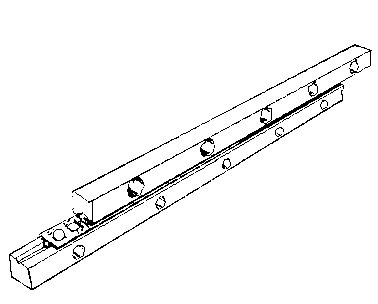

Surface induction hardening inductor for V-shaped roller cross linear guide rail

A quenching inductor and linear guide technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of inability to machine mounting holes, high hardness of the bottom surface, and inability to form a uniform V-shaped raceway surface, so as to meet the requirements of quenching deformation. Compatible with mounting hole processing requirements and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

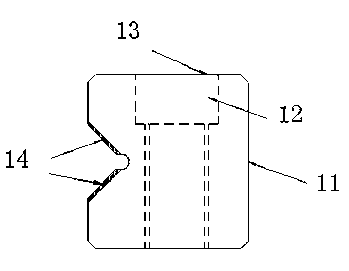

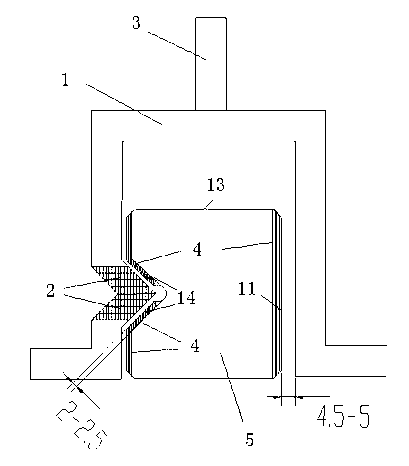

[0017] A V-type roller cross linear guide surface induction hardening sensor, see image 3 , the inductor includes an inductive conductor 1, a magnetizer 2 and a fixing piece 3. The inductive conductor 1 made of a hollow copper tube is a door-shaped structure that is adapted to the section of the V-shaped roller cross linear guide 5, wherein, in The position corresponding to the V-shaped raceway surface 14 of the V-shaped roller cross linear guide is also V-shaped. The gap between the side edge of the inductive conductor 1 of the gate structure and the bottom surface 11 close to the bottom surface 11 of the V-shaped roller cross linear guide rail is 4.5-5.0mm. The magnetizer 2 adapted to the V-shaped raceway surface 14 of the V-shaped roller cross linear guide is arranged on the inductive conductor 1 and is located at the V-shaped place; the magnetizer 2 is also the V-shaped roller cross linear guide. The V-shaped raceway surface 14 is matched with a V-shaped structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com