Novel 9SiCrAlBN alloy tool steel

A technology of alloy tool steel and tool steel, which is applied in the field of alloy steel, can solve the problems of small steel plus alloy content, high quenching temperature, and not suitable for environmental protection, and achieve the effect of saving energy and reducing quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

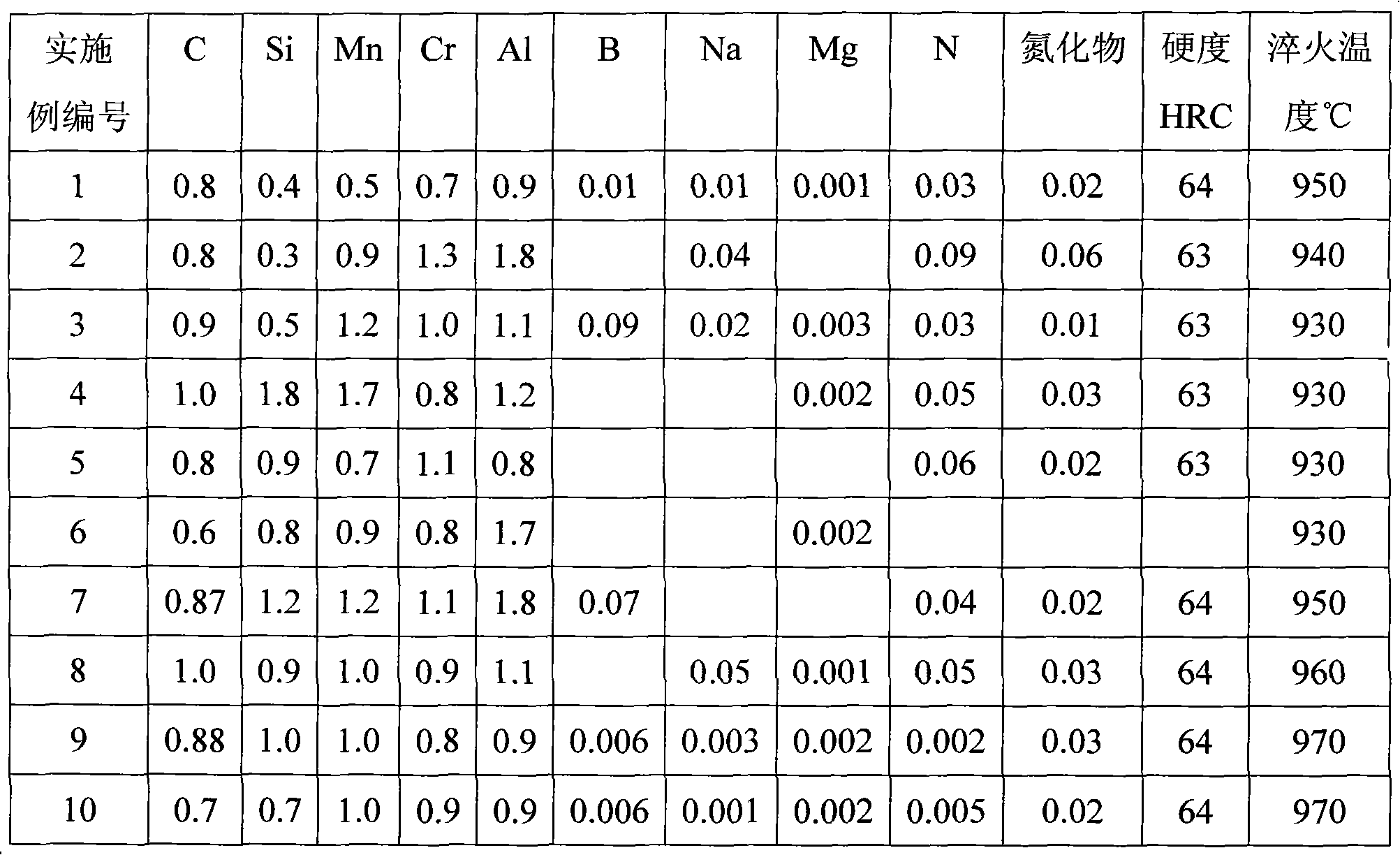

[0028] In the 9SiCrAlBN alloy tool steel provided by the present invention, it comprises by weight percentage:

[0029] Carbon C_0.80, Silicon Si_0.40, Manganese Mn_0.50, Chromium Cr_0.70,

[0030] Aluminum Al_0.90, Boron B_0.01, Sodium Na_0.01, Magnesium Mg_0.001,

[0031] Nitrogen N_0.03, Nitride_0.02, the balance being Fe and unavoidable impurities.

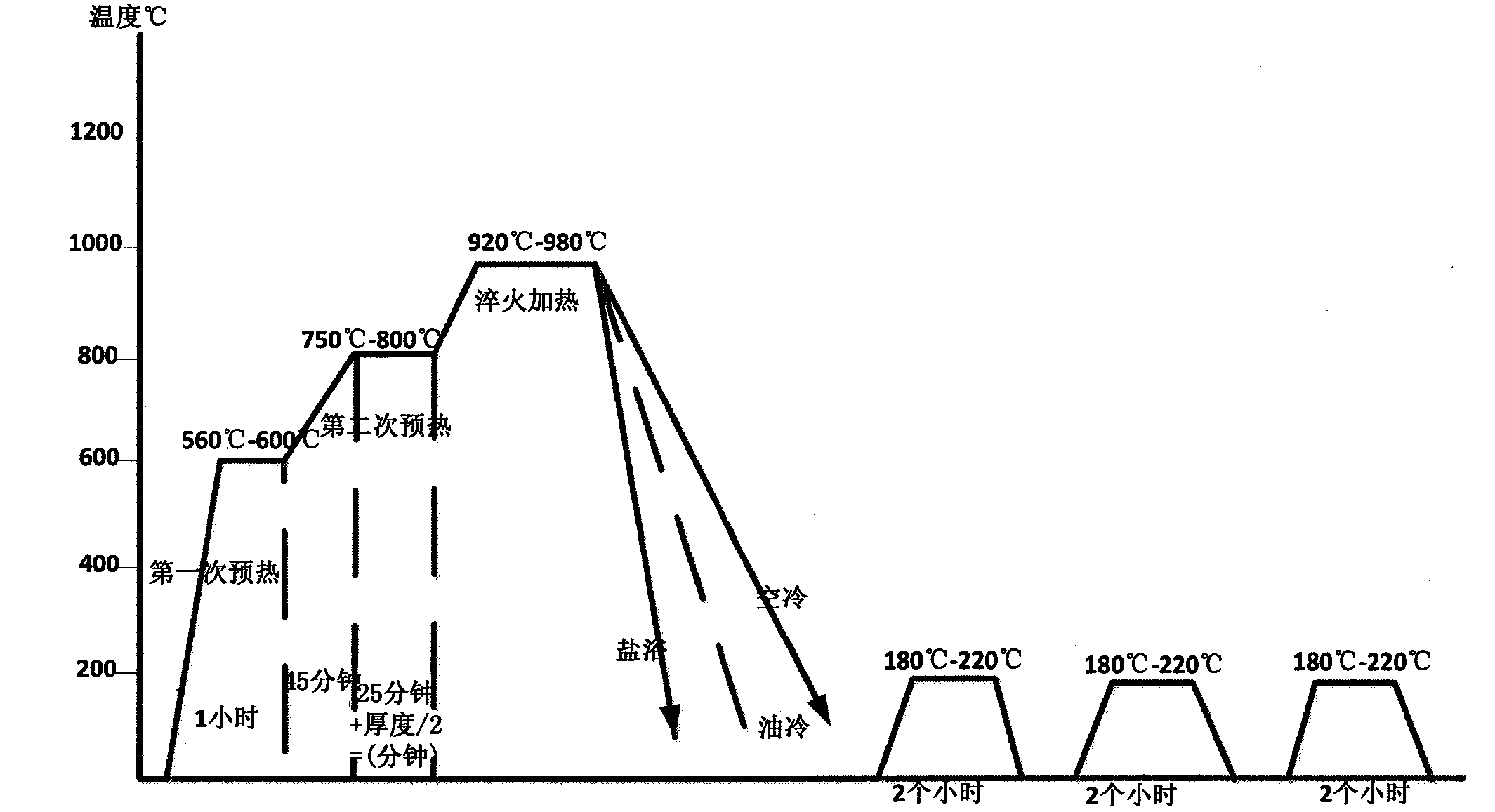

[0032] The steps of the above-mentioned novel 9SiCrAlBN alloy tool steel heat treatment process are as follows:

[0033] (1), preheating: all raw materials are preheated at a temperature of 560°C to 600°C, and the preheating time is 60 minutes;

[0034] (2) Quenching heating: the quenching heating temperature is 920°C to 980°C, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 to 30 minutes;

[0035] (3) Tempering: the tempering temperature is 180°C to 220°C, and then air cooled to room temperature.

Embodiment 2

[0037] In the 9SiCrAlBN alloy tool steel provided by the present invention, it comprises by weight percentage:

[0038] Carbon C_0.80, Silicon Si_0.30, Manganese Mn_0.90, Chromium Cr_1.30,

[0039] Aluminum Al_1.80, Sodium Na_0.04, Nitrogen N_0.09, Nitride_0.06,

[0040] The balance is Fe and unavoidable impurities.

[0041] The steps of the above-mentioned novel 9SiCrAlBN alloy tool steel heat treatment process are as follows:

[0042] (1), the first preheating: the preheating temperature of all raw materials is 560 ℃ ~ 600 ℃, and the preheating time is 60 minutes;

[0043] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 750 ℃ ~ 800 ℃, the second preheating time is 40 ~ 50 minute.

[0044] (3) Quenching heating: the quenching heating temperature is 920°C to 980°C, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time is 20 to 30 minutes;

[0045] (4), th...

Embodiment 3

[0048] In the 9SiCrAlBN alloy tool steel provided by the present invention, it comprises by weight percentage:

[0049] Carbon C_0.90, Silicon Si_0.50, Manganese Mn_1.20, Chromium Cr_1.00,

[0050] Aluminum Al_1.10, Boron B_0.09, Sodium Na_0.02, Magnesium Mg_0.003,

[0051] Nitrogen N_0.03, Nitride_0.01, the balance being Fe and unavoidable impurities.

[0052] The steps of the above-mentioned novel 9SiCrAlBN alloy tool steel heat treatment process are as follows:

[0053] (1), the first preheating: the preheating temperature of all raw materials is 560 ℃ ~ 600 ℃, and the preheating time is 60 minutes;

[0054] (2), the second preheating: after the first preheating, the second preheating, and then quenching, the second preheating temperature is 750 ℃ ~ 800 ℃, the second preheating time is 40 ~ 50 minute.

[0055] (3) Quenching heating: the quenching heating temperature is 920°C to 980°C, oil cooling or air cooling or salt bath cooling is adopted, and the quenching time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com