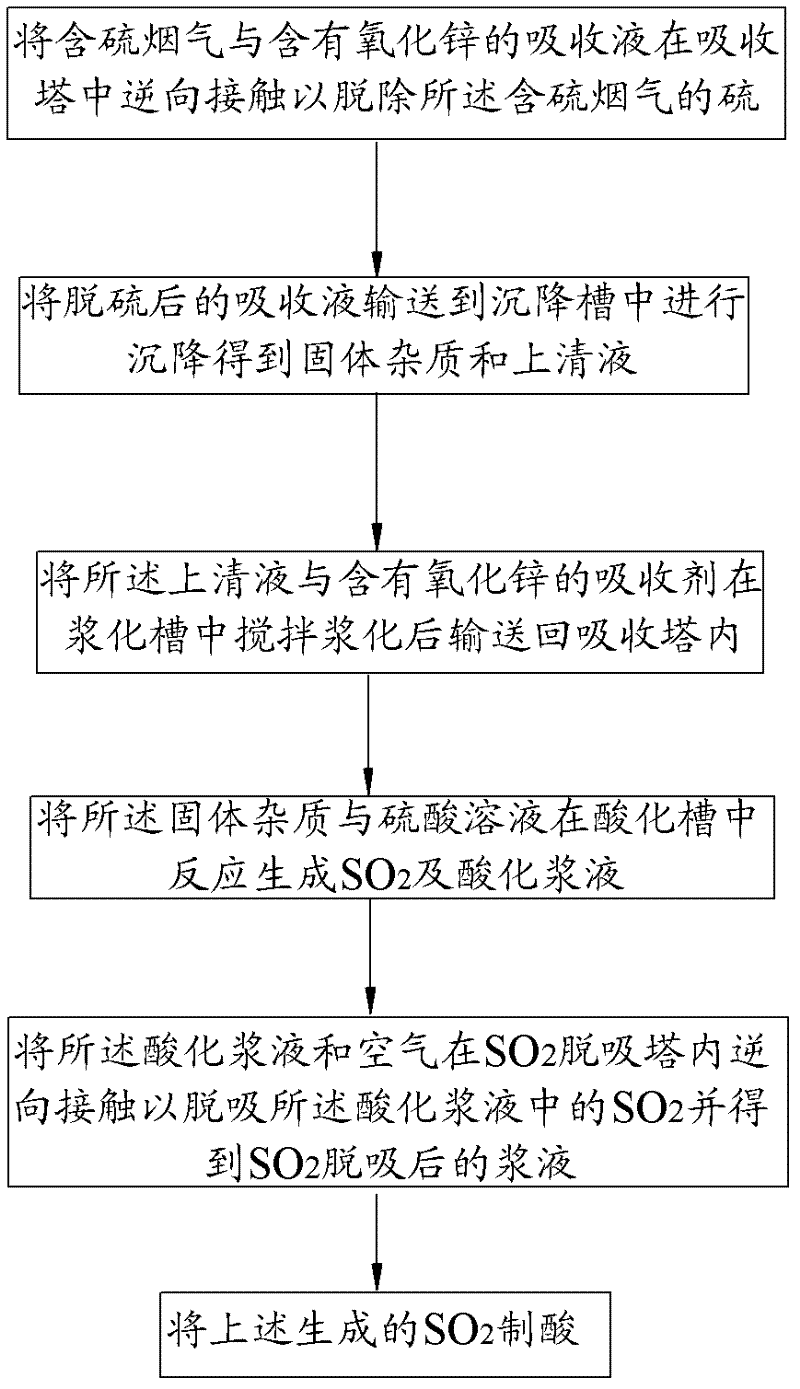

Zinc oxide desulfuration technology

InactiveCN102423622ALow costMeet the needs of environmental protectionZinc sulatesDispersed particle separationDesorptionSlurry

The invention discloses a zinc oxide desulfuration technology, which comprises the following steps of: reversely contacting sulfurous flue gas with a zinc-oxide-contained absorption solution in an absorption tower so as to remove sulfur from the sulfurous flue gas; conveying the desulfurated absorption solution into a settling tank and carrying out settling so as to obtain solid impurities and a supernatant; stirring and pulpifying the supernatant and a zinc-oxide-contained absorbent in a pulpifying tank, and then, conveying the mixture back the absorption tower; subjecting the solid impurities and a waste acidic solution to reacting in an acidifying tank so as to produce SO2 and acidified serous fluid; reversely contacting the acidified serous fluid with air in a sulfur dioxide desorption tower so as to desorb the SO2 from the acidified serous fluid and obtain SO2-desorbed serous fluid; and carrying out acid making by using the produced SO2. According to the zinc oxide desulfuration technology disclosed by the embodiment of the invention, the cost for raw materials in each system is saved, and no waste gas, waste liquid and waste solid are discharged in the whole system, so that the totally-closed operation is realized, and the requirements on environmental protection are met. In addition, the technology is simple, the process is short, further, the operation is convenient, and the continuous operation can be realized.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for removing volatile substances in polyether polyol and reducing smell

The invention discloses a method for removing volatile substances in polyether polyol and reducing smell. The method comprises the following steps: adding an antioxidant and a reducing agent into polyether polyol, treating with a stripping tower and a short-range evaporator, and collecting a polyether polyol product. Through the use of both antioxidant and reducing agent, the antioxidant prevents oxidation of unsaturated bond in polyether, and the source for generating some aldehyde ketone volatile substances is cut; and moreover, the reducing agent can reduce the aldehyde ketone substances into alcohols, the hydrogen bond interaction between hydroxyls is obviously lower than a chemical bond, and thus the volatile substances are removed more easily.

Owner:WANHUA CHEM GRP CO LTD

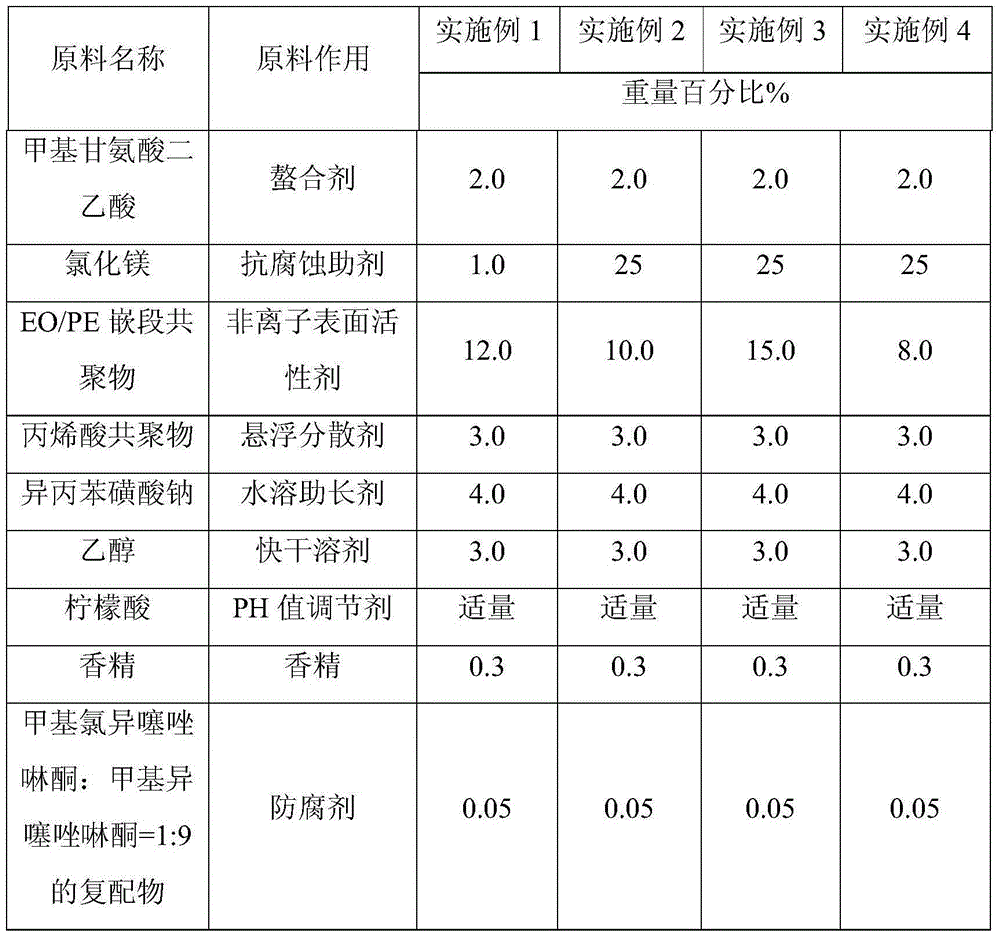

Automatic domestic dishwasher rinsing agent with sterilization effect

ActiveCN105062715AEfficient removalEnsure stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEscherichia coliHydrotrope

The invention discloses an automatic domestic dishwasher rinsing agent with a sterilization effect. The rinsing agent comprises components of raw materials in percentage by weight as follows: 5.0%-15.0% of a non-ionic surfactant, 1.0%-5.0% of a chelating agent, 0.05%-2.0% of a preservative, 2.0%-10.0% of a suspension dispersing agent, 1.0%-10.0% of a hydrotropic agent, 0.1%-10.0% of a solvent, 0.1%-8.0% of an anti-corrosion aid, 0.5%-3% of a pH value regulator and 0.1%-0.3% of essence. Specific anti-corrosion and sterilization components are added to the rinsing agent, Escherichia coli or staphylococcus aureus possibly existing on tableware can be removed effectively while the product safety is guaranteed, the removal rate for the Escherichia coli and the staphylococcus aureus is higher than 99.00%, and the rinsing agent can be used in home life, is energy-saving and environment-friendly and has bright application prospect.

Owner:GUANGZHOU LIBY

Hybrid dynamic polymer composition and applications thereof

PendingCN109666178AImprove performanceImprove self-healing abilityBulk chemical productionCross-linkDevice material

The present invention discloses a hybrid dynamic polymer composition, which at least comprises two components A and B, wherein the component A is a dynamic polymer, the dynamic polymer at least contains a cross-linking network, and further simultaneously contains an unsaturated carbon-carbon triple bond capable of being subjected to an alkyne cross translocation double decomposition reaction and ahydrogen bond group capable of forming supramolecular hydrogen bond action, and the component B is a catalyst and / or a complex thereof for catalyzing the exchange reaction of the dynamic covalent bond in the component A. According to the present invention, the composition integrates the dynamic covalent properties and the supramolecular dynamic characteristics, wherein the supramolecular dynamiccharacteristics can make the material have stimuli responsiveness and self-healing property, and the dynamic covalent characteristics can make the covalently-cross-linked polymer have the structural stability and the mechanical strength under non-catalytic reaction conditions, and have dynamic reversibility under catalytic reaction conditions, such that the composition has characteristics of self-healing property, recyclability, repeatable processability and the like, and can be widely used in self-healing materials, toughness materials, thermal insulation materials, shape memory materials, energy storage device materials, toys, toy fillers and the like.

Owner:厦门逍扬运动科技有限公司

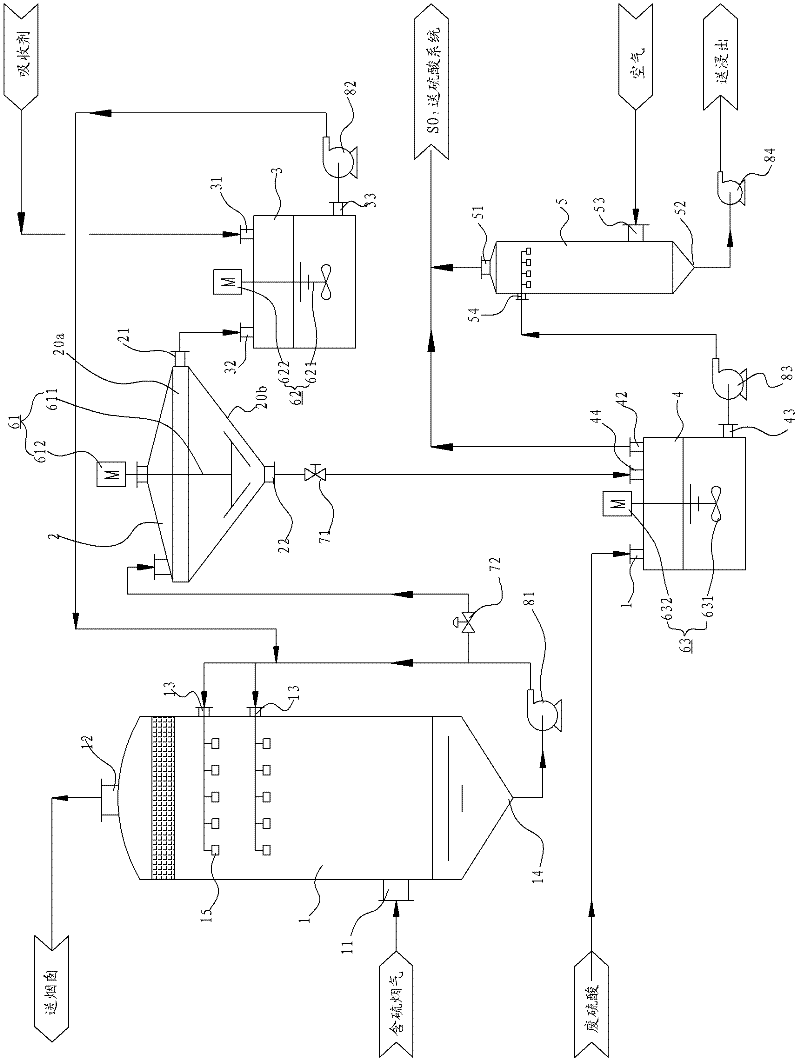

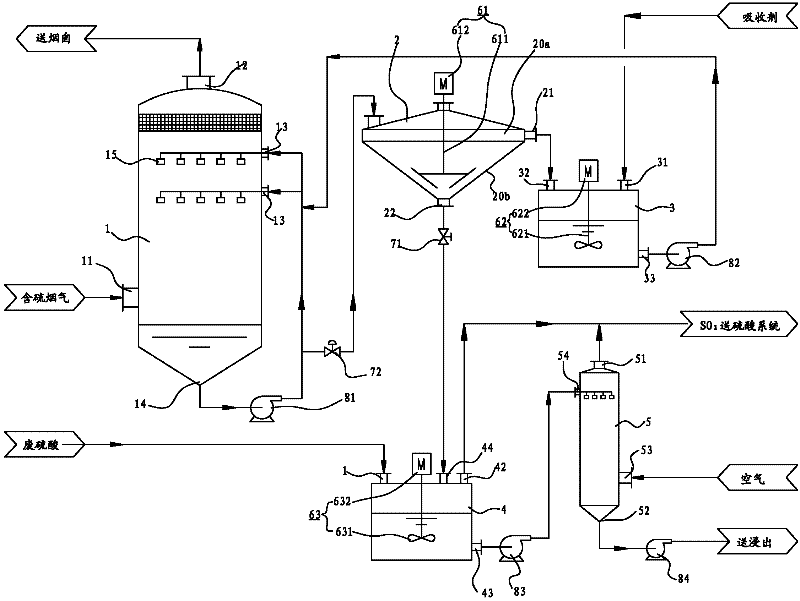

Zinc oxide desulphurization system

ActiveCN102389705AReduce foulingReduce cloggingZinc sulatesDispersed particle separationLiquid wasteDesorption

The invention discloses a zinc oxide desulphurization system comprising an absorption tower, a settling tank, a slurrying tank, an acidifying tank and a sulfur dioxide desorption tower, wherein the absorption tower is provided with an air inlet, an air outlet, an absorption liquid inlet and an absorption liquid outlet; the settling tank is communicated with the absorption liquid outlet; the slurrying tank is communicated with the settling tank, so that absorbent and supernatant liquor are sent to the absorption tower after being stirred; the acidifying tank is connected with a solid-contained slurry outlet of the settling tank; and the sulfur dioxide desorption tower is connected with the acidifying tank. According to the zinc oxide desulphurization system, by the control on the solid content and the pH value of the absorption liquid in the absorption tower, the problems of equipment blockage and scaling are obviously reduced and the absorption efficiency of SO2 is not influenced. In addition, without the discharge of any waste gas, waste liquid and waste solid, fully-closed operation is achieved. The equipment is simple, the operation and the maintenance are convenient and the cost is low; and compared with the traditional zinc oxide desulphurization, the zinc oxide desulphurization of the invention is short in process, convenient to operate and capable of realizing continuous operation.

Owner:CHINA ENFI ENGINEERING CORPORATION

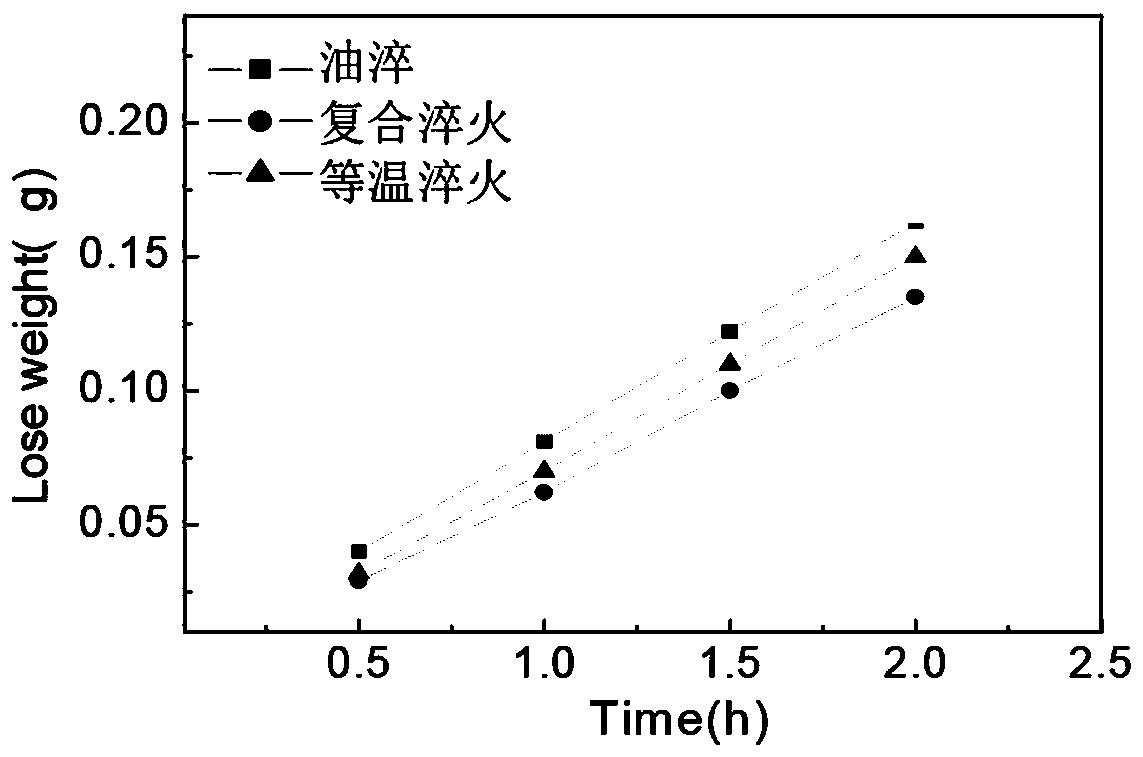

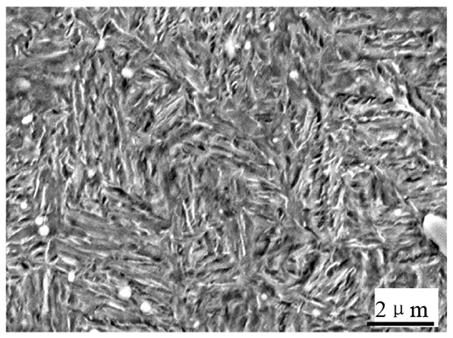

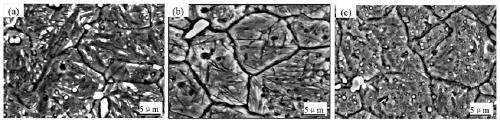

Method for optimized quenching process for obtaining 8Cr4Mo4V steel

The invention relates to a method for an optimized quenching process for obtaining 8Cr4Mo4V steel. The method comprises the following steps of (1) determining a heating solution process; (2) determining the time point of the highest hardness of isothermal hardening; (3) carrying out composite quenching treatment on the basis of the step (2); (4) selecting an optimized composite quenching process sample; and (5) carrying out tempering treatment on the optimized composite quenching process sample obtained in the step (4) at 510-550 DEG C for 1.8-2.5 h for 3-4 times, and obtaining the 8Cr4Mo4V steel subjected to final optimized heat treatment. The method has the advantages of scientificity, feasibility, simplicity in operation and the remarkable effect, and a space for improving the performance of the 8Cr4Mo4V steel is enlarged.

Owner:SHENYANG POLYTECHNIC UNIV

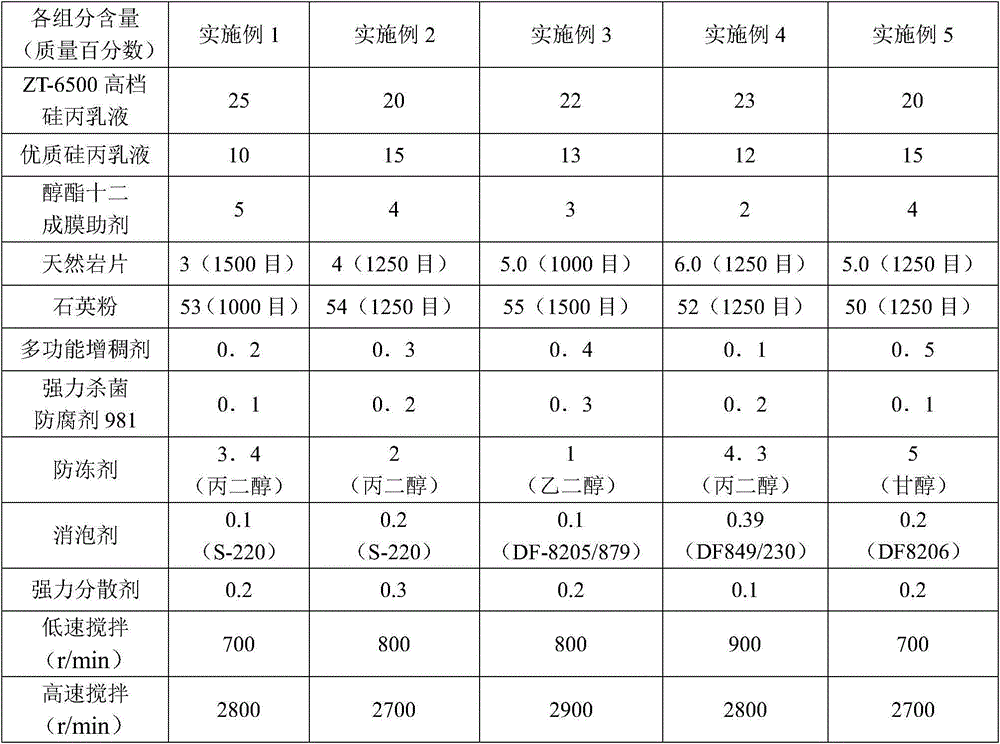

Waterborne environment-friendly silicone-acrylic real stone exterior wall coating and preparation method thereof

The invention discloses a waterborne environment-friendly silicone-acrylic real stone exterior wall coating. The coating comprises the following components in percentage by mass: 30-40% of silicone-acrylic emulsion, 2-5% of texanol ester alcohol film forming aid, 2-6% of natural rock slices, 50-55% of quartz powder, 0.1-0.5% of thickener, 1-5% of anti-freezing agent, 0.1-0.3% of dispersant, 0.1-0.3% of defoaming agent and 0.1-0.3% of preservative. The coating is natural, environment-friendly and non-fading and has the advantages of extremely good acid and alkali resistance, water resistance and pollution resistance, strong third dimension, good texture, good decoration effect and the like, a coating film is tough and extremely strong in adhesive force, the defects that a traditional real stone coating is easy to whiten when being scoured by water and easy to yellow under the irradiation of sunlight is overcome, the rock grain effect of natural granite is imitated, the texture of the granite is vividly revealed, the original appearance of the granite is restored, and the exterior wall coating has rich texture similar to stone, and brings solemn and gorgeous visual enjoyment like the granite.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

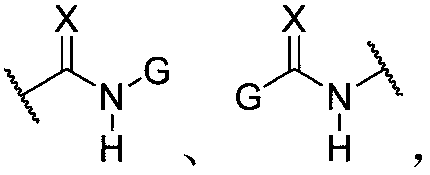

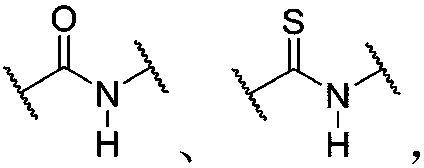

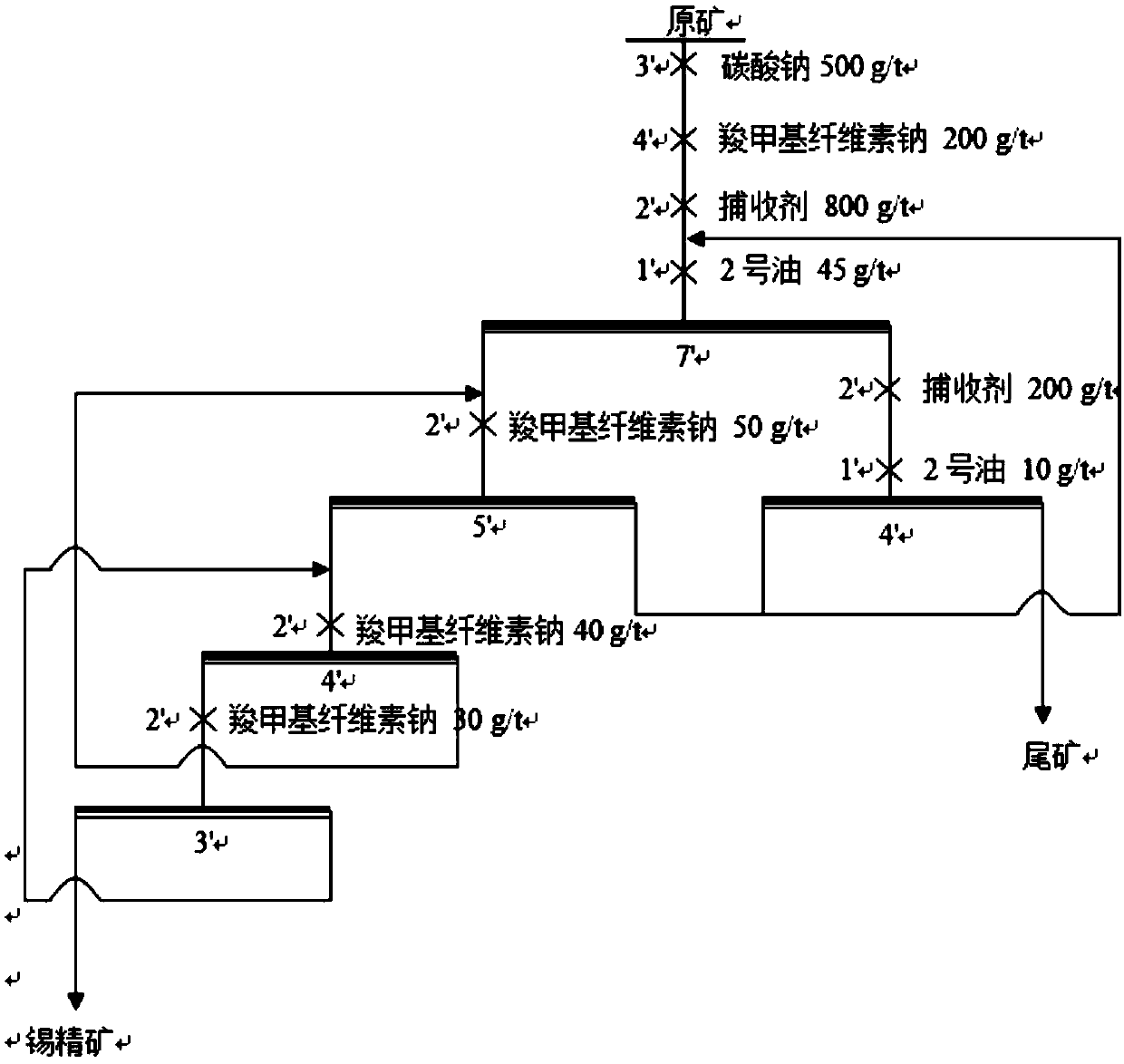

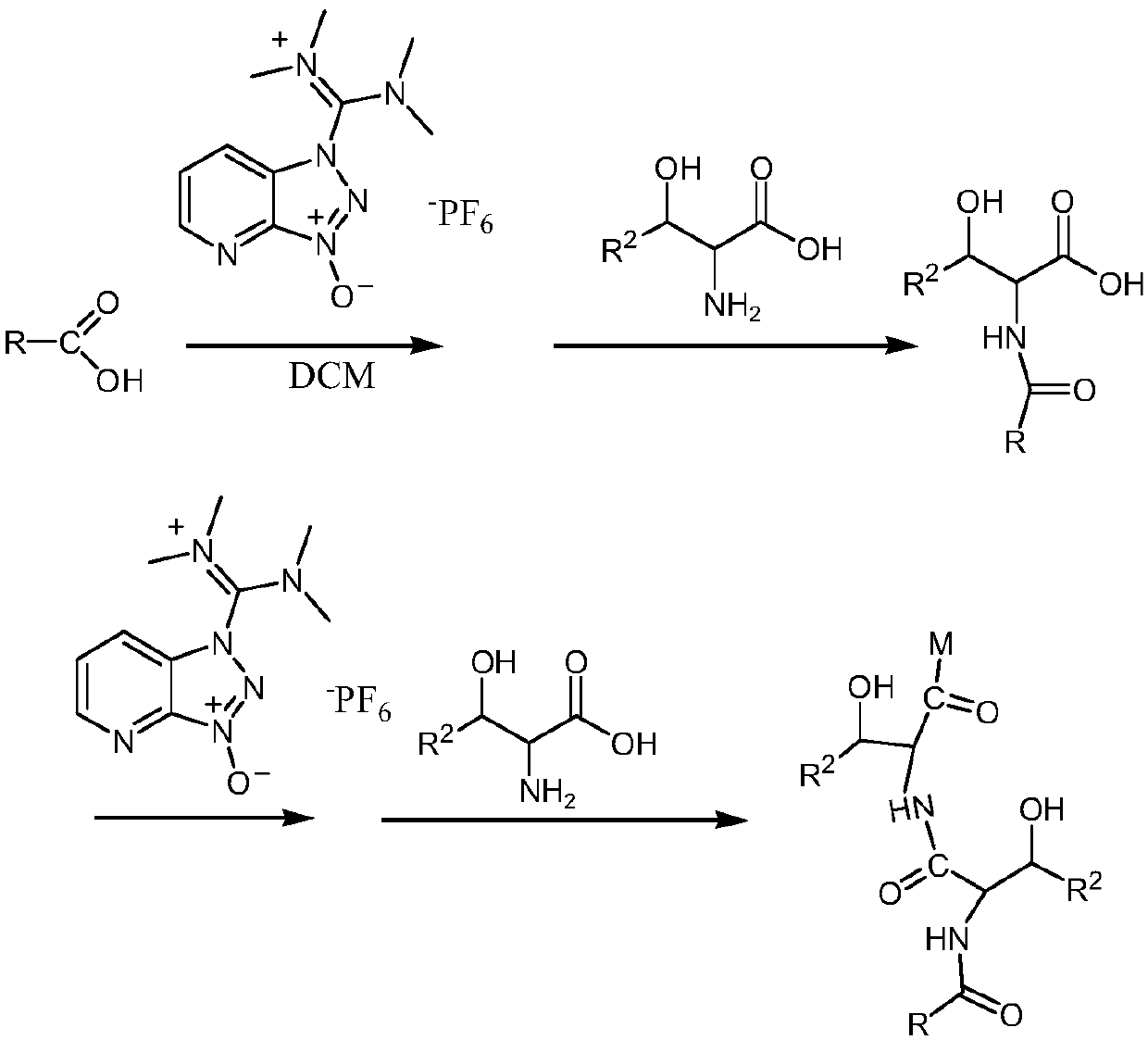

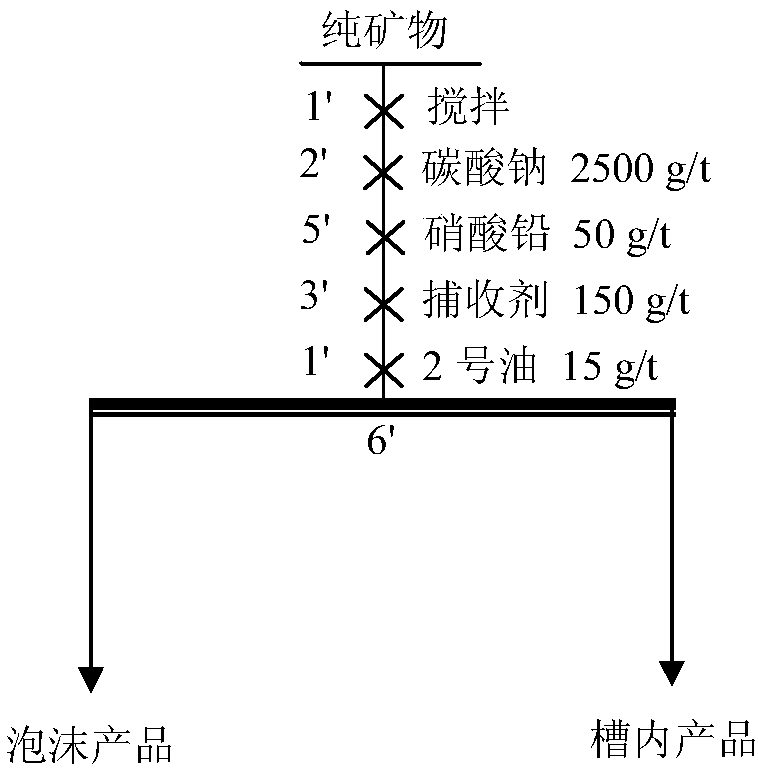

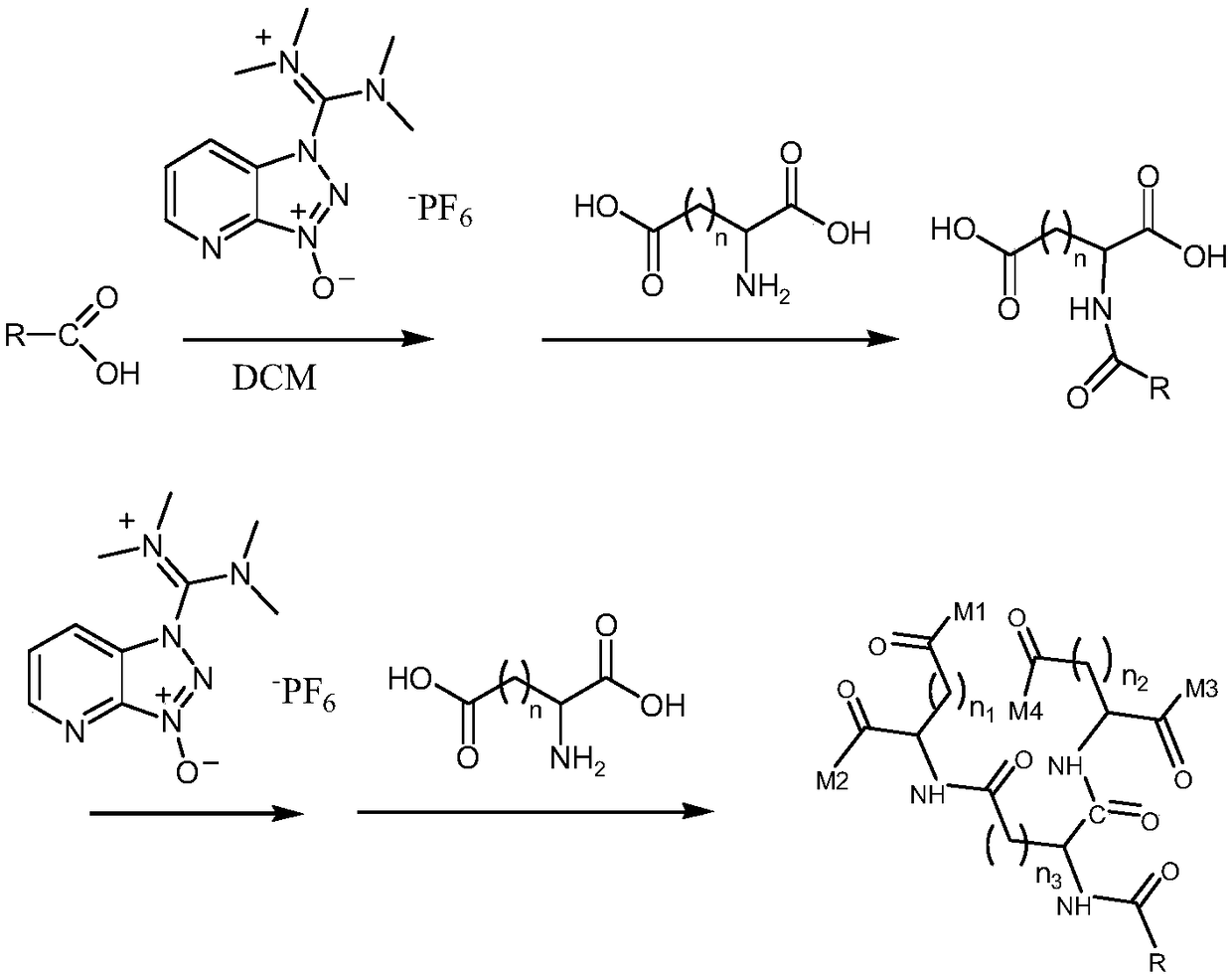

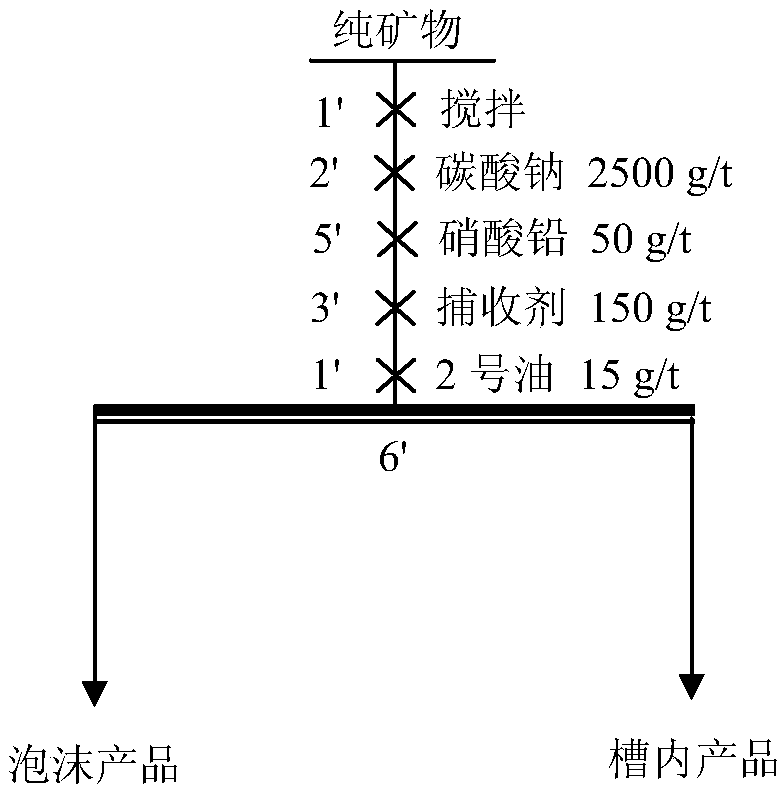

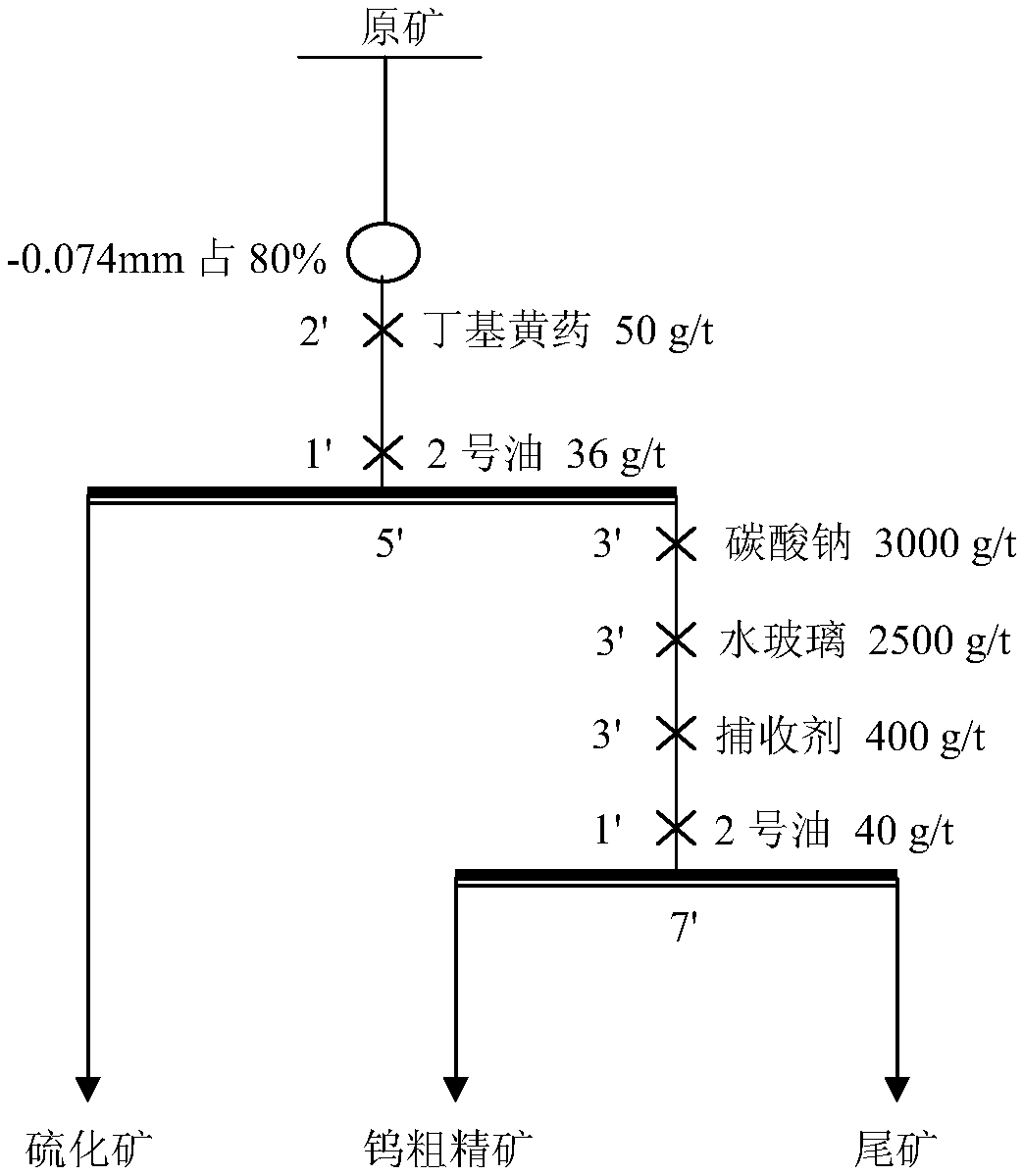

Amidohydroxycarboxylic acid/hydroximic acid compound and application thereof to ore flotation

ActiveCN109530094AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides an amidohydroxycarboxylic acid / hydroximic acid compound and application thereof to ore flotation. The compound has a structural formula shown as a formula (I) in the description, wherein in the formula (I), R1 represents C6-C18 aliphatic groups; R2 represents C1-C4 aliphatic groups; M represents -OH, -ONa, -OK, -NHOH, -NHONa or -NHOK. The amidohydroxycarboxylic acid / hydroximic acid compound provided by the invention is used as a collecting agent, and can reinforce the chelation and recognition effects of the collecting agent on metal oxidized ore; the ordered arrangementof the collecting agent on the surface of the ore is promoted; tungsten ore, rare earth ore, tin ore, lithium mineral, phosphorite, manganese oxide roe, copper oxide ore, fluorite or ilmenite can beeffectively recovered through floatation; the advantages of high collecting capability, high selectivity, low ton ore dosage and the like are realized; the compound is particularly suitable for beingused for treating refractory fine particle ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

Treatment method for waste water with high chloride ion content in polysilicon production

InactiveCN102351362AImprove qualityOptimal treatment processWater contaminantsMultistage water/sewage treatmentIon contentEvaporation

The invention relates to a treatment method for waste water with high chloride ion content in polysilicon production. The treatment method comprises steps of: A. pretreating the waste water with high chloride ion content aggregated in the pool to obtain a sodium chloride solution with a clarification degree and a pH reaching standards and deposition; B. concentrating the sodium chloride solution to obtain 40-50% sodium chloride concentrate and 50-60% reuse water and filtering the deposition; C. carrying out evaporation crystallization on the sodium chloride solution to obtain a sodium chloride solid-liquid mixture; D. filtering and drying the sodium chloride solid-liquid mixture containing crystals to obtain high purity sodium chloride salt. The invention employs a technology containing aconcentration before an evaporation to change waste into valuables, reuse and save water resource as possible and produce high quality solid sodium chloride salt; besides a relative cost, steam amount and electric energy are reduced and saved.

Owner:天威四川硅业有限责任公司

Application of acyl amino polycarboxylic acid/hydroximic acid like compound in mineral flotation

ActiveCN109499773AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides application of acyl amino polycarboxylic acid / hydroximic acid like compound in mineral flotation. A structural formula of the acyl amino polycarboxylic acid / hydroximic acid likecompound is shown as a formula (I); (shown in the description) wherein R in the formula (I) represents aliphatic hydrocarbyl of C<6>-C<18>, n=1-3, and M1, M2, M3 and M4 are separately selected from one or several of -OH, -ON, -OK, -NHOH, -NHON or -NHOK. And n<1>=1-3, n<2>=1-3, and n<3>=1-3. The acyl amino polycarboxylic acid / hydroximic acid like compound is used as a collecting agent to enhance the chelation and recognition action on metal oxidized ores, facilitate ordered arrangement of the collecting agent on the mineral surface, effective flotation recovery is carried out on tungstenores, rare earth ores, tin ores, lithium ores, phosphorus ores, manganese oxide ores, cooper oxide ores, fluorites or titanium iron ores, the acyl amino polycarboxylic acid / hydroximic acid collectingagent has the advantages of high collecting capacity, high selectivity, low ton ore use amounts and the like, and is especially suitable for processing difficultly selected fine grain ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

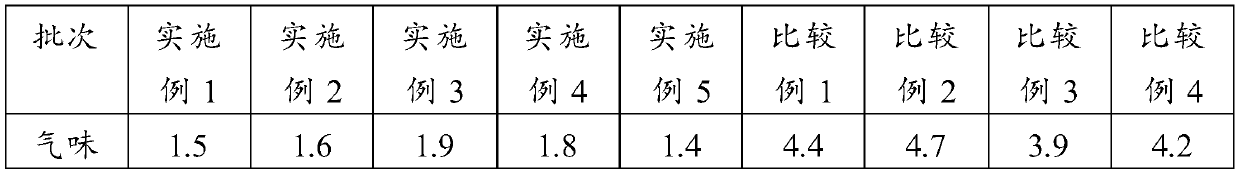

Method for reducing odor of mercaptocarboxylic acid ester

ActiveCN110041238ASmall smellMeet health needsOrganic compound preparationThiol preparationPolyolDistillation

The invention provides a method for reducing odor of a polymercaptic carboxylic acid ester, and the method comprises the following steps of: a) esterifying mercaptocarboxylic acid and polyol to obtainpolymercaptic carboxylic acid ester; (b) mixing the polythiol carboxylic ester and a weak alkali aqueous solution, heating, stirring, layering, and washing with water to obtain a washed crude product; C) distilling the washed crude product under a reduced pressure while introducing of nitrogen to obtain low-odor polythiol carboxylic ester. According to the invention, a raw material carboxylic acid is neutralized by a weak alkali, and converted into a carboxylic acid salt, the weak alkali is cleaned by subsequent water washing, and odor components are discharged by matching with specific nitrogen introduction and reduced pressure distillation, so that the odor of the product is greatly reduced, and the requirements of health and environmental protection in most application fields in contact with human bodies can be met.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

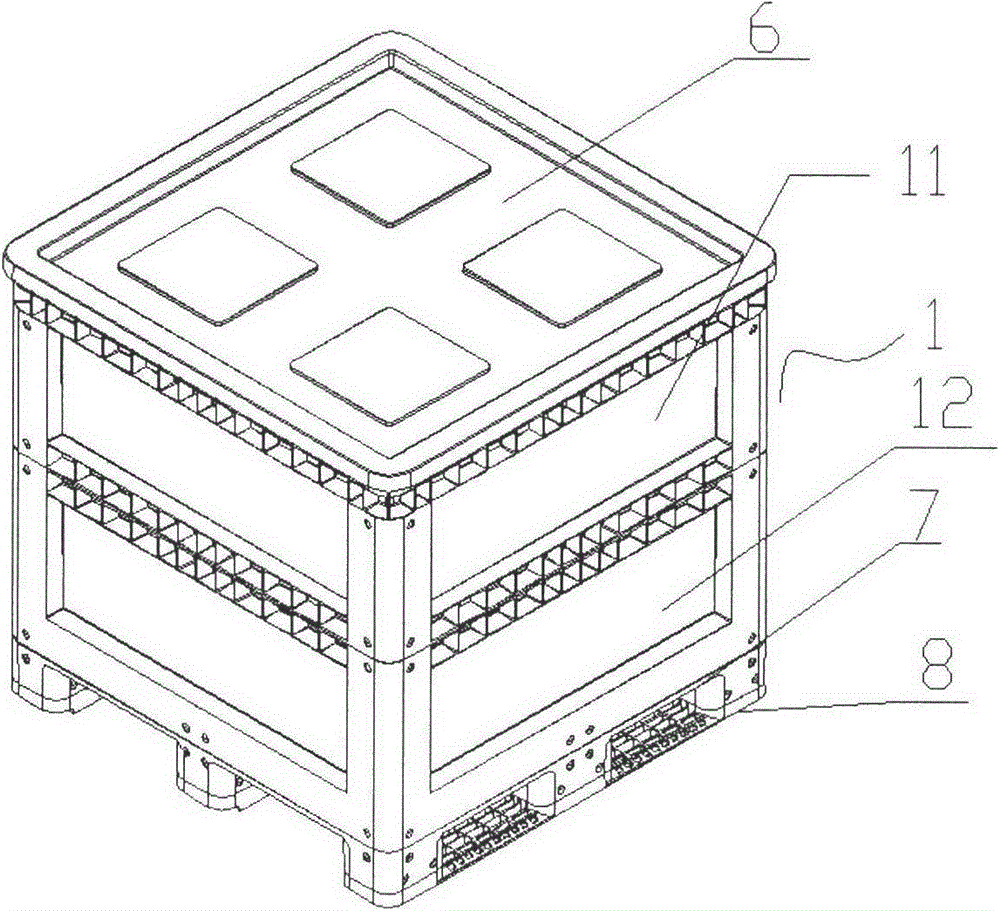

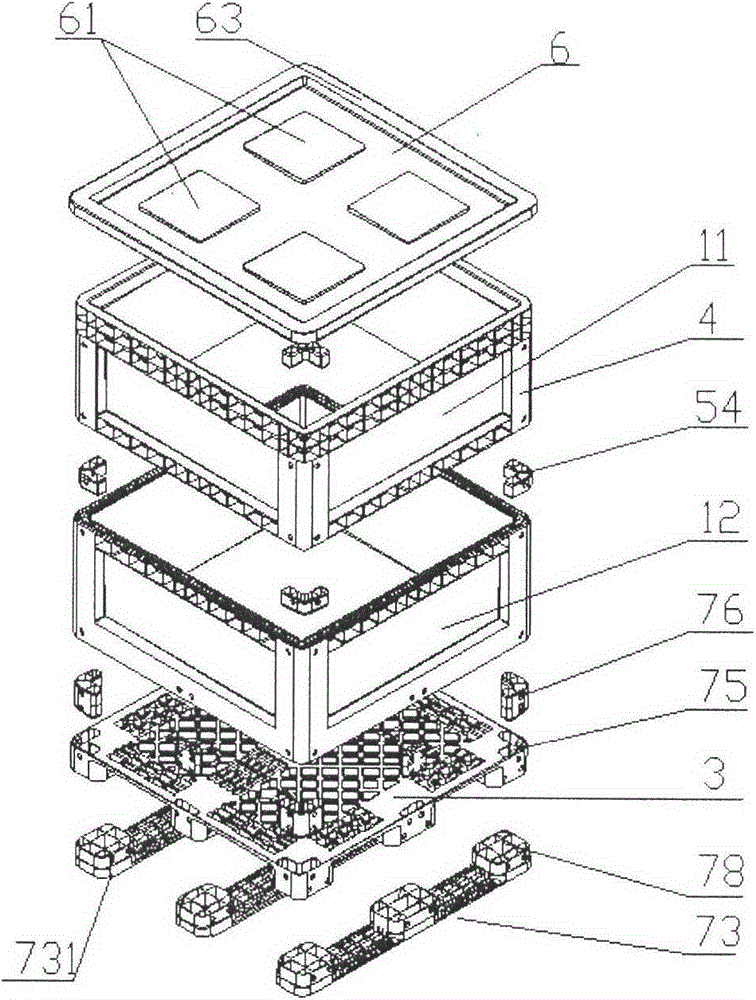

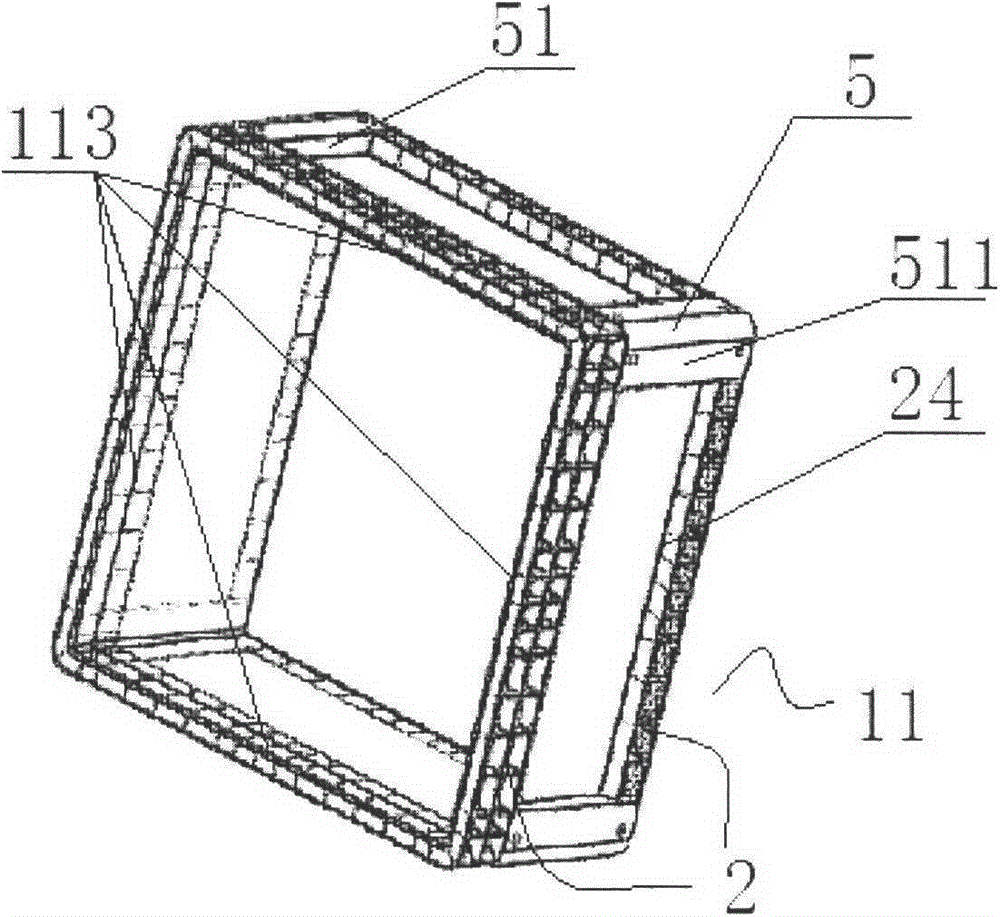

Tobacco box

The invention provides a tobacco box. The tobacco box comprises an upper box body and a lower box body, the upper box body is provided with a first opening end and a second opening end which are oppositely arranged, the lower box body is provided with a third opening end, and the second opening end and the third opening end are hermetically and fixedly connected to form the tobacco box. The upper box body and the lower box body are molding parts, the tobacco box is 700 cm by 700 cm by 700 to 1300 cm by 1300 cm by 1300 cm and is applicable to the fields of automatic production lines and storage and transport and the like; the tobacco box is manufactured by molding, industrial batch production is easy to realize, production cost can be reduced, and the tobacco box has high functional expansibility.

Owner:青岛冠宇工业设备有限公司 +1

Oxidizing and granulating device for pigment carbon black and pigment carbon black prepared by same

The invention discloses an oxidizing and granulating device for a pigment carbon black. The device is composed of a primary oxidizing granulator, a secondary oxidizing granulator and a rotary dryer. The pigment carbon black is prepared by the following steps: by taking the powdered pigment carbon black as a raw material, performing online wet granulation, simultaneously performing continuous wet oxidization on the carbon black, and drying to obtain the powdered, granulated and oxidized pigment carbon black product with high methylbenzene luminousness; or the pigment carbon black is prepared by the following steps: independently using the secondary oxidizing granulator provided by the device, and by taking an ozone as an oxidant and taking granular carbon black as a raw material, performing dry oxidization on the carbon black. The device can be flexibly matched to produce the oxidized carbon black product in different degrees. The invention additionally discloses a pigment carbon black product produced by the device. The pigment carbon black is powdered and granulated and the methylbenzene luminousness is high.

Owner:安徽黑猫新材料有限公司

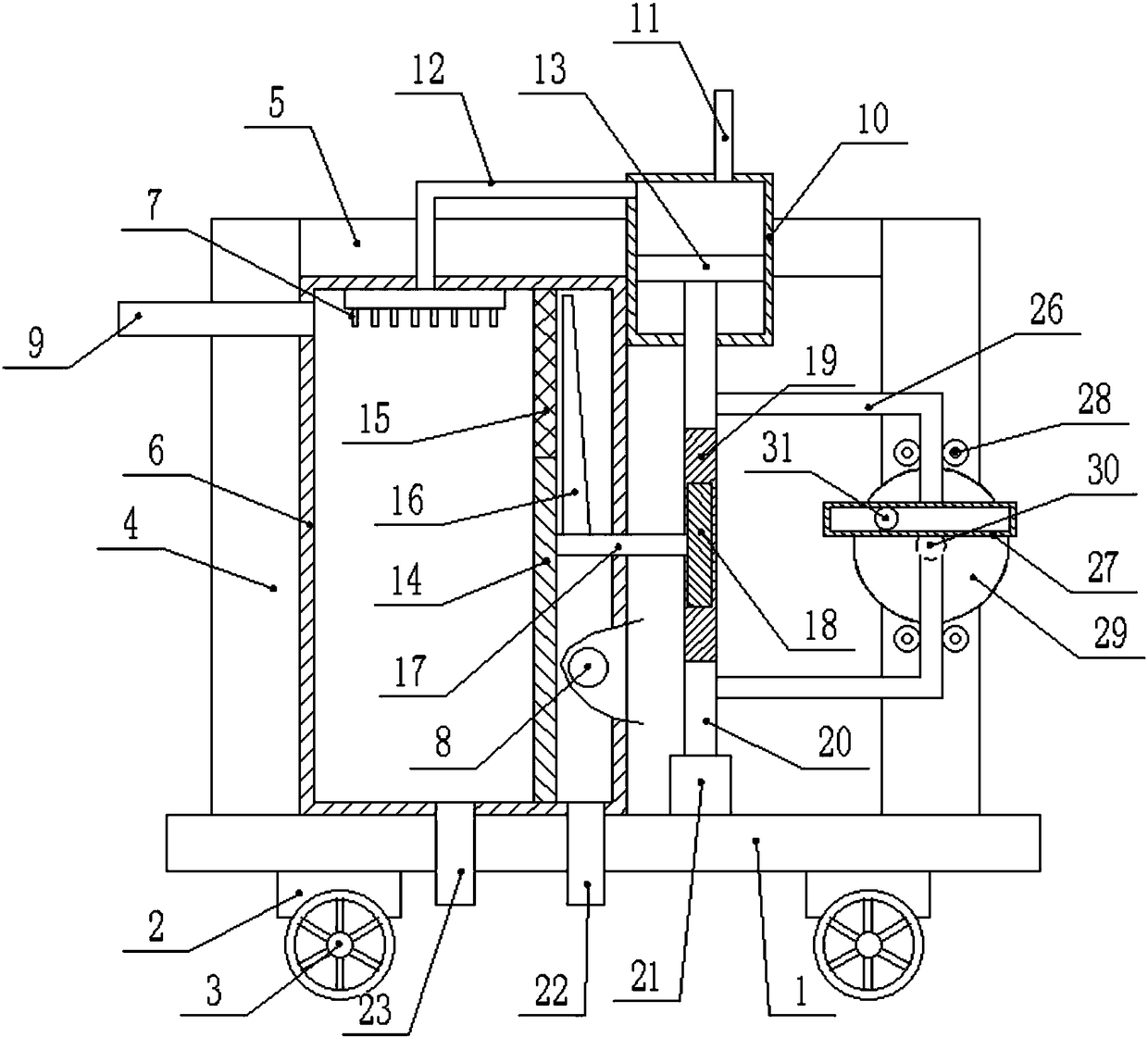

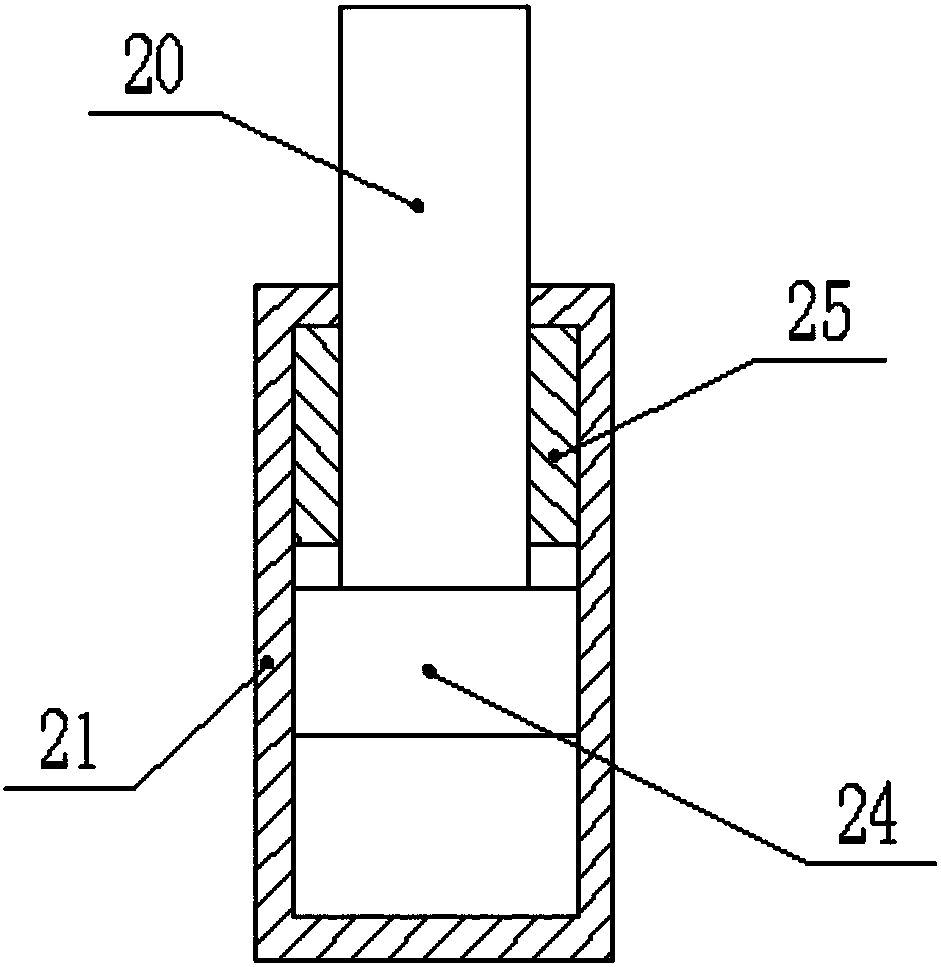

Eccentric hoisting type environment-friendly waste gas spraying treatment device

InactiveCN108310953AReasonable structureInnovative designCombination devicesAlkaline waterDrive wheel

The invention discloses an eccentric hoisting type environment-friendly waste gas spraying treatment device. The eccentric hoisting type environment-friendly waste gas spraying treatment device comprises a supporting base, wherein supporting frames are mounted at two sides of the upper end of the supporting base; the top ends of the supporting frames are connected with a top plate; a water diversion cylinder is mounted in the middle of the right side of the top plate; a piston plate is arranged in the water diversion cylinder; a hoisting rod is connected with the lower end of the piston plate;a limiting block is mounted at the bottom end of the hoisting rod; a limiting cylinder is arranged at the outer side of the limiting block; a treatment box is arranged at the left side of the upper end of the supporting base; a baffle plate is arranged in the middle of the treatment box; a filtering screen is arranged at the upper end of the baffle plate; a rotary gear is mounted at the right endof the rotary shaft; a driving wheel is mounted in the middle of the front end of the driving shaft; an eccentric column is mounted in the middle of the front end of the driving wheel; a guide framesleeves the outer side of the eccentric column; upper and lower ends of the guide frame are connected with guide columns. The eccentric hoisting type environment-friendly waste gas spraying treatmentdevice disclosed by the invention has the advantages that on one hand, a scraping plate to clean dust attached on the filtering screen; on the other hand, the water diversion cylinder works and alkaline water is sprayed out through a spraying head, so that the effect of removing dust before sulfur-containing waste gas is sprayed is realized.

Owner:卢庆芝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com