Manufacturing method of valve forged piece for ultra-supercritical turbine and valve forged piece

An ultra-supercritical and steam turbine technology, which is applied to mechanical equipment, engine components, valve devices, etc., can solve the problems of high waste rate, coarse grain, and affecting high-end steam turbines, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

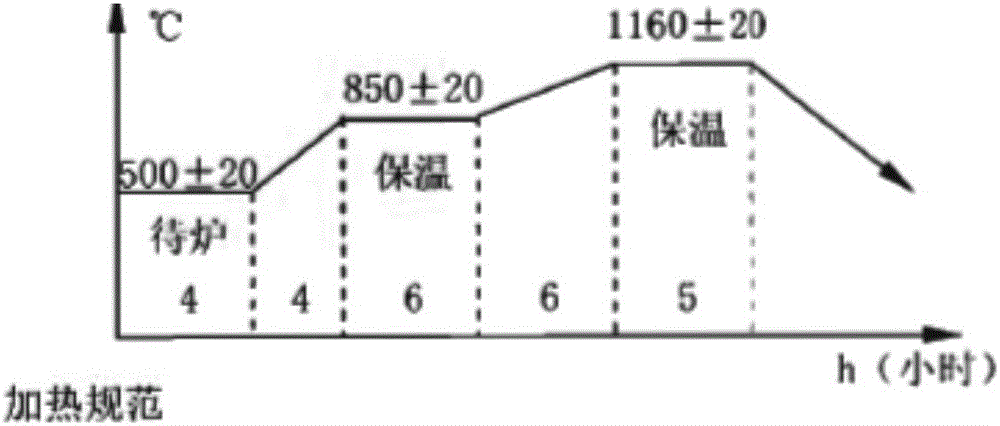

[0077] The preparation method of the FB2 valve seat forging specifically includes the following steps:

[0078] (1) Melting steps:

[0079] In this step, the 13Cr9Mo2Co1NiVNbB steel ingot is made into a valve forging billet by successively adopting an electric arc furnace melting step, an external refining step, and an electroslag remelting step; wherein the electric arc furnace melting step is as follows:

[0080] 1) Ingredients: S, P≤0.030% high-quality steel scrap and pure Cr, Mo, Co, N, V, Nb, B alloy materials;

[0081] 2) Melting period:

[0082] Before starting the furnace, add 1-2% Feo (iron ore) and 2% lime as the bottom material of the furnace;

[0083] At the end of melting and at the beginning of oxidation: add 20-25% Feo (iron ore), the temperature of molten steel is 1540-1560°C, the alkalinity is 2-3, and the P is removed to ≤0.0004%;

[0084] 3) Oxidation period: the amount of C removal ≥ 0.40%;

[0085] 4) Reduction period: P≤0.0005%, S≤0.0005%, C: 0.80~1.0...

Embodiment 2

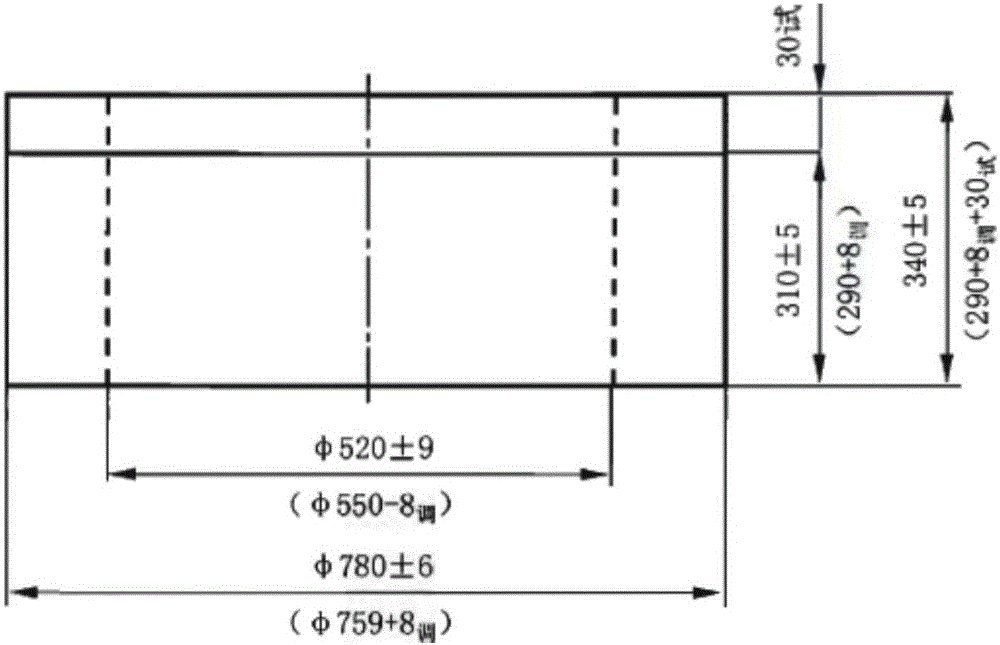

[0115] The preparation method of the FB2 valve disc forging specifically includes the following steps:

[0116] (1) Melting steps:

[0117] In this step, the 13Cr9Mo2Co1NiVNbB steel ingot is made into a valve forging billet by successively adopting an electric arc furnace melting step, an external refining step, and an electroslag remelting step; wherein the electric arc furnace melting step is as follows:

[0118] 1) Ingredients: S, P≤0.030% high-quality steel scrap and pure Cr, Mo, Co, N, V, Nb, B alloy materials;

[0119] 2) Melting period:

[0120] Before starting the furnace, add 1-2% Feo (iron ore) and 2% lime as the bottom material of the furnace;

[0121] At the end of melting and at the beginning of oxidation: add 20-25% Feo (iron ore), the temperature of molten steel is 1540-1560°C, the alkalinity is 2-3, and the P is removed to ≤0.0004%;

[0122] 3) Oxidation period: the amount of C removal ≥ 0.40%;

[0123] 4) Reduction period: P≤0.0005%, S≤0.0005%, C: 0.80~1.0...

Embodiment 3

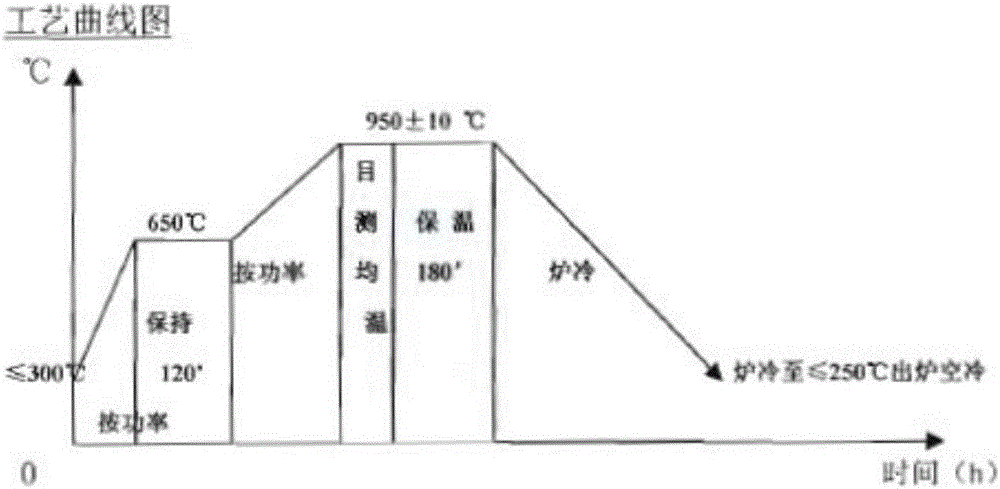

[0139] The preparation method of the FB2 valve stem forging specifically comprises the following steps:

[0140] (1) Melting steps:

[0141] In this step, the 13Cr9Mo2Co1NiVNbB steel ingot is made into a valve forging blank by successively adopting an electric arc furnace melting step, an external refining step, a vacuum degassing step, and an electroslag remelting step; wherein the electric arc furnace melting step is as follows:

[0142] 1) Ingredients: S, P≤0.030% high-quality steel scrap and pure Cr, Mo, Co, N, V, Nb, B alloy materials;

[0143] 2) Melting period:

[0144] Before starting the furnace, add 1-2% Feo (iron ore) and 2% lime as the bottom material of the furnace;

[0145] At the end of melting and at the beginning of oxidation: add 20-25% Feo (iron ore), the temperature of molten steel is 1540-1560°C, the alkalinity is 2-3, and the P is removed to ≤0.0004%;

[0146] 3) Oxidation period: the amount of C removal ≥ 0.40%;

[0147]4) Reduction period: P≤0.0005%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com