Method for optimized quenching process for obtaining 8Cr4Mo4V steel

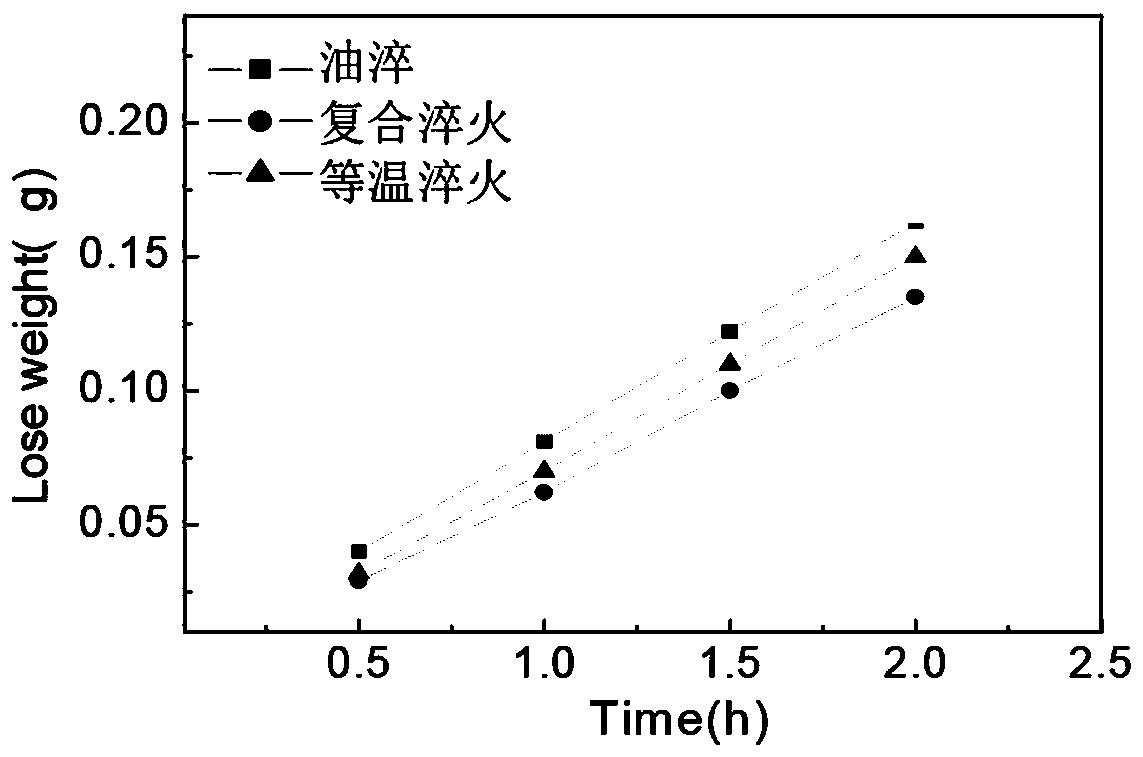

A process, austempering technology, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of inability to effectively control the steel structure, unsatisfactory wear resistance, low hardness, etc., to achieve space for performance improvement, the effect is remarkable , the effect of low quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

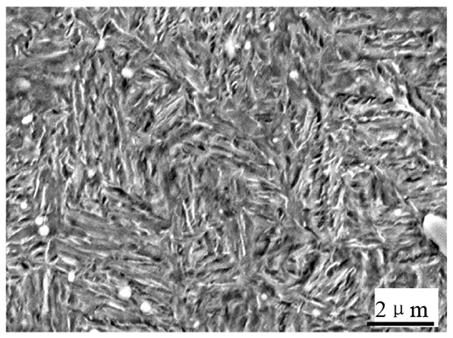

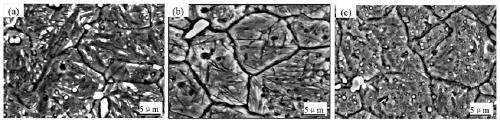

[0036] First, determine the heating and solid solution process of 8Cr4Mo4V steel: take three spheroidized annealed steel samples and heat them at 1095 ° C for 20 minutes, 30 minutes, and 40 minutes respectively for heating and solution treatment, and then oil quenching to obtain the first batch of quenched samples; The test found that the micrograin size grade of the sample with a temperature of 1095°C and a heat preservation of 20 minutes was the highest, which was 9.0. It was determined that 1095°C and 20 minutes were the heat preservation temperature and heat preservation time of the heating solid solution process; at the same time, after a series of tests And microstructure observation confirmed that the austempering temperature is about 200℃. On this basis, heat treatment is carried out according to the following steps:

[0037] (1) Heat and solid solution treat 7 spheroidized annealed steel samples at 1095°C for 20 minutes;

[0038] (2) Put the heated sample in step (1)...

Embodiment 2

[0049] First, determine the heating solution process of 8Cr4Mo4V steel: take 4 spheroidizing annealed steel samples and heat solution treatment at 1050 ° C for 60 minutes, 70 minutes, 80 minutes and 90 minutes respectively, and then oil quenching to obtain the first batch of quenched samples; After testing, it was found that the micrograin size grade of the sample with a temperature of 1050°C and a heat preservation of 60 minutes was the highest, which was 9.5. It was determined that 1050°C and 60 minutes were the heat preservation temperature and heat preservation time of the heating solid solution process; at the same time, after a series of Experiments and organizational observations determined that the austempering temperature was about 160°C. On this basis, heat treatment is carried out according to the following steps:

[0050] (1) Heat and solid solution treat 7 spheroidized annealed steel samples at 1050°C for 60 minutes;

[0051] (2) Put the heated sample in step (1)...

Embodiment 3

[0061] First, determine the heating and solid solution process of 8Cr4Mo4V steel: take three spheroidized annealed steel samples and heat them at 1140 °C for 8 minutes, 15 minutes, and 22 minutes respectively for heating and solution treatment, and then oil quenching to obtain the first batch of quenched samples; The test found that the micrograin size grade of the sample with a temperature of 1140°C and a heat preservation of 8 minutes was the highest, which was 7.6 grades. It was determined that 1140°C and 8 minutes were the heat preservation temperature and heat preservation time of the heating solid solution process; at the same time, after a series of tests And microstructure observation confirmed that the austempering temperature is about 280 ℃. On this basis, heat treatment is carried out according to the following steps:

[0062] (1) Heat and solid solution treat 5 spheroidized annealed steel samples at 1140°C for 8 minutes;

[0063] (2) Put the heated sample in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com