Silicon steel sheet with low iron loss, low noise, high magnetic flux and high laminating speed and preparation method thereof

A silicon steel sheet, low-noise technology, applied in the direction of transformer/inductor core, transformer/inductor parts, electrical components, etc., can solve the problems of high cost, slow stacking speed, high noise, etc., to reduce the impact, Firmly fixed, low-height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

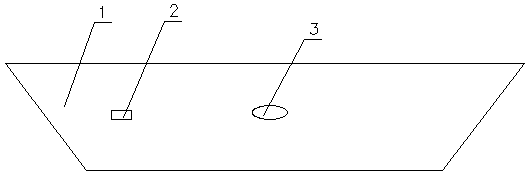

[0032] Embodiment 1: as figure 1 As shown, a silicon steel sheet with low iron loss, low noise, high magnetic flux, and fast stacking includes a silicon steel sheet 1, and at least one flat hole 3 is provided on the silicon steel sheet.

[0033] Further, preferably, the number of the flat holes is preferably one.

[0034] Further, preferably, the flat hole is an oval hole or a rhombus hole or a square hole.

[0035] Further, preferably, the flat hole is an oval hole.

[0036] Further, the silicon steel sheet also includes a positioning support, the support includes a square bottom plate, and four guide rods matching the size of the flat holes are arranged on the bottom plate.

[0037] Further, a groove 2 is provided on one side of the silicon steel sheet, and the groove 2 has a square structure, and a bump matching the groove 2 is provided on the other side of the groove of the silicon steel sheet corresponding to the source.

[0038] Further, preferably, the flat hole is l...

Embodiment 2

[0053] Embodiment 2: as figure 1 As shown, a silicon steel sheet with low iron loss, low noise, high magnetic flux, and fast stacking includes a silicon steel sheet, and at least one flat hole is provided on the silicon steel sheet.

[0054] Further, preferably, the number of the flat holes is preferably one.

[0055] Further, preferably, the flat hole is an oval hole or a rhombus hole or a square hole.

[0056] Further, preferably, the flat hole is an oval hole.

[0057] Further, preferably, the flat hole is located on the horizontal center line of the silicon steel sheet and is 5-10 mm away from the center point of the silicon steel sheet.

[0058] Further, preferably, the flat hole is located on the horizontal center line of the silicon steel sheet and is 7-9 mm away from the center point of the silicon steel sheet.

[0059] Further, preferably, the flat hole is located on the center horizontal line of the silicon steel sheet and is 8mm away from the center point of the ...

Embodiment 3

[0072] Embodiment 3: as figure 1 As shown, a silicon steel sheet with low iron loss, low noise, high magnetic flux, and fast stacking includes a silicon steel sheet, and at least one flat hole is provided on the silicon steel sheet.

[0073] Further, preferably, the number of the flat holes is preferably one.

[0074] Further, preferably, the flat hole is an oval hole or a rhombus hole or a square hole.

[0075] Further, preferably, the flat hole is an oval hole.

[0076] Further, preferably, the flat hole is located on the horizontal center line of the silicon steel sheet and is 5-10 mm away from the center point of the silicon steel sheet.

[0077] Further, preferably, the flat hole is located on the horizontal center line of the silicon steel sheet and is 7-9 mm away from the center point of the silicon steel sheet.

[0078] Further, preferably, the flat hole is located on the center horizontal line of the silicon steel sheet and is 8mm away from the center point of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com