Patents

Literature

67results about How to "Quenching temperature is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate for hot stamping, hot stamping process and hot-stamped member

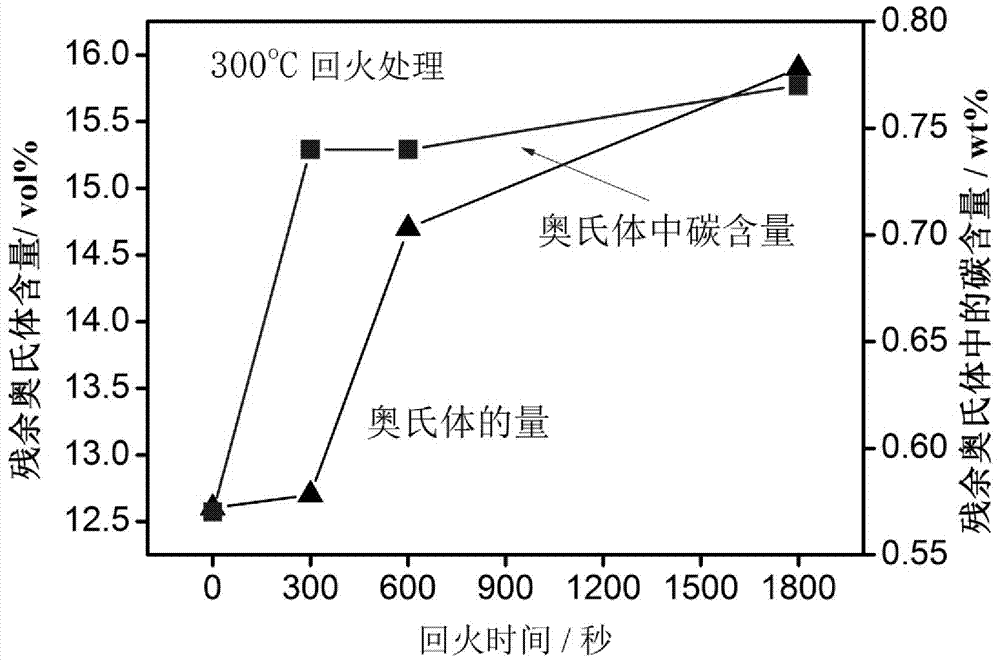

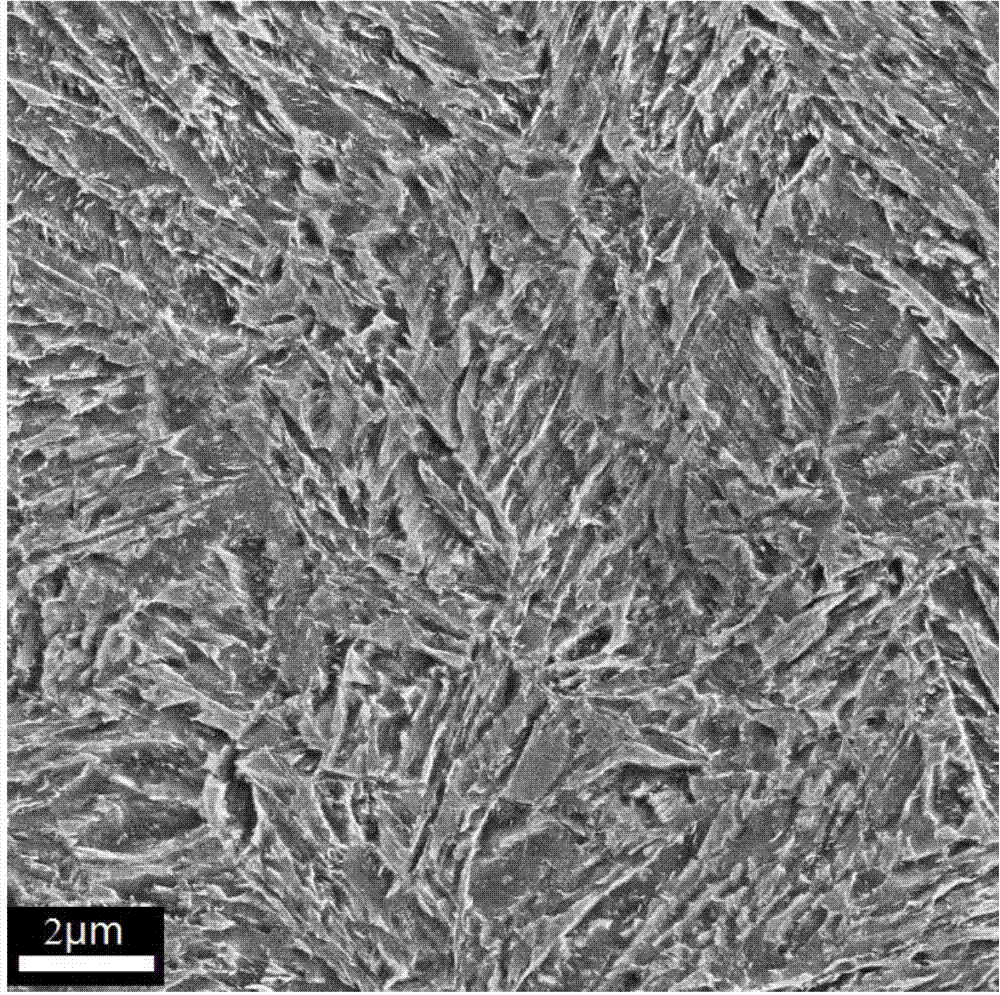

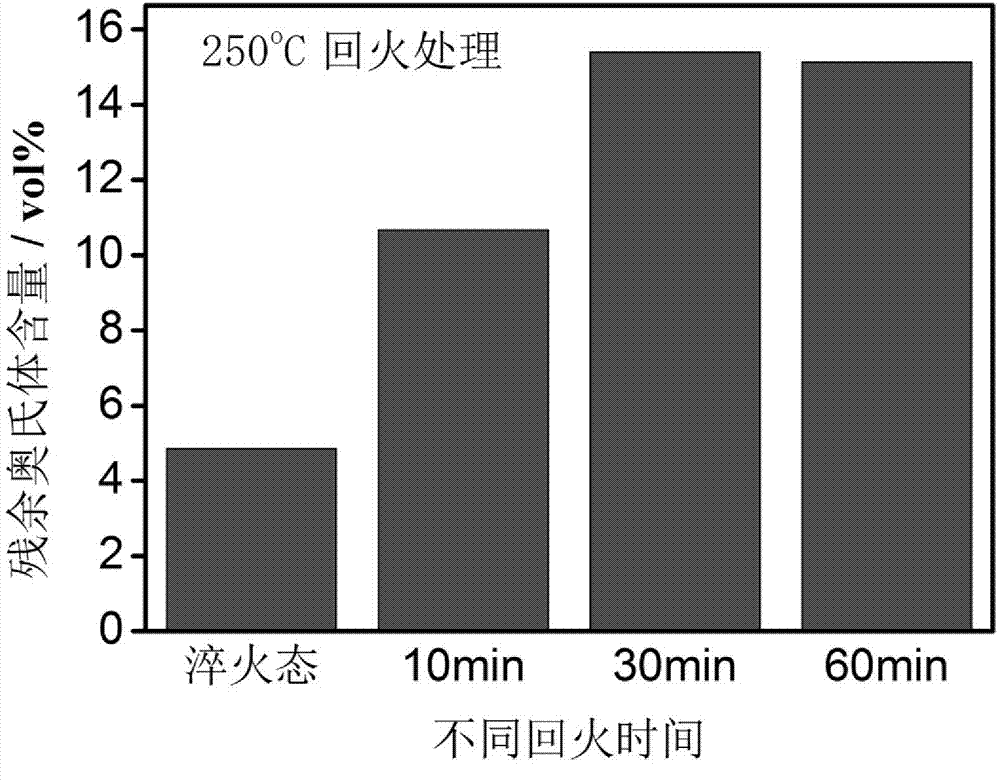

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

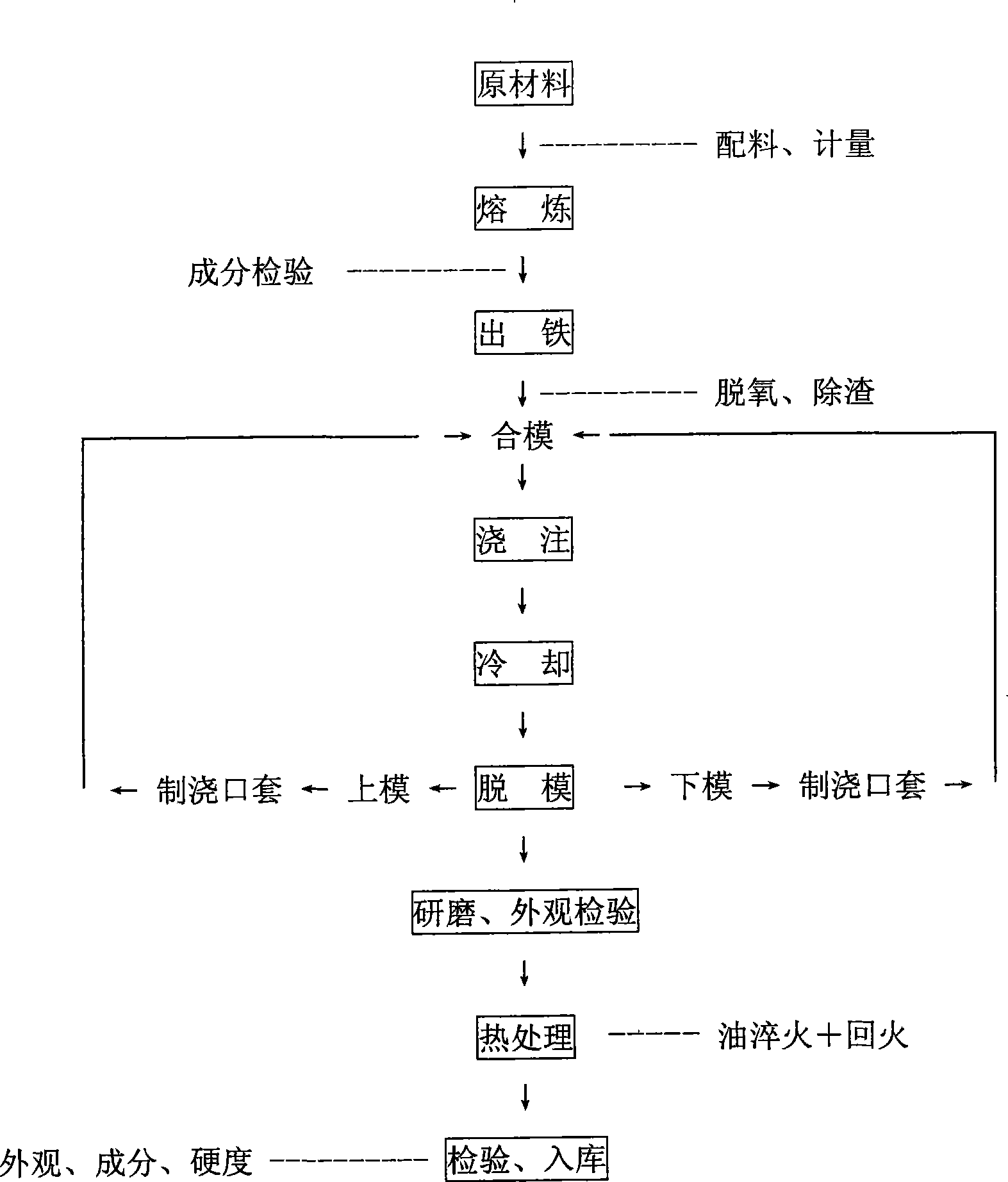

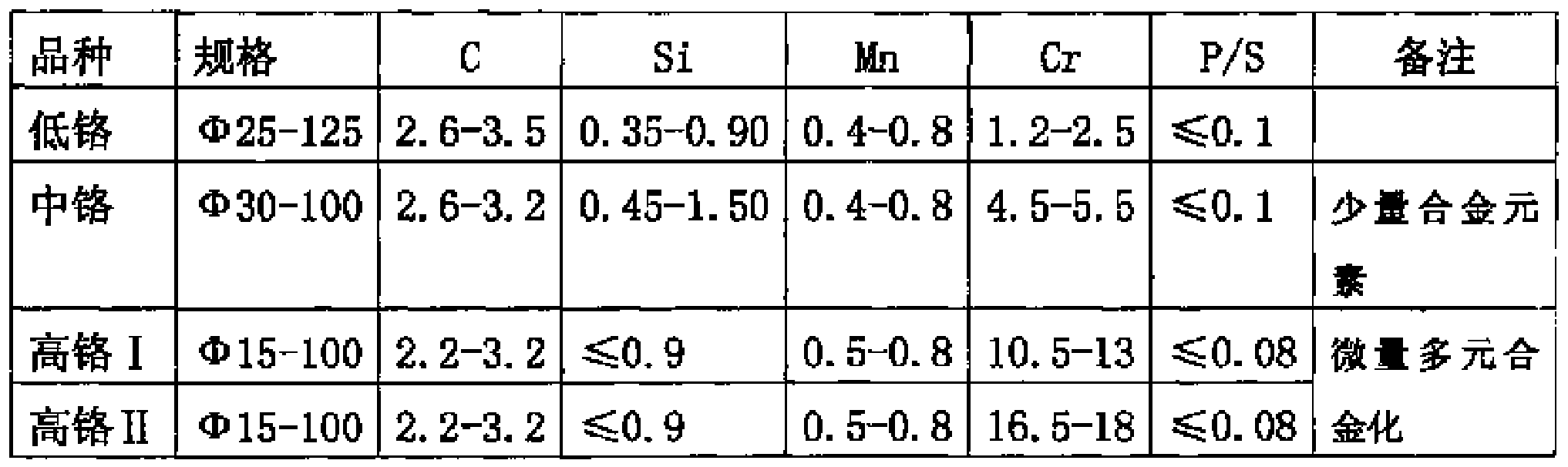

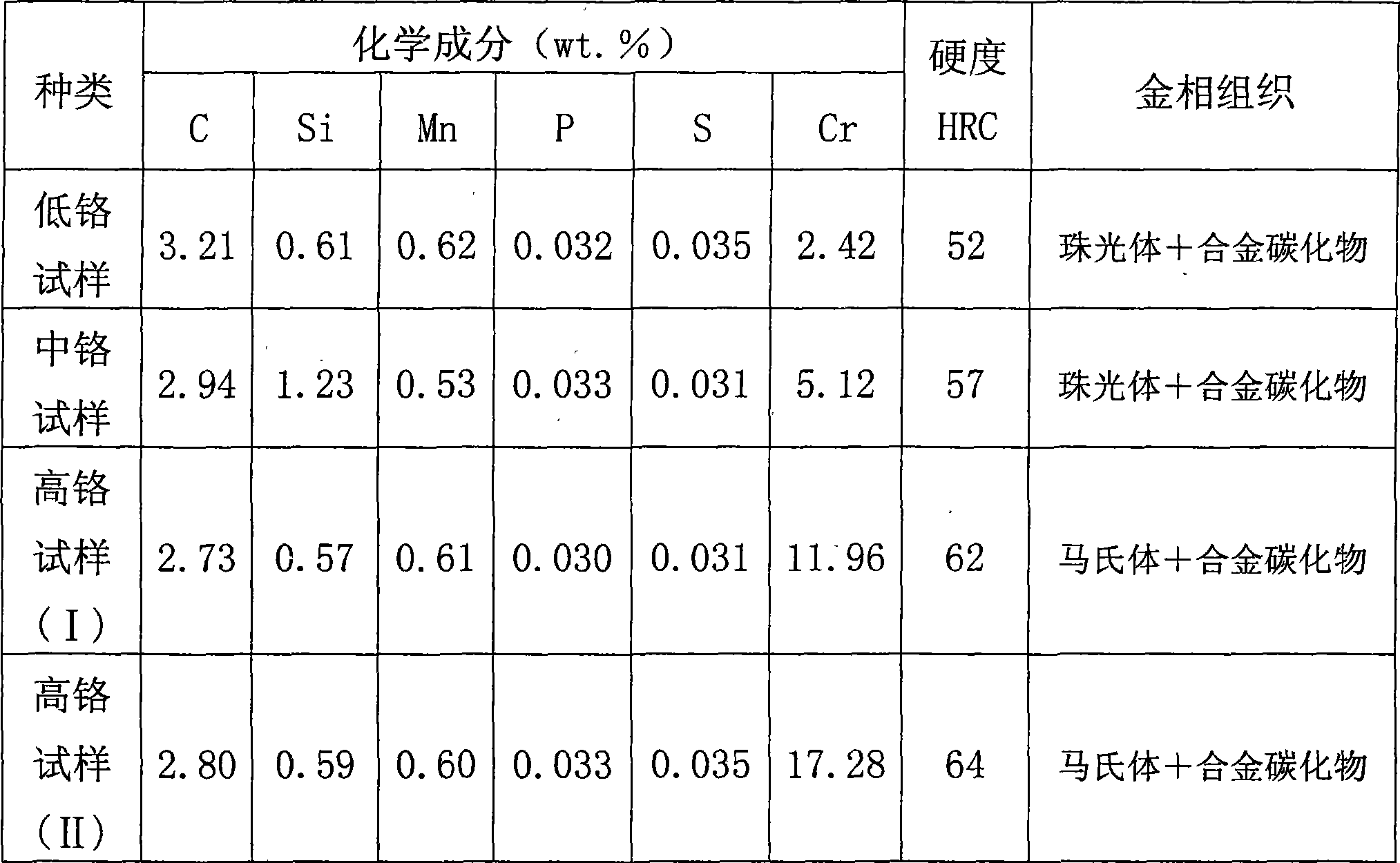

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

Grain-refined extruded aluminum alloy tubular product with large wall thickness and preparation method thereof

The invention discloses a grain-refined extruded aluminum alloy tubular product with large wall thickness and a preparation method thereof. The tubular product comprises the following metallic substances in percentage by weight: 1.0-1.15% of Mg, 0.60-0.75% of Si, 0.20-0.35% of Cu, 0.35% of Fe, 0.10% of Mn, 0.05-0.08% of Cr, 0.15% of Zn, 0.10% of Ti and the balance of aluminum. The invention further discloses a preparation method of the grain-refined extruded aluminum alloy tubular product with large wall thickness. The grain-refined extruded aluminum alloy tubular product with large wall thickness provided by the invention solves the problem that the grains of the base and surface of a 6061 alloy extruded aluminum alloy tubular product with great wall thickness are thick and big, the deficiency of bulky crystal spots generated after anodic oxidation can be eliminated and indexes of the final product, such as inner welding quality and mechanical performance, can satisfy the GB / T6892-2006 standard requirement.

Owner:龙口市丛林铝材有限公司

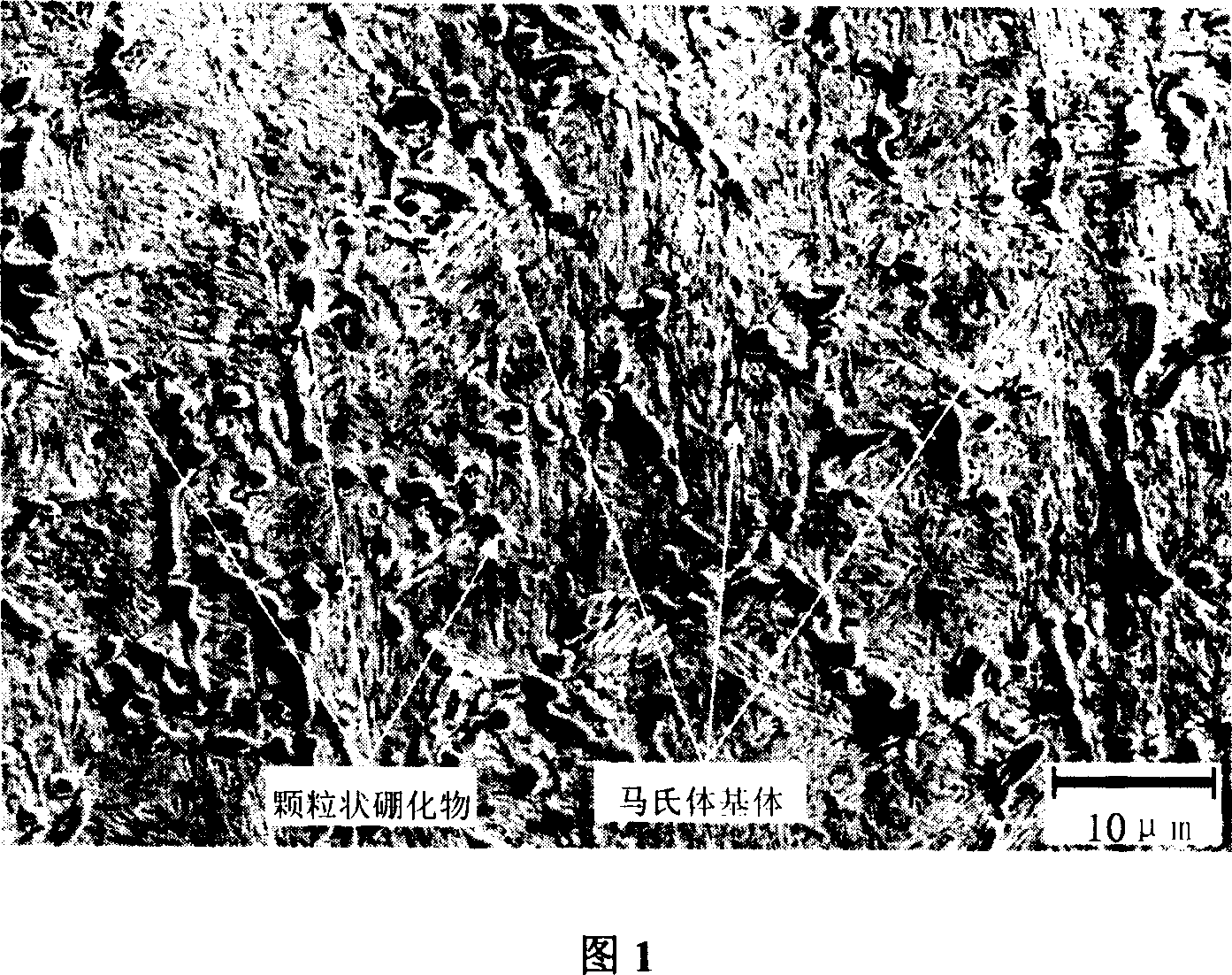

High-boron cast steel containing granular boride and preparing method thereof

The invention discloses a preparing method of granular boride high-boron cast steel, which comprises the following steps: allocating 0.15%-0.45% C,0.75%-2.70% B, 0.34 %-1.50% Ti, 0.80%-1.20% Cr, 0.50%-1.50% Si, 0.50%-1.50% Mn, 0.04%-0.12% Ce, 0.08%-0.20% Al, 0.03%-0.10% Ca, 0.01%-0.06 N, P<0.05%, S<0.05% and Fe; setting B / C=5.0-6.0, B / Ti=1.8-2.2; adopting electric stove to melt; mixing common scrap steel, pig iron and chromium iron; heating to melt; adding into silicon iron and manganese iron; adding into ferroboron and ferrotitanium before tapping; adjusting furnace-front element to be quality; heating-up; adding into silicon-calcium alloy; pre-deoxidizing; end-deoxidizing with aluminum; micro-alloying; proceeding composite deteriorating process outside of the furnace with cerium and nitrogen; keeping the temperature; proceeding oil-cooling quenching; tempering under the low temperature; getting the product. This invention possesses merits of high hardness and strength and good tenacity and resistance, which can increase the durability of wear resisting part.

Owner:XI AN JIAOTONG UNIV

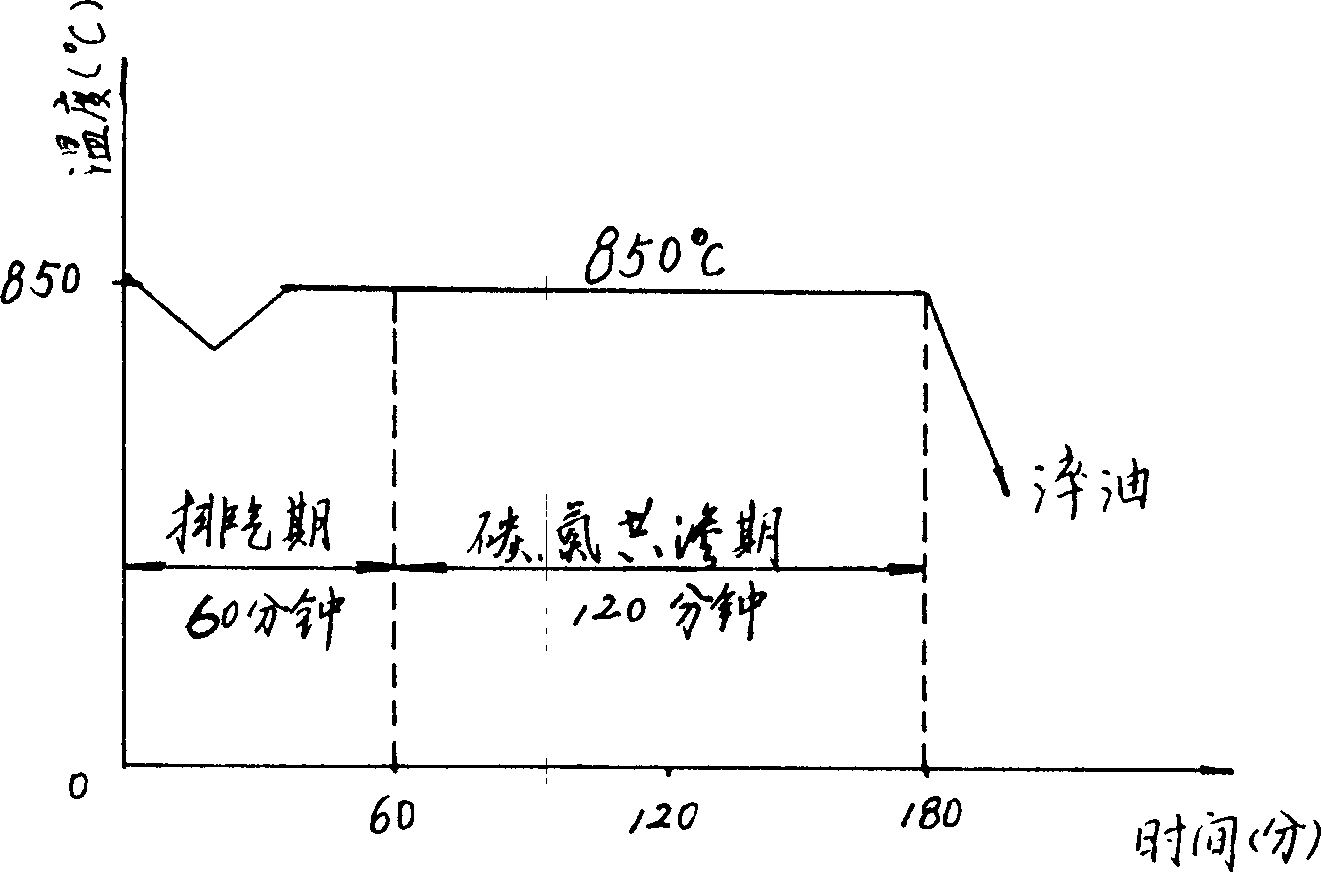

Composite heat treatment

A duplex heat treating process for workpiece includes such steps as heating to austenite state, penetrating C or C and N to obtain a prepenetrated layer, lowering temp to 620-720 deg.c, penetrating N or N and C, direct quenching, and having time effect at 200-300 deg.c or isothermal quenching at 200-300 deg.c. Its advantages are high hardness (greater than 900 HV) and lower deformation.

Owner:SHANGHAI JIAO TONG UNIV

Automobile gearbox gear carburizing and quenching heat treatment method

ActiveCN103710714AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

Automobile drive axle ring gear heat treatment process

InactiveCN102409151ALow percolation temperatureReduce heating distortionSolid state diffusion coatingFurnace typesNitrogenEngineering

The present invention discloses an automobile drive axle ring gear heat treatment process. The process comprises treatment steps of carbonitriding, quenching, cleaning, tempering, and correction and deformation, wherein the following step is performed after the low temperature carbonitriding process and before the quenching process: a mandrel for controlling ring gear deformation is immediately filled in the ring gear. The diameter size of the mandrel is 100.02-100.03% of the diameter size of the ring gear tip circle, wherein the ring gear is subjected to the low temperature carbonitriding treatment and the direct quenching treatment. The shaped teeth are processed on the mandrel excircle, such that the problems of out of roundness, deformation and oversize of the ring gear after the carburizing and quenching heat treatment are solved, the qualification rate of the heat treated product is improved, and the process is especially suitable for the heat treatment of the drive axle ring gear for the heavy truck.

Owner:SINO TRUK JINAN POWER

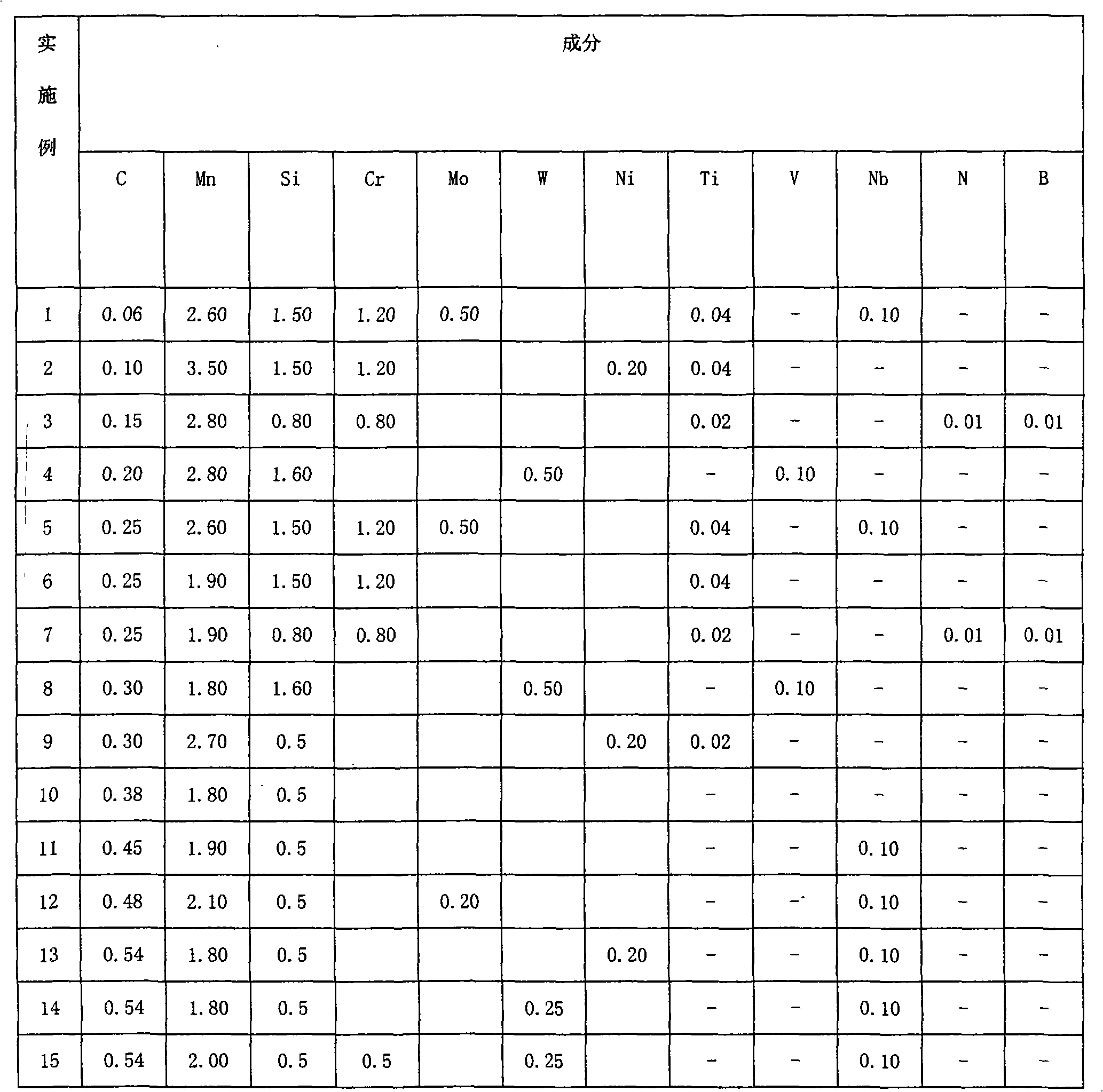

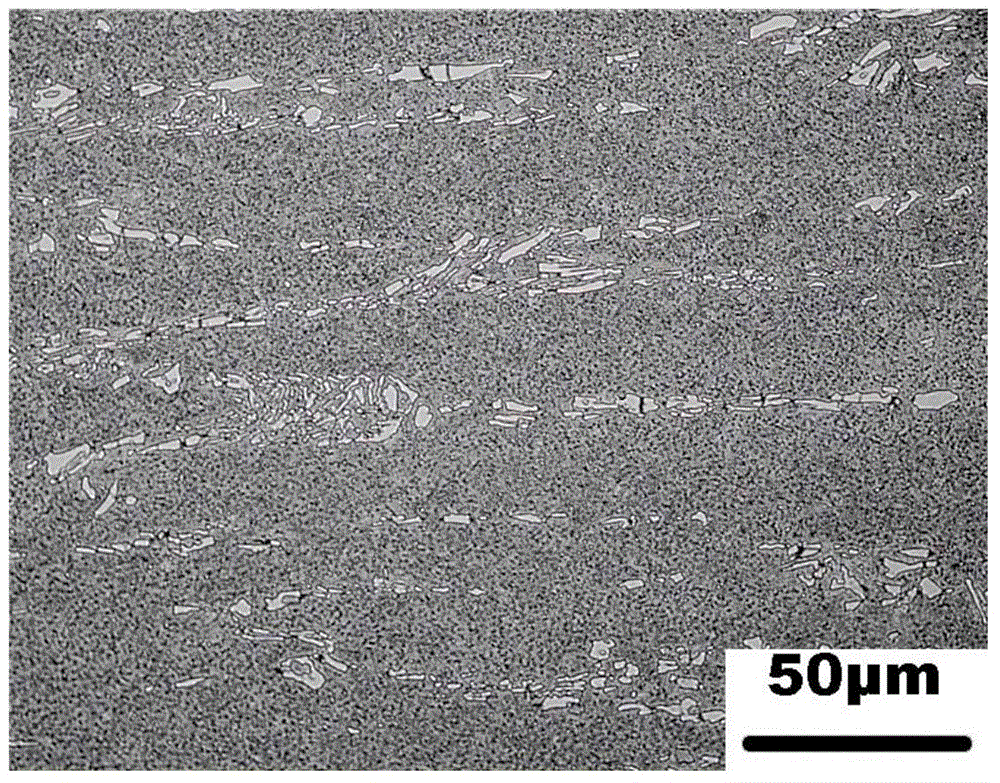

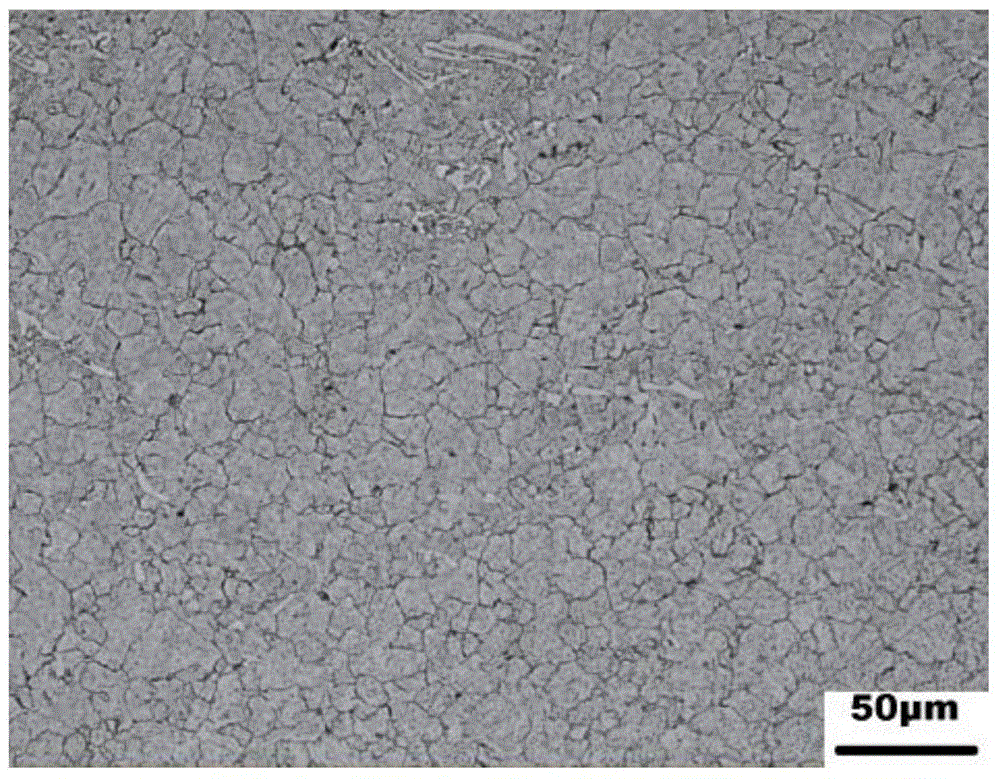

Method for preparing manganese chilled bainitic steel

The invention relates to a method for preparing manganese chilled bainitic steel, belonging to the field of alloy steel. Firstly, after smelted by the normal steelmaking process, steel is forged, rolled or cast into a product, the product is air-cooled to 480 to 700 DEG C, is processed by water-cooling or oil cooling or salt-alkali solution cooling until 200 to 250 DEG C (or the product is reheated to a temperature of 30 to 50 DEG C higher than the austenitic transformation critical point, is air-cooled to 480 to 700 DEG C and then is processed by water-cooling or oil cooling or salt-alkali solution cooling until 200 to 250 DEG C), and then is taken out to be air-cooled or slowly cooled to room temperature; and the product is heated to 200 to 600 DEG C and then is tempered after the temperature is preserved for 1 to 5 hours. Compared with other types of steel with the same strength, the manganese chilled bainitic steel of the invention has the advantages of low alloy cost, increased performance and no complex working procedure in the whole production technology, thereby obviously reducing the production cost.

Owner:TSINGHUA UNIV

Processing technology for gearbox gear

InactiveCN104762629AProlong carburizing timeReduce energy consumptionSolid state diffusion coatingGear transmissionCarburizing

The invention relates to a processing method for a gear, especially to a processing technology for a gearbox gear. The processing technology comprises the following steps: step 1, blanking and forging so as to obtain a cylindrical blank; step 2, homogenization treatment of components of the forged blank and drilling of a center hole through lathing; step 3, gear hobbing out of the cylindrical blank via a hobbing machine; step 4, carbonization of a workpiece; step 5, cooling and quenching after carbonization; and step 6, machining of the workpiece so as to form the gear. The processing technology provided by the invention has the following beneficial effects: a, carburizing temperature and quenching temperature are reduced, carburizing time is not prolonged, and energy consumption is reduced; b, generation of a black structure is prevented, a uniform carburizing layer is obtained, the microstructure of the carburizing layer having undergone carbonization and quenching is improved, an optimal metallographic structure is obtained, and thus, surface hardness, wear resistance and fatigue resistance of the gear are obviously improved; and c, deformation is reduced, gear processing and assembling dimension precision of the gear is improved, gear transmission balance is enhanced, noise is reduced, and the service life of the gear is prolonged.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Thermal treatment method for carburizing and quenching of gearbox gears

InactiveCN105586599AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a thermal treatment method for carburizing and quenching of gearbox gears. The thermal treatment method includes the steps of A, carburizing, B, quenching and C tempering. In the step of A, carburizing, the gears are placed in a heating furnace, the temperature of the heating furnace is increased from the room temperature to the temperature of 850-900 DEG C for carburizing, and carburizing time is 2-5 h; the carburizing process includes a beginning stage, a strong carburizing stage and a diffusion stage; the carbon potential (CP) of the beginning stage is 0.9-1 C%, the CP of the strong carburizing stage is 1-1.1 C%, and the CP of the diffusion stage is 0.8-0.9 C%; the time of the beginning stage is 12-15 min, the time of the strong carburizing stage is 200-220 min, and the time of the diffusion stage is 20-40 min. In the step of B, quenching, the carburized gears are cooled to 810-850 DEG C, then temperature equilibrium is carried out for 20-40 min, and then the gears are quenched in quenching oil with the temperature being 85-95 DEG C. In the step C, tempering, the quenched gears are subjected to tempering at the temperature of 155-170 DEG C for 1-2 h.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

Heat treatment process for surface hardening and carbonitriding of hydraulic parts

ActiveCN102534465AReasonable heating distributionReasonable heating distribution makes hydraulic parts heated reasonablySolid state diffusion coatingCarbon potentialNitrogen

The invention provides a heat treatment process for surface hardening and carbonitriding of hydraulic parts, which includes the following steps: a washing the hydraulic parts preparing for heat treatment to remove greasy dirt; b warming a carburizing multi-purpose furnace, and performing pre-carburizing treatment; c putting the hydraulic parts washed cleanly through the step a in the carburizing multi-purpose furnace, and performing strong carburizing; d adjusting carbon potential after the strong carburizing to perform diffusion; e putting the hydraulic parts after carbonitriding in the stepd in a quenching chamber of the carburizing multi-purpose furnace to be quenched, filtering oil and discharging from the furnace; and f washing the hydraulic parts of the step e, and putting the hydraulic parts in a tempering furnace to be tempered to obtain products.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Heat processing method for carburizing and quenching

InactiveCN105986220AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a heat processing method for carburizing and quenching. The method comprises the following steps: A) a carburizing step, placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 850-900 DEG C for carburizing for 2-5 h, wherein the carbon potential CP in a strong carburizing stage is 1.02-1.1C%, and the carbon potential CP in a diffusion stage is 0.8-0.9C%; B) a quenching step: cooling the obtained carburized gear to 810-850 DEG C, equalizing the temperature for 20-40min, and quenching in 85-95 DEG C quenching oil; and C) a tempering step: tempering the obtained quenched gear at 155-170 DEG C for 1-2 h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:重庆文力机械有限公司

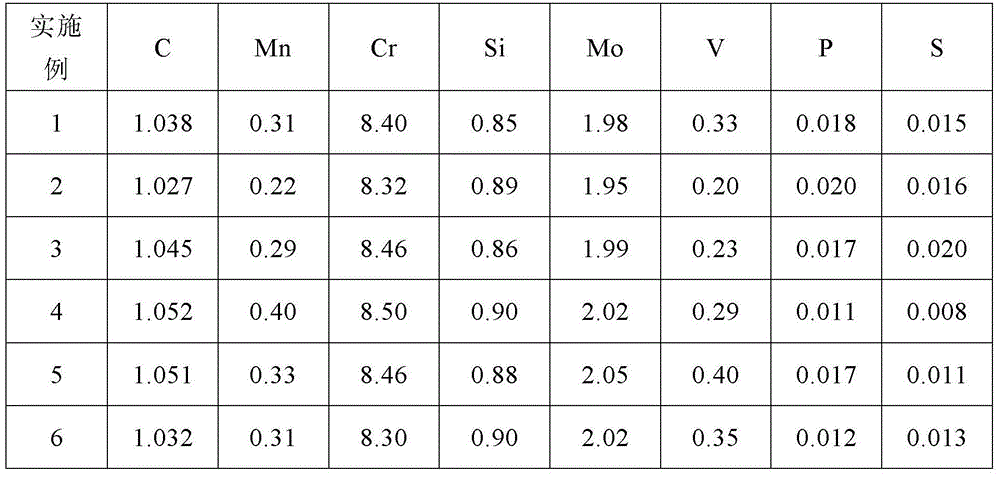

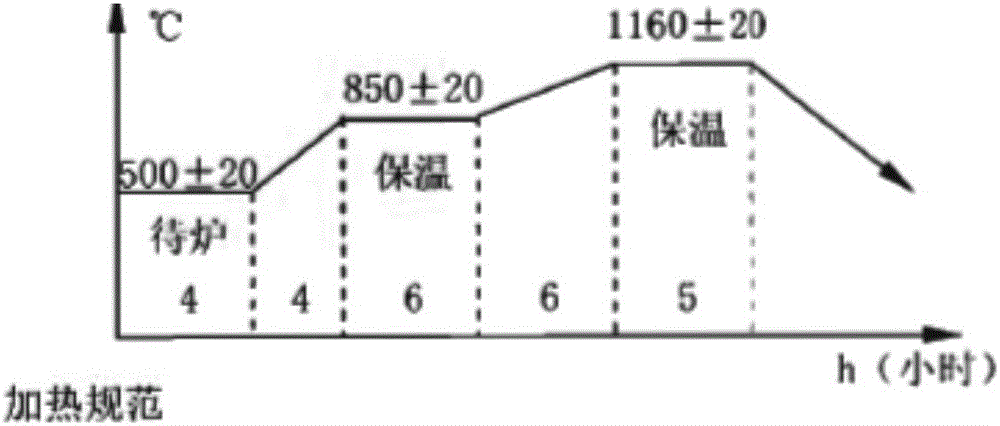

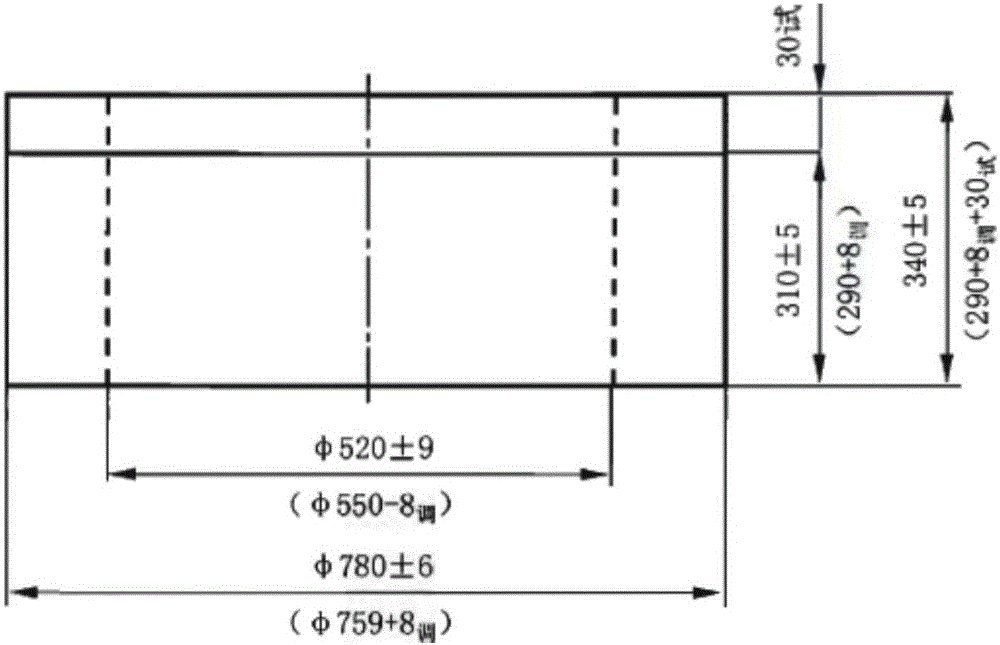

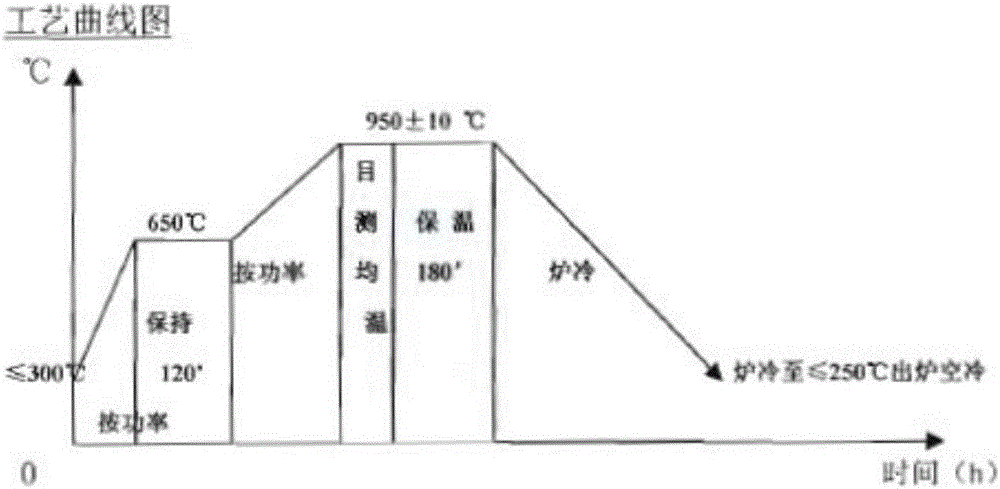

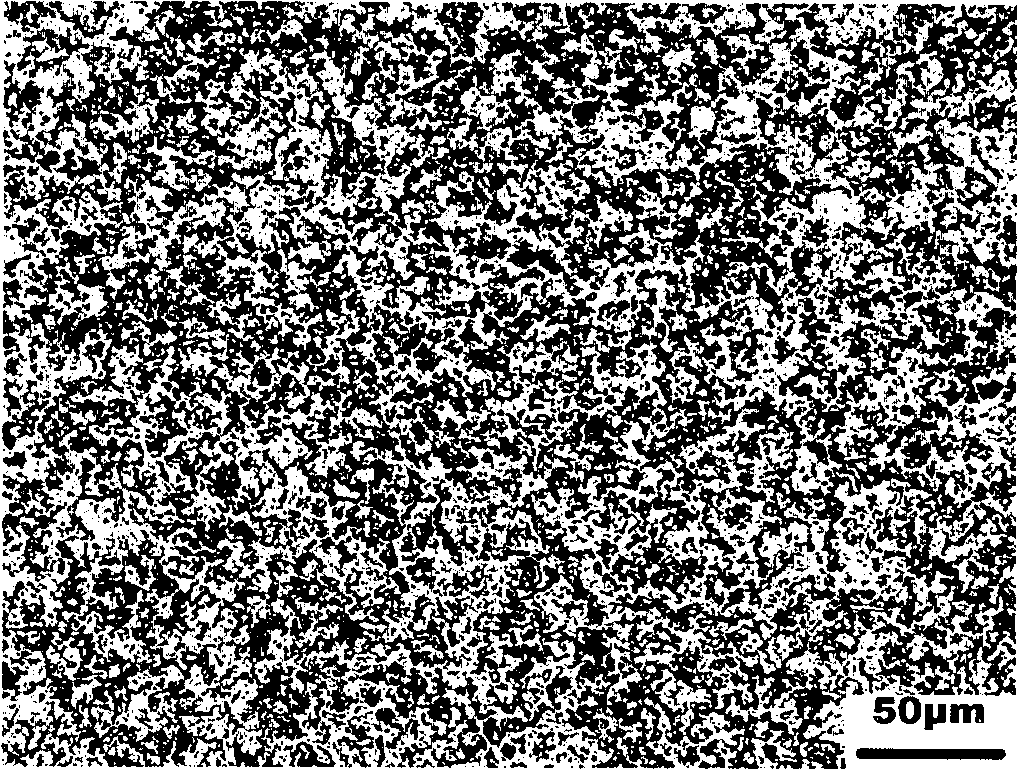

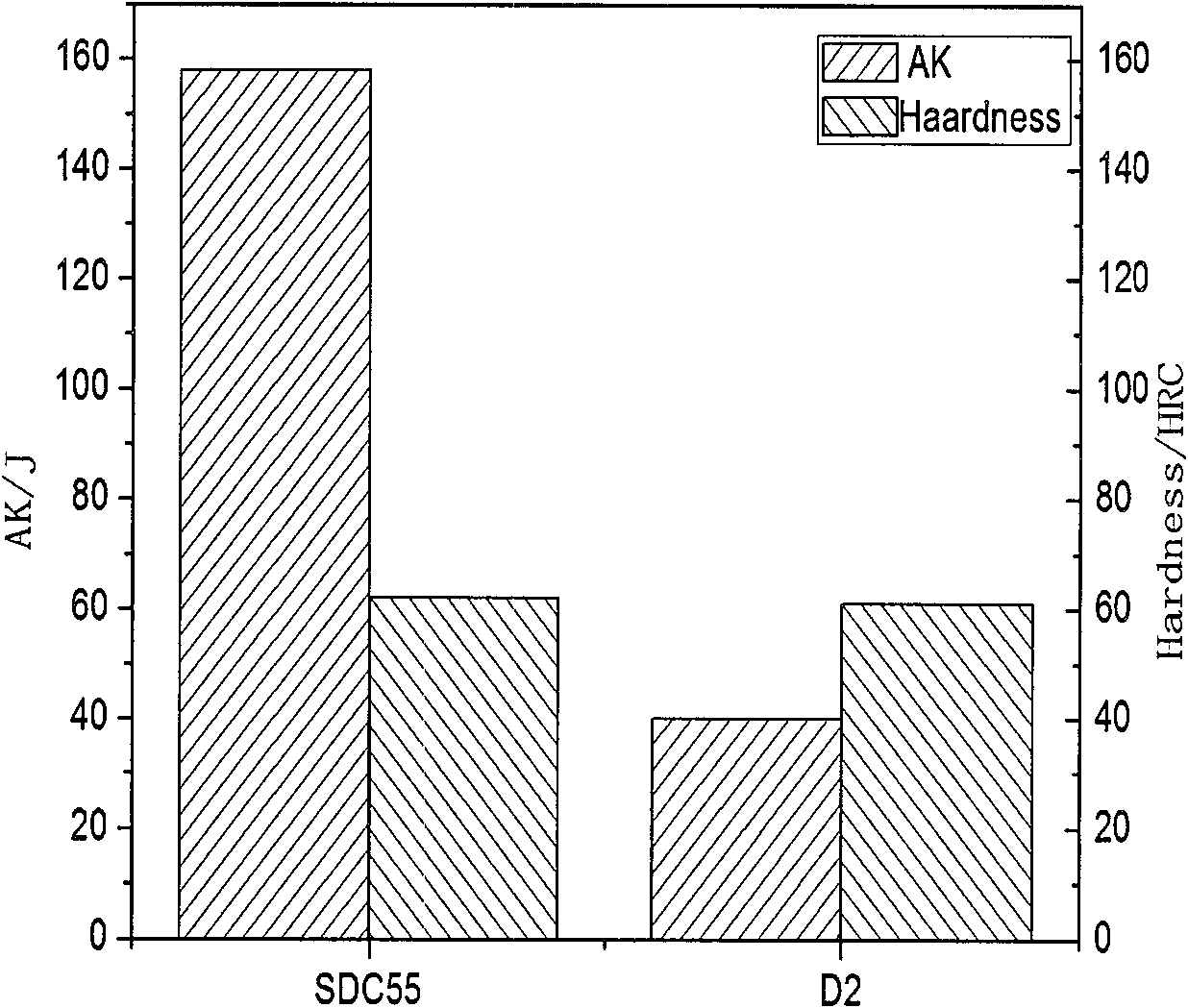

High-hardness high-toughness cold work die steel as well as preparation method thereof

The invention relates to high-hardness high-toughness cold work die steel as well as a preparation method thereof. The high-hardness high-toughness cold work die steel comprises the following chemical components in percentage by weight: 1.025-1.055% of C, 0.85-0.90% of Si, 0.20-0.40% of Mn, less than 0.02% of P, less than 0.02% of S, 8.30-8.50% of Cr, 1.95-2.05% of Mo, 0.20-0.40% of V and the balance of Fe and inevitable impurities, wherein the elements satisfy the following relationship: C=0.1(Cr+Mo). The preparation method comprises the following steps: smelting and pouring to obtain a steel ingot which serves as a consumable electrode and is placed in an electroslag remelting device for electroslag remelting and then re-solidifying to form the steel ingot; and heating the re-solidified steel ingot to 1200-1220 DEG C and then forging, quenching and tempering to obtain the cold work die steel. The impact energy of the steel is greater than or equal to 76J and the hardness of the steel is greater than or equal to 63HRC, and the steel has relatively good hardness and toughness match.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Manufacturing method of valve forged piece for ultra-supercritical turbine and valve forged piece

InactiveCN106480253AImprove yieldUpgrade the smelting processValve arrangementsMachines/enginesHardenabilitySupercritical fluid

The invention discloses a manufacturing method of an FB2 valve forged piece for an ultra-supercritical turbine. The method comprises the following steps of smelting, forging, valve forged piece heat treatment, machining and heat treatment. The invention further discloses a valve forged piece manufactured by the adoption of the manufacturing method of the FB2 valve forged piece for the ultra-supercritical turbine. According to the manufacturing method, operation is reasonable, effective boron is contained, hardenability of the forged piece reaches the standard, the grain size of the final forged piece is larger than or equal to the grade 3, and according to the manufacturing method of the FB2 valve forged piece for the 625 DEG C ultra-supercritical turbine and the FB2 valve forged piece, the situation that Y-shaped cracks appear in the center of the forged piece is avoided.

Owner:SHANGHAI TENGHUI FORGING +2

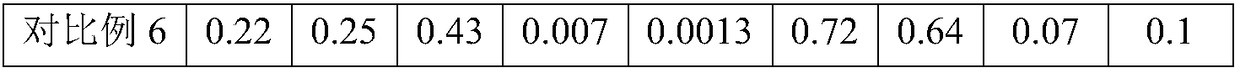

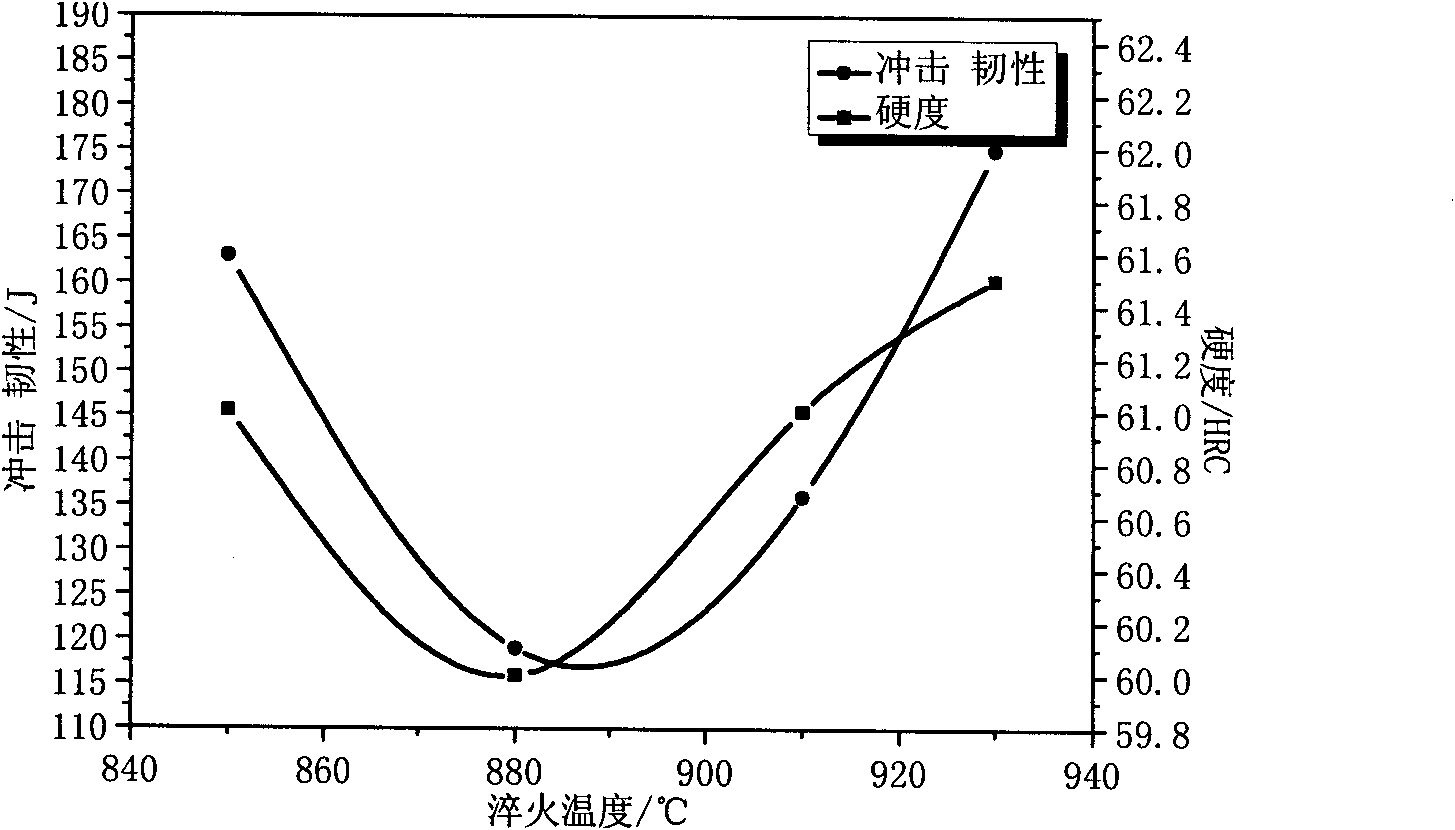

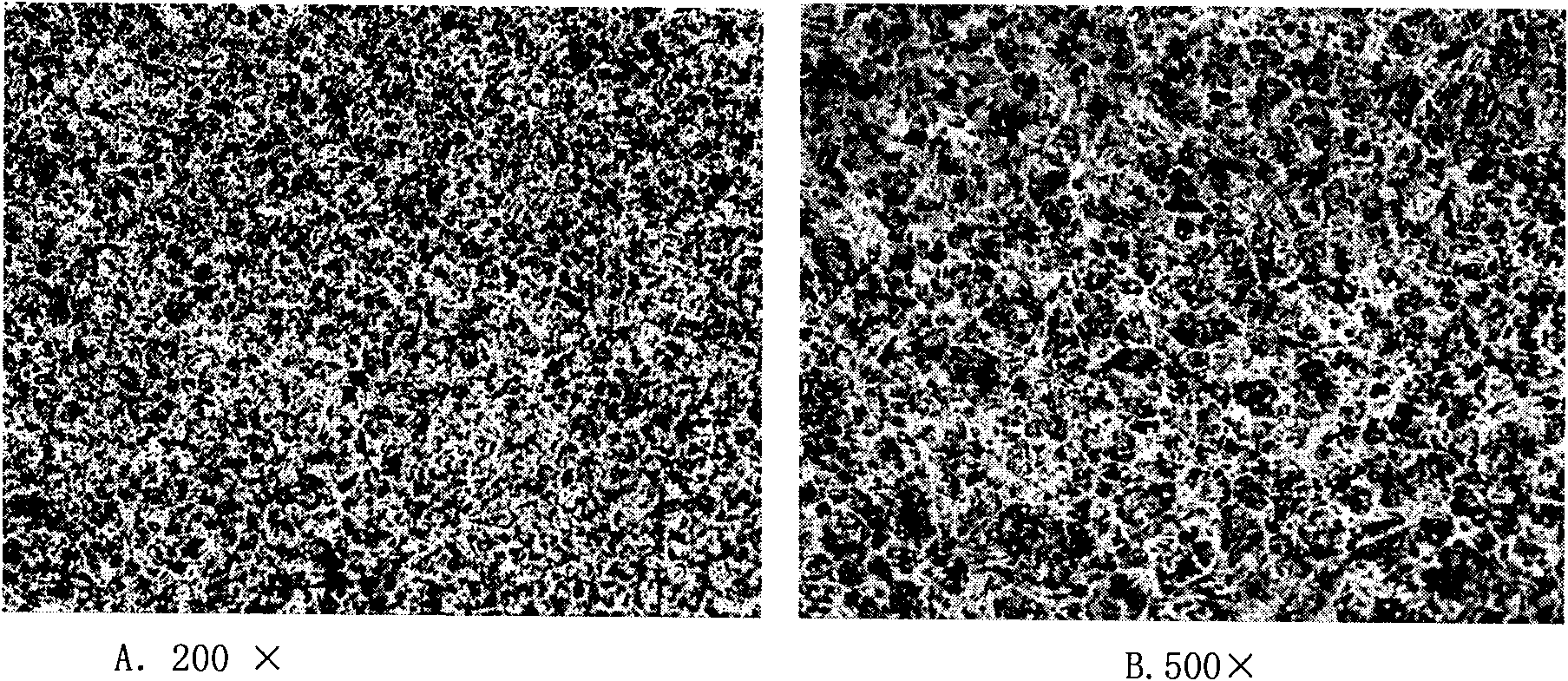

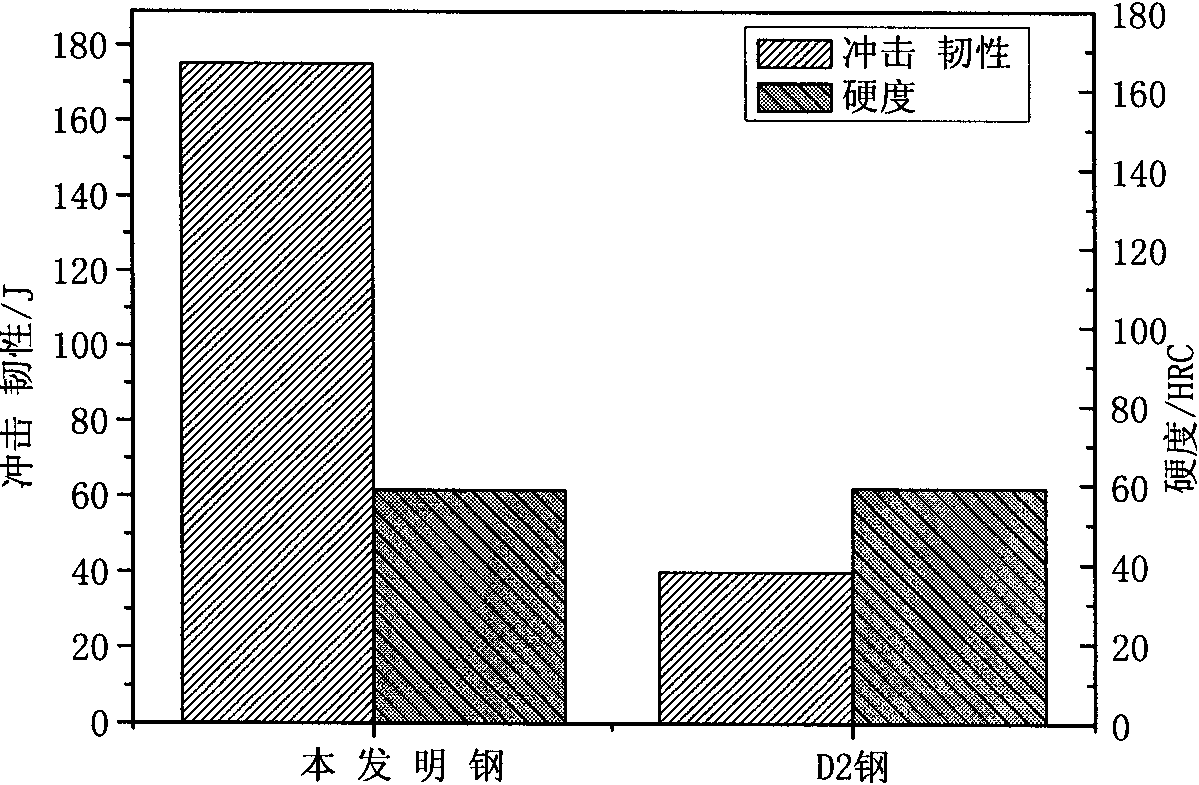

Low alloy die steel

The invention relates to a low alloy die steel material which comprises the following components by weight: 0.68-0.78% of C, 0.7-1.0% of Si, 0.7-1.1% of Mn, not more than 0.02% of P, not more than 0.02% of S, 2.2-2.5% of Cr, 0.2-0.3% of Mo, 0.15-0.35% of V, 0.3-0.4% of Ni, the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing smelting and casting of the components to obtain a steel ingot; adding the steel ingot into a radial forging machine heating furnace at 600-800 DEG C, heating to 1200-1230 DEG C with a heating speed of 60-120 DEG C / h, then performing thermal insulation for 3-5 hours; forging in a forging machine to obtain steel materials with an initial forging temperature of 1050-1100 DEG C and a final forging temperature of not less than 850 DEG C. After the obtained die steel is subject to quenching at 910-950 DEG C and tempering heat treatment at 160-200 DEG C, the impact toughness is above 135 J / cm2, and the hardness HRC is above 62.

Owner:宝武特种冶金有限公司

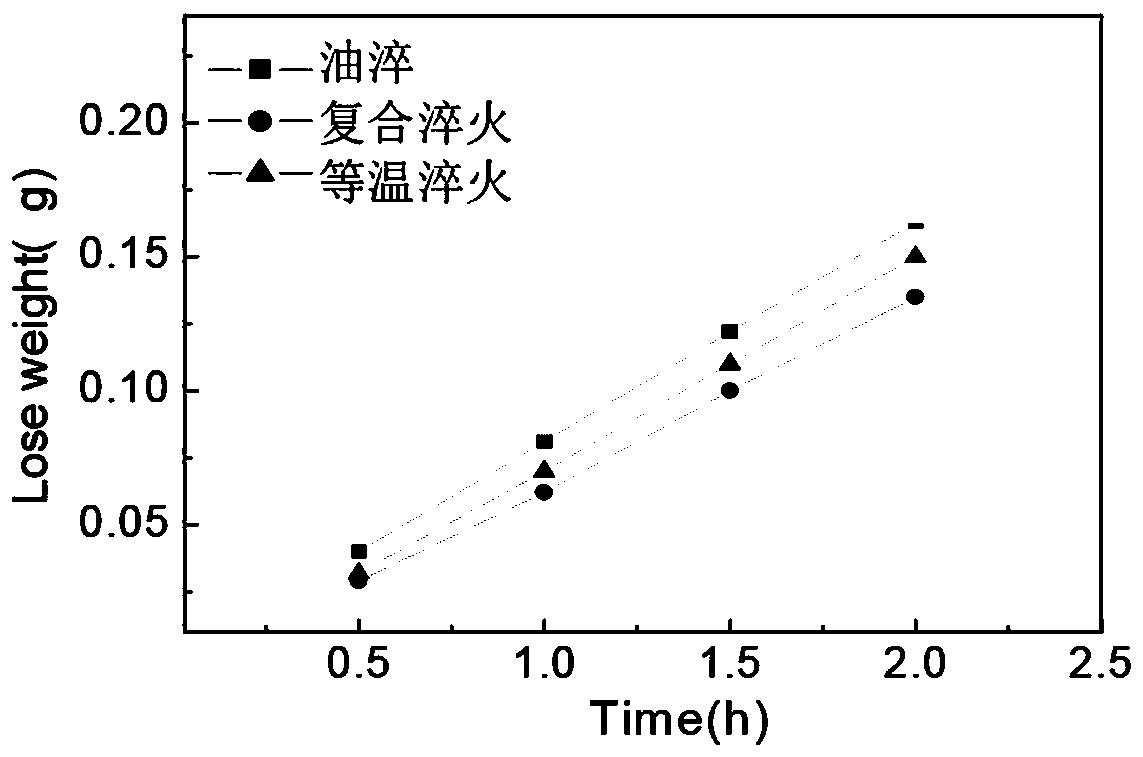

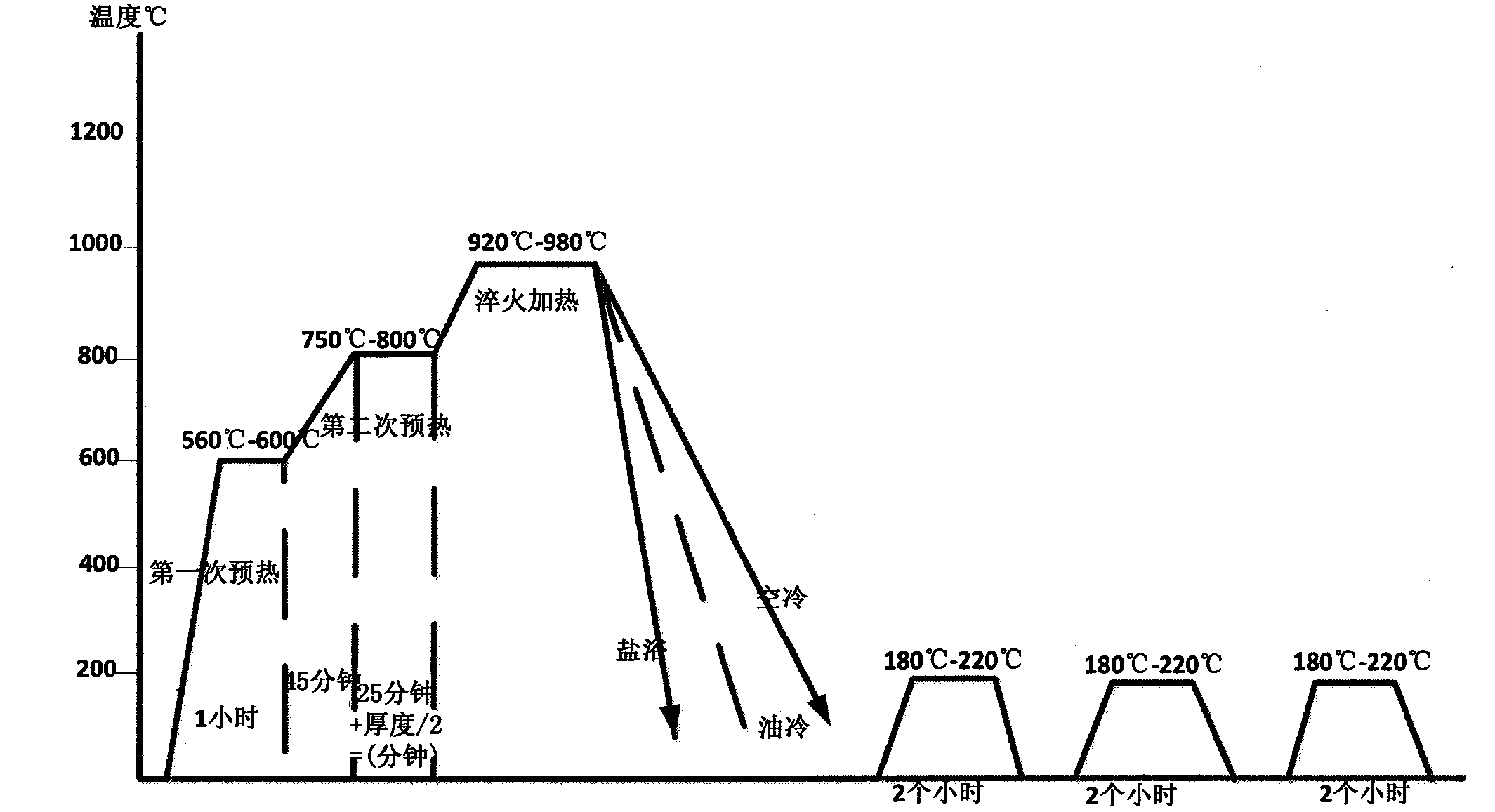

Method for optimized quenching process for obtaining 8Cr4Mo4V steel

The invention relates to a method for an optimized quenching process for obtaining 8Cr4Mo4V steel. The method comprises the following steps of (1) determining a heating solution process; (2) determining the time point of the highest hardness of isothermal hardening; (3) carrying out composite quenching treatment on the basis of the step (2); (4) selecting an optimized composite quenching process sample; and (5) carrying out tempering treatment on the optimized composite quenching process sample obtained in the step (4) at 510-550 DEG C for 1.8-2.5 h for 3-4 times, and obtaining the 8Cr4Mo4V steel subjected to final optimized heat treatment. The method has the advantages of scientificity, feasibility, simplicity in operation and the remarkable effect, and a space for improving the performance of the 8Cr4Mo4V steel is enlarged.

Owner:SHENYANG POLYTECHNIC UNIV

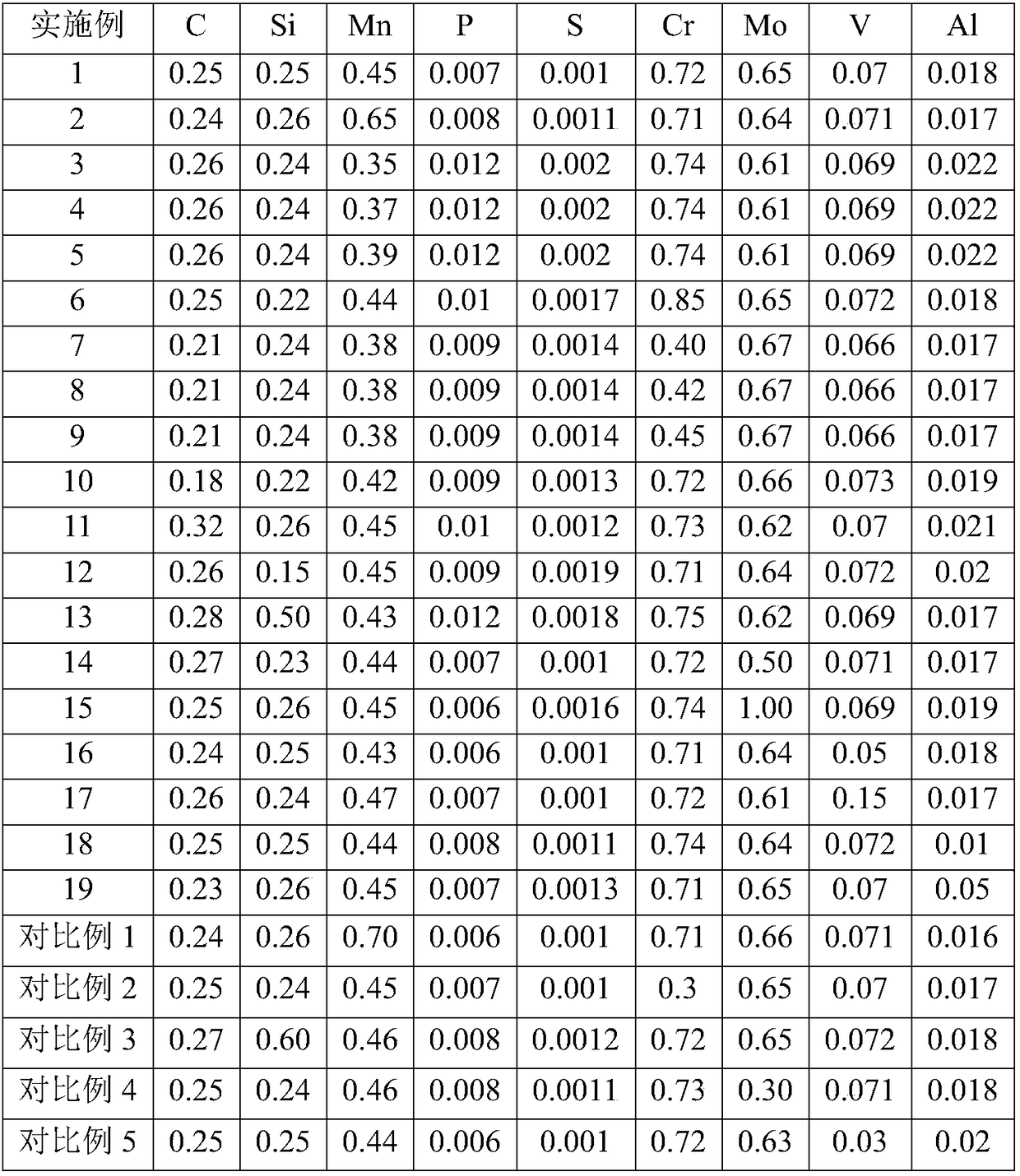

Seamless steel tube and preparation method of seamless steel tube

InactiveCN108660377AImprove toughnessHigh strengthProcess efficiency improvementRigid pipesHigh pressureUltimate tensile strength

The invention provides a seamless steel tube and a preparation method of the seamless steel tube. Relative to the total weight of the seamless steel tube, the seamless steel tube is prepared from thefollowing components in percent by weight: 0.18-0.32% of C, 0.15-0.50% of Si, 0.35-0.65% of Mn, 0.40-0.85% of Cr, 0.50-1.00% of Mo, 0.05-0.15% of V, 0.01-0.05% of Al, less than 0.015% of P, less than0.003% of S and the balance Fe and inevitable impurities. By strictly controlling the chemical constituent contents of raw materials, the chemical components are reasonably proportioned, so that the strength, toughness and hydrogen sulfide stress corrosion resistance of the obtained seamless steel tube can meet the exploiting demands on high-pressure and high-temperature oil and gas fields in severe corrosive environments.

Owner:HENGYANG VALIN STEEL TUBE

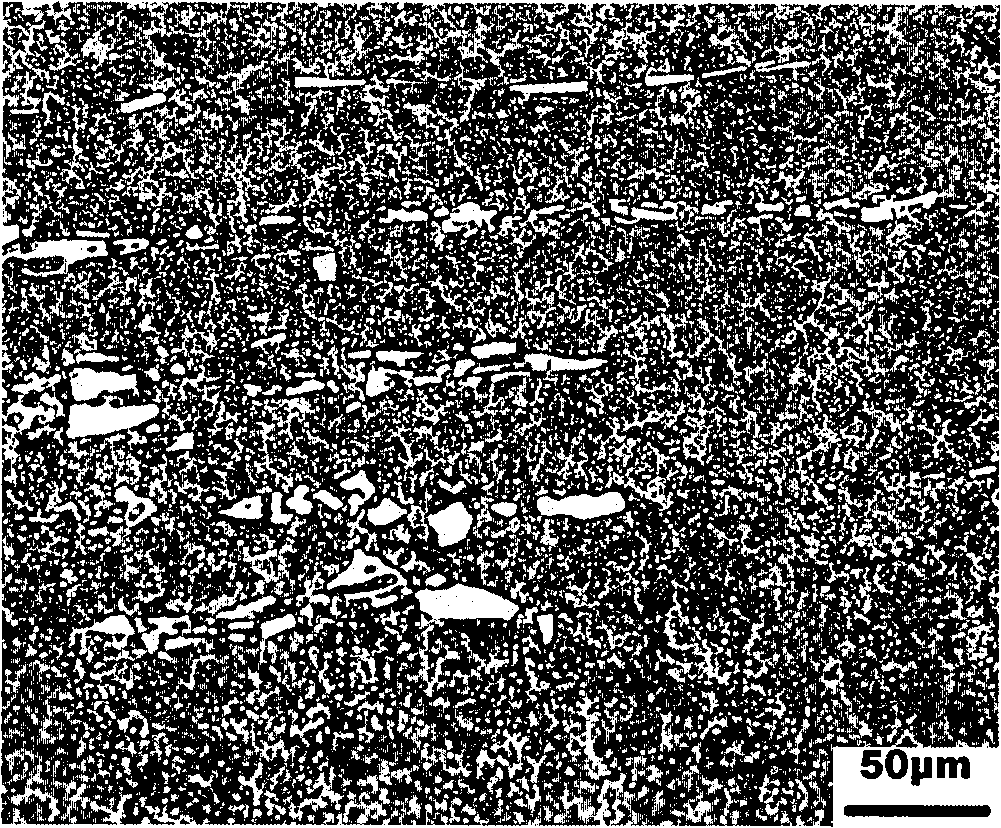

High-toughness cold-work mould steel and preparation method thereof

The invention relates to high-toughness cold-work mould steel and a preparation method thereof, belonging to the technical field of alloy steel manufacturing processes. The steel comprises the following chemical components in weight percentage: 0.5%-0.72% of C, 0.6%-0.8% of Si, 0.6%-1.0% of Mn, 2.0%-2.4% of Cr, 0.15%-0.25% of Mo, 0.1%-0.25% of V, 0.5%-0.8% of Ni and the balance of Fe. The preparation method of the cold-work mould steel comprises the following steps of: mixing the raw materials according to the a formula, smelting and pouring the batch mixtures in an induction furnace, and then carrying out electroslag remelting; and then forging and annealing, heating the mixtures to 850-930 DEG C for austenitization, and then carrying out secondary annealing at 180-200 DEG C after oil quenching to finally obtain the high-toughness cold-work mould steel. The cold-work mould steel has higher toughness matching and higher hardness and is a steel type suitable for manufacturing precise complex moulds.

Owner:SHANGHAI UNIV

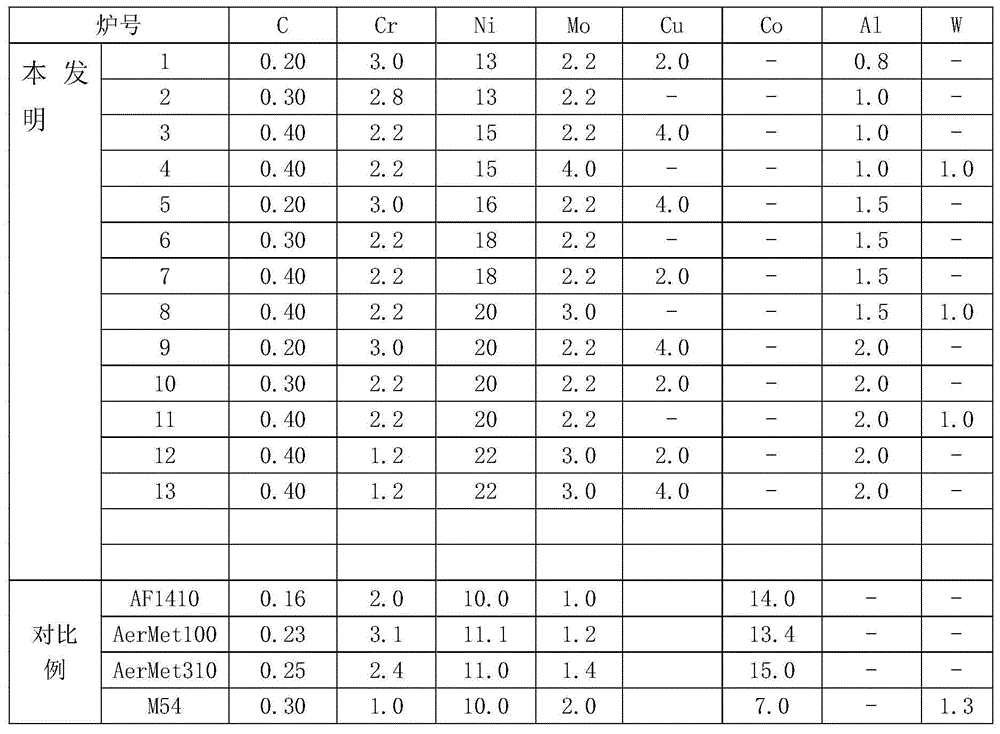

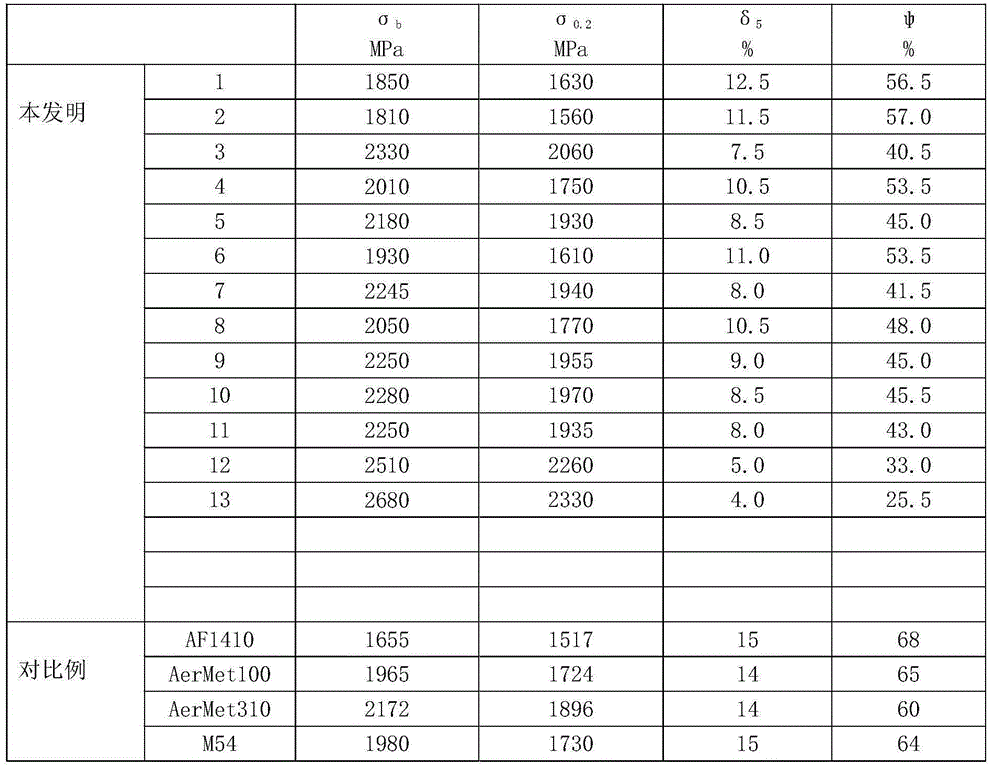

Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and preparation method thereof

ActiveCN104911499ASave Co element contentImprove performanceChemical compositionUltimate tensile strength

The invention discloses Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and a preparation method, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.20-0.50% of C, 1.0-5.0% of Cr, 8.0-30.0% of Ni, 1.0-5.0% of Mo, 1.0-5.0% of Cu, 0-3.0% of Al, 0-2.0% of W, less than or equal to 0.30% of V, less than or equal to 0.20% of Nb and the balance of Fe and unavoidable impurities. According to the preparation method, the vacuum induction and vacuum consumable remelting technology or the vacuum induction and electroslag remelting technology can be adopted. Compared with the prior art, the Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel has the advantages of good comprehensive performance, higher strength, good plasticity and toughness, good heat treatment process performance and higher tempering resistance and overaging resistance; the content of strategic resource Co element is saved and the economical efficiency is remarkably improved.

Owner:CENT IRON & STEEL RES INST

Method for heat treatment of 65Mn steel-made electronic scale sensor elastic body

InactiveCN101775473AImprove plasticityImprove toughnessFurnace typesHeat treatment furnacesElastomerHardness

The invention discloses a method for the heat treatment of a 65Mn steel-made electronic scale sensor elastic body, which completes the heat treatment on a heat treatment continuous production line and which comprises the following specific steps: stamping molding material of the 65Mn steel-made electronic scale sensor elastic body is heated to 830 DEG C, quenching the material for 5 minutes in hot oil at 100 DEG C after heat preservation is performed for 15 to 30 minutes, then cleaning and drying the material; subsequently heating at 400 DEG C and preserving the heat for 80 minutes, followed by tempering; after the tempering, rapidly hydrocooling and drying, and detecting product; in the method according to the invention, the tempering temperature is raised to 400 DEG C, the resultant hardness is in a range of 43+ / -1.5, so the demand of linearity can be met; plasticity and toughness of parts are enhanced by increasing the proportion of tempered sorbite; the method according to the invention rapidly hydrocools the material after tempering to prohibit harmful impurity elements such as P, S O, etc. in the material from grain boundary segregation, thereby suppressing temper brittleness.

Owner:GUANGDONG UNIV OF TECH

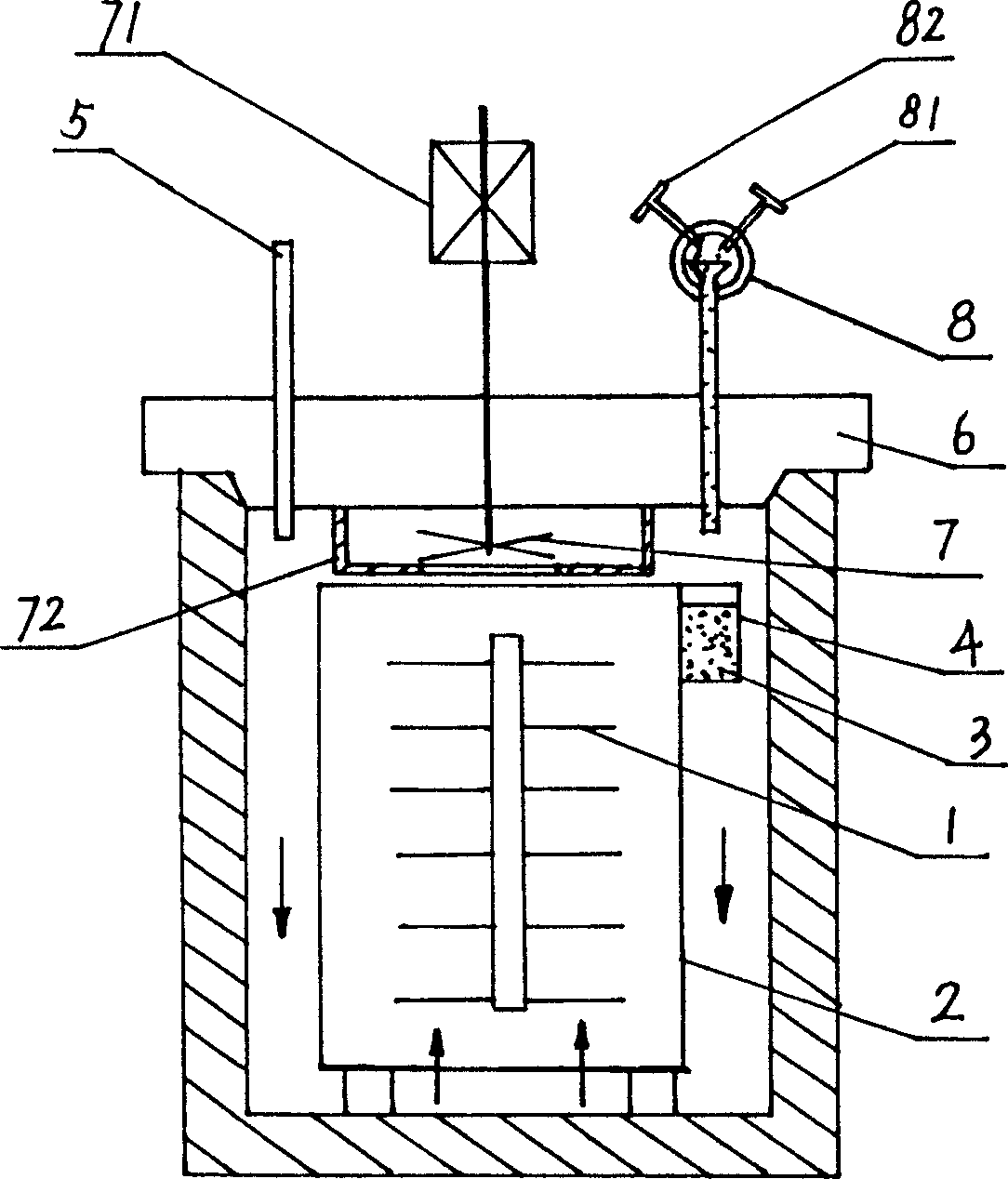

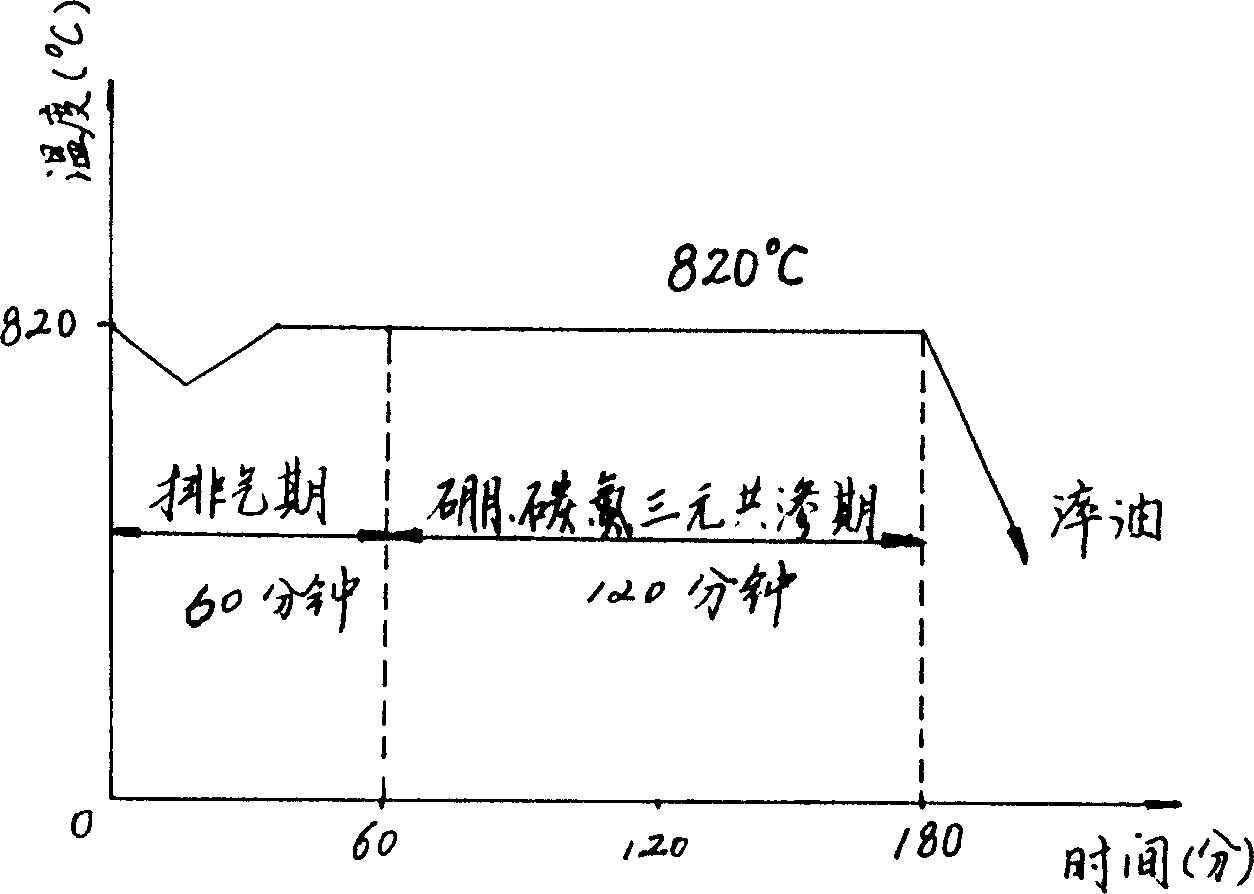

Boron carbon nitrogen trielement coexudation method

InactiveCN1442504ASmall amount of deformationReduce the temperatureSolid state diffusion coatingHardnessWater cooling

A three-element (B, C and N) co-osmosizing process for metal surface includes such steps as loading the solid boronizing agent in carburizing furnace but isolating from the workpiece, dropping the co-osmosizing C-N liquid in the carburizing furnace, co-osmosizing at 780-880 deg.c and 0.15-0.2 mm / hr of speed, and cooling in oil or water. Its advantages are low co-osmosizing temp and quenching temp. less deformation of workpiece, and high effect on improving performance of workpiece.

Owner:杨玉林

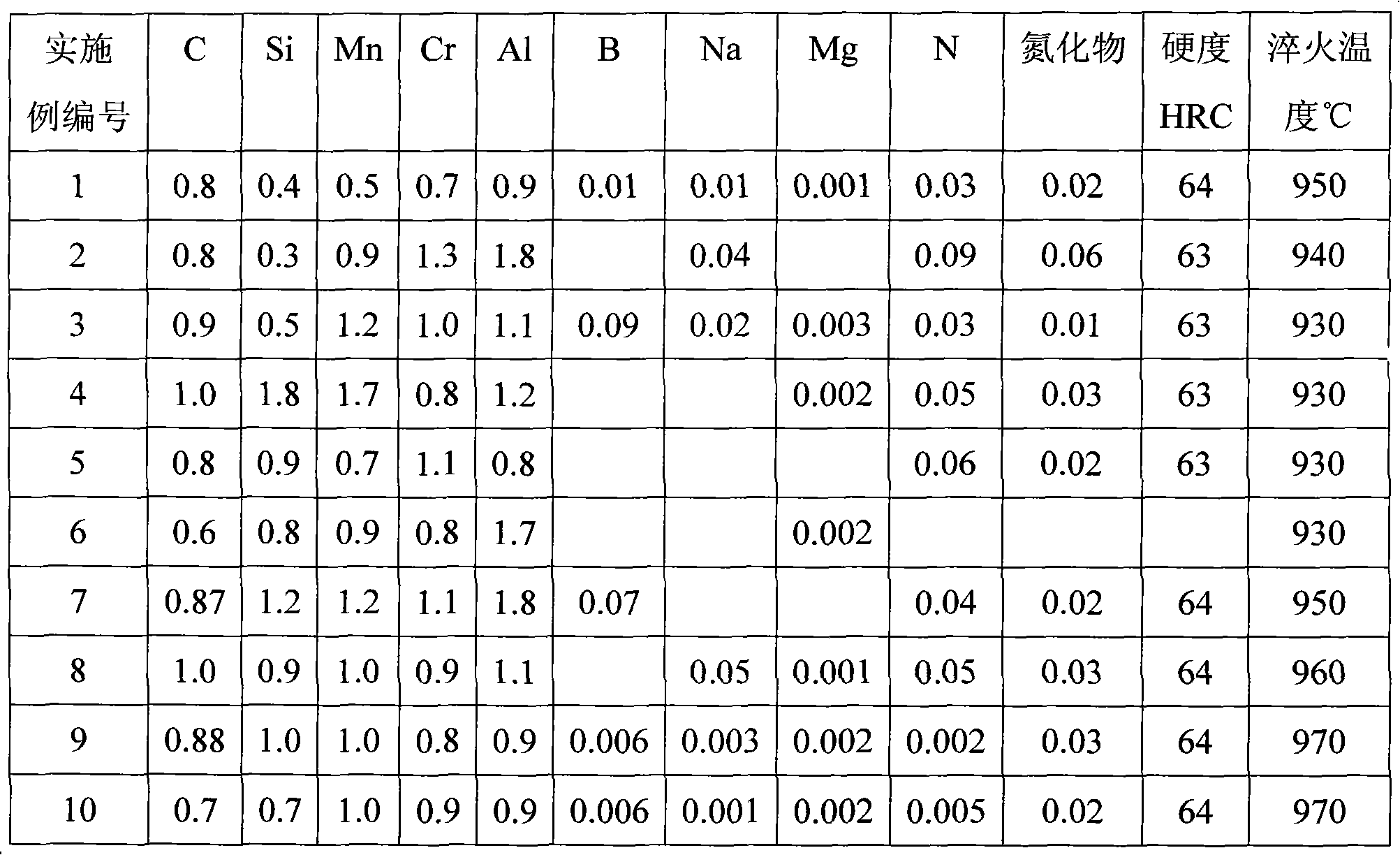

Novel 9SiCrAlBN alloy tool steel

InactiveCN102936690AGuaranteed mechanical propertiesQuenching temperature is lowAlloyMechanical property

The present invention provides a novel 9SiCrAlBN alloy tool steel, which contains C, Si, Mn, Cr, Al, B, Na, Mg, N and a nitride, wherein the improvement comprises that the tool steel comprises, by mass, 0.8-1.0 part of C, 0.3-1.8 parts of Si, 0.3-1.8 parts of Mn, 0.6-1.4 parts of Cr, 0-0.006 part of Na, 0-0.003 part of Mg, 0.8-1.8 parts of Al, 0-0.10 part of B, 0.01-0.10 part of N, 0.01-0.08 part of a nitride, and the balance of Fe and unavoidable impurities. Compared with the 9SiCrAlBN alloy tool steel in the prior art, the novel 9SiCrAlBN alloy tool steel of the present invention has the following excellent effects that: mechanical properties of the cold work mold steel Cr12 and Cr12Mo1V1 are maintained, a quenching temperature is substantially reduced, and a lot of energy sources are saved.

Owner:周畅超

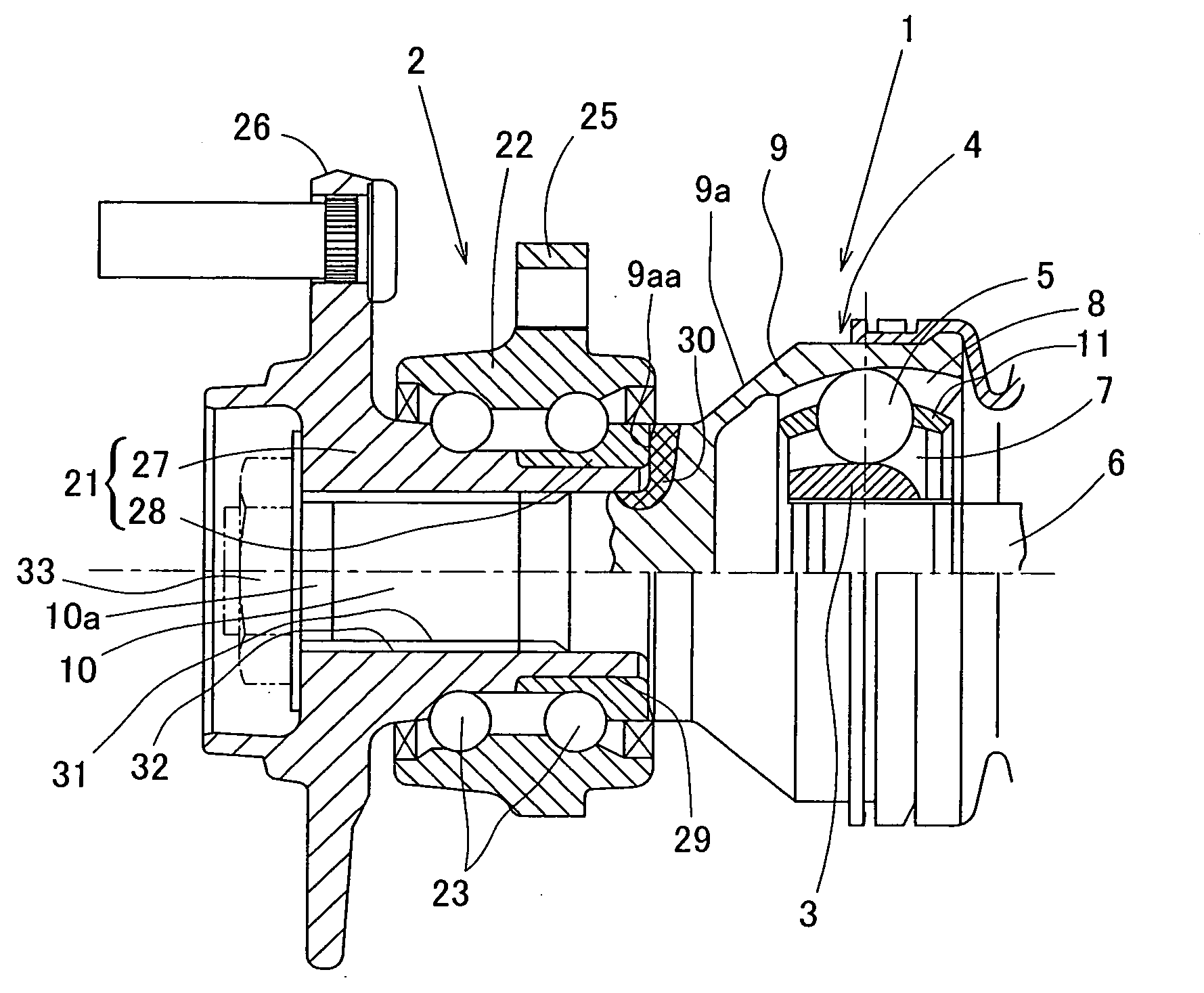

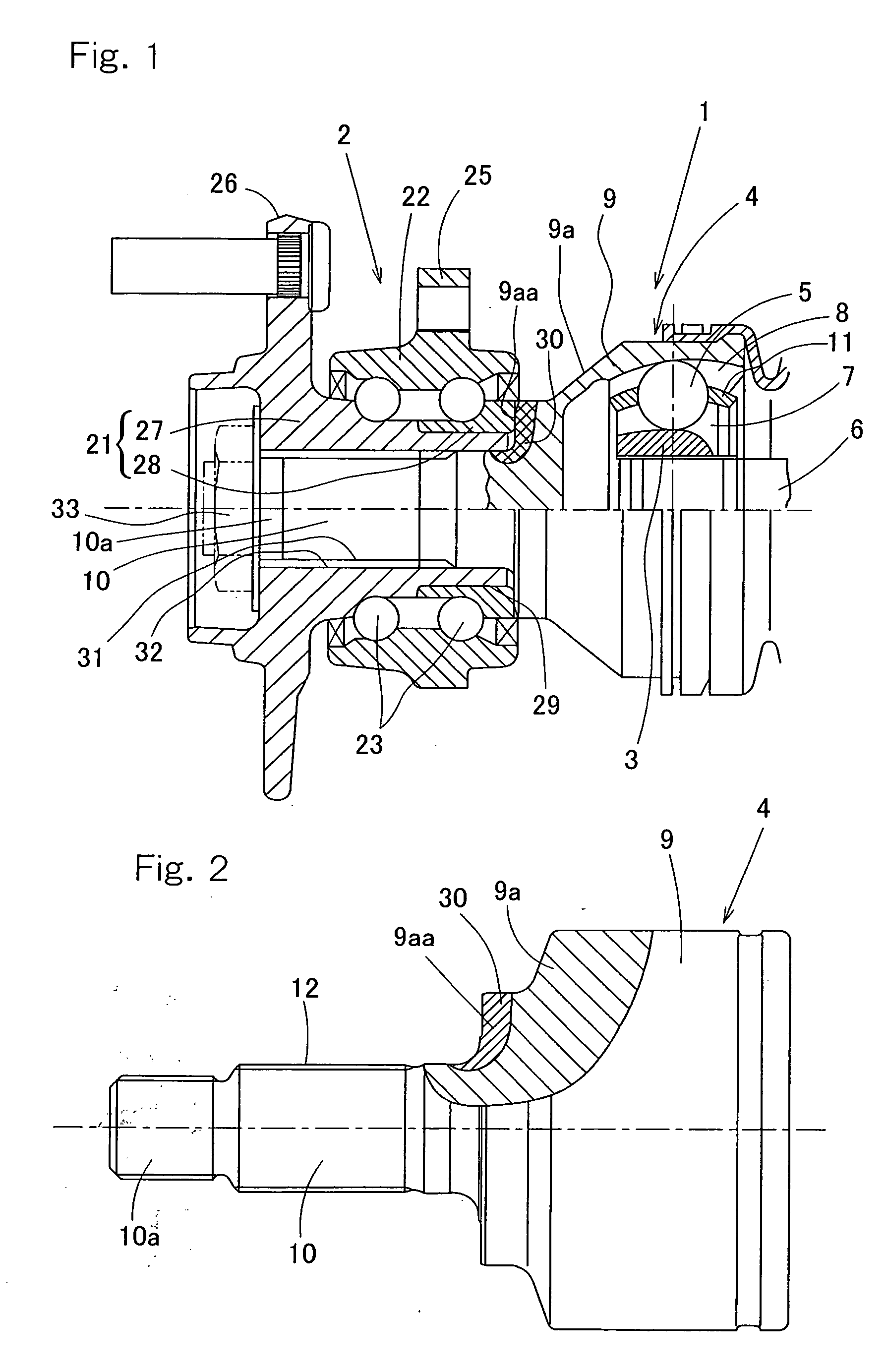

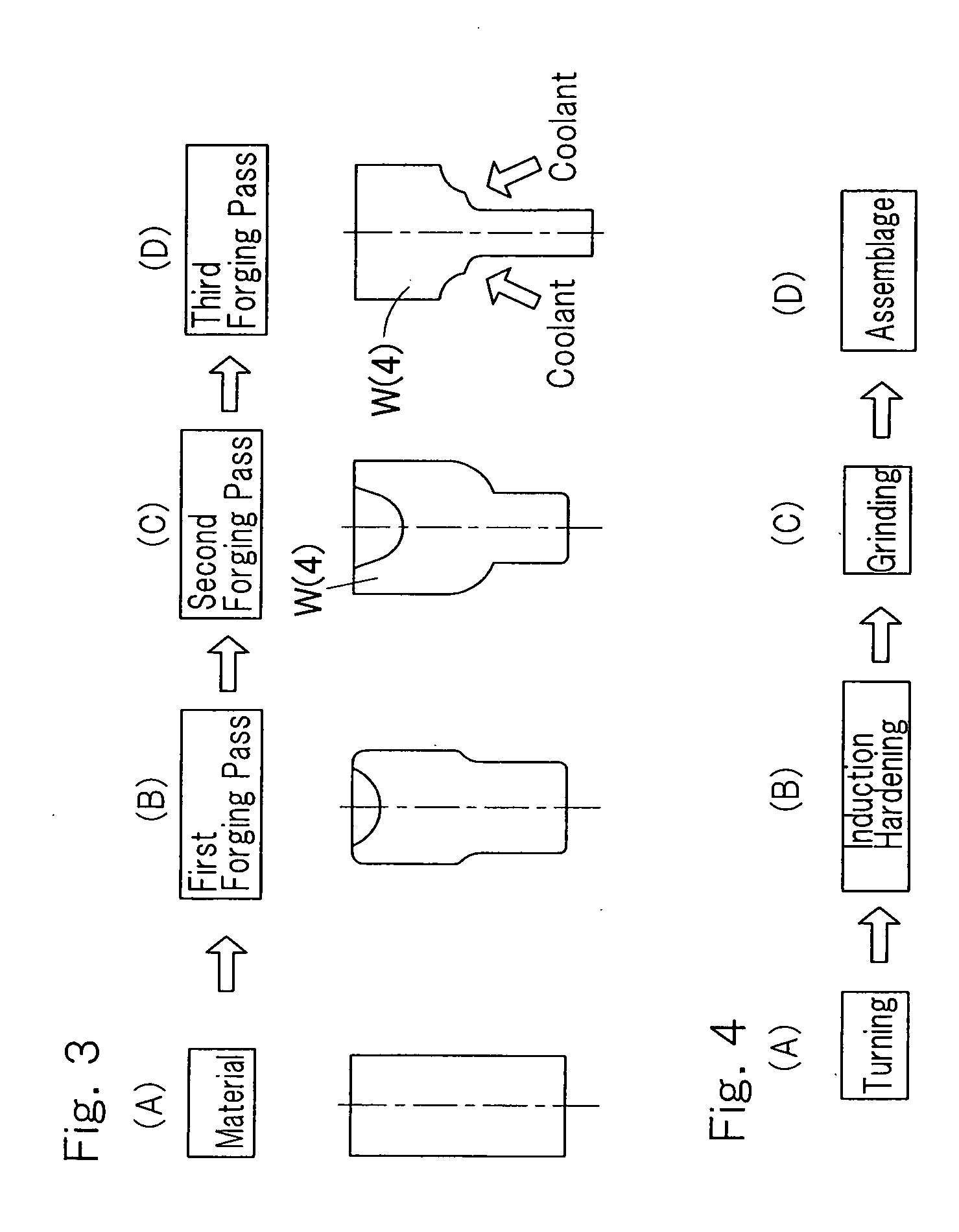

Constant velocity joint

InactiveUS20090137326A1Easy to carrySufficient quenching hardnessYielding couplingRolling contact bearingsSurface layerBainite

A joint outer ring (4) of a constant-velocity joint (1) has a stem portion (10) protruding from of a cup portion (9) and inserted to a through hole (31) of a hub (27) in a bearing device (2). The joint outer ring (4) has an abutment face (9aa) abutting against an end face of a bearing inner ring (28) fitted to an outer periphery of the hub (27) in an outer bottom face (9a) of the cup portion, and is composed of a forged product of a steel material. The joint outer ring (4) has a base material portion composed of a standard structure and an outer surface layer partially formed as a non-standard structure portion (30). The non-standard structure may be any one of an upper bainite structure, a lower bainite structure and a tempered martensite structure, or a mixed structure of at least two of the structures.

Owner:NTN CORP

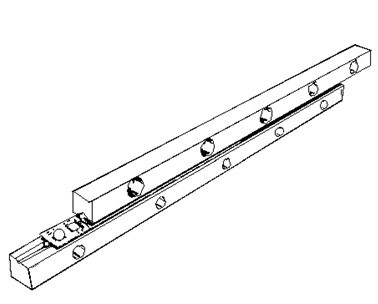

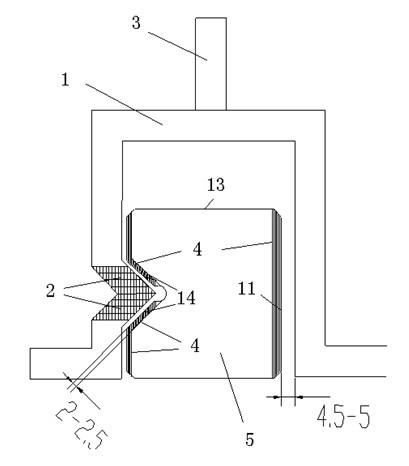

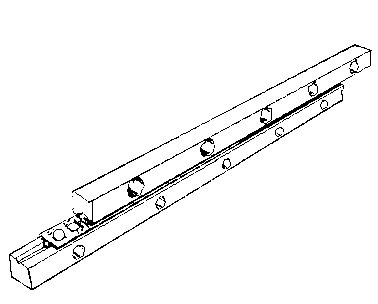

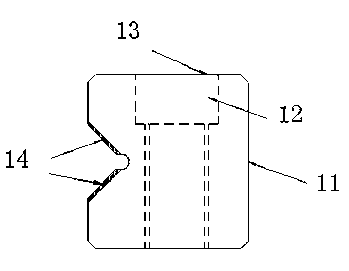

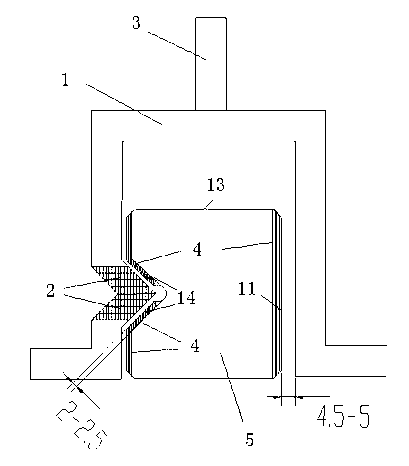

Surface induction hardening inductor for V-shaped roller cross linear guide rail

ActiveCN102560016AEasy to processReduce magnetic fluxFurnace typesIncreasing energy efficiencyElectrical conductorInductor

The invention discloses a surface induction hardening inductor for a V-shaped roller cross linear guide rail, which comprises an inducing conductor, a magnetizer and a fixing piece, wherein the inducing conductor made of a hollow copper tube adopts a door-type structure adapting to the cross section of the V-shaped roller cross linear guide rail; the magnetizer adapting to a V-shaped raceway surface of the V-shaped roller cross linear guide rail is arranged on the inducing conductor; and the fixing piece is arranged on the inducing conductor. The surface induction hardening inductor can achieve surface induction heating on the raceway surface and the bottom surface of the guide rail at the same time under different temperatures, different surface hardness and different hardening layer depths, ensures that a hardening layer with high hardness and high strength is formed on the raceway surface and the hardening layer has the bottom surface with certain hardness at the same time, and satisfies the requirements of quenching deformation of the guiding rail and the mounting hole processing.

Owner:NANJING TECHN EQUIP MFG

High-manganese medium carbon steel wear-resisting chute lining plate

The invention relates to smelting of metal components on a chute, and provides a high-manganese medium carbon steel wear-resisting chute lining plate. Steel materials are smelted through an electric-arc furnace and then transferred into a finery, the component proportion of the molten steel is adjusted, and then the steel is discharged. The molten steel is subjected to vacuum degassing and then full mold casting, and an obtained casting is subjected to heat treatment including water quenching and oil quenching to obtain a finished part. The components of the molten steel include, by weight, 0.54-0.58% of C, 12-16% of Mn, 1.5-3.5% of Cr, 2.5-3.5% of Al, 0.15-0.25% of Nb, 0.60-0.80% of Ti, 0.5-2.5% of B, 0.05-0.07% of Zr, less than 0.04% of P, less than 0.5% of Si and the balance Fe.

Owner:ANHUI SANFANG NEW MATERIAL TECH CO LTD

Surface induction hardening inductor for V-shaped roller cross linear guide rail

ActiveCN102560016BReduce hardnessReduced processing performanceFurnace typesIncreasing energy efficiencyElectrical conductorEngineering

The invention discloses a surface induction hardening inductor for a V-shaped roller cross linear guide rail, which comprises an inducing conductor, a magnetizer and a fixing piece, wherein the inducing conductor made of a hollow copper tube adopts a door-type structure adapting to the cross section of the V-shaped roller cross linear guide rail; the magnetizer adapting to a V-shaped raceway surface of the V-shaped roller cross linear guide rail is arranged on the inducing conductor; and the fixing piece is arranged on the inducing conductor. The surface induction hardening inductor can achieve surface induction heating on the raceway surface and the bottom surface of the guide rail at the same time under different temperatures, different surface hardness and different hardening layer depths, ensures that a hardening layer with high hardness and high strength is formed on the raceway surface and the hardening layer has the bottom surface with certain hardness at the same time, and satisfies the requirements of quenching deformation of the guiding rail and the mounting hole processing.

Owner:NANJING TECHN EQUIP MFG

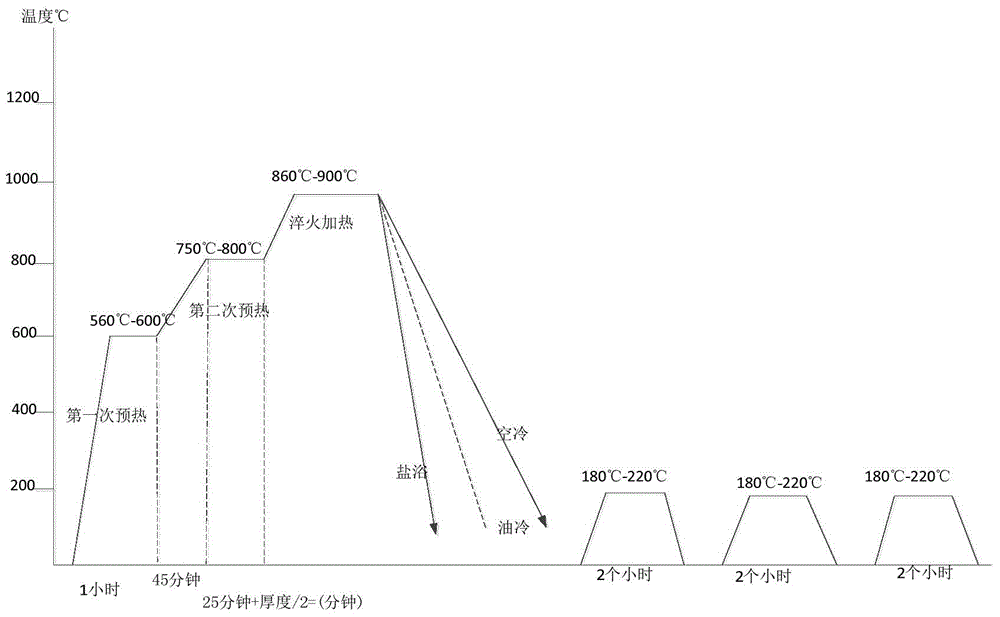

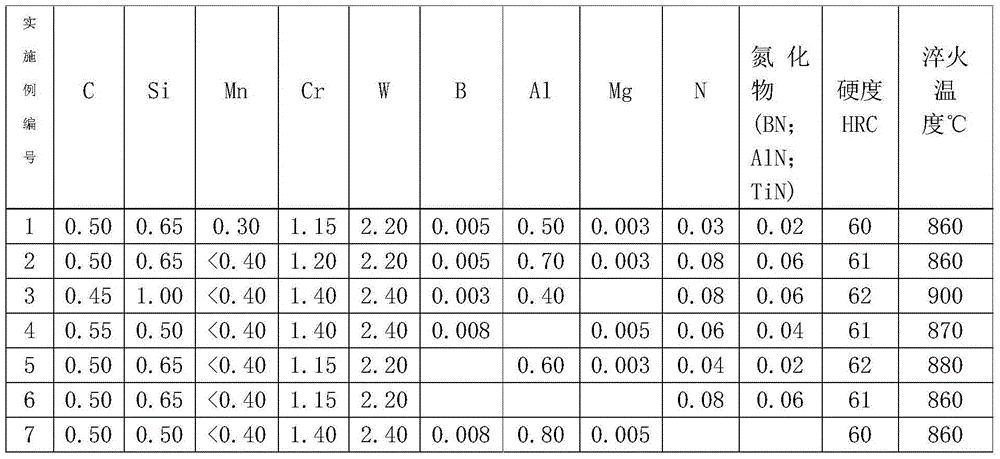

Novel 5CrW2SiBAlN shock-resisting tool steel

Novel 5CrW2SiBAlN shock-resisting tool steel is provided. The tool steel comprises C, Si, Cr, W, B, Al, Mg, N and nitrides (BN, AlN and / or TiN). An improvement of the tool steel is that: the tool steel comprises 0.40-0.60 part by mass of the C, 0.30-1.20 parts by mass of the Si, less than 0.40 part by mass of Mn, 1.00-1.60 parts by mass of the Cr, 2.00-3.00 parts by mass of the W, 0-0.008 part by mass of the B, 0-0.80 part by mass of the Al, 0-0.005 part by mass of the Mg and 0-0.10 part by mass of the N, with the total content of the nitrides being 0-0.80 part by mass and with the balance being Fe and unavoidable impurities. Compared with the prior art, beneficial effects of the novel 5CrW2SiBAlN are that the tool steel achieves mechanical performance of middle-chromium high alloy cold work die steel (with a code LD), largely reduces the quenching temperature and saves a large amount of energy.

Owner:徐恒易

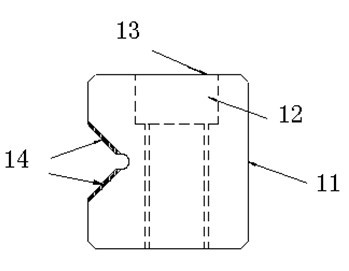

Silicon steel sheet with low iron loss, low noise, high magnetic flux and high laminating speed and preparation method thereof

InactiveCN104217844AInfluence of Small Magnetic FluxThe influence of magnetic flux is reducedTransformers/inductances magnetic coresLow noiseDistribution transformer

The invention discloses a silicon steel sheet with low iron loss, low noise, high magnetic flux and high laminating speed. The silicon steel sheet comprises a silicon steel sheet body, wherein at least one flat hole is formed in the silicon steel sheet body; a groove is formed in one side of the silicon steel sheet body and is of a square structure; a bump matched with the groove is arranged at the corresponding place on the other side of the groove of the silicon steel sheet body. A silicon steel sheet formula and a preparation method play a synergistic effect, so that vortex generated during work of a transformer is very low, and the heat dissipating capacity is 0.2 times that of the traditional transformer; the loading capacity of the transformer which adopts the iron core is greatly improved and is 1.8 times that of the traditional transformer with the same model, the transformer is stable in running, and after the transformer provided by the invention is compared with the traditional transformer with the same model, according to observation for 12 months, failure time of the transformer provided by the invention is zero, and the failure time of the traditional transformer is seven.

Owner:南阳市力矩软磁材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com